How Sodium Alginate Drives Innovation in Oral Therapeutics?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate in Oral Therapeutics: Background and Objectives

Sodium alginate, a naturally derived polysaccharide extracted from brown seaweed, has emerged as a pivotal component in the field of oral therapeutics. Its unique properties and versatile applications have positioned it at the forefront of pharmaceutical innovation. The journey of sodium alginate in oral therapeutics began in the mid-20th century, with initial applications in antacid formulations. Since then, its potential has expanded exponentially, driving significant advancements in drug delivery systems and biomedical applications.

The evolution of sodium alginate in oral therapeutics has been marked by continuous research and development, leading to a deeper understanding of its molecular structure and behavior. This knowledge has enabled scientists to harness its gel-forming abilities, biocompatibility, and mucoadhesive properties for various therapeutic purposes. The trend in recent years has shifted towards exploiting these characteristics for controlled release formulations, targeted drug delivery, and enhanced bioavailability of active pharmaceutical ingredients.

One of the primary objectives in utilizing sodium alginate for oral therapeutics is to overcome the limitations associated with conventional drug delivery methods. These include poor solubility of certain drugs, rapid degradation in the gastrointestinal tract, and inadequate absorption. By incorporating sodium alginate into drug formulations, researchers aim to develop more efficient and patient-friendly oral medications that can improve therapeutic outcomes and reduce side effects.

Another crucial goal is to leverage sodium alginate's potential in personalized medicine. As the healthcare industry moves towards tailored treatments, sodium alginate-based systems offer the flexibility to design drug release profiles that can be customized to individual patient needs. This aligns with the broader trend of precision medicine, where treatments are optimized based on genetic, environmental, and lifestyle factors.

The ongoing research in this field also focuses on exploring novel combinations of sodium alginate with other polymers and materials to create advanced drug delivery platforms. These efforts are driven by the need for more sophisticated oral therapeutic solutions that can address complex medical conditions and improve patient compliance. The ultimate aim is to develop innovative formulations that can revolutionize the way oral medications are designed, administered, and absorbed in the body.

As we delve deeper into the role of sodium alginate in oral therapeutics, it becomes evident that this versatile material is not just a component but a catalyst for innovation. Its continued exploration and application hold the promise of transforming oral drug delivery, potentially leading to breakthroughs in treating a wide range of diseases and improving overall healthcare outcomes.

The evolution of sodium alginate in oral therapeutics has been marked by continuous research and development, leading to a deeper understanding of its molecular structure and behavior. This knowledge has enabled scientists to harness its gel-forming abilities, biocompatibility, and mucoadhesive properties for various therapeutic purposes. The trend in recent years has shifted towards exploiting these characteristics for controlled release formulations, targeted drug delivery, and enhanced bioavailability of active pharmaceutical ingredients.

One of the primary objectives in utilizing sodium alginate for oral therapeutics is to overcome the limitations associated with conventional drug delivery methods. These include poor solubility of certain drugs, rapid degradation in the gastrointestinal tract, and inadequate absorption. By incorporating sodium alginate into drug formulations, researchers aim to develop more efficient and patient-friendly oral medications that can improve therapeutic outcomes and reduce side effects.

Another crucial goal is to leverage sodium alginate's potential in personalized medicine. As the healthcare industry moves towards tailored treatments, sodium alginate-based systems offer the flexibility to design drug release profiles that can be customized to individual patient needs. This aligns with the broader trend of precision medicine, where treatments are optimized based on genetic, environmental, and lifestyle factors.

The ongoing research in this field also focuses on exploring novel combinations of sodium alginate with other polymers and materials to create advanced drug delivery platforms. These efforts are driven by the need for more sophisticated oral therapeutic solutions that can address complex medical conditions and improve patient compliance. The ultimate aim is to develop innovative formulations that can revolutionize the way oral medications are designed, administered, and absorbed in the body.

As we delve deeper into the role of sodium alginate in oral therapeutics, it becomes evident that this versatile material is not just a component but a catalyst for innovation. Its continued exploration and application hold the promise of transforming oral drug delivery, potentially leading to breakthroughs in treating a wide range of diseases and improving overall healthcare outcomes.

Market Analysis for Alginate-Based Oral Drugs

The market for alginate-based oral drugs is experiencing significant growth, driven by the increasing demand for innovative drug delivery systems and the unique properties of sodium alginate. This natural polysaccharide, derived from brown seaweed, has gained considerable attention in the pharmaceutical industry due to its biocompatibility, biodegradability, and versatile functionalities.

The global market for alginate-based oral drugs is projected to expand at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of chronic diseases, the need for controlled drug release formulations, and the increasing adoption of natural polymers in pharmaceutical applications.

One of the key factors driving market demand is the ability of sodium alginate to form hydrogels in acidic environments, making it an ideal candidate for targeted drug delivery to the gastrointestinal tract. This property has led to the development of various oral formulations, including tablets, capsules, and suspensions, that offer improved bioavailability and reduced side effects compared to conventional dosage forms.

The market for alginate-based oral drugs is segmented based on application, with gastrointestinal disorders representing the largest share. This is due to the effectiveness of alginate formulations in treating conditions such as gastroesophageal reflux disease (GERD) and peptic ulcers. Other significant application areas include diabetes management, pain relief, and cardiovascular diseases.

Geographically, North America and Europe dominate the market, accounting for over 60% of the global share. This is attributed to the presence of well-established pharmaceutical companies, advanced healthcare infrastructure, and favorable regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing healthcare expenditure, rising awareness about advanced drug delivery systems, and the growing prevalence of chronic diseases.

The competitive landscape of the alginate-based oral drugs market is characterized by the presence of both large pharmaceutical companies and specialized drug delivery firms. Key players are focusing on research and development activities to enhance the properties of alginate-based formulations and expand their application areas. Collaborations between academic institutions and industry players are also contributing to market growth by accelerating the development of novel drug delivery technologies.

Despite the positive outlook, challenges such as the variability in alginate quality, potential allergic reactions in some patients, and competition from other polymeric drug delivery systems may impact market growth. However, ongoing research into alginate modifications and hybrid systems is expected to address these challenges and further drive innovation in oral therapeutics.

The global market for alginate-based oral drugs is projected to expand at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of chronic diseases, the need for controlled drug release formulations, and the increasing adoption of natural polymers in pharmaceutical applications.

One of the key factors driving market demand is the ability of sodium alginate to form hydrogels in acidic environments, making it an ideal candidate for targeted drug delivery to the gastrointestinal tract. This property has led to the development of various oral formulations, including tablets, capsules, and suspensions, that offer improved bioavailability and reduced side effects compared to conventional dosage forms.

The market for alginate-based oral drugs is segmented based on application, with gastrointestinal disorders representing the largest share. This is due to the effectiveness of alginate formulations in treating conditions such as gastroesophageal reflux disease (GERD) and peptic ulcers. Other significant application areas include diabetes management, pain relief, and cardiovascular diseases.

Geographically, North America and Europe dominate the market, accounting for over 60% of the global share. This is attributed to the presence of well-established pharmaceutical companies, advanced healthcare infrastructure, and favorable regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing healthcare expenditure, rising awareness about advanced drug delivery systems, and the growing prevalence of chronic diseases.

The competitive landscape of the alginate-based oral drugs market is characterized by the presence of both large pharmaceutical companies and specialized drug delivery firms. Key players are focusing on research and development activities to enhance the properties of alginate-based formulations and expand their application areas. Collaborations between academic institutions and industry players are also contributing to market growth by accelerating the development of novel drug delivery technologies.

Despite the positive outlook, challenges such as the variability in alginate quality, potential allergic reactions in some patients, and competition from other polymeric drug delivery systems may impact market growth. However, ongoing research into alginate modifications and hybrid systems is expected to address these challenges and further drive innovation in oral therapeutics.

Current Challenges in Sodium Alginate Formulations

Despite the promising potential of sodium alginate in oral therapeutics, several challenges persist in its formulation and application. One of the primary issues is the variability in the composition and quality of sodium alginate derived from different sources. This inconsistency can lead to unpredictable behavior in drug release profiles and overall formulation performance, making it difficult to achieve reproducible results in pharmaceutical applications.

Another significant challenge lies in controlling the gelation process of sodium alginate. While its ability to form hydrogels is a key advantage, precisely manipulating the gelation kinetics and resulting gel properties remains complex. Factors such as pH, temperature, and the presence of divalent cations can significantly influence the gelation process, affecting drug encapsulation efficiency and release characteristics.

The stability of sodium alginate formulations under various physiological conditions poses another hurdle. In the acidic environment of the stomach, alginate-based systems may undergo premature degradation, potentially compromising their intended function in targeted drug delivery. Conversely, in neutral or alkaline environments, the gel structure may become too stable, hindering drug release at the desired site of action.

Biocompatibility and immunogenicity concerns also present challenges in sodium alginate formulations. Although generally regarded as safe, some alginate preparations may contain impurities or elicit immune responses in certain individuals. This necessitates rigorous purification processes and careful selection of alginate sources to ensure consistent safety profiles across different batches and applications.

The scalability of sodium alginate-based formulations from laboratory to industrial production presents technical and economic challenges. Maintaining uniform quality and performance characteristics during large-scale manufacturing requires sophisticated process control and may incur significant costs, potentially limiting commercial viability for some applications.

Furthermore, achieving controlled and sustained drug release profiles with sodium alginate formulations remains a complex task. While alginate's gel-forming properties offer potential for extended-release formulations, fine-tuning the release kinetics to match therapeutic needs across diverse drug molecules and treatment regimens is an ongoing challenge. This is particularly evident in the development of oral dosage forms for drugs with narrow therapeutic windows or those requiring precise temporal control of delivery.

Lastly, the interaction between sodium alginate and various active pharmaceutical ingredients (APIs) can be unpredictable. Some drugs may interact unfavorably with alginate, leading to reduced stability, altered bioavailability, or compromised therapeutic efficacy. Understanding and mitigating these interactions requires extensive compatibility studies and formulation optimization, adding complexity to the development process of alginate-based oral therapeutics.

Another significant challenge lies in controlling the gelation process of sodium alginate. While its ability to form hydrogels is a key advantage, precisely manipulating the gelation kinetics and resulting gel properties remains complex. Factors such as pH, temperature, and the presence of divalent cations can significantly influence the gelation process, affecting drug encapsulation efficiency and release characteristics.

The stability of sodium alginate formulations under various physiological conditions poses another hurdle. In the acidic environment of the stomach, alginate-based systems may undergo premature degradation, potentially compromising their intended function in targeted drug delivery. Conversely, in neutral or alkaline environments, the gel structure may become too stable, hindering drug release at the desired site of action.

Biocompatibility and immunogenicity concerns also present challenges in sodium alginate formulations. Although generally regarded as safe, some alginate preparations may contain impurities or elicit immune responses in certain individuals. This necessitates rigorous purification processes and careful selection of alginate sources to ensure consistent safety profiles across different batches and applications.

The scalability of sodium alginate-based formulations from laboratory to industrial production presents technical and economic challenges. Maintaining uniform quality and performance characteristics during large-scale manufacturing requires sophisticated process control and may incur significant costs, potentially limiting commercial viability for some applications.

Furthermore, achieving controlled and sustained drug release profiles with sodium alginate formulations remains a complex task. While alginate's gel-forming properties offer potential for extended-release formulations, fine-tuning the release kinetics to match therapeutic needs across diverse drug molecules and treatment regimens is an ongoing challenge. This is particularly evident in the development of oral dosage forms for drugs with narrow therapeutic windows or those requiring precise temporal control of delivery.

Lastly, the interaction between sodium alginate and various active pharmaceutical ingredients (APIs) can be unpredictable. Some drugs may interact unfavorably with alginate, leading to reduced stability, altered bioavailability, or compromised therapeutic efficacy. Understanding and mitigating these interactions requires extensive compatibility studies and formulation optimization, adding complexity to the development process of alginate-based oral therapeutics.

Existing Sodium Alginate Formulation Techniques

01 Use of sodium alginate in drug delivery systems

Sodium alginate is utilized in various drug delivery systems due to its biocompatibility and ability to form hydrogels. It can be used to encapsulate drugs, control release rates, and improve drug stability. This versatile polymer is particularly useful in developing oral, topical, and injectable formulations.- Use of sodium alginate in drug delivery systems: Sodium alginate is utilized in various drug delivery systems due to its biocompatibility and ability to form gels. It can be used to encapsulate drugs, control release rates, and improve drug stability. This versatile polymer is particularly useful in developing oral, topical, and injectable formulations.

- Sodium alginate in wound healing applications: Sodium alginate is employed in wound dressings and healing products due to its moisture-retaining properties and ability to create a protective barrier. It can absorb wound exudates, maintain a moist environment conducive to healing, and facilitate the removal of dressings without damaging newly formed tissue.

- Sodium alginate as a thickening and stabilizing agent: In food and cosmetic industries, sodium alginate serves as an effective thickening and stabilizing agent. It can improve texture, viscosity, and emulsion stability in various products such as ice creams, sauces, and skincare formulations. Its ability to form gels in the presence of calcium ions is particularly useful in food texturing applications.

- Use of sodium alginate in 3D bioprinting: Sodium alginate is increasingly used in 3D bioprinting applications due to its biocompatibility and ability to form hydrogels. It can be used to create scaffolds for tissue engineering, encapsulate cells, and develop complex tissue-like structures. The rapid gelation of sodium alginate allows for precise control over the printing process and resultant structures.

- Sodium alginate in environmental applications: Sodium alginate finds applications in environmental remediation and water treatment processes. It can be used as a flocculant for removing contaminants from water, as an adsorbent for heavy metals, and in the development of biodegradable materials for reducing plastic pollution. Its natural origin and biodegradability make it an eco-friendly choice for various environmental applications.

02 Sodium alginate in wound healing applications

Sodium alginate is employed in wound dressings and healing products due to its moisture-retaining properties and ability to create a protective barrier. It can absorb wound exudates, maintain a moist environment conducive to healing, and facilitate the removal of dressings without damaging newly formed tissue.Expand Specific Solutions03 Sodium alginate as a thickening and stabilizing agent

In food and pharmaceutical industries, sodium alginate is used as a thickening and stabilizing agent. It can improve the texture and consistency of various products, including sauces, ice creams, and cosmetics. Its ability to form gels in the presence of calcium ions makes it useful in restructured food products and 3D food printing applications.Expand Specific Solutions04 Sodium alginate in tissue engineering and regenerative medicine

Sodium alginate is utilized in tissue engineering and regenerative medicine applications due to its biocompatibility and ability to form scaffolds. It can be used to create 3D structures for cell growth, deliver growth factors, and support tissue regeneration in various medical applications, including bone and cartilage repair.Expand Specific Solutions05 Sodium alginate in environmental applications

Sodium alginate finds use in environmental applications, particularly in water treatment and soil remediation. It can be used as a flocculant to remove contaminants from water, as a soil conditioner to improve water retention and nutrient availability, and in the development of biodegradable materials for reducing environmental pollution.Expand Specific Solutions

Key Players in Alginate-Based Drug Delivery Systems

The oral therapeutics market driven by sodium alginate innovation is in a growth phase, with increasing market size and technological advancements. The industry is characterized by a mix of established players and emerging companies, reflecting a competitive landscape. Companies like Colgate-Palmolive, Bausch & Lomb, and Johnson & Johnson are leveraging their R&D capabilities to develop novel oral care products. Simultaneously, specialized firms such as Klaria Pharma and Gelteq are focusing on innovative drug delivery systems using alginate-based technologies. Academic institutions like China Pharmaceutical University and Ocean University of China are contributing to the research ecosystem, potentially accelerating technological maturity in this field.

Colgate-Palmolive Co.

Technical Solution: Colgate-Palmolive Co. has leveraged sodium alginate in oral care products to drive innovation in dental therapeutics. The company has developed advanced toothpaste formulations incorporating sodium alginate as a key ingredient. These formulations create a protective biofilm on tooth surfaces, helping to prevent dental caries and reduce tooth sensitivity [4]. Colgate has also explored the use of sodium alginate in mouthwash products, where it acts as a natural thickening agent and helps in the sustained release of active ingredients like fluoride and antimicrobials [5]. Furthermore, the company has investigated sodium alginate's potential in developing novel dental gels for professional use, which can aid in the treatment of periodontal diseases by promoting tissue regeneration and reducing inflammation [6].

Strengths: Strong brand recognition in oral care, extensive distribution network, and established consumer trust. Weaknesses: Limited focus on pharmaceutical applications beyond oral care products.

Bausch & Lomb, Inc.

Technical Solution: Bausch & Lomb has incorporated sodium alginate into innovative oral therapeutic solutions, particularly in the field of ophthalmology. The company has developed advanced artificial tear formulations using sodium alginate as a key ingredient. These formulations provide enhanced lubrication and prolonged retention on the ocular surface, offering relief for dry eye syndrome [10]. Bausch & Lomb has also explored the use of sodium alginate in contact lens care solutions, where it acts as a natural moisturizing agent and helps in maintaining lens hydration [11]. Furthermore, the company has investigated sodium alginate's potential in developing novel drug delivery systems for ophthalmic medications, utilizing its gel-forming properties to achieve sustained release of active ingredients on the eye surface [12].

Strengths: Specialized expertise in eye care products, strong brand recognition in the ophthalmology sector. Weaknesses: Limited focus on broader oral therapeutic applications beyond eye-related products.

Innovative Alginate Technologies in Oral Drug Delivery

Solid dispersions

PatentPendingUS20230059619A1

Innovation

- A solid dispersion comprising a low solubility active ingredient combined with sodium or potassium alginate, with specific weight ratios and viscosity-dependent formulations to enhance drug release, using methods like solvent evaporation or supercritical fluid methods.

Pharmaceutical Formulation

PatentPendingUS20240041761A1

Innovation

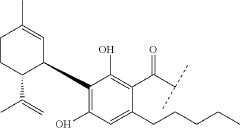

- A film comprising an alginate salt of a monovalent cation and one or more cannabinoids, designed for oral administration, which dissolves in the oral cavity, providing a bioadhesive and controlled release of the active pharmaceutical ingredient, thereby addressing the limitations of existing methods.

Regulatory Framework for Alginate-Based Pharmaceuticals

The regulatory framework for alginate-based pharmaceuticals is a critical aspect of the development and commercialization process for oral therapeutics utilizing sodium alginate. As a naturally derived polymer, sodium alginate falls under specific regulatory guidelines that govern its use in pharmaceutical applications.

In the United States, the Food and Drug Administration (FDA) classifies sodium alginate as Generally Recognized as Safe (GRAS) for certain food applications. However, its use in pharmaceuticals requires additional scrutiny and approval processes. The FDA evaluates alginate-based drug products under the New Drug Application (NDA) pathway, which involves comprehensive safety and efficacy assessments.

The European Medicines Agency (EMA) has established guidelines for the use of alginates in medicinal products. These guidelines outline the quality requirements, safety considerations, and efficacy standards that must be met for alginate-based pharmaceuticals. The EMA emphasizes the importance of consistent sourcing and characterization of alginate materials to ensure product quality and safety.

Regulatory bodies worldwide have recognized the potential of alginate-based drug delivery systems and have developed specific frameworks to address their unique properties. For instance, Japan's Pharmaceuticals and Medical Devices Agency (PMDA) has implemented guidelines for the evaluation of polymeric excipients, including alginates, in drug formulations.

One of the key regulatory considerations for alginate-based pharmaceuticals is the demonstration of batch-to-batch consistency. Manufacturers must establish robust quality control measures to ensure the reproducibility of alginate properties, such as molecular weight distribution and viscosity, which can significantly impact drug release profiles.

The regulatory framework also addresses the potential for impurities in alginate-derived products. Manufacturers are required to implement stringent purification processes and conduct thorough analyses to detect and control any contaminants that may be present in the raw materials or introduced during production.

As alginate-based oral therapeutics often involve controlled release mechanisms, regulatory agencies require extensive in vitro and in vivo studies to characterize the drug release kinetics and bioavailability. This includes dissolution testing under various physiological conditions to simulate the gastrointestinal environment.

The evolving nature of alginate-based technologies has prompted regulatory bodies to adopt a flexible approach, allowing for case-by-case evaluations of novel formulations. This adaptability encourages innovation while maintaining rigorous safety and efficacy standards. As the field advances, it is anticipated that regulatory frameworks will continue to evolve, potentially leading to more streamlined approval processes for alginate-based oral therapeutics.

In the United States, the Food and Drug Administration (FDA) classifies sodium alginate as Generally Recognized as Safe (GRAS) for certain food applications. However, its use in pharmaceuticals requires additional scrutiny and approval processes. The FDA evaluates alginate-based drug products under the New Drug Application (NDA) pathway, which involves comprehensive safety and efficacy assessments.

The European Medicines Agency (EMA) has established guidelines for the use of alginates in medicinal products. These guidelines outline the quality requirements, safety considerations, and efficacy standards that must be met for alginate-based pharmaceuticals. The EMA emphasizes the importance of consistent sourcing and characterization of alginate materials to ensure product quality and safety.

Regulatory bodies worldwide have recognized the potential of alginate-based drug delivery systems and have developed specific frameworks to address their unique properties. For instance, Japan's Pharmaceuticals and Medical Devices Agency (PMDA) has implemented guidelines for the evaluation of polymeric excipients, including alginates, in drug formulations.

One of the key regulatory considerations for alginate-based pharmaceuticals is the demonstration of batch-to-batch consistency. Manufacturers must establish robust quality control measures to ensure the reproducibility of alginate properties, such as molecular weight distribution and viscosity, which can significantly impact drug release profiles.

The regulatory framework also addresses the potential for impurities in alginate-derived products. Manufacturers are required to implement stringent purification processes and conduct thorough analyses to detect and control any contaminants that may be present in the raw materials or introduced during production.

As alginate-based oral therapeutics often involve controlled release mechanisms, regulatory agencies require extensive in vitro and in vivo studies to characterize the drug release kinetics and bioavailability. This includes dissolution testing under various physiological conditions to simulate the gastrointestinal environment.

The evolving nature of alginate-based technologies has prompted regulatory bodies to adopt a flexible approach, allowing for case-by-case evaluations of novel formulations. This adaptability encourages innovation while maintaining rigorous safety and efficacy standards. As the field advances, it is anticipated that regulatory frameworks will continue to evolve, potentially leading to more streamlined approval processes for alginate-based oral therapeutics.

Biocompatibility and Safety Considerations of Sodium Alginate

Sodium alginate, a naturally derived polysaccharide, has gained significant attention in the field of oral therapeutics due to its biocompatibility and safety profile. As a key component in innovative drug delivery systems, it is crucial to thoroughly evaluate its interactions with biological systems and potential risks associated with its use.

The biocompatibility of sodium alginate is primarily attributed to its non-toxic nature and biodegradability. Extensive in vitro and in vivo studies have demonstrated that sodium alginate does not elicit significant immune responses or cytotoxicity when used in oral formulations. This favorable characteristic makes it an ideal candidate for various oral therapeutic applications, including controlled drug release systems and tissue engineering scaffolds.

One of the key safety considerations for sodium alginate is its potential for allergic reactions. While rare, some individuals may exhibit hypersensitivity to alginate-derived products. Therefore, comprehensive allergenicity testing and patient screening are essential when developing oral therapeutics containing sodium alginate.

The degradation profile of sodium alginate in the gastrointestinal tract is another critical aspect of its safety assessment. Studies have shown that alginate undergoes partial degradation in the stomach and small intestine, with complete breakdown occurring in the colon. This gradual degradation process contributes to its sustained release properties and minimizes the risk of accumulation in the body.

Regulatory bodies, such as the FDA and EMA, have recognized sodium alginate as Generally Recognized as Safe (GRAS) for oral consumption. However, it is important to note that the safety profile may vary depending on the specific formulation, concentration, and intended use. Therefore, comprehensive toxicological studies are necessary for each novel application of sodium alginate in oral therapeutics.

The potential for drug-excipient interactions is another crucial consideration when incorporating sodium alginate into oral formulations. While generally inert, sodium alginate may interact with certain active pharmaceutical ingredients, potentially affecting their stability or bioavailability. Thorough compatibility studies are essential to ensure the efficacy and safety of the final product.

Long-term safety studies have shown that chronic oral administration of sodium alginate does not lead to significant adverse effects. However, as with any biomaterial, continuous monitoring and post-market surveillance are necessary to identify any rare or delayed adverse reactions that may emerge over time.

In conclusion, the biocompatibility and safety profile of sodium alginate make it a promising candidate for innovative oral therapeutics. However, careful consideration of potential allergic reactions, degradation kinetics, regulatory compliance, and drug-excipient interactions is essential to ensure the development of safe and effective oral drug delivery systems.

The biocompatibility of sodium alginate is primarily attributed to its non-toxic nature and biodegradability. Extensive in vitro and in vivo studies have demonstrated that sodium alginate does not elicit significant immune responses or cytotoxicity when used in oral formulations. This favorable characteristic makes it an ideal candidate for various oral therapeutic applications, including controlled drug release systems and tissue engineering scaffolds.

One of the key safety considerations for sodium alginate is its potential for allergic reactions. While rare, some individuals may exhibit hypersensitivity to alginate-derived products. Therefore, comprehensive allergenicity testing and patient screening are essential when developing oral therapeutics containing sodium alginate.

The degradation profile of sodium alginate in the gastrointestinal tract is another critical aspect of its safety assessment. Studies have shown that alginate undergoes partial degradation in the stomach and small intestine, with complete breakdown occurring in the colon. This gradual degradation process contributes to its sustained release properties and minimizes the risk of accumulation in the body.

Regulatory bodies, such as the FDA and EMA, have recognized sodium alginate as Generally Recognized as Safe (GRAS) for oral consumption. However, it is important to note that the safety profile may vary depending on the specific formulation, concentration, and intended use. Therefore, comprehensive toxicological studies are necessary for each novel application of sodium alginate in oral therapeutics.

The potential for drug-excipient interactions is another crucial consideration when incorporating sodium alginate into oral formulations. While generally inert, sodium alginate may interact with certain active pharmaceutical ingredients, potentially affecting their stability or bioavailability. Thorough compatibility studies are essential to ensure the efficacy and safety of the final product.

Long-term safety studies have shown that chronic oral administration of sodium alginate does not lead to significant adverse effects. However, as with any biomaterial, continuous monitoring and post-market surveillance are necessary to identify any rare or delayed adverse reactions that may emerge over time.

In conclusion, the biocompatibility and safety profile of sodium alginate make it a promising candidate for innovative oral therapeutics. However, careful consideration of potential allergic reactions, degradation kinetics, regulatory compliance, and drug-excipient interactions is essential to ensure the development of safe and effective oral drug delivery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!