How Sodium Alginate Enhances Shelf Stability in Food Products?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Background and Objectives

Sodium alginate, a versatile polysaccharide derived from brown seaweed, has gained significant attention in the food industry due to its unique properties and potential applications. The exploration of sodium alginate's role in enhancing shelf stability of food products has become a crucial area of research and development in recent years.

The primary objective of this technical investigation is to comprehensively examine how sodium alginate contributes to extending the shelf life of various food products. This involves understanding the fundamental mechanisms by which sodium alginate interacts with food components and the environment to preserve quality and safety over extended periods.

Historically, sodium alginate has been utilized in food production for its gelling, thickening, and stabilizing properties. However, its potential for shelf-life extension has only recently come to the forefront of food technology research. This shift in focus is driven by the increasing demand for natural preservatives and clean-label products, as consumers become more health-conscious and environmentally aware.

The evolution of sodium alginate applications in food preservation can be traced back to its initial use as a texturizing agent. Over time, researchers and food technologists have uncovered its multifaceted benefits, including moisture retention, oxidation prevention, and microbial growth inhibition. These properties collectively contribute to the enhanced shelf stability of food products.

Current technological trends in sodium alginate research are focused on optimizing its performance in various food matrices. This includes investigating synergistic effects with other natural preservatives, developing novel encapsulation techniques, and exploring its potential in active packaging systems. The goal is to maximize the shelf-life extension capabilities of sodium alginate while maintaining the sensory and nutritional qualities of food products.

As we delve deeper into this technical exploration, we aim to elucidate the specific mechanisms by which sodium alginate enhances shelf stability. This involves examining its interactions with water molecules, its ability to form protective barriers, and its impact on microbial ecology within food systems. Additionally, we will assess the influence of environmental factors such as pH, temperature, and ionic strength on sodium alginate's preservative efficacy.

Furthermore, this investigation seeks to identify potential limitations and challenges associated with sodium alginate usage in food preservation. By understanding these constraints, we can pave the way for innovative solutions and future research directions to overcome existing barriers and expand the application scope of sodium alginate in the food industry.

The primary objective of this technical investigation is to comprehensively examine how sodium alginate contributes to extending the shelf life of various food products. This involves understanding the fundamental mechanisms by which sodium alginate interacts with food components and the environment to preserve quality and safety over extended periods.

Historically, sodium alginate has been utilized in food production for its gelling, thickening, and stabilizing properties. However, its potential for shelf-life extension has only recently come to the forefront of food technology research. This shift in focus is driven by the increasing demand for natural preservatives and clean-label products, as consumers become more health-conscious and environmentally aware.

The evolution of sodium alginate applications in food preservation can be traced back to its initial use as a texturizing agent. Over time, researchers and food technologists have uncovered its multifaceted benefits, including moisture retention, oxidation prevention, and microbial growth inhibition. These properties collectively contribute to the enhanced shelf stability of food products.

Current technological trends in sodium alginate research are focused on optimizing its performance in various food matrices. This includes investigating synergistic effects with other natural preservatives, developing novel encapsulation techniques, and exploring its potential in active packaging systems. The goal is to maximize the shelf-life extension capabilities of sodium alginate while maintaining the sensory and nutritional qualities of food products.

As we delve deeper into this technical exploration, we aim to elucidate the specific mechanisms by which sodium alginate enhances shelf stability. This involves examining its interactions with water molecules, its ability to form protective barriers, and its impact on microbial ecology within food systems. Additionally, we will assess the influence of environmental factors such as pH, temperature, and ionic strength on sodium alginate's preservative efficacy.

Furthermore, this investigation seeks to identify potential limitations and challenges associated with sodium alginate usage in food preservation. By understanding these constraints, we can pave the way for innovative solutions and future research directions to overcome existing barriers and expand the application scope of sodium alginate in the food industry.

Market Demand Analysis for Shelf-Stable Foods

The market demand for shelf-stable foods has been steadily increasing, driven by various factors such as changing consumer lifestyles, urbanization, and the need for convenient food options. Sodium alginate, a natural polysaccharide derived from brown seaweed, plays a crucial role in enhancing the shelf stability of food products, thereby meeting this growing market demand.

Consumer preferences have shifted towards products with longer shelf lives, reduced preservatives, and maintained nutritional value. This trend has been further accelerated by the global pandemic, which has led to increased stockpiling behaviors and a preference for foods that can be stored for extended periods. As a result, the market for shelf-stable foods is projected to experience significant growth in the coming years.

Sodium alginate's unique properties make it an ideal ingredient for improving shelf stability in various food products. Its ability to form gels, act as a thickener, and stabilize emulsions contributes to maintaining food quality over time. This versatility allows manufacturers to address multiple aspects of shelf stability, including texture preservation, moisture retention, and prevention of ingredient separation.

The demand for sodium alginate in the food industry is closely tied to the growing market for convenience foods, ready-to-eat meals, and packaged products. These segments have shown robust growth, particularly in developed economies where consumers prioritize time-saving food options without compromising on quality or nutritional value.

In the beverage industry, sodium alginate's application in stabilizing and thickening drinks has led to increased demand for shelf-stable beverages. This includes both alcoholic and non-alcoholic options, where the ingredient helps maintain consistency and prevent separation during storage.

The clean label trend has also positively impacted the demand for sodium alginate. As a natural ingredient, it aligns with consumer preferences for cleaner, more transparent ingredient lists. This has led to its increased adoption in organic and natural food products, further expanding its market potential.

Geographically, the demand for sodium alginate in shelf-stable foods varies. Developed markets in North America and Europe show a strong preference for convenience foods with extended shelf lives. Meanwhile, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in this sector, driven by urbanization and changing dietary habits.

The COVID-19 pandemic has further underscored the importance of shelf-stable foods, leading to a surge in demand for products that can be stored for long periods. This has created new opportunities for sodium alginate applications in food preservation and stability enhancement.

Consumer preferences have shifted towards products with longer shelf lives, reduced preservatives, and maintained nutritional value. This trend has been further accelerated by the global pandemic, which has led to increased stockpiling behaviors and a preference for foods that can be stored for extended periods. As a result, the market for shelf-stable foods is projected to experience significant growth in the coming years.

Sodium alginate's unique properties make it an ideal ingredient for improving shelf stability in various food products. Its ability to form gels, act as a thickener, and stabilize emulsions contributes to maintaining food quality over time. This versatility allows manufacturers to address multiple aspects of shelf stability, including texture preservation, moisture retention, and prevention of ingredient separation.

The demand for sodium alginate in the food industry is closely tied to the growing market for convenience foods, ready-to-eat meals, and packaged products. These segments have shown robust growth, particularly in developed economies where consumers prioritize time-saving food options without compromising on quality or nutritional value.

In the beverage industry, sodium alginate's application in stabilizing and thickening drinks has led to increased demand for shelf-stable beverages. This includes both alcoholic and non-alcoholic options, where the ingredient helps maintain consistency and prevent separation during storage.

The clean label trend has also positively impacted the demand for sodium alginate. As a natural ingredient, it aligns with consumer preferences for cleaner, more transparent ingredient lists. This has led to its increased adoption in organic and natural food products, further expanding its market potential.

Geographically, the demand for sodium alginate in shelf-stable foods varies. Developed markets in North America and Europe show a strong preference for convenience foods with extended shelf lives. Meanwhile, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in this sector, driven by urbanization and changing dietary habits.

The COVID-19 pandemic has further underscored the importance of shelf-stable foods, leading to a surge in demand for products that can be stored for long periods. This has created new opportunities for sodium alginate applications in food preservation and stability enhancement.

Current Challenges in Food Preservation

Food preservation remains a critical challenge in the food industry, with manufacturers constantly seeking innovative methods to extend product shelf life while maintaining quality and safety. Despite advancements in technology, several key issues persist in the realm of food preservation.

One of the primary challenges is the prevention of microbial growth and spoilage. Microorganisms such as bacteria, yeasts, and molds can rapidly proliferate in food products, leading to deterioration and potential health risks. Traditional preservation methods like heat treatment and chemical additives often fall short in providing long-term protection without compromising the product's sensory attributes.

Oxidation is another significant hurdle in food preservation. Many food products, especially those containing fats and oils, are susceptible to oxidative rancidity, resulting in off-flavors, odors, and reduced nutritional value. Antioxidants are commonly used to combat this issue, but finding natural alternatives that are both effective and label-friendly remains a challenge.

Moisture control presents yet another obstacle in preserving food quality. Excess moisture can promote microbial growth and enzymatic reactions, while insufficient moisture can lead to textural changes and loss of palatability. Striking the right balance is crucial, particularly in products with multiple components or those exposed to varying environmental conditions during storage and distribution.

The demand for clean label products has further complicated food preservation efforts. Consumers increasingly seek products with minimal artificial additives, putting pressure on manufacturers to find natural preservation solutions. This shift has led to a growing interest in biopreservatives and plant-based antimicrobials, though their efficacy and stability often fall short of synthetic alternatives.

Packaging plays a vital role in food preservation, but current materials and technologies face limitations. While modified atmosphere packaging and active packaging systems show promise, challenges remain in terms of cost-effectiveness, scalability, and environmental sustainability. Additionally, the interaction between packaging materials and food products can sometimes lead to undesired chemical migrations or sensory changes.

Temperature control throughout the supply chain is another persistent challenge. Maintaining the cold chain for perishable products from production to consumption is complex and energy-intensive. Fluctuations in temperature during transportation and storage can significantly impact product quality and safety, necessitating more robust and efficient cooling systems.

As the food industry grapples with these challenges, there is a growing need for innovative, multifunctional preservation solutions that can address multiple issues simultaneously. The exploration of novel technologies, such as high-pressure processing, pulsed electric fields, and nanotechnology, offers potential avenues for overcoming current limitations in food preservation.

One of the primary challenges is the prevention of microbial growth and spoilage. Microorganisms such as bacteria, yeasts, and molds can rapidly proliferate in food products, leading to deterioration and potential health risks. Traditional preservation methods like heat treatment and chemical additives often fall short in providing long-term protection without compromising the product's sensory attributes.

Oxidation is another significant hurdle in food preservation. Many food products, especially those containing fats and oils, are susceptible to oxidative rancidity, resulting in off-flavors, odors, and reduced nutritional value. Antioxidants are commonly used to combat this issue, but finding natural alternatives that are both effective and label-friendly remains a challenge.

Moisture control presents yet another obstacle in preserving food quality. Excess moisture can promote microbial growth and enzymatic reactions, while insufficient moisture can lead to textural changes and loss of palatability. Striking the right balance is crucial, particularly in products with multiple components or those exposed to varying environmental conditions during storage and distribution.

The demand for clean label products has further complicated food preservation efforts. Consumers increasingly seek products with minimal artificial additives, putting pressure on manufacturers to find natural preservation solutions. This shift has led to a growing interest in biopreservatives and plant-based antimicrobials, though their efficacy and stability often fall short of synthetic alternatives.

Packaging plays a vital role in food preservation, but current materials and technologies face limitations. While modified atmosphere packaging and active packaging systems show promise, challenges remain in terms of cost-effectiveness, scalability, and environmental sustainability. Additionally, the interaction between packaging materials and food products can sometimes lead to undesired chemical migrations or sensory changes.

Temperature control throughout the supply chain is another persistent challenge. Maintaining the cold chain for perishable products from production to consumption is complex and energy-intensive. Fluctuations in temperature during transportation and storage can significantly impact product quality and safety, necessitating more robust and efficient cooling systems.

As the food industry grapples with these challenges, there is a growing need for innovative, multifunctional preservation solutions that can address multiple issues simultaneously. The exploration of novel technologies, such as high-pressure processing, pulsed electric fields, and nanotechnology, offers potential avenues for overcoming current limitations in food preservation.

Sodium Alginate Applications in Food Preservation

01 Stabilization through pH control

Controlling the pH of sodium alginate solutions can significantly improve their shelf stability. Maintaining the pH within an optimal range, typically slightly acidic to neutral, helps prevent degradation and maintains the viscosity of the alginate solution over time. This approach is often combined with other stabilization methods for enhanced effectiveness.- pH control for stability enhancement: Controlling the pH of sodium alginate solutions can significantly improve their shelf stability. Maintaining the pH within an optimal range, typically between 5.5 and 7.5, helps prevent degradation and maintains the viscosity of the solution over time. This approach is particularly effective for preserving the functional properties of sodium alginate in various applications.

- Addition of stabilizing agents: Incorporating specific stabilizing agents into sodium alginate formulations can enhance their shelf life. These agents may include antioxidants, chelating agents, or preservatives that protect against oxidation, microbial growth, and other degradation processes. The choice of stabilizing agent depends on the intended application and storage conditions of the sodium alginate product.

- Moisture control and packaging: Controlling moisture content and using appropriate packaging materials are crucial for maintaining the stability of sodium alginate. Reducing exposure to humidity through the use of moisture-resistant packaging or desiccants can prevent clumping and degradation. Vacuum packaging or nitrogen flushing may also be employed to extend shelf life by minimizing oxidation.

- Temperature-controlled storage: Storing sodium alginate products under controlled temperature conditions can significantly impact their shelf stability. Generally, cool and consistent temperatures are preferred to prevent degradation. Some formulations may require refrigeration or specific temperature ranges to maintain their properties over extended periods.

- Modified alginate structures: Developing modified forms of sodium alginate through chemical or physical treatments can enhance its stability. These modifications may include cross-linking, grafting with other polymers, or creating composite materials. Such structural changes can improve resistance to degradation, enhance thermal stability, and extend the overall shelf life of the product.

02 Addition of preservatives

Incorporating suitable preservatives into sodium alginate formulations can extend their shelf life by inhibiting microbial growth and preventing degradation. Common preservatives used include potassium sorbate, sodium benzoate, and various antimicrobial agents. The choice and concentration of preservatives depend on the specific application and desired shelf life.Expand Specific Solutions03 Moisture control and packaging

Controlling moisture content and using appropriate packaging materials are crucial for maintaining the stability of sodium alginate. Moisture-resistant packaging, desiccants, and proper sealing techniques can prevent water absorption, which can lead to degradation and loss of functionality. Vacuum packaging or nitrogen flushing may also be employed to reduce oxidation and extend shelf life.Expand Specific Solutions04 Antioxidant addition

Adding antioxidants to sodium alginate formulations can help prevent oxidative degradation and maintain stability over time. Common antioxidants used include ascorbic acid, tocopherols, and butylated hydroxyanisole (BHA). These additives scavenge free radicals and inhibit oxidation reactions that can compromise the integrity of the alginate.Expand Specific Solutions05 Temperature-controlled storage

Proper temperature control during storage is essential for maintaining the stability of sodium alginate. Storing the product at cool temperatures, typically below 25°C, can significantly slow down degradation processes and extend shelf life. Some formulations may require refrigeration or even freezing for optimal long-term stability, depending on their specific composition and intended use.Expand Specific Solutions

Key Players in Food Additives Industry

The market for sodium alginate in food products is in a growth phase, driven by increasing demand for natural food additives and shelf-life extension solutions. The global market size is expanding, with a projected CAGR of 4-6% over the next five years. Technologically, sodium alginate applications are well-established, but innovation continues in formulation and production methods. Companies like Ueno Fine Chemicals Industry, Shandong Jiejing Group, and FMC Biopolymer are at the forefront, leveraging their expertise in alginate production and application. Research institutions such as Singapore Polytechnic and the University of Manitoba are contributing to advancements in sodium alginate technology, particularly in areas of food preservation and texture enhancement.

Tianjin University of Science & Technology

Technical Solution: Researchers at Tianjin University of Science & Technology have made significant advancements in the application of sodium alginate for food preservation. Their work has focused on developing nanocomposite films incorporating sodium alginate and nanoparticles for active packaging solutions. These films have shown remarkable ability to extend the shelf life of perishable foods by providing antimicrobial protection and controlling gas permeability[8]. The university's team has also explored the use of sodium alginate-based edible coatings enriched with essential oils, demonstrating synergistic effects in preserving fruit quality and safety during storage[9]. Their research extends to the encapsulation of probiotics using sodium alginate matrices, which has shown promise in enhancing the viability of beneficial bacteria in functional food products[10].

Strengths: Cutting-edge research in nanocomposite and active packaging technologies, potential for significant breakthroughs in food preservation. Weaknesses: Some technologies may be in early stages of development, requiring further validation for commercial application.

Norwegian University of Science & Technology

Technical Solution: The Norwegian University of Science & Technology has conducted extensive research on the molecular structure and functional properties of sodium alginate in food systems. Their work has led to the development of novel cross-linking techniques that enhance the gel strength and stability of sodium alginate in various food matrices. By manipulating the guluronic to mannuronic acid ratio in alginate molecules, researchers have created tailored solutions for specific food applications, such as improved water retention in meat products and enhanced freeze-thaw stability in frozen desserts[11]. The university's team has also investigated the use of enzymatically modified alginates, which have shown superior emulsifying properties and increased resistance to acidic conditions, expanding the potential applications of sodium alginate in acidified foods and beverages[12].

Strengths: Fundamental research leading to advanced understanding of alginate functionality, potential for creating highly specialized alginate derivatives. Weaknesses: Some advanced modifications may be costly to implement on an industrial scale, potentially limiting widespread adoption.

Core Innovations in Alginate-Based Stabilization

A method of improving the shelf life of a food product and a food product with an improved shelf life

PatentWO2025038036A1

Innovation

- A method involving a food product with alginate, treated with a solution containing a calcium source to form a calcium alginate coating, which extends shelf life without affecting organoleptic properties and eliminates the need for chemical preservatives.

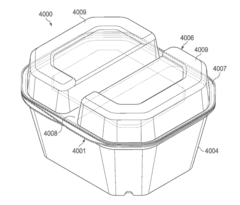

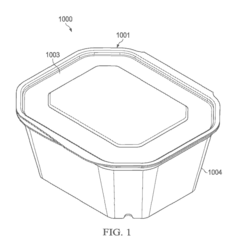

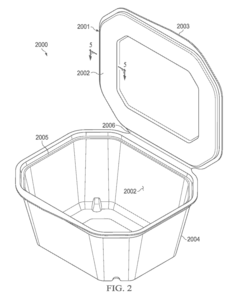

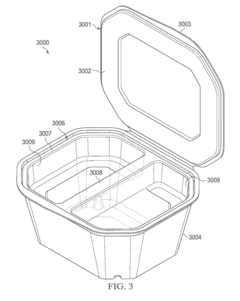

Heat-able On-the-Go Food Products Apparatus and Method

PatentInactiveUS20160311564A1

Innovation

- A molded pulp container with a food-safe barrier and sealant layer, coated with Michem® Coat materials, that can be heated in microwaves or hot air ovens, using a brine solution and sodium to control heating, while maintaining the package's safety and recyclability.

Regulatory Framework for Food Additives

The regulatory framework for food additives plays a crucial role in ensuring the safety and efficacy of sodium alginate as a shelf-life enhancing agent in food products. In the United States, the Food and Drug Administration (FDA) oversees the regulation of food additives, including sodium alginate, under the Federal Food, Drug, and Cosmetic Act (FD&C Act).

Sodium alginate is classified as a Generally Recognized as Safe (GRAS) substance by the FDA, which means it has been deemed safe for its intended use in food products. This classification allows for its use in various food applications without the need for premarket approval, provided it meets certain criteria and is used in accordance with good manufacturing practices.

The European Food Safety Authority (EFSA) also recognizes sodium alginate as a safe food additive, designated with the E-number E401. The European Union has established specific purity criteria and maximum usage levels for sodium alginate in different food categories, ensuring its safe application across member states.

In Japan, sodium alginate is approved as a food additive by the Ministry of Health, Labour and Welfare. The Japanese regulatory framework allows for its use in various food products, subject to specific guidelines and restrictions.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference for their national regulations. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in food products.

Regulatory bodies typically require manufacturers to adhere to specific labeling requirements when using sodium alginate in food products. This often includes listing it as an ingredient and, in some cases, specifying its function (e.g., "stabilizer" or "thickener").

It is important to note that while sodium alginate is generally considered safe, regulatory frameworks may impose limitations on its use in certain food categories or set maximum levels to ensure consumer safety. Manufacturers must stay informed about any changes in regulations and comply with the specific requirements of the markets in which they operate.

As research continues to evolve, regulatory bodies periodically review and update their guidelines for food additives. This ongoing process ensures that the use of sodium alginate and other additives remains in line with the latest scientific evidence and safety assessments, maintaining consumer trust and product integrity in the food industry.

Sodium alginate is classified as a Generally Recognized as Safe (GRAS) substance by the FDA, which means it has been deemed safe for its intended use in food products. This classification allows for its use in various food applications without the need for premarket approval, provided it meets certain criteria and is used in accordance with good manufacturing practices.

The European Food Safety Authority (EFSA) also recognizes sodium alginate as a safe food additive, designated with the E-number E401. The European Union has established specific purity criteria and maximum usage levels for sodium alginate in different food categories, ensuring its safe application across member states.

In Japan, sodium alginate is approved as a food additive by the Ministry of Health, Labour and Welfare. The Japanese regulatory framework allows for its use in various food products, subject to specific guidelines and restrictions.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference for their national regulations. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in food products.

Regulatory bodies typically require manufacturers to adhere to specific labeling requirements when using sodium alginate in food products. This often includes listing it as an ingredient and, in some cases, specifying its function (e.g., "stabilizer" or "thickener").

It is important to note that while sodium alginate is generally considered safe, regulatory frameworks may impose limitations on its use in certain food categories or set maximum levels to ensure consumer safety. Manufacturers must stay informed about any changes in regulations and comply with the specific requirements of the markets in which they operate.

As research continues to evolve, regulatory bodies periodically review and update their guidelines for food additives. This ongoing process ensures that the use of sodium alginate and other additives remains in line with the latest scientific evidence and safety assessments, maintaining consumer trust and product integrity in the food industry.

Environmental Impact of Alginate Production

The production of sodium alginate, while beneficial for food preservation, has significant environmental implications that warrant careful consideration. The primary source of alginate is brown seaweed, and its harvesting can impact marine ecosystems. Large-scale seaweed farming and wild harvesting may lead to habitat disruption and biodiversity loss in coastal areas. However, when managed sustainably, seaweed cultivation can also provide ecosystem services such as carbon sequestration and nutrient absorption from surrounding waters.

The extraction process of alginate from seaweed involves chemical treatments that generate waste and potentially harmful byproducts. The use of alkaline solutions and acids in the extraction process can result in effluents with high pH levels and chemical residues. If not properly treated, these effluents can cause water pollution and affect aquatic life. Additionally, the energy-intensive nature of alginate production contributes to greenhouse gas emissions, particularly when fossil fuels are used as the primary energy source.

Water consumption is another environmental concern in alginate production. The extraction and purification processes require substantial amounts of freshwater, which can strain local water resources, especially in water-scarce regions. The industry is increasingly adopting water recycling and treatment technologies to mitigate this impact, but challenges remain in achieving widespread implementation.

Transportation of raw materials and finished products also contributes to the environmental footprint of alginate production. As seaweed harvesting and processing often occur in coastal areas, the distribution of alginate to global markets involves long-distance shipping, leading to increased carbon emissions. The industry is exploring more efficient logistics and considering localized production to reduce transportation-related environmental impacts.

On a positive note, alginate production can potentially contribute to circular economy practices. Research is ongoing to utilize waste streams from the food industry as alternative sources for alginate extraction, which could reduce reliance on wild seaweed harvesting and minimize waste. Furthermore, the biodegradable nature of alginate offers an environmentally friendly alternative to synthetic polymers in various applications, potentially reducing plastic pollution.

As the demand for sodium alginate in food preservation grows, balancing production needs with environmental stewardship becomes crucial. The industry is increasingly focusing on developing more sustainable harvesting methods, improving extraction efficiencies, and implementing cleaner production technologies. These efforts aim to minimize the ecological footprint of alginate production while maintaining its valuable role in enhancing food shelf stability.

The extraction process of alginate from seaweed involves chemical treatments that generate waste and potentially harmful byproducts. The use of alkaline solutions and acids in the extraction process can result in effluents with high pH levels and chemical residues. If not properly treated, these effluents can cause water pollution and affect aquatic life. Additionally, the energy-intensive nature of alginate production contributes to greenhouse gas emissions, particularly when fossil fuels are used as the primary energy source.

Water consumption is another environmental concern in alginate production. The extraction and purification processes require substantial amounts of freshwater, which can strain local water resources, especially in water-scarce regions. The industry is increasingly adopting water recycling and treatment technologies to mitigate this impact, but challenges remain in achieving widespread implementation.

Transportation of raw materials and finished products also contributes to the environmental footprint of alginate production. As seaweed harvesting and processing often occur in coastal areas, the distribution of alginate to global markets involves long-distance shipping, leading to increased carbon emissions. The industry is exploring more efficient logistics and considering localized production to reduce transportation-related environmental impacts.

On a positive note, alginate production can potentially contribute to circular economy practices. Research is ongoing to utilize waste streams from the food industry as alternative sources for alginate extraction, which could reduce reliance on wild seaweed harvesting and minimize waste. Furthermore, the biodegradable nature of alginate offers an environmentally friendly alternative to synthetic polymers in various applications, potentially reducing plastic pollution.

As the demand for sodium alginate in food preservation grows, balancing production needs with environmental stewardship becomes crucial. The industry is increasingly focusing on developing more sustainable harvesting methods, improving extraction efficiencies, and implementing cleaner production technologies. These efforts aim to minimize the ecological footprint of alginate production while maintaining its valuable role in enhancing food shelf stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!