How Sodium Alginate Drives Quality in Food Emulsification?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Evolution

Sodium alginate, a versatile polysaccharide derived from brown seaweed, has undergone significant evolution in its application to food emulsification. Initially discovered in the late 19th century, it wasn't until the mid-20th century that its potential in food technology began to be fully realized.

In the 1950s and 1960s, researchers started exploring sodium alginate's unique gelling properties, which laid the foundation for its use in food emulsification. The ability of sodium alginate to form stable gels in the presence of calcium ions became a key factor in its early applications, particularly in restructured foods and as a thickening agent.

The 1970s and 1980s saw a surge in research focused on understanding the molecular structure and behavior of sodium alginate in various food systems. This period marked a significant shift from empirical applications to a more scientific approach in utilizing sodium alginate for emulsification. Scientists began to unravel the mechanisms by which sodium alginate interacts with other food components, leading to improved emulsion stability.

By the 1990s, advances in food processing technology allowed for more sophisticated applications of sodium alginate in emulsification. The development of microencapsulation techniques using sodium alginate opened new possibilities in flavor retention and controlled release of active ingredients in food products. This era also saw the emergence of sodium alginate as a key ingredient in molecular gastronomy, pushing the boundaries of culinary innovation.

The turn of the millennium brought about a renewed interest in natural and clean label ingredients, propelling sodium alginate to the forefront of food emulsification technology. Its plant-based origin and versatility made it an attractive alternative to synthetic emulsifiers. Research in this period focused on optimizing sodium alginate's performance in various food matrices and understanding its synergistic effects with other hydrocolloids.

Recent years have witnessed a shift towards tailoring sodium alginate for specific applications in food emulsification. Advanced modification techniques have been developed to alter its molecular weight and chemical structure, allowing for fine-tuning of its emulsifying properties. This has led to the creation of sodium alginate variants with enhanced functionality in different food systems.

The evolution of sodium alginate in food emulsification continues to be driven by consumer demands for cleaner labels, improved texture, and enhanced nutritional profiles. Current research is exploring the potential of sodium alginate in creating stable emulsions for plant-based alternatives to dairy and meat products, as well as its role in developing functional foods with improved bioavailability of nutrients.

In the 1950s and 1960s, researchers started exploring sodium alginate's unique gelling properties, which laid the foundation for its use in food emulsification. The ability of sodium alginate to form stable gels in the presence of calcium ions became a key factor in its early applications, particularly in restructured foods and as a thickening agent.

The 1970s and 1980s saw a surge in research focused on understanding the molecular structure and behavior of sodium alginate in various food systems. This period marked a significant shift from empirical applications to a more scientific approach in utilizing sodium alginate for emulsification. Scientists began to unravel the mechanisms by which sodium alginate interacts with other food components, leading to improved emulsion stability.

By the 1990s, advances in food processing technology allowed for more sophisticated applications of sodium alginate in emulsification. The development of microencapsulation techniques using sodium alginate opened new possibilities in flavor retention and controlled release of active ingredients in food products. This era also saw the emergence of sodium alginate as a key ingredient in molecular gastronomy, pushing the boundaries of culinary innovation.

The turn of the millennium brought about a renewed interest in natural and clean label ingredients, propelling sodium alginate to the forefront of food emulsification technology. Its plant-based origin and versatility made it an attractive alternative to synthetic emulsifiers. Research in this period focused on optimizing sodium alginate's performance in various food matrices and understanding its synergistic effects with other hydrocolloids.

Recent years have witnessed a shift towards tailoring sodium alginate for specific applications in food emulsification. Advanced modification techniques have been developed to alter its molecular weight and chemical structure, allowing for fine-tuning of its emulsifying properties. This has led to the creation of sodium alginate variants with enhanced functionality in different food systems.

The evolution of sodium alginate in food emulsification continues to be driven by consumer demands for cleaner labels, improved texture, and enhanced nutritional profiles. Current research is exploring the potential of sodium alginate in creating stable emulsions for plant-based alternatives to dairy and meat products, as well as its role in developing functional foods with improved bioavailability of nutrients.

Market Demand Analysis

The market demand for sodium alginate in food emulsification has been steadily growing due to its unique properties and versatile applications. This natural polysaccharide, derived from brown seaweed, has gained significant traction in the food industry as a stabilizer, thickener, and emulsifier. Its ability to form stable emulsions and improve texture in various food products has made it an essential ingredient for manufacturers seeking to enhance product quality and shelf life.

The global food emulsifiers market, of which sodium alginate is a key component, has been experiencing robust growth. This growth is primarily driven by the increasing consumer demand for processed and convenience foods, as well as the rising awareness of clean label ingredients. Sodium alginate, being a natural and plant-based ingredient, aligns well with the clean label trend, making it an attractive option for food manufacturers looking to meet consumer preferences for healthier and more natural food products.

In the beverage industry, sodium alginate has found extensive use in stabilizing and improving the mouthfeel of dairy-based drinks, fruit juices, and plant-based milk alternatives. The growing popularity of plant-based diets has further boosted the demand for sodium alginate as a crucial ingredient in creating stable emulsions in non-dairy products. This trend is expected to continue as more consumers shift towards plant-based alternatives for health and environmental reasons.

The bakery and confectionery sectors have also contributed significantly to the market demand for sodium alginate. Its ability to improve dough stability, enhance texture, and extend shelf life has made it a valuable ingredient in various baked goods and confectionery products. The increasing consumption of bakery products, particularly in developing economies, is expected to drive further growth in the sodium alginate market.

Moreover, the pharmaceutical and nutraceutical industries have shown growing interest in sodium alginate for its potential in drug delivery systems and as a dietary fiber supplement. This diversification of applications beyond traditional food emulsification is likely to open up new market opportunities and drive further demand for sodium alginate.

The Asia-Pacific region has emerged as a key market for sodium alginate, driven by the rapid growth of the food processing industry in countries like China and India. The increasing adoption of Western dietary habits and the rising demand for processed foods in these markets are expected to fuel the growth of sodium alginate usage in food emulsification applications.

As consumers become more health-conscious and demand cleaner labels, the market for natural emulsifiers like sodium alginate is projected to expand further. Food manufacturers are increasingly looking for alternatives to synthetic emulsifiers, positioning sodium alginate as a preferred choice due to its natural origin and functional benefits. This shift towards natural ingredients is likely to sustain the market demand for sodium alginate in food emulsification applications in the foreseeable future.

The global food emulsifiers market, of which sodium alginate is a key component, has been experiencing robust growth. This growth is primarily driven by the increasing consumer demand for processed and convenience foods, as well as the rising awareness of clean label ingredients. Sodium alginate, being a natural and plant-based ingredient, aligns well with the clean label trend, making it an attractive option for food manufacturers looking to meet consumer preferences for healthier and more natural food products.

In the beverage industry, sodium alginate has found extensive use in stabilizing and improving the mouthfeel of dairy-based drinks, fruit juices, and plant-based milk alternatives. The growing popularity of plant-based diets has further boosted the demand for sodium alginate as a crucial ingredient in creating stable emulsions in non-dairy products. This trend is expected to continue as more consumers shift towards plant-based alternatives for health and environmental reasons.

The bakery and confectionery sectors have also contributed significantly to the market demand for sodium alginate. Its ability to improve dough stability, enhance texture, and extend shelf life has made it a valuable ingredient in various baked goods and confectionery products. The increasing consumption of bakery products, particularly in developing economies, is expected to drive further growth in the sodium alginate market.

Moreover, the pharmaceutical and nutraceutical industries have shown growing interest in sodium alginate for its potential in drug delivery systems and as a dietary fiber supplement. This diversification of applications beyond traditional food emulsification is likely to open up new market opportunities and drive further demand for sodium alginate.

The Asia-Pacific region has emerged as a key market for sodium alginate, driven by the rapid growth of the food processing industry in countries like China and India. The increasing adoption of Western dietary habits and the rising demand for processed foods in these markets are expected to fuel the growth of sodium alginate usage in food emulsification applications.

As consumers become more health-conscious and demand cleaner labels, the market for natural emulsifiers like sodium alginate is projected to expand further. Food manufacturers are increasingly looking for alternatives to synthetic emulsifiers, positioning sodium alginate as a preferred choice due to its natural origin and functional benefits. This shift towards natural ingredients is likely to sustain the market demand for sodium alginate in food emulsification applications in the foreseeable future.

Technical Challenges

The use of sodium alginate in food emulsification presents several technical challenges that researchers and food technologists must address. One of the primary issues is the sensitivity of sodium alginate to pH levels. In acidic environments, sodium alginate tends to form gels, which can significantly alter the desired emulsion properties. This pH sensitivity limits its application in certain food products and requires careful formulation to maintain stability across various pH ranges.

Another challenge lies in the molecular weight distribution of sodium alginate. The performance of sodium alginate as an emulsifier is highly dependent on its molecular weight, with higher molecular weight generally providing better emulsification properties. However, controlling and maintaining consistent molecular weight distributions during production and processing can be difficult, leading to variability in emulsion quality and stability.

The interaction of sodium alginate with other food components, particularly proteins and divalent cations, poses additional challenges. In the presence of calcium ions, for example, sodium alginate can form strong gels, which may be desirable in some applications but can disrupt emulsion stability in others. Balancing these interactions to achieve the desired emulsion properties requires precise control and understanding of the food matrix.

Viscosity control is another significant technical hurdle. While the thickening properties of sodium alginate can contribute to emulsion stability, excessive viscosity can impede processing and affect the final product texture. Achieving the optimal viscosity for both processing efficiency and desired product characteristics often requires extensive experimentation and fine-tuning.

The thermal stability of sodium alginate-based emulsions is also a concern, particularly in food products that undergo heat treatment during processing or preparation. High temperatures can degrade the alginate structure, potentially leading to emulsion breakdown. Developing heat-stable formulations that maintain emulsion integrity across various temperature ranges remains an ongoing challenge.

Furthermore, the sensory impact of sodium alginate on food products must be carefully managed. While it can improve texture and mouthfeel, excessive use may impart undesirable flavors or aftertastes. Balancing the functional benefits with sensory acceptability requires careful optimization and often involves trade-offs between emulsion stability and organoleptic properties.

Lastly, the clean label trend in the food industry presents a challenge for sodium alginate usage. As consumers demand more natural and recognizable ingredients, food manufacturers must find ways to incorporate sodium alginate in a manner that aligns with clean label expectations or explore alternative natural emulsifiers that can match its functionality.

Another challenge lies in the molecular weight distribution of sodium alginate. The performance of sodium alginate as an emulsifier is highly dependent on its molecular weight, with higher molecular weight generally providing better emulsification properties. However, controlling and maintaining consistent molecular weight distributions during production and processing can be difficult, leading to variability in emulsion quality and stability.

The interaction of sodium alginate with other food components, particularly proteins and divalent cations, poses additional challenges. In the presence of calcium ions, for example, sodium alginate can form strong gels, which may be desirable in some applications but can disrupt emulsion stability in others. Balancing these interactions to achieve the desired emulsion properties requires precise control and understanding of the food matrix.

Viscosity control is another significant technical hurdle. While the thickening properties of sodium alginate can contribute to emulsion stability, excessive viscosity can impede processing and affect the final product texture. Achieving the optimal viscosity for both processing efficiency and desired product characteristics often requires extensive experimentation and fine-tuning.

The thermal stability of sodium alginate-based emulsions is also a concern, particularly in food products that undergo heat treatment during processing or preparation. High temperatures can degrade the alginate structure, potentially leading to emulsion breakdown. Developing heat-stable formulations that maintain emulsion integrity across various temperature ranges remains an ongoing challenge.

Furthermore, the sensory impact of sodium alginate on food products must be carefully managed. While it can improve texture and mouthfeel, excessive use may impart undesirable flavors or aftertastes. Balancing the functional benefits with sensory acceptability requires careful optimization and often involves trade-offs between emulsion stability and organoleptic properties.

Lastly, the clean label trend in the food industry presents a challenge for sodium alginate usage. As consumers demand more natural and recognizable ingredients, food manufacturers must find ways to incorporate sodium alginate in a manner that aligns with clean label expectations or explore alternative natural emulsifiers that can match its functionality.

Current Solutions

01 Purification and quality control methods

Various techniques are employed to purify sodium alginate and control its quality. These methods include filtration, precipitation, and chromatography. Quality control measures involve testing for viscosity, molecular weight, and chemical composition to ensure consistency and purity of the final product.- Purification and quality control methods: Various techniques are employed to purify sodium alginate and control its quality. These methods include filtration, precipitation, and chromatography. Quality control measures involve testing for viscosity, molecular weight distribution, and impurity levels to ensure consistent product quality.

- Modification of sodium alginate properties: Researchers have developed methods to modify sodium alginate properties, such as improving its stability, solubility, and gelation characteristics. These modifications can be achieved through chemical reactions, physical treatments, or blending with other polymers to enhance its performance in various applications.

- Extraction and production processes: Innovative extraction and production processes have been developed to obtain high-quality sodium alginate from various algae sources. These processes focus on optimizing yield, reducing environmental impact, and improving the efficiency of extraction and purification steps.

- Characterization and analysis techniques: Advanced characterization and analysis techniques are used to assess the quality of sodium alginate. These methods include spectroscopic analysis, rheological measurements, and thermal analysis to determine the structural and functional properties of the polymer.

- Application-specific quality requirements: Different applications of sodium alginate require specific quality attributes. For example, in biomedical applications, high purity and biocompatibility are crucial, while in food applications, factors such as viscosity and gelling properties are important. Tailoring the quality of sodium alginate to meet these application-specific requirements is an active area of research.

02 Modification of sodium alginate properties

Researchers have developed methods to modify sodium alginate properties to enhance its performance in specific applications. These modifications include chemical crosslinking, grafting with other polymers, and adjusting the ratio of mannuronic to guluronic acid residues. Such modifications can improve gel strength, stability, and biocompatibility.Expand Specific Solutions03 Extraction and production processes

Innovative extraction and production processes have been developed to obtain high-quality sodium alginate from various algal sources. These processes focus on optimizing yield, reducing impurities, and maintaining the structural integrity of the alginate molecules. Techniques such as enzymatic extraction and microwave-assisted extraction have shown promising results.Expand Specific Solutions04 Characterization and analysis techniques

Advanced characterization and analysis techniques are crucial for assessing sodium alginate quality. These include spectroscopic methods (NMR, FTIR), chromatographic techniques (GPC, HPLC), and rheological measurements. Such techniques provide detailed information on the structure, composition, and physical properties of sodium alginate samples.Expand Specific Solutions05 Application-specific quality requirements

Different applications of sodium alginate require specific quality attributes. For example, biomedical applications may demand high purity and controlled molecular weight distribution, while food industry applications may focus on gelling properties and viscosity. Tailoring sodium alginate quality to meet these application-specific requirements involves adjusting production parameters and implementing targeted quality control measures.Expand Specific Solutions

Key Industry Players

The sodium alginate market in food emulsification is in a growth phase, driven by increasing demand for natural emulsifiers and stabilizers. The market size is expanding due to rising applications in various food products. Technologically, sodium alginate is well-established, with ongoing research to enhance its functionality. Key players like FMC Corp., Kikkoman Biochemifa Co., and Shandong Jiejing Group Co. Ltd. are at the forefront, continuously improving product quality and applications. Academic institutions such as Jiangnan University and Tianjin University of Science & Technology are contributing to advancements in sodium alginate technology, indicating a collaborative ecosystem between industry and academia for further innovation.

Jiangnan University

Technical Solution: Jiangnan University has conducted extensive research on sodium alginate's role in food emulsification, focusing on molecular-level interactions and novel applications. Their studies have revealed that sodium alginate can form electrostatic complexes with proteins, significantly enhancing emulsion stability in acidic conditions[10]. The university's research team has developed a method to modify sodium alginate through partial oxidation, improving its emulsifying properties and expanding its application in high-fat emulsions[11]. Additionally, they have explored the use of sodium alginate in combination with other polysaccharides to create multi-layered emulsions with enhanced stability and controlled release properties, particularly useful in functional food applications[12]. Their work has also demonstrated the potential of sodium alginate-based emulsions as delivery systems for bioactive compounds, improving their bioavailability and stability during digestion[13].

Strengths: Cutting-edge research on molecular interactions, innovative modification techniques. Weaknesses: Findings may require further development for commercial application.

Tianjin University of Science & Technology

Technical Solution: Tianjin University of Science & Technology has made significant contributions to understanding sodium alginate's role in food emulsification through systematic research. Their studies have focused on the structural characteristics of sodium alginate and how they influence emulsion properties. The university's research team has developed a novel approach to modify sodium alginate through controlled depolymerization, resulting in improved emulsifying capacity and stability[14]. They have also investigated the synergistic effects of sodium alginate with various surfactants, identifying optimal combinations for different food systems[15]. Additionally, their work has explored the use of sodium alginate in nano-emulsions, demonstrating its potential in creating ultra-stable emulsions with enhanced bioavailability of lipophilic compounds[16]. The university has also conducted research on the application of sodium alginate in emulsion-based edible films and coatings, showing promising results in extending the shelf life of perishable foods[17].

Strengths: Comprehensive understanding of structure-function relationships, innovative modification techniques. Weaknesses: Some findings may be at early research stages, requiring further validation for industrial applications.

Core Innovations

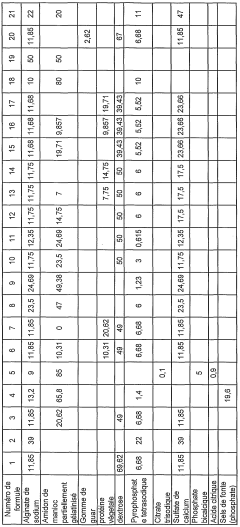

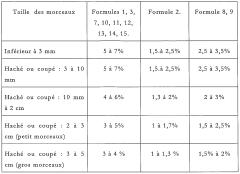

Method and composition for preparing a food product at least partly gelled

PatentWO2006021642A1

Innovation

- A composition comprising sodium alginate, a slowly dissolving calcium salt, a reaction retarding agent, and water-retaining texturizing agents is mixed with food raw materials to create a homogeneous, easily dispersible mixture that gels without delayed addition of alginate, allowing for improved texture, water retention, and yield.

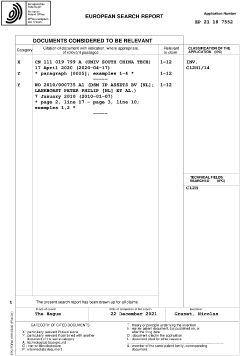

Process for tartaric stabilization of wines and products derived from wine or derived from grapes

PatentInactiveEP4123009A1

Innovation

- The use of alginic acid or alginate, derived from algae or bacteria, as a protective colloid to slow the growth of potassium hydrogen tartrate and calcium tartrate crystals in wines, with concentrations between 5 g/hL and 100 g/hL, effectively stabilizing wines and grape derivatives by inhibiting crystal formation without affecting wine quality or causing allergenic concerns.

Food Safety Regulations

The use of sodium alginate in food emulsification is subject to stringent food safety regulations across various jurisdictions. In the United States, the Food and Drug Administration (FDA) classifies sodium alginate as Generally Recognized as Safe (GRAS) for use in food products. However, its application must adhere to Good Manufacturing Practices (GMP) and specific usage limits outlined in the Code of Federal Regulations (CFR).

The European Food Safety Authority (EFSA) has also evaluated sodium alginate and approved its use as a food additive (E401) within the European Union. The EFSA has established an Acceptable Daily Intake (ADI) for alginates, including sodium alginate, which is considered "not specified," indicating a low level of toxicity when used as intended in food applications.

In Japan, sodium alginate is approved as a food additive by the Ministry of Health, Labour and Welfare. The Japanese regulations specify permitted uses and maximum levels for sodium alginate in various food categories, ensuring its safe application in food emulsification processes.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in food products, setting guidelines for its application in emulsification.

Food manufacturers must comply with labeling requirements when using sodium alginate in their products. In most jurisdictions, sodium alginate must be declared in the ingredient list, often by its specific name or E-number (E401). This transparency allows consumers to make informed choices about the products they consume.

Regulatory bodies also require food producers to implement quality control measures to ensure the purity and safety of sodium alginate used in food production. This includes sourcing from approved suppliers, conducting regular testing for contaminants, and maintaining proper documentation of its use in food formulations.

As food safety regulations continue to evolve, manufacturers must stay informed about any changes or updates regarding the use of sodium alginate in food emulsification. Regular compliance audits and adherence to current Good Manufacturing Practices (cGMP) are essential to maintain regulatory compliance and ensure the safe use of sodium alginate in food products.

The European Food Safety Authority (EFSA) has also evaluated sodium alginate and approved its use as a food additive (E401) within the European Union. The EFSA has established an Acceptable Daily Intake (ADI) for alginates, including sodium alginate, which is considered "not specified," indicating a low level of toxicity when used as intended in food applications.

In Japan, sodium alginate is approved as a food additive by the Ministry of Health, Labour and Welfare. The Japanese regulations specify permitted uses and maximum levels for sodium alginate in various food categories, ensuring its safe application in food emulsification processes.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in food products, setting guidelines for its application in emulsification.

Food manufacturers must comply with labeling requirements when using sodium alginate in their products. In most jurisdictions, sodium alginate must be declared in the ingredient list, often by its specific name or E-number (E401). This transparency allows consumers to make informed choices about the products they consume.

Regulatory bodies also require food producers to implement quality control measures to ensure the purity and safety of sodium alginate used in food production. This includes sourcing from approved suppliers, conducting regular testing for contaminants, and maintaining proper documentation of its use in food formulations.

As food safety regulations continue to evolve, manufacturers must stay informed about any changes or updates regarding the use of sodium alginate in food emulsification. Regular compliance audits and adherence to current Good Manufacturing Practices (cGMP) are essential to maintain regulatory compliance and ensure the safe use of sodium alginate in food products.

Sustainability Aspects

Sodium alginate's role in food emulsification extends beyond its functional properties, encompassing significant sustainability aspects that align with the growing demand for environmentally responsible food production practices. As a natural, biodegradable polymer derived from brown seaweed, sodium alginate offers a sustainable alternative to synthetic emulsifiers, contributing to the reduction of environmental impact in the food industry.

The cultivation and harvesting of seaweed for alginate production present several environmental benefits. Seaweed farms act as carbon sinks, absorbing substantial amounts of CO2 from the atmosphere and helping to mitigate climate change. Additionally, these aquaculture operations require no freshwater, fertilizers, or arable land, making them a highly sustainable source of raw materials compared to land-based crops.

In food processing, the use of sodium alginate can lead to improved resource efficiency. Its ability to stabilize emulsions at lower concentrations than some synthetic alternatives means that less material is required to achieve the desired effect. This efficiency translates to reduced energy consumption in production and transportation, further lowering the carbon footprint of food products.

The biodegradability of sodium alginate addresses concerns about the accumulation of non-degradable substances in the environment. Unlike some synthetic emulsifiers that persist in ecosystems, sodium alginate breaks down naturally, minimizing long-term environmental impact. This characteristic is particularly relevant in the context of food packaging and waste management.

From a circular economy perspective, the production of sodium alginate can be integrated into broader sustainability initiatives. Waste streams from alginate extraction can be repurposed for other applications, such as biofuel production or as organic fertilizers, maximizing resource utilization and minimizing waste.

The use of sodium alginate in food emulsification also supports the development of plant-based and clean-label products. As consumers increasingly seek alternatives to animal-derived ingredients, sodium alginate's versatility in creating textures similar to those traditionally achieved with animal-based emulsifiers facilitates the formulation of sustainable, vegan food options.

Furthermore, the stability provided by sodium alginate in emulsions can extend the shelf life of food products, potentially reducing food waste throughout the supply chain. This aspect is crucial in addressing global food security challenges and minimizing the environmental impact associated with food spoilage and disposal.

The cultivation and harvesting of seaweed for alginate production present several environmental benefits. Seaweed farms act as carbon sinks, absorbing substantial amounts of CO2 from the atmosphere and helping to mitigate climate change. Additionally, these aquaculture operations require no freshwater, fertilizers, or arable land, making them a highly sustainable source of raw materials compared to land-based crops.

In food processing, the use of sodium alginate can lead to improved resource efficiency. Its ability to stabilize emulsions at lower concentrations than some synthetic alternatives means that less material is required to achieve the desired effect. This efficiency translates to reduced energy consumption in production and transportation, further lowering the carbon footprint of food products.

The biodegradability of sodium alginate addresses concerns about the accumulation of non-degradable substances in the environment. Unlike some synthetic emulsifiers that persist in ecosystems, sodium alginate breaks down naturally, minimizing long-term environmental impact. This characteristic is particularly relevant in the context of food packaging and waste management.

From a circular economy perspective, the production of sodium alginate can be integrated into broader sustainability initiatives. Waste streams from alginate extraction can be repurposed for other applications, such as biofuel production or as organic fertilizers, maximizing resource utilization and minimizing waste.

The use of sodium alginate in food emulsification also supports the development of plant-based and clean-label products. As consumers increasingly seek alternatives to animal-derived ingredients, sodium alginate's versatility in creating textures similar to those traditionally achieved with animal-based emulsifiers facilitates the formulation of sustainable, vegan food options.

Furthermore, the stability provided by sodium alginate in emulsions can extend the shelf life of food products, potentially reducing food waste throughout the supply chain. This aspect is crucial in addressing global food security challenges and minimizing the environmental impact associated with food spoilage and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!