How Sodium Alginate Enables Development of Novel Emulsifiers?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Emulsifier Development Background

Sodium alginate, a naturally occurring polysaccharide extracted from brown seaweed, has emerged as a promising ingredient in the development of novel emulsifiers. This versatile compound has gained significant attention in the food, pharmaceutical, and cosmetic industries due to its unique properties and potential applications in emulsion stabilization.

The journey of sodium alginate as an emulsifier began in the mid-20th century when researchers first recognized its ability to form stable emulsions. Initially, its use was limited to simple oil-in-water emulsions, but as understanding of its molecular structure and behavior deepened, more sophisticated applications emerged. The growing demand for natural, sustainable, and multifunctional ingredients in various industries has further accelerated research and development efforts in this field.

Sodium alginate's effectiveness as an emulsifier stems from its amphiphilic nature, which allows it to interact with both oil and water phases. Its long, linear polymer chains consist of mannuronic and guluronic acid residues, providing a unique balance of hydrophilic and hydrophobic properties. This molecular structure enables sodium alginate to adsorb at oil-water interfaces, forming a protective layer around oil droplets and preventing coalescence.

The evolution of sodium alginate-based emulsifiers has been marked by several key technological advancements. These include the development of modified alginates with enhanced emulsifying properties, the exploration of synergistic effects with other emulsifiers, and the investigation of alginate-protein complexes for improved stability and functionality. Additionally, the advent of nanotechnology has opened up new possibilities for creating nanoscale alginate-based emulsifiers with superior performance characteristics.

As research in this area progresses, the focus has shifted towards understanding the fundamental mechanisms of sodium alginate's emulsifying action at the molecular level. This includes studying the impact of alginate's molecular weight, composition, and conformation on its emulsifying properties. Furthermore, researchers are exploring the potential of sodium alginate in creating responsive and smart emulsions that can adapt to environmental stimuli such as pH, temperature, or ionic strength.

The development of novel emulsifiers based on sodium alginate aligns with the broader trend towards sustainable and bio-based materials in various industries. As consumers become increasingly conscious of the environmental impact and health implications of synthetic additives, natural emulsifiers like sodium alginate offer a compelling alternative. This shift in consumer preferences, coupled with stringent regulations on food additives and cosmetic ingredients, has created a favorable environment for the continued development and adoption of sodium alginate-based emulsifiers.

The journey of sodium alginate as an emulsifier began in the mid-20th century when researchers first recognized its ability to form stable emulsions. Initially, its use was limited to simple oil-in-water emulsions, but as understanding of its molecular structure and behavior deepened, more sophisticated applications emerged. The growing demand for natural, sustainable, and multifunctional ingredients in various industries has further accelerated research and development efforts in this field.

Sodium alginate's effectiveness as an emulsifier stems from its amphiphilic nature, which allows it to interact with both oil and water phases. Its long, linear polymer chains consist of mannuronic and guluronic acid residues, providing a unique balance of hydrophilic and hydrophobic properties. This molecular structure enables sodium alginate to adsorb at oil-water interfaces, forming a protective layer around oil droplets and preventing coalescence.

The evolution of sodium alginate-based emulsifiers has been marked by several key technological advancements. These include the development of modified alginates with enhanced emulsifying properties, the exploration of synergistic effects with other emulsifiers, and the investigation of alginate-protein complexes for improved stability and functionality. Additionally, the advent of nanotechnology has opened up new possibilities for creating nanoscale alginate-based emulsifiers with superior performance characteristics.

As research in this area progresses, the focus has shifted towards understanding the fundamental mechanisms of sodium alginate's emulsifying action at the molecular level. This includes studying the impact of alginate's molecular weight, composition, and conformation on its emulsifying properties. Furthermore, researchers are exploring the potential of sodium alginate in creating responsive and smart emulsions that can adapt to environmental stimuli such as pH, temperature, or ionic strength.

The development of novel emulsifiers based on sodium alginate aligns with the broader trend towards sustainable and bio-based materials in various industries. As consumers become increasingly conscious of the environmental impact and health implications of synthetic additives, natural emulsifiers like sodium alginate offer a compelling alternative. This shift in consumer preferences, coupled with stringent regulations on food additives and cosmetic ingredients, has created a favorable environment for the continued development and adoption of sodium alginate-based emulsifiers.

Market Demand Analysis

The market demand for novel emulsifiers enabled by sodium alginate has been steadily growing, driven by increasing consumer preferences for natural and sustainable ingredients in various industries. The food and beverage sector, in particular, has shown significant interest in these innovative emulsifiers due to their ability to improve product texture, stability, and shelf life while meeting clean label requirements.

In the food industry, there is a rising demand for plant-based alternatives to traditional emulsifiers, especially in dairy-free and vegan products. Sodium alginate-based emulsifiers offer a solution to this challenge, providing manufacturers with a versatile and effective option for creating stable emulsions in plant-based milk, yogurt, and cheese alternatives. This trend aligns with the global shift towards plant-based diets and sustainability, further fueling the market growth for these novel emulsifiers.

The cosmetics and personal care industry has also recognized the potential of sodium alginate-enabled emulsifiers. With consumers increasingly seeking natural and eco-friendly beauty products, there is a growing demand for emulsifiers that can provide stability and texture without synthetic additives. Sodium alginate-based emulsifiers meet these requirements, offering formulators a way to create stable, luxurious textures in creams, lotions, and other personal care products.

In the pharmaceutical sector, the demand for novel emulsifiers is driven by the need for improved drug delivery systems and enhanced bioavailability of active ingredients. Sodium alginate-enabled emulsifiers show promise in creating stable emulsions for topical and oral medications, potentially improving drug efficacy and patient compliance.

The industrial sector, including paints, coatings, and adhesives, is another area where sodium alginate-based emulsifiers are gaining traction. These industries are seeking more sustainable and environmentally friendly alternatives to traditional petroleum-based emulsifiers, driving the demand for bio-based options like those derived from sodium alginate.

Market research indicates that the global emulsifier market is expected to continue its growth trajectory, with natural and plant-based emulsifiers playing an increasingly important role. The unique properties of sodium alginate-enabled emulsifiers position them well to capture a significant portion of this growing market, particularly in regions with stringent regulations on synthetic additives and a strong focus on sustainability.

As consumer awareness of ingredient sourcing and environmental impact continues to rise, the demand for sodium alginate-based emulsifiers is likely to expand further. This trend is reinforced by ongoing research and development efforts to enhance the functionality and applicability of these novel emulsifiers across various industries, promising continued market growth and innovation in the coming years.

In the food industry, there is a rising demand for plant-based alternatives to traditional emulsifiers, especially in dairy-free and vegan products. Sodium alginate-based emulsifiers offer a solution to this challenge, providing manufacturers with a versatile and effective option for creating stable emulsions in plant-based milk, yogurt, and cheese alternatives. This trend aligns with the global shift towards plant-based diets and sustainability, further fueling the market growth for these novel emulsifiers.

The cosmetics and personal care industry has also recognized the potential of sodium alginate-enabled emulsifiers. With consumers increasingly seeking natural and eco-friendly beauty products, there is a growing demand for emulsifiers that can provide stability and texture without synthetic additives. Sodium alginate-based emulsifiers meet these requirements, offering formulators a way to create stable, luxurious textures in creams, lotions, and other personal care products.

In the pharmaceutical sector, the demand for novel emulsifiers is driven by the need for improved drug delivery systems and enhanced bioavailability of active ingredients. Sodium alginate-enabled emulsifiers show promise in creating stable emulsions for topical and oral medications, potentially improving drug efficacy and patient compliance.

The industrial sector, including paints, coatings, and adhesives, is another area where sodium alginate-based emulsifiers are gaining traction. These industries are seeking more sustainable and environmentally friendly alternatives to traditional petroleum-based emulsifiers, driving the demand for bio-based options like those derived from sodium alginate.

Market research indicates that the global emulsifier market is expected to continue its growth trajectory, with natural and plant-based emulsifiers playing an increasingly important role. The unique properties of sodium alginate-enabled emulsifiers position them well to capture a significant portion of this growing market, particularly in regions with stringent regulations on synthetic additives and a strong focus on sustainability.

As consumer awareness of ingredient sourcing and environmental impact continues to rise, the demand for sodium alginate-based emulsifiers is likely to expand further. This trend is reinforced by ongoing research and development efforts to enhance the functionality and applicability of these novel emulsifiers across various industries, promising continued market growth and innovation in the coming years.

Current Challenges in Emulsifier Technology

The emulsifier industry faces several significant challenges in meeting the evolving demands of various sectors, including food, cosmetics, and pharmaceuticals. One of the primary concerns is the increasing consumer preference for natural and clean-label products, which has put pressure on manufacturers to develop emulsifiers from natural sources. This shift has led to difficulties in maintaining the same level of functionality and stability as synthetic emulsifiers while ensuring cost-effectiveness and scalability.

Another major challenge is the need for emulsifiers that can perform effectively in complex formulations. As product compositions become more intricate, emulsifiers must be able to stabilize multiple phases and ingredients, often under varying pH levels, temperatures, and processing conditions. This requirement has pushed the boundaries of current emulsifier technology, necessitating the development of more versatile and robust solutions.

The demand for emulsifiers with enhanced nutritional profiles has also emerged as a significant challenge. Consumers are increasingly seeking products that not only perform their primary function but also offer additional health benefits. This has led to a focus on developing emulsifiers that can contribute to improved nutritional value, such as those with prebiotic properties or the ability to reduce fat content without compromising texture and mouthfeel.

Sustainability and environmental concerns present another set of challenges for the emulsifier industry. There is growing pressure to develop emulsifiers from renewable resources and to ensure that production processes are environmentally friendly. This includes reducing water usage, minimizing waste, and lowering carbon footprints throughout the supply chain.

Regulatory compliance and safety considerations continue to be critical challenges. As regulations become more stringent and vary across different regions, emulsifier manufacturers must navigate a complex landscape of approvals and certifications. Ensuring the safety of novel emulsifiers, particularly those derived from new sources, requires extensive testing and documentation, which can be time-consuming and costly.

The need for emulsifiers with improved functionality in specific applications poses another challenge. For instance, in the food industry, there is a growing demand for emulsifiers that can withstand high-temperature processing or provide extended shelf life without affecting taste or texture. Similarly, in cosmetics, emulsifiers that offer better skin compatibility and enhanced sensory properties are highly sought after.

Lastly, the challenge of developing emulsifiers that can address specific dietary requirements, such as vegan, kosher, or halal certifications, has become increasingly important. This necessitates careful sourcing of raw materials and adaptation of production processes to meet these specialized needs while maintaining the desired emulsification properties.

Another major challenge is the need for emulsifiers that can perform effectively in complex formulations. As product compositions become more intricate, emulsifiers must be able to stabilize multiple phases and ingredients, often under varying pH levels, temperatures, and processing conditions. This requirement has pushed the boundaries of current emulsifier technology, necessitating the development of more versatile and robust solutions.

The demand for emulsifiers with enhanced nutritional profiles has also emerged as a significant challenge. Consumers are increasingly seeking products that not only perform their primary function but also offer additional health benefits. This has led to a focus on developing emulsifiers that can contribute to improved nutritional value, such as those with prebiotic properties or the ability to reduce fat content without compromising texture and mouthfeel.

Sustainability and environmental concerns present another set of challenges for the emulsifier industry. There is growing pressure to develop emulsifiers from renewable resources and to ensure that production processes are environmentally friendly. This includes reducing water usage, minimizing waste, and lowering carbon footprints throughout the supply chain.

Regulatory compliance and safety considerations continue to be critical challenges. As regulations become more stringent and vary across different regions, emulsifier manufacturers must navigate a complex landscape of approvals and certifications. Ensuring the safety of novel emulsifiers, particularly those derived from new sources, requires extensive testing and documentation, which can be time-consuming and costly.

The need for emulsifiers with improved functionality in specific applications poses another challenge. For instance, in the food industry, there is a growing demand for emulsifiers that can withstand high-temperature processing or provide extended shelf life without affecting taste or texture. Similarly, in cosmetics, emulsifiers that offer better skin compatibility and enhanced sensory properties are highly sought after.

Lastly, the challenge of developing emulsifiers that can address specific dietary requirements, such as vegan, kosher, or halal certifications, has become increasingly important. This necessitates careful sourcing of raw materials and adaptation of production processes to meet these specialized needs while maintaining the desired emulsification properties.

Existing Sodium Alginate Emulsifier Solutions

01 Sodium alginate as a natural emulsifier

Sodium alginate, derived from brown algae, is used as a natural emulsifier in various formulations. It can stabilize oil-in-water emulsions and improve the texture and consistency of products. Its ability to form gels and its biocompatibility make it suitable for use in food, cosmetic, and pharmaceutical applications.- Sodium alginate as a natural emulsifier: Sodium alginate, derived from brown algae, serves as an effective natural emulsifier in various formulations. It stabilizes emulsions by forming a protective layer around oil droplets, preventing coalescence. This biodegradable and biocompatible compound is widely used in food, cosmetic, and pharmaceutical industries due to its emulsifying properties and ability to improve product texture and stability.

- Combination with other emulsifiers: Sodium alginate can be combined with other emulsifiers to enhance emulsion stability and improve overall product performance. These combinations often result in synergistic effects, allowing for reduced usage of individual emulsifiers while maintaining or improving emulsion quality. Common co-emulsifiers include lecithin, polysorbates, and other natural or synthetic surfactants.

- Application in controlled release systems: Sodium alginate emulsifiers are utilized in controlled release systems for various active ingredients. The ability of sodium alginate to form gels in the presence of divalent cations allows for the creation of matrix systems that can modulate the release of encapsulated compounds. This property is particularly useful in pharmaceutical and nutraceutical applications for targeted and sustained delivery of drugs or nutrients.

- Use in personal care and cosmetic products: Sodium alginate emulsifiers find extensive use in personal care and cosmetic formulations. They contribute to the stability and texture of creams, lotions, and other emulsion-based products. The natural origin and skin-friendly properties of sodium alginate make it a popular choice for clean label and natural cosmetic products, providing both functional and marketing benefits.

- Modification and functionalization of sodium alginate: Research focuses on modifying and functionalizing sodium alginate to enhance its emulsifying properties and expand its applications. Chemical modifications, such as esterification or grafting with hydrophobic groups, can improve the emulsifying capacity and stability of sodium alginate-based emulsions. These modifications allow for tailoring the properties of sodium alginate to meet specific formulation requirements in various industries.

02 Combination with other emulsifiers

Sodium alginate can be combined with other emulsifiers to enhance stability and performance. These combinations can create synergistic effects, improving emulsion stability, texture, and shelf life. Common combinations include sodium alginate with lecithin, polysorbates, or other natural emulsifiers.Expand Specific Solutions03 Application in controlled release systems

Sodium alginate emulsifiers are utilized in controlled release systems for various active ingredients. The gel-forming properties of sodium alginate allow for the encapsulation of drugs, flavors, or other compounds, providing sustained release and improved bioavailability. This technology is particularly useful in pharmaceutical and nutraceutical applications.Expand Specific Solutions04 Use in personal care and cosmetic products

Sodium alginate emulsifiers are widely used in personal care and cosmetic formulations. They contribute to the stability and texture of creams, lotions, and gels. The natural origin and skin-friendly properties of sodium alginate make it an attractive choice for clean beauty and natural cosmetic products.Expand Specific Solutions05 Modification and functionalization of sodium alginate

Research focuses on modifying and functionalizing sodium alginate to enhance its emulsifying properties. This includes chemical modifications, grafting with other polymers, or creating nanoparticles. These modifications can improve emulsion stability, increase compatibility with different ingredients, and expand the range of applications for sodium alginate emulsifiers.Expand Specific Solutions

Key Players in Alginate-Based Emulsifiers

The development of novel emulsifiers using sodium alginate is currently in a growth phase, with increasing market demand and technological advancements. The global market for alginate-based emulsifiers is expanding, driven by the food, pharmaceutical, and cosmetic industries. While the technology is not fully mature, significant progress has been made in recent years. Companies like FMC Corp., Clariant Produkte, and SEPPIC SA are leading the way in research and development, focusing on improving stability, functionality, and sustainability of alginate-based emulsifiers. Collaborations between industry players and research institutions, such as the National University of Singapore and Osaka University, are accelerating innovation in this field, promising new applications and improved performance in various sectors.

National University of Singapore

Technical Solution: Researchers at the National University of Singapore have developed a novel approach to using sodium alginate as an emulsifier by combining it with nanocellulose. This innovative system involves creating a composite material that leverages the synergistic effects of sodium alginate's gelling properties and nanocellulose's high surface area and mechanical strength. The resulting emulsifier demonstrates exceptional stability in oil-in-water emulsions, even at low concentrations[9]. The team has shown that this composite emulsifier can create Pickering emulsions, where solid particles stabilize the interface between oil and water phases. This technology has potential applications in food, cosmetics, and pharmaceutical industries, offering improved emulsion stability and the ability to encapsulate active ingredients effectively[10]. The researchers have also explored the use of this system in creating responsive emulsions that can be triggered to release their contents under specific environmental conditions.

Strengths: High emulsion stability at low concentrations, potential for responsive and controlled release systems, eco-friendly components. Weaknesses: May require specialized production processes, potential scalability challenges for industrial applications.

The Lubrizol Corp.

Technical Solution: The Lubrizol Corporation has developed a novel emulsifier system that incorporates sodium alginate as a key component in their Carbopol® Aqua SF-2 polymer. This technology combines the thickening and stabilizing properties of sodium alginate with the company's proprietary cross-linked acrylic acid polymer. The resulting emulsifier system provides excellent stability in oil-in-water emulsions, particularly in challenging environments such as high-salt or high-acid conditions[5]. Lubrizol's approach allows for the creation of emulsions with improved texture and sensory properties, while also offering enhanced suspension capabilities for particulates in the formulation. The company has successfully applied this technology in various personal care and pharmaceutical applications, including lotions, creams, and topical drug delivery systems[6].

Strengths: Excellent stability in challenging conditions, improved texture and sensory properties, versatile applications. Weaknesses: May require specific formulation expertise, potential limitations in food applications due to synthetic polymer components.

Core Innovations in Alginate Emulsification

Non-stick antibiotic gels

PatentPendingUS20230113554A1

Innovation

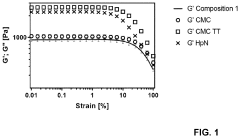

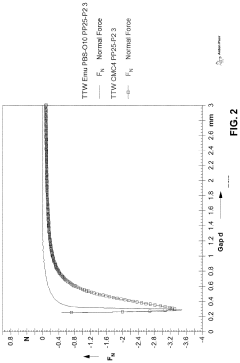

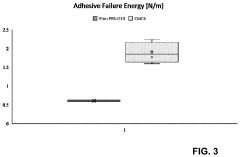

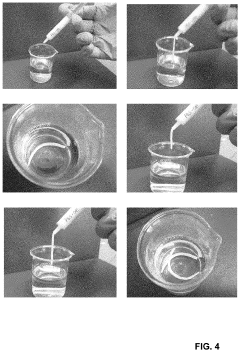

- An oil-in-water emulsion gel with specific rheological properties is developed, which exhibits low stickiness to medical gloves and cohesive properties, allowing it to be effectively applied and stay in place, comprising a pharmaceutically acceptable oil, an aqueous phase, an osmotic agent, an emulsifying agent, and a gelling polysaccharide, optionally mixed with bioactive agents.

Process for tartaric stabilization of wines and products derived from wine or derived from grapes

PatentInactiveEP4123009A1

Innovation

- The use of alginic acid or alginate, derived from algae or bacteria, as a protective colloid to slow the growth of potassium hydrogen tartrate and calcium tartrate crystals in wines, with concentrations between 5 g/hL and 100 g/hL, effectively stabilizing wines and grape derivatives by inhibiting crystal formation without affecting wine quality or causing allergenic concerns.

Regulatory Landscape for Novel Food Emulsifiers

The regulatory landscape for novel food emulsifiers, particularly those derived from sodium alginate, is complex and evolving. In the United States, the Food and Drug Administration (FDA) oversees the approval process for new food additives, including emulsifiers. Sodium alginate is generally recognized as safe (GRAS) for use in food, but novel emulsifiers derived from it may require additional safety assessments.

The European Food Safety Authority (EFSA) regulates food additives in the European Union. EFSA has established specific purity criteria and specifications for sodium alginate (E401) as a food additive. However, novel emulsifiers based on sodium alginate modifications would likely require separate evaluations and approvals.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates food additives. Sodium alginate is approved for use, but new derivatives would need to undergo safety assessments and obtain approval before market introduction.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards. These standards often influence national regulations and can impact the approval process for novel emulsifiers.

Regulatory bodies typically require extensive safety data, including toxicological studies, for novel food additives. This process can be time-consuming and costly, potentially impacting the commercialization timeline for new sodium alginate-based emulsifiers.

Environmental regulations may also come into play, particularly if the production process for these novel emulsifiers involves chemical modifications or generates waste products. Manufacturers must consider sustainability and environmental impact alongside food safety regulations.

Labeling requirements for novel emulsifiers vary by region but generally demand clear identification of the additive on product packaging. In some jurisdictions, additional information about the source or production method may be required, especially for ingredients derived from genetically modified organisms.

As consumer demand for "clean label" products grows, regulatory bodies are increasingly scrutinizing synthetic additives. This trend may favor naturally derived emulsifiers like those based on sodium alginate, potentially streamlining their approval process in some markets.

Regulatory harmonization efforts, such as mutual recognition agreements between countries, may facilitate the approval of novel emulsifiers across multiple markets. However, significant differences in regulatory approaches still exist, necessitating tailored strategies for global market entry.

The European Food Safety Authority (EFSA) regulates food additives in the European Union. EFSA has established specific purity criteria and specifications for sodium alginate (E401) as a food additive. However, novel emulsifiers based on sodium alginate modifications would likely require separate evaluations and approvals.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates food additives. Sodium alginate is approved for use, but new derivatives would need to undergo safety assessments and obtain approval before market introduction.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards. These standards often influence national regulations and can impact the approval process for novel emulsifiers.

Regulatory bodies typically require extensive safety data, including toxicological studies, for novel food additives. This process can be time-consuming and costly, potentially impacting the commercialization timeline for new sodium alginate-based emulsifiers.

Environmental regulations may also come into play, particularly if the production process for these novel emulsifiers involves chemical modifications or generates waste products. Manufacturers must consider sustainability and environmental impact alongside food safety regulations.

Labeling requirements for novel emulsifiers vary by region but generally demand clear identification of the additive on product packaging. In some jurisdictions, additional information about the source or production method may be required, especially for ingredients derived from genetically modified organisms.

As consumer demand for "clean label" products grows, regulatory bodies are increasingly scrutinizing synthetic additives. This trend may favor naturally derived emulsifiers like those based on sodium alginate, potentially streamlining their approval process in some markets.

Regulatory harmonization efforts, such as mutual recognition agreements between countries, may facilitate the approval of novel emulsifiers across multiple markets. However, significant differences in regulatory approaches still exist, necessitating tailored strategies for global market entry.

Sustainability Aspects of Alginate Emulsifiers

The sustainability aspects of alginate emulsifiers derived from sodium alginate present a compelling case for their adoption in various industries. These emulsifiers offer significant environmental benefits compared to traditional synthetic alternatives, aligning with the growing demand for eco-friendly and sustainable products.

Sodium alginate, extracted from brown seaweed, is a renewable and biodegradable resource. Its production has a lower environmental impact compared to petroleum-based emulsifiers, reducing the carbon footprint associated with manufacturing processes. The cultivation of seaweed for alginate extraction also contributes to carbon sequestration, as seaweed absorbs CO2 from the atmosphere during growth.

The biodegradability of alginate emulsifiers is a key sustainability advantage. Unlike many synthetic emulsifiers that persist in the environment, alginate-based emulsifiers break down naturally, minimizing long-term ecological impact. This characteristic is particularly important in applications where the emulsifier may enter water systems or soil.

In terms of resource efficiency, alginate emulsifiers often require lower concentrations to achieve the desired emulsification effect compared to some synthetic alternatives. This efficiency translates to reduced raw material consumption and potentially lower transportation costs, further enhancing their sustainability profile.

The versatility of alginate emulsifiers allows for their use across multiple industries, including food, cosmetics, and pharmaceuticals. This cross-industry applicability promotes the development of more sustainable product formulations across various sectors, contributing to a broader shift towards environmentally friendly practices.

From a health and safety perspective, alginate emulsifiers are generally recognized as safe (GRAS) by regulatory bodies. This natural origin and safety profile align with consumer preferences for clean label products, potentially reducing the need for additional synthetic additives in formulations.

However, it is important to consider the potential environmental impacts of large-scale seaweed cultivation for alginate production. Sustainable harvesting practices and careful management of marine ecosystems are crucial to ensure the long-term viability of this resource without causing ecological disruption.

In conclusion, the sustainability aspects of alginate emulsifiers offer significant advantages in terms of renewability, biodegradability, and reduced environmental impact. As industries continue to prioritize sustainable solutions, the development and adoption of alginate-based emulsifiers represent a promising direction for more environmentally responsible product formulations.

Sodium alginate, extracted from brown seaweed, is a renewable and biodegradable resource. Its production has a lower environmental impact compared to petroleum-based emulsifiers, reducing the carbon footprint associated with manufacturing processes. The cultivation of seaweed for alginate extraction also contributes to carbon sequestration, as seaweed absorbs CO2 from the atmosphere during growth.

The biodegradability of alginate emulsifiers is a key sustainability advantage. Unlike many synthetic emulsifiers that persist in the environment, alginate-based emulsifiers break down naturally, minimizing long-term ecological impact. This characteristic is particularly important in applications where the emulsifier may enter water systems or soil.

In terms of resource efficiency, alginate emulsifiers often require lower concentrations to achieve the desired emulsification effect compared to some synthetic alternatives. This efficiency translates to reduced raw material consumption and potentially lower transportation costs, further enhancing their sustainability profile.

The versatility of alginate emulsifiers allows for their use across multiple industries, including food, cosmetics, and pharmaceuticals. This cross-industry applicability promotes the development of more sustainable product formulations across various sectors, contributing to a broader shift towards environmentally friendly practices.

From a health and safety perspective, alginate emulsifiers are generally recognized as safe (GRAS) by regulatory bodies. This natural origin and safety profile align with consumer preferences for clean label products, potentially reducing the need for additional synthetic additives in formulations.

However, it is important to consider the potential environmental impacts of large-scale seaweed cultivation for alginate production. Sustainable harvesting practices and careful management of marine ecosystems are crucial to ensure the long-term viability of this resource without causing ecological disruption.

In conclusion, the sustainability aspects of alginate emulsifiers offer significant advantages in terms of renewability, biodegradability, and reduced environmental impact. As industries continue to prioritize sustainable solutions, the development and adoption of alginate-based emulsifiers represent a promising direction for more environmentally responsible product formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!