Sodium Alginate Applications in Antioxidant Stability Techniques

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Background and Research Objectives

Sodium alginate, a naturally occurring polysaccharide extracted from brown seaweed, has gained significant attention in various industries due to its unique properties and versatile applications. The history of sodium alginate research dates back to the early 20th century when it was first isolated and characterized. Since then, its potential has been explored in fields ranging from food technology to biomedical engineering.

In recent years, the focus on sodium alginate has intensified, particularly in the realm of antioxidant stability techniques. This surge of interest is driven by the growing demand for natural, sustainable solutions in food preservation and pharmaceutical formulations. The ability of sodium alginate to form stable gels and its biocompatibility make it an attractive candidate for encapsulating and protecting sensitive compounds, such as antioxidants, from degradation.

The evolution of sodium alginate research has been marked by several key milestones. Initially, its use was primarily limited to the food industry as a thickening and gelling agent. However, as understanding of its molecular structure and behavior deepened, researchers began to explore its potential in more advanced applications. The discovery of its ability to form hydrogels under mild conditions opened up new avenues in drug delivery and tissue engineering.

Current research objectives in the field of sodium alginate applications for antioxidant stability techniques are multifaceted. One primary goal is to optimize the encapsulation efficiency of antioxidants within sodium alginate matrices. This involves investigating various crosslinking methods and studying the interaction between sodium alginate and different types of antioxidants at a molecular level.

Another critical objective is to enhance the controlled release properties of sodium alginate-based systems. Researchers are exploring ways to modulate the release kinetics of encapsulated antioxidants, ensuring their availability over extended periods. This is particularly important in food preservation applications, where sustained antioxidant activity is crucial for prolonging shelf life.

Furthermore, there is a growing interest in developing composite materials that combine sodium alginate with other natural polymers or nanoparticles. These hybrid systems aim to synergize the beneficial properties of multiple components, potentially leading to superior antioxidant stability and delivery mechanisms.

The environmental impact and sustainability of sodium alginate production and application are also key considerations in current research. Efforts are being made to optimize extraction processes and explore alternative sources of alginates to meet the increasing demand while minimizing ecological footprint.

As research in this field progresses, the ultimate goal is to translate laboratory findings into practical, scalable solutions for industry. This involves addressing challenges related to large-scale production, quality control, and regulatory compliance, particularly in food and pharmaceutical applications.

In recent years, the focus on sodium alginate has intensified, particularly in the realm of antioxidant stability techniques. This surge of interest is driven by the growing demand for natural, sustainable solutions in food preservation and pharmaceutical formulations. The ability of sodium alginate to form stable gels and its biocompatibility make it an attractive candidate for encapsulating and protecting sensitive compounds, such as antioxidants, from degradation.

The evolution of sodium alginate research has been marked by several key milestones. Initially, its use was primarily limited to the food industry as a thickening and gelling agent. However, as understanding of its molecular structure and behavior deepened, researchers began to explore its potential in more advanced applications. The discovery of its ability to form hydrogels under mild conditions opened up new avenues in drug delivery and tissue engineering.

Current research objectives in the field of sodium alginate applications for antioxidant stability techniques are multifaceted. One primary goal is to optimize the encapsulation efficiency of antioxidants within sodium alginate matrices. This involves investigating various crosslinking methods and studying the interaction between sodium alginate and different types of antioxidants at a molecular level.

Another critical objective is to enhance the controlled release properties of sodium alginate-based systems. Researchers are exploring ways to modulate the release kinetics of encapsulated antioxidants, ensuring their availability over extended periods. This is particularly important in food preservation applications, where sustained antioxidant activity is crucial for prolonging shelf life.

Furthermore, there is a growing interest in developing composite materials that combine sodium alginate with other natural polymers or nanoparticles. These hybrid systems aim to synergize the beneficial properties of multiple components, potentially leading to superior antioxidant stability and delivery mechanisms.

The environmental impact and sustainability of sodium alginate production and application are also key considerations in current research. Efforts are being made to optimize extraction processes and explore alternative sources of alginates to meet the increasing demand while minimizing ecological footprint.

As research in this field progresses, the ultimate goal is to translate laboratory findings into practical, scalable solutions for industry. This involves addressing challenges related to large-scale production, quality control, and regulatory compliance, particularly in food and pharmaceutical applications.

Market Analysis for Antioxidant Stability Solutions

The market for antioxidant stability solutions has been experiencing significant growth in recent years, driven by increasing consumer awareness of health benefits and the rising demand for natural preservatives in food and beverage industries. The global antioxidant market was valued at $3.9 billion in 2020 and is projected to reach $6.4 billion by 2028, with a compound annual growth rate (CAGR) of 6.8% during the forecast period.

The food and beverage sector remains the largest consumer of antioxidants, accounting for over 60% of the market share. This is primarily due to the growing preference for clean-label products and the need to extend shelf life without compromising nutritional value. The cosmetics and personal care industry is also emerging as a significant market for antioxidants, driven by the increasing demand for anti-aging products and natural skincare solutions.

Geographically, North America and Europe dominate the antioxidant market, collectively accounting for over 50% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.5% during the forecast period, driven by rapid industrialization, changing dietary habits, and increasing disposable income in countries like China and India.

The market for sodium alginate as an antioxidant stability enhancer is particularly promising. Sodium alginate, derived from brown seaweed, has gained traction due to its natural origin and multifunctional properties. Its ability to form gels and act as a thickening agent while simultaneously providing antioxidant stability has made it a preferred choice in various food applications.

The demand for sodium alginate in antioxidant stability techniques is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth is attributed to its wide range of applications in the food industry, including bakery products, dairy, and meat processing. The pharmaceutical and nutraceutical sectors are also showing increased interest in sodium alginate for its potential in drug delivery systems and dietary supplements.

Key market drivers for sodium alginate in antioxidant stability solutions include the growing demand for clean-label products, increasing health consciousness among consumers, and stringent regulations on synthetic additives. However, challenges such as fluctuating raw material prices and the need for sustainable sourcing of seaweed may impact market growth.

In conclusion, the market for antioxidant stability solutions, particularly those utilizing sodium alginate, shows strong growth potential. As research continues to uncover new applications and benefits of sodium alginate in antioxidant stability techniques, the market is expected to expand further, offering significant opportunities for innovation and product development in the food, pharmaceutical, and cosmetic industries.

The food and beverage sector remains the largest consumer of antioxidants, accounting for over 60% of the market share. This is primarily due to the growing preference for clean-label products and the need to extend shelf life without compromising nutritional value. The cosmetics and personal care industry is also emerging as a significant market for antioxidants, driven by the increasing demand for anti-aging products and natural skincare solutions.

Geographically, North America and Europe dominate the antioxidant market, collectively accounting for over 50% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.5% during the forecast period, driven by rapid industrialization, changing dietary habits, and increasing disposable income in countries like China and India.

The market for sodium alginate as an antioxidant stability enhancer is particularly promising. Sodium alginate, derived from brown seaweed, has gained traction due to its natural origin and multifunctional properties. Its ability to form gels and act as a thickening agent while simultaneously providing antioxidant stability has made it a preferred choice in various food applications.

The demand for sodium alginate in antioxidant stability techniques is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth is attributed to its wide range of applications in the food industry, including bakery products, dairy, and meat processing. The pharmaceutical and nutraceutical sectors are also showing increased interest in sodium alginate for its potential in drug delivery systems and dietary supplements.

Key market drivers for sodium alginate in antioxidant stability solutions include the growing demand for clean-label products, increasing health consciousness among consumers, and stringent regulations on synthetic additives. However, challenges such as fluctuating raw material prices and the need for sustainable sourcing of seaweed may impact market growth.

In conclusion, the market for antioxidant stability solutions, particularly those utilizing sodium alginate, shows strong growth potential. As research continues to uncover new applications and benefits of sodium alginate in antioxidant stability techniques, the market is expected to expand further, offering significant opportunities for innovation and product development in the food, pharmaceutical, and cosmetic industries.

Current Challenges in Antioxidant Preservation

The preservation of antioxidants presents several significant challenges in the field of food science and pharmaceutical research. One of the primary issues is the inherent instability of many antioxidant compounds when exposed to environmental factors such as light, heat, and oxygen. This instability can lead to rapid degradation, reducing the efficacy and shelf life of products containing these beneficial substances.

Another major challenge lies in maintaining the bioavailability of antioxidants throughout the product's lifecycle. Many antioxidants are prone to oxidation or chemical changes that can diminish their ability to neutralize free radicals effectively. This is particularly problematic in liquid formulations or products with high water content, where the antioxidants may undergo hydrolysis or other degradation processes.

The interaction between antioxidants and other ingredients in complex formulations poses additional difficulties. Some antioxidants may react with other components, leading to undesired color changes, off-flavors, or reduced potency. This challenge is especially pronounced in food products where maintaining sensory qualities is crucial for consumer acceptance.

Furthermore, the controlled release of antioxidants presents a significant hurdle. Ideally, antioxidants should be released gradually to provide continuous protection against oxidative stress. However, achieving this controlled release while ensuring stability and maintaining the antioxidant's activity throughout the product's shelf life remains a complex task.

The encapsulation of antioxidants has emerged as a potential solution to some of these challenges, but it brings its own set of difficulties. Developing effective encapsulation techniques that protect the antioxidants without compromising their functionality or bioavailability is an ongoing area of research. Additionally, ensuring that the encapsulation materials are food-grade, cost-effective, and compatible with various product formulations adds another layer of complexity.

Regulatory constraints also contribute to the challenges in antioxidant preservation. Strict guidelines on the use of synthetic preservatives have led to increased demand for natural antioxidants. However, natural antioxidants often exhibit lower stability and potency compared to their synthetic counterparts, necessitating higher concentrations or more sophisticated preservation techniques.

Lastly, the scalability of antioxidant preservation methods from laboratory to industrial production represents a significant challenge. Techniques that work well on a small scale may face issues when implemented in large-scale manufacturing processes, requiring substantial research and development efforts to overcome these hurdles.

Another major challenge lies in maintaining the bioavailability of antioxidants throughout the product's lifecycle. Many antioxidants are prone to oxidation or chemical changes that can diminish their ability to neutralize free radicals effectively. This is particularly problematic in liquid formulations or products with high water content, where the antioxidants may undergo hydrolysis or other degradation processes.

The interaction between antioxidants and other ingredients in complex formulations poses additional difficulties. Some antioxidants may react with other components, leading to undesired color changes, off-flavors, or reduced potency. This challenge is especially pronounced in food products where maintaining sensory qualities is crucial for consumer acceptance.

Furthermore, the controlled release of antioxidants presents a significant hurdle. Ideally, antioxidants should be released gradually to provide continuous protection against oxidative stress. However, achieving this controlled release while ensuring stability and maintaining the antioxidant's activity throughout the product's shelf life remains a complex task.

The encapsulation of antioxidants has emerged as a potential solution to some of these challenges, but it brings its own set of difficulties. Developing effective encapsulation techniques that protect the antioxidants without compromising their functionality or bioavailability is an ongoing area of research. Additionally, ensuring that the encapsulation materials are food-grade, cost-effective, and compatible with various product formulations adds another layer of complexity.

Regulatory constraints also contribute to the challenges in antioxidant preservation. Strict guidelines on the use of synthetic preservatives have led to increased demand for natural antioxidants. However, natural antioxidants often exhibit lower stability and potency compared to their synthetic counterparts, necessitating higher concentrations or more sophisticated preservation techniques.

Lastly, the scalability of antioxidant preservation methods from laboratory to industrial production represents a significant challenge. Techniques that work well on a small scale may face issues when implemented in large-scale manufacturing processes, requiring substantial research and development efforts to overcome these hurdles.

Existing Sodium Alginate-based Antioxidant Stabilization Methods

01 Sodium alginate as a stabilizer for antioxidants

Sodium alginate can be used as a stabilizing agent for antioxidants in various formulations. Its ability to form gels and its interactions with other compounds help protect antioxidants from degradation, thereby enhancing their stability and effectiveness over time.- Sodium alginate as a stabilizer for antioxidants: Sodium alginate can be used as a stabilizing agent for antioxidants in various formulations. Its ability to form gels and its interactions with other compounds help protect antioxidants from degradation, thereby improving their stability and effectiveness over time.

- Encapsulation techniques using sodium alginate: Encapsulation of antioxidants using sodium alginate-based matrices can significantly enhance their stability. This technique creates a protective barrier around the antioxidant molecules, shielding them from environmental factors that could lead to degradation.

- Synergistic effects of sodium alginate with other stabilizers: Combining sodium alginate with other stabilizing agents can create synergistic effects, leading to improved antioxidant stability. These combinations often result in more robust protection against oxidation and degradation compared to using sodium alginate alone.

- pH-dependent stability of sodium alginate-antioxidant complexes: The stability of antioxidants in sodium alginate formulations can be influenced by pH. Optimizing the pH of the system can enhance the protective effects of sodium alginate on antioxidants, leading to improved stability across various environmental conditions.

- Sodium alginate in controlled release systems for antioxidants: Sodium alginate can be utilized in controlled release systems for antioxidants. These systems can provide sustained release of antioxidants over time, maintaining their stability and effectiveness for extended periods in various applications.

02 Encapsulation techniques using sodium alginate

Encapsulation of antioxidants using sodium alginate-based systems can significantly improve their stability. This technique involves creating a protective barrier around the antioxidant molecules, shielding them from environmental factors that could lead to degradation.Expand Specific Solutions03 Combination with other natural polymers

Combining sodium alginate with other natural polymers, such as chitosan or pectin, can create synergistic effects that enhance the stability of antioxidants. These combinations often result in improved encapsulation efficiency and controlled release properties.Expand Specific Solutions04 pH-responsive antioxidant delivery systems

Sodium alginate can be used to develop pH-responsive delivery systems for antioxidants. These systems can protect antioxidants in acidic environments and release them under specific pH conditions, improving their stability and bioavailability.Expand Specific Solutions05 Cross-linking methods for enhanced stability

Various cross-linking methods involving sodium alginate can be employed to create more stable matrices for antioxidants. These techniques can include ionic cross-linking with divalent cations or covalent cross-linking with specific agents, resulting in improved antioxidant stability.Expand Specific Solutions

Key Players in Sodium Alginate and Antioxidant Industries

The research on sodium alginate applications in antioxidant stability techniques is in a developing stage, with growing market potential due to increasing demand for natural preservatives in various industries. The market is characterized by moderate competition, with a mix of established companies and research institutions driving innovation. Key players like BASF Corp., Evonik Operations GmbH, and Qingdao Bright Moon Seaweed Group Co., Ltd. are investing in R&D to enhance the technology's efficacy and expand its applications. The technology's maturity is progressing, with academic institutions such as McMaster University and Shandong University contributing to fundamental research, while companies focus on commercialization and industrial applications. As the market evolves, collaborations between industry and academia are likely to accelerate advancements in this field.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative sodium alginate-based formulations for enhancing antioxidant stability in various applications. Their research focuses on creating advanced encapsulation systems using sodium alginate as a primary matrix material. These systems effectively protect sensitive antioxidant compounds from degradation due to environmental factors such as light, heat, and oxygen exposure. BASF's technology involves cross-linking sodium alginate with divalent cations to form a stable gel network that entraps antioxidant molecules[1]. This approach has shown to significantly extend the shelf life of antioxidants in food, cosmetic, and pharmaceutical products[3]. Additionally, BASF has explored the synergistic effects of combining sodium alginate with other natural polymers to create hybrid systems with enhanced protective properties[5].

Strengths: Extensive research and development capabilities, wide range of applications across industries, proven effectiveness in extending antioxidant stability. Weaknesses: Potential cost implications for large-scale production, dependency on specific raw materials for optimal performance.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has made significant strides in sodium alginate applications for antioxidant stability. Their approach involves the development of specialized sodium alginate derivatives with enhanced functional properties. Evonik's research has led to the creation of modified sodium alginates with improved film-forming capabilities and increased resistance to pH changes[2]. These innovations have resulted in more effective barrier properties against oxygen permeation, thereby enhancing antioxidant stability in various formulations. The company has also explored the use of sodium alginate in combination with their proprietary antioxidant compounds to create synergistic effects[4]. Evonik's technology has found particular success in the personal care and nutraceutical sectors, where maintaining the potency of antioxidants is crucial for product efficacy[6].

Strengths: Innovative sodium alginate derivatives, strong presence in personal care and nutraceutical markets, synergistic formulations with proprietary antioxidants. Weaknesses: Potentially higher production costs for specialized derivatives, limited application in some food sectors due to regulatory constraints.

Innovative Sodium Alginate Applications for Antioxidant Stability

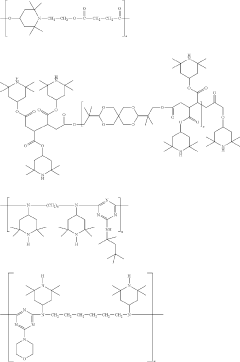

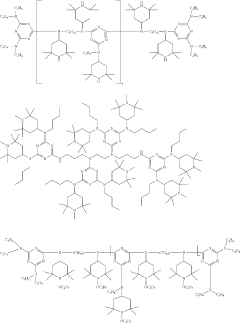

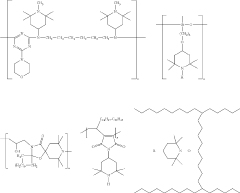

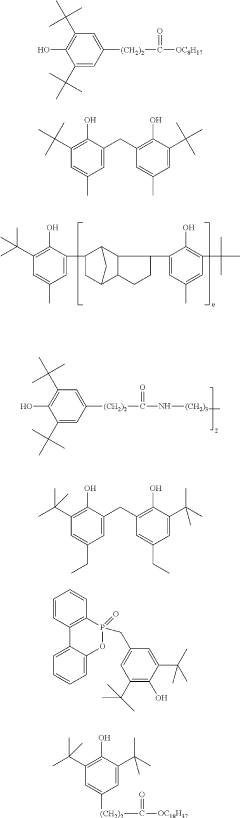

Use of a stabilizer composition for stabilizing organic materials, stabilizer composition, master batch, composition, molding compound for moldings, process for oxidative, thermal and actinic stabilization of a thermoplastic, and use of a composition

PatentPendingUS20240174840A1

Innovation

- The use of a stabilizer composition comprising sulfites and/or thiosulfates in combination with polymeric or oligomeric hindered amines, specifically inorganic sulfites and thiosulfates, provides a stabilizing effect for plastics against oxidative, thermal, and actinic degradation, offering a favorable cost structure and environmental friendliness.

Environmental Impact of Sodium Alginate-based Solutions

The environmental impact of sodium alginate-based solutions in antioxidant stability techniques is a crucial aspect to consider in the development and application of these technologies. Sodium alginate, derived from brown seaweed, is generally considered an eco-friendly and sustainable material. However, its large-scale production and use in antioxidant stability applications may have both positive and negative environmental implications.

One of the primary environmental benefits of sodium alginate-based solutions is their biodegradability. Unlike synthetic polymers, sodium alginate naturally decomposes in the environment, reducing the risk of long-term pollution and accumulation in ecosystems. This characteristic makes it an attractive option for industries seeking to reduce their environmental footprint and align with sustainability goals.

The production of sodium alginate from seaweed also presents potential environmental advantages. Seaweed cultivation requires minimal land use and does not compete with food crops for agricultural resources. Additionally, seaweed farming can contribute to carbon sequestration, as these marine plants absorb significant amounts of CO2 during their growth cycle.

However, the increasing demand for sodium alginate in various applications, including antioxidant stability techniques, may lead to intensified seaweed harvesting. This could potentially disrupt marine ecosystems if not managed sustainably. Overharvesting of seaweed can impact local marine biodiversity and alter coastal habitats. Therefore, it is crucial to implement responsible harvesting practices and promote sustainable seaweed cultivation methods to mitigate these risks.

The processing of seaweed into sodium alginate involves chemical extraction methods that may generate waste and consume energy. While these processes are generally less environmentally harmful compared to the production of synthetic polymers, there is still room for improvement in terms of energy efficiency and waste reduction. Research into more environmentally friendly extraction techniques and the use of renewable energy sources in production facilities could further enhance the sustainability profile of sodium alginate.

In antioxidant stability applications, sodium alginate-based solutions can contribute to reducing food waste by extending the shelf life of products. This indirect environmental benefit should not be overlooked, as food waste is a significant contributor to greenhouse gas emissions and resource depletion. By improving the stability and longevity of food products, these solutions can help minimize the environmental impact associated with food production, transportation, and disposal.

The disposal of products containing sodium alginate-based antioxidant stabilizers also warrants consideration. While the material itself is biodegradable, it may be combined with other substances or packaging materials that are not as environmentally friendly. Developing comprehensive end-of-life strategies for these products, including proper disposal methods and potential recycling or composting options, is essential to maximize their environmental benefits.

One of the primary environmental benefits of sodium alginate-based solutions is their biodegradability. Unlike synthetic polymers, sodium alginate naturally decomposes in the environment, reducing the risk of long-term pollution and accumulation in ecosystems. This characteristic makes it an attractive option for industries seeking to reduce their environmental footprint and align with sustainability goals.

The production of sodium alginate from seaweed also presents potential environmental advantages. Seaweed cultivation requires minimal land use and does not compete with food crops for agricultural resources. Additionally, seaweed farming can contribute to carbon sequestration, as these marine plants absorb significant amounts of CO2 during their growth cycle.

However, the increasing demand for sodium alginate in various applications, including antioxidant stability techniques, may lead to intensified seaweed harvesting. This could potentially disrupt marine ecosystems if not managed sustainably. Overharvesting of seaweed can impact local marine biodiversity and alter coastal habitats. Therefore, it is crucial to implement responsible harvesting practices and promote sustainable seaweed cultivation methods to mitigate these risks.

The processing of seaweed into sodium alginate involves chemical extraction methods that may generate waste and consume energy. While these processes are generally less environmentally harmful compared to the production of synthetic polymers, there is still room for improvement in terms of energy efficiency and waste reduction. Research into more environmentally friendly extraction techniques and the use of renewable energy sources in production facilities could further enhance the sustainability profile of sodium alginate.

In antioxidant stability applications, sodium alginate-based solutions can contribute to reducing food waste by extending the shelf life of products. This indirect environmental benefit should not be overlooked, as food waste is a significant contributor to greenhouse gas emissions and resource depletion. By improving the stability and longevity of food products, these solutions can help minimize the environmental impact associated with food production, transportation, and disposal.

The disposal of products containing sodium alginate-based antioxidant stabilizers also warrants consideration. While the material itself is biodegradable, it may be combined with other substances or packaging materials that are not as environmentally friendly. Developing comprehensive end-of-life strategies for these products, including proper disposal methods and potential recycling or composting options, is essential to maximize their environmental benefits.

Regulatory Considerations for Food-grade Antioxidant Stabilizers

The regulatory landscape for food-grade antioxidant stabilizers, including sodium alginate applications, is complex and varies across different regions. In the United States, the Food and Drug Administration (FDA) regulates the use of food additives, including antioxidants and stabilizers, under the Federal Food, Drug, and Cosmetic Act. Sodium alginate is generally recognized as safe (GRAS) for use in food products, but its specific applications as an antioxidant stabilizer may require additional regulatory scrutiny.

The European Union (EU) has established a comprehensive framework for food additives through Regulation (EC) No 1333/2008. This regulation sets out the conditions for the use of food additives, including antioxidants and stabilizers. Sodium alginate is approved for use in various food categories within the EU, but manufacturers must adhere to specific usage limits and labeling requirements.

In Japan, the Ministry of Health, Labour and Welfare oversees the regulation of food additives. Sodium alginate is permitted for use in food products, but its application as an antioxidant stabilizer must comply with the standards set forth in the Food Sanitation Act.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that serve as a reference for many countries. These standards include guidelines for the use of food additives, including antioxidants and stabilizers.

When developing new applications for sodium alginate in antioxidant stability techniques, manufacturers must consider the regulatory requirements for safety assessments, toxicological studies, and efficacy demonstrations. This may involve conducting extensive research to prove the safety and effectiveness of sodium alginate in its proposed application.

Labeling regulations are another crucial aspect to consider. In many jurisdictions, the use of sodium alginate as an antioxidant stabilizer must be clearly indicated on product labels. This often includes listing it by name or E-number (E401 for sodium alginate) in the ingredients list.

Environmental regulations may also come into play, particularly concerning the sourcing and processing of algae used to produce sodium alginate. Sustainable harvesting practices and potential environmental impacts of production processes may be subject to regulatory oversight in some regions.

As research on sodium alginate applications in antioxidant stability techniques progresses, it is essential for manufacturers to maintain ongoing dialogue with regulatory bodies. This ensures compliance with current regulations and helps anticipate potential regulatory changes that may affect the development and commercialization of new antioxidant stabilizer technologies.

The European Union (EU) has established a comprehensive framework for food additives through Regulation (EC) No 1333/2008. This regulation sets out the conditions for the use of food additives, including antioxidants and stabilizers. Sodium alginate is approved for use in various food categories within the EU, but manufacturers must adhere to specific usage limits and labeling requirements.

In Japan, the Ministry of Health, Labour and Welfare oversees the regulation of food additives. Sodium alginate is permitted for use in food products, but its application as an antioxidant stabilizer must comply with the standards set forth in the Food Sanitation Act.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that serve as a reference for many countries. These standards include guidelines for the use of food additives, including antioxidants and stabilizers.

When developing new applications for sodium alginate in antioxidant stability techniques, manufacturers must consider the regulatory requirements for safety assessments, toxicological studies, and efficacy demonstrations. This may involve conducting extensive research to prove the safety and effectiveness of sodium alginate in its proposed application.

Labeling regulations are another crucial aspect to consider. In many jurisdictions, the use of sodium alginate as an antioxidant stabilizer must be clearly indicated on product labels. This often includes listing it by name or E-number (E401 for sodium alginate) in the ingredients list.

Environmental regulations may also come into play, particularly concerning the sourcing and processing of algae used to produce sodium alginate. Sustainable harvesting practices and potential environmental impacts of production processes may be subject to regulatory oversight in some regions.

As research on sodium alginate applications in antioxidant stability techniques progresses, it is essential for manufacturers to maintain ongoing dialogue with regulatory bodies. This ensures compliance with current regulations and helps anticipate potential regulatory changes that may affect the development and commercialization of new antioxidant stabilizer technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!