How Sodium Alginate Supports Adaptive Food Formulations?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Background and Objectives

Sodium alginate, a versatile polysaccharide derived from brown seaweed, has been a subject of increasing interest in the food industry due to its unique properties and potential applications. The evolution of this natural compound as a food ingredient can be traced back to its discovery in the 1880s, with significant advancements in its extraction and purification processes occurring throughout the 20th century.

The primary objective of exploring sodium alginate in adaptive food formulations is to leverage its exceptional gelling, thickening, and stabilizing properties to create innovative and functional food products. As consumer demands for healthier, more sustainable, and customizable food options continue to grow, sodium alginate presents an opportunity to meet these evolving needs while addressing various technological challenges in food production.

One of the key trends driving the development of sodium alginate applications is the increasing focus on clean label ingredients and natural food additives. As a plant-derived compound, sodium alginate aligns well with consumer preferences for minimally processed and natural food components. This trend has spurred research into optimizing the extraction and modification processes of sodium alginate to enhance its functionality while maintaining its clean label status.

Another significant trend is the growing interest in texture modification and structure formation in food products. Sodium alginate's ability to form gels in the presence of calcium ions makes it an ideal candidate for creating unique textures and structures in foods, ranging from spherification techniques in molecular gastronomy to the development of plant-based meat alternatives.

The potential of sodium alginate in adaptive food formulations extends beyond texture modification. Its film-forming properties have led to investigations into its use in edible coatings and packaging materials, addressing the need for sustainable and biodegradable food packaging solutions. Additionally, its ability to encapsulate and protect bioactive compounds has opened up possibilities in the development of functional foods and nutraceuticals.

As we look towards the future, the technical goals for sodium alginate in adaptive food formulations include enhancing its stability under various processing conditions, improving its compatibility with a wider range of food matrices, and developing novel modification techniques to expand its functional properties. These advancements aim to position sodium alginate as a key ingredient in the creation of next-generation food products that are not only delicious and nutritious but also adaptable to individual dietary needs and preferences.

The primary objective of exploring sodium alginate in adaptive food formulations is to leverage its exceptional gelling, thickening, and stabilizing properties to create innovative and functional food products. As consumer demands for healthier, more sustainable, and customizable food options continue to grow, sodium alginate presents an opportunity to meet these evolving needs while addressing various technological challenges in food production.

One of the key trends driving the development of sodium alginate applications is the increasing focus on clean label ingredients and natural food additives. As a plant-derived compound, sodium alginate aligns well with consumer preferences for minimally processed and natural food components. This trend has spurred research into optimizing the extraction and modification processes of sodium alginate to enhance its functionality while maintaining its clean label status.

Another significant trend is the growing interest in texture modification and structure formation in food products. Sodium alginate's ability to form gels in the presence of calcium ions makes it an ideal candidate for creating unique textures and structures in foods, ranging from spherification techniques in molecular gastronomy to the development of plant-based meat alternatives.

The potential of sodium alginate in adaptive food formulations extends beyond texture modification. Its film-forming properties have led to investigations into its use in edible coatings and packaging materials, addressing the need for sustainable and biodegradable food packaging solutions. Additionally, its ability to encapsulate and protect bioactive compounds has opened up possibilities in the development of functional foods and nutraceuticals.

As we look towards the future, the technical goals for sodium alginate in adaptive food formulations include enhancing its stability under various processing conditions, improving its compatibility with a wider range of food matrices, and developing novel modification techniques to expand its functional properties. These advancements aim to position sodium alginate as a key ingredient in the creation of next-generation food products that are not only delicious and nutritious but also adaptable to individual dietary needs and preferences.

Market Demand Analysis for Adaptive Food Formulations

The market demand for adaptive food formulations utilizing sodium alginate has been steadily increasing in recent years. This growth is driven by several key factors, including the rising consumer interest in personalized nutrition, the need for functional foods that cater to specific dietary requirements, and the growing awareness of the health benefits associated with tailored food products.

Consumers are increasingly seeking food products that can be easily adapted to their individual nutritional needs and preferences. This trend has created a significant opportunity for food manufacturers to develop innovative products that can be customized on-demand. Sodium alginate, with its unique gelling properties and versatility, plays a crucial role in enabling these adaptive formulations.

The health and wellness sector has been a major driver of market demand for adaptive food formulations. As consumers become more health-conscious, there is a growing demand for foods that can be tailored to address specific health concerns, such as weight management, digestive health, and nutrient deficiencies. Sodium alginate's ability to modify texture, control nutrient release, and enhance the stability of food products makes it an ideal ingredient for creating such adaptive formulations.

The sports nutrition market has also shown significant interest in adaptive food formulations. Athletes and fitness enthusiasts are looking for products that can be easily adjusted to meet their changing nutritional needs based on training intensity, competition schedules, and recovery requirements. Sodium alginate's gel-forming capabilities allow for the development of products with variable nutrient densities and release profiles, catering to this demand.

In the aging population segment, there is a growing need for foods that can be easily modified in texture and nutrient content to accommodate changing dietary needs and swallowing difficulties. Adaptive food formulations using sodium alginate can address these concerns by allowing for easy texture modification while maintaining nutritional value.

The food service industry has also recognized the potential of adaptive food formulations. Restaurants and catering services are exploring ways to offer personalized menu options that can be quickly adjusted to meet individual customer preferences and dietary restrictions. Sodium alginate's ability to create unique textures and encapsulate flavors makes it a valuable tool in this context.

Market analysts predict that the global market for adaptive food formulations will continue to grow at a compound annual growth rate of over 7% in the coming years. This growth is expected to be particularly strong in developed markets such as North America and Europe, where consumer awareness and willingness to pay for personalized nutrition solutions are high.

Consumers are increasingly seeking food products that can be easily adapted to their individual nutritional needs and preferences. This trend has created a significant opportunity for food manufacturers to develop innovative products that can be customized on-demand. Sodium alginate, with its unique gelling properties and versatility, plays a crucial role in enabling these adaptive formulations.

The health and wellness sector has been a major driver of market demand for adaptive food formulations. As consumers become more health-conscious, there is a growing demand for foods that can be tailored to address specific health concerns, such as weight management, digestive health, and nutrient deficiencies. Sodium alginate's ability to modify texture, control nutrient release, and enhance the stability of food products makes it an ideal ingredient for creating such adaptive formulations.

The sports nutrition market has also shown significant interest in adaptive food formulations. Athletes and fitness enthusiasts are looking for products that can be easily adjusted to meet their changing nutritional needs based on training intensity, competition schedules, and recovery requirements. Sodium alginate's gel-forming capabilities allow for the development of products with variable nutrient densities and release profiles, catering to this demand.

In the aging population segment, there is a growing need for foods that can be easily modified in texture and nutrient content to accommodate changing dietary needs and swallowing difficulties. Adaptive food formulations using sodium alginate can address these concerns by allowing for easy texture modification while maintaining nutritional value.

The food service industry has also recognized the potential of adaptive food formulations. Restaurants and catering services are exploring ways to offer personalized menu options that can be quickly adjusted to meet individual customer preferences and dietary restrictions. Sodium alginate's ability to create unique textures and encapsulate flavors makes it a valuable tool in this context.

Market analysts predict that the global market for adaptive food formulations will continue to grow at a compound annual growth rate of over 7% in the coming years. This growth is expected to be particularly strong in developed markets such as North America and Europe, where consumer awareness and willingness to pay for personalized nutrition solutions are high.

Current State and Challenges in Food Adaptability

The current state of food adaptability using sodium alginate presents both significant advancements and notable challenges. Sodium alginate, a versatile polysaccharide derived from brown seaweed, has gained prominence in the food industry due to its unique properties that support adaptive food formulations. Its ability to form gels, stabilize emulsions, and act as a thickening agent has made it invaluable in creating texturally diverse and nutritionally enhanced food products.

In recent years, the food industry has witnessed a surge in the application of sodium alginate across various product categories. Its use in molecular gastronomy has revolutionized culinary techniques, enabling chefs to create innovative textures and presentations. Moreover, the incorporation of sodium alginate in functional foods has allowed for the development of products with improved nutritional profiles and extended shelf life.

However, the widespread adoption of sodium alginate in adaptive food formulations faces several challenges. One primary concern is the variability in alginate quality and composition depending on its source and extraction method. This inconsistency can lead to unpredictable behavior in food systems, making it difficult for manufacturers to maintain product consistency across batches.

Another significant challenge lies in the interaction of sodium alginate with other food components. While its gelling properties are advantageous in many applications, they can also lead to undesired textural changes when combined with certain ingredients or subjected to specific processing conditions. This necessitates extensive research and testing to optimize formulations for each specific application.

The regulatory landscape surrounding sodium alginate usage in food products also presents challenges. Although generally recognized as safe (GRAS) by the FDA, there are variations in regulations across different countries and regions. This can complicate the development and marketing of globally distributed food products incorporating sodium alginate.

Furthermore, consumer perception and acceptance of food additives, including sodium alginate, remain a hurdle. As the clean label trend continues to gain momentum, manufacturers must navigate the balance between leveraging the functional benefits of sodium alginate and meeting consumer demands for minimally processed, natural ingredients.

From a technological standpoint, the current state of sodium alginate in food adaptability is marked by ongoing research into novel extraction methods and modification techniques. Scientists are exploring ways to enhance the functionality of sodium alginate, such as improving its stability in acidic conditions or increasing its binding capacity with specific nutrients. These advancements aim to expand the range of applications and overcome some of the existing limitations in food formulations.

In conclusion, while sodium alginate has proven to be a valuable tool in creating adaptive food formulations, the industry continues to grapple with challenges related to consistency, interactions, regulations, and consumer acceptance. Addressing these challenges through continued research and innovation will be crucial in fully realizing the potential of sodium alginate in the evolving landscape of food technology.

In recent years, the food industry has witnessed a surge in the application of sodium alginate across various product categories. Its use in molecular gastronomy has revolutionized culinary techniques, enabling chefs to create innovative textures and presentations. Moreover, the incorporation of sodium alginate in functional foods has allowed for the development of products with improved nutritional profiles and extended shelf life.

However, the widespread adoption of sodium alginate in adaptive food formulations faces several challenges. One primary concern is the variability in alginate quality and composition depending on its source and extraction method. This inconsistency can lead to unpredictable behavior in food systems, making it difficult for manufacturers to maintain product consistency across batches.

Another significant challenge lies in the interaction of sodium alginate with other food components. While its gelling properties are advantageous in many applications, they can also lead to undesired textural changes when combined with certain ingredients or subjected to specific processing conditions. This necessitates extensive research and testing to optimize formulations for each specific application.

The regulatory landscape surrounding sodium alginate usage in food products also presents challenges. Although generally recognized as safe (GRAS) by the FDA, there are variations in regulations across different countries and regions. This can complicate the development and marketing of globally distributed food products incorporating sodium alginate.

Furthermore, consumer perception and acceptance of food additives, including sodium alginate, remain a hurdle. As the clean label trend continues to gain momentum, manufacturers must navigate the balance between leveraging the functional benefits of sodium alginate and meeting consumer demands for minimally processed, natural ingredients.

From a technological standpoint, the current state of sodium alginate in food adaptability is marked by ongoing research into novel extraction methods and modification techniques. Scientists are exploring ways to enhance the functionality of sodium alginate, such as improving its stability in acidic conditions or increasing its binding capacity with specific nutrients. These advancements aim to expand the range of applications and overcome some of the existing limitations in food formulations.

In conclusion, while sodium alginate has proven to be a valuable tool in creating adaptive food formulations, the industry continues to grapple with challenges related to consistency, interactions, regulations, and consumer acceptance. Addressing these challenges through continued research and innovation will be crucial in fully realizing the potential of sodium alginate in the evolving landscape of food technology.

Existing Solutions Using Sodium Alginate in Food

01 Sodium alginate in drug delivery systems

Sodium alginate is widely used in drug delivery systems due to its biocompatibility and ability to form hydrogels. It can be used to encapsulate various drugs, providing controlled release and improved stability. The adaptability of sodium alginate allows for its use in different formulations, including oral, topical, and injectable drug delivery systems.- Biomedical applications of sodium alginate: Sodium alginate demonstrates versatility in biomedical applications due to its biocompatibility and ability to form hydrogels. It is used in wound dressings, tissue engineering scaffolds, and drug delivery systems. The adaptability of sodium alginate in these applications stems from its ability to form stable structures and its responsiveness to various stimuli.

- Food industry applications: Sodium alginate's adaptability extends to the food industry, where it is used as a thickening agent, stabilizer, and emulsifier. Its ability to form gels in the presence of calcium ions makes it useful in various food products, including restructured foods, desserts, and beverages. The adaptability of sodium alginate in food applications is due to its non-toxicity and versatile gelling properties.

- Environmental remediation applications: Sodium alginate shows adaptability in environmental remediation processes. It can be used to create adsorbents for heavy metal removal from water and soil, as well as in the development of biodegradable materials for reducing environmental pollution. The adaptability of sodium alginate in this field is attributed to its biodegradability and ability to form complexes with metal ions.

- Textile industry applications: In the textile industry, sodium alginate demonstrates adaptability as a thickening agent for textile printing pastes and as a sizing agent for yarns. It can also be used in the production of flame-retardant fabrics and in the development of smart textiles. The adaptability of sodium alginate in textiles is due to its film-forming properties and compatibility with various dyes and finishes.

- Pharmaceutical formulations: Sodium alginate's adaptability in pharmaceutical formulations is evident in its use as a controlled release matrix, tablet disintegrant, and in the development of novel drug delivery systems. It can be used to create floating drug delivery systems, mucoadhesive formulations, and nanoparticles for targeted drug delivery. The adaptability of sodium alginate in this field is due to its biocompatibility, pH-sensitivity, and ability to form stable matrices.

02 Sodium alginate in wound healing applications

The adaptability of sodium alginate makes it suitable for wound healing applications. It can be used to create wound dressings that provide a moist environment, absorb exudates, and promote tissue regeneration. Sodium alginate-based dressings can be easily applied and removed, making them convenient for both patients and healthcare providers.Expand Specific Solutions03 Sodium alginate in food and beverage industry

Sodium alginate's adaptability extends to the food and beverage industry, where it is used as a thickening agent, stabilizer, and emulsifier. It can improve texture, viscosity, and shelf life of various products, including dairy, bakery, and processed foods. Its ability to form gels and films makes it versatile in food packaging applications as well.Expand Specific Solutions04 Sodium alginate in 3D bioprinting

The adaptability of sodium alginate makes it suitable for use in 3D bioprinting applications. It can be used as a bioink to create scaffolds for tissue engineering and regenerative medicine. Sodium alginate's ability to form hydrogels and its biocompatibility allow for the encapsulation and support of living cells during the printing process.Expand Specific Solutions05 Sodium alginate in environmental applications

Sodium alginate's adaptability extends to environmental applications, particularly in water treatment and soil remediation. It can be used as a flocculant to remove contaminants from water and as a soil conditioner to improve soil structure and water retention. Its biodegradability makes it an eco-friendly option for various environmental applications.Expand Specific Solutions

Key Players in Sodium Alginate Production and Application

The market for sodium alginate in adaptive food formulations is in a growth phase, driven by increasing demand for functional and clean-label ingredients. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, sodium alginate applications are evolving, with companies like Unilever, Hindustan Unilever, and Fuji Oil Co. leading innovation in food formulations. Research institutions such as Guilin University of Technology and Shandong University are contributing to advancements in alginate technology. The competitive landscape is diverse, including established multinational corporations and specialized ingredient suppliers like Gelteq Ltd. and Red Arrow Products Co., indicating a maturing but still dynamic market with opportunities for both large players and niche innovators.

BK Giulini GmbH

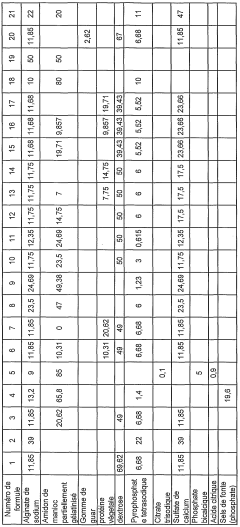

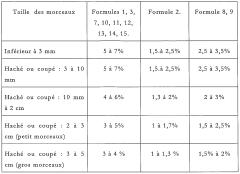

Technical Solution: BK Giulini has developed specialized sodium alginate blends for use in restructured meat products. Their technology involves combining sodium alginate with calcium salts and other functional ingredients to create a system that binds meat pieces together, improving texture and reducing cooking losses[7]. This allows for the creation of value-added meat products from lower-grade cuts. The company has also explored using sodium alginate in combination with phosphates for improved water retention and texture in processed meats[8]. Additionally, BK Giulini has developed sodium alginate-based solutions for gluten-free bakery products, leveraging the ingredient's ability to mimic gluten's viscoelastic properties[9].

Strengths: Expertise in phosphate and alginate chemistry, strong presence in the meat processing industry. Weaknesses: Potential regulatory challenges related to phosphate usage in some markets, limited presence in non-meat applications.

Unilever NV

Technical Solution: Unilever has developed innovative applications of sodium alginate in adaptive food formulations. They utilize sodium alginate's unique gelling properties to create texture-modifying solutions for various food products. Their approach involves combining sodium alginate with calcium salts to form heat-stable gels that can withstand processing conditions[1]. This allows for the creation of low-fat alternatives that maintain desirable mouthfeel and texture. Unilever has also explored using sodium alginate in microencapsulation techniques for controlled release of flavors and nutrients in functional foods[2]. Their research extends to using sodium alginate-based edible films and coatings to improve shelf life and quality of fresh produce[3].

Strengths: Extensive R&D capabilities, global market presence, and diverse product portfolio. Weaknesses: Potential higher costs associated with advanced formulations and the need for consumer education on novel ingredients.

Core Innovations in Sodium Alginate Technology

Method and composition for preparing a food product at least partly gelled

PatentWO2006021642A1

Innovation

- A composition comprising sodium alginate, a slowly dissolving calcium salt, a reaction retarding agent, and water-retaining texturizing agents is mixed with food raw materials to create a homogeneous, easily dispersible mixture that gels without delayed addition of alginate, allowing for improved texture, water retention, and yield.

Use of sodium alginate-gelatin 3D scaffold in supporting differentiation of preadipocytes

PatentWO2023225995A1

Innovation

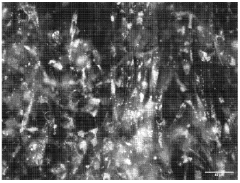

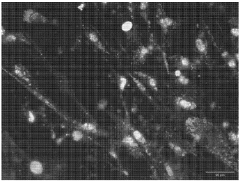

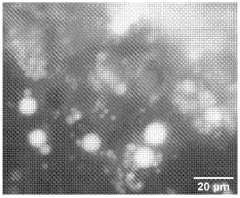

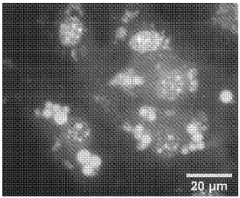

- The sodium alginate-gelatin 3D scaffold is used to form a 3D scaffold with a loose porous structure through the cross-linking reaction of sodium alginate, gelatin and cross-linking agents, which provides a suitable cell growth environment and supports the differentiation of adipose precursor cells into large fat cells. Drops of mature adipocytes.

Regulatory Framework for Food Additives

The regulatory framework for food additives plays a crucial role in ensuring the safety and efficacy of sodium alginate in adaptive food formulations. In the United States, the Food and Drug Administration (FDA) oversees the regulation of food additives, including sodium alginate, under the Federal Food, Drug, and Cosmetic Act (FD&C Act).

Sodium alginate is classified as a Generally Recognized as Safe (GRAS) substance by the FDA, which means it is considered safe for use in food products without the need for premarket approval. However, manufacturers must still comply with Good Manufacturing Practices (GMPs) and ensure that the use of sodium alginate in their products is safe and appropriate.

The European Union (EU) also has a comprehensive regulatory framework for food additives. The European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives, including sodium alginate. In the EU, sodium alginate is approved for use as a food additive under the E-number E401.

Globally, the Joint FAO/WHO Expert Committee on Food Additives (JECFA) provides international standards and guidelines for the use of food additives. JECFA has evaluated sodium alginate and established specifications for its use in food products.

When using sodium alginate in adaptive food formulations, manufacturers must adhere to specific regulations regarding labeling, maximum permitted levels, and specific applications. For example, in the EU, sodium alginate must be declared on food labels as "E401" or "sodium alginate" when used as an additive.

The regulatory framework also addresses the purity and quality standards for sodium alginate. Manufacturers must ensure that their sodium alginate meets these standards, which typically include specifications for heavy metal content, microbial contamination, and other impurities.

As the food industry continues to innovate with adaptive formulations, regulatory bodies are likely to review and update their guidelines for sodium alginate and other food additives. This ongoing process ensures that regulations keep pace with technological advancements and emerging safety considerations.

Manufacturers developing adaptive food formulations with sodium alginate should stay informed about regulatory changes and consult with regulatory experts to ensure compliance across different markets and jurisdictions. This proactive approach helps maintain product safety, consumer trust, and market access for innovative food products utilizing sodium alginate's unique properties.

Sodium alginate is classified as a Generally Recognized as Safe (GRAS) substance by the FDA, which means it is considered safe for use in food products without the need for premarket approval. However, manufacturers must still comply with Good Manufacturing Practices (GMPs) and ensure that the use of sodium alginate in their products is safe and appropriate.

The European Union (EU) also has a comprehensive regulatory framework for food additives. The European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives, including sodium alginate. In the EU, sodium alginate is approved for use as a food additive under the E-number E401.

Globally, the Joint FAO/WHO Expert Committee on Food Additives (JECFA) provides international standards and guidelines for the use of food additives. JECFA has evaluated sodium alginate and established specifications for its use in food products.

When using sodium alginate in adaptive food formulations, manufacturers must adhere to specific regulations regarding labeling, maximum permitted levels, and specific applications. For example, in the EU, sodium alginate must be declared on food labels as "E401" or "sodium alginate" when used as an additive.

The regulatory framework also addresses the purity and quality standards for sodium alginate. Manufacturers must ensure that their sodium alginate meets these standards, which typically include specifications for heavy metal content, microbial contamination, and other impurities.

As the food industry continues to innovate with adaptive formulations, regulatory bodies are likely to review and update their guidelines for sodium alginate and other food additives. This ongoing process ensures that regulations keep pace with technological advancements and emerging safety considerations.

Manufacturers developing adaptive food formulations with sodium alginate should stay informed about regulatory changes and consult with regulatory experts to ensure compliance across different markets and jurisdictions. This proactive approach helps maintain product safety, consumer trust, and market access for innovative food products utilizing sodium alginate's unique properties.

Sustainability Aspects of Sodium Alginate Use

Sodium alginate, derived from brown seaweed, has gained significant attention in the food industry due to its versatile properties and potential for supporting adaptive food formulations. When considering the sustainability aspects of sodium alginate use, several key factors come into play.

The production of sodium alginate primarily relies on the harvesting of brown seaweed, which is a renewable resource. This natural sourcing aligns with the growing consumer demand for sustainable and plant-based ingredients in food products. The cultivation of seaweed for alginate extraction can be done in a manner that supports marine ecosystems, providing habitats for various aquatic species and contributing to carbon sequestration.

However, the sustainability of sodium alginate production is not without challenges. The increasing demand for this ingredient has led to concerns about overharvesting in some regions. Sustainable harvesting practices and proper management of seaweed farms are crucial to maintain the long-term viability of this resource and minimize environmental impact.

From a processing perspective, the extraction of sodium alginate from seaweed involves chemical treatments that require careful management to minimize waste and energy consumption. Advancements in extraction technologies have led to more efficient processes, reducing the environmental footprint of alginate production. Additionally, the byproducts of alginate extraction can be utilized in various applications, further enhancing the overall sustainability of the production cycle.

In food formulations, sodium alginate's ability to form gels and act as a thickening agent allows for the reduction of other, potentially less sustainable ingredients. Its use can lead to improved texture and stability in plant-based alternatives to dairy and meat products, supporting the shift towards more sustainable food choices. The extended shelf life provided by sodium alginate in certain applications also contributes to reducing food waste, a significant sustainability concern in the food industry.

Furthermore, the biodegradability of sodium alginate aligns with sustainability goals in packaging and food service applications. As a natural polymer, it can be used to develop eco-friendly food packaging solutions, potentially replacing some petroleum-based plastics.

Looking ahead, research into optimizing seaweed cultivation methods and improving alginate extraction processes continues to enhance the sustainability profile of sodium alginate. The development of new applications that leverage its unique properties may further contribute to sustainable food systems and circular economy initiatives in the food industry.

The production of sodium alginate primarily relies on the harvesting of brown seaweed, which is a renewable resource. This natural sourcing aligns with the growing consumer demand for sustainable and plant-based ingredients in food products. The cultivation of seaweed for alginate extraction can be done in a manner that supports marine ecosystems, providing habitats for various aquatic species and contributing to carbon sequestration.

However, the sustainability of sodium alginate production is not without challenges. The increasing demand for this ingredient has led to concerns about overharvesting in some regions. Sustainable harvesting practices and proper management of seaweed farms are crucial to maintain the long-term viability of this resource and minimize environmental impact.

From a processing perspective, the extraction of sodium alginate from seaweed involves chemical treatments that require careful management to minimize waste and energy consumption. Advancements in extraction technologies have led to more efficient processes, reducing the environmental footprint of alginate production. Additionally, the byproducts of alginate extraction can be utilized in various applications, further enhancing the overall sustainability of the production cycle.

In food formulations, sodium alginate's ability to form gels and act as a thickening agent allows for the reduction of other, potentially less sustainable ingredients. Its use can lead to improved texture and stability in plant-based alternatives to dairy and meat products, supporting the shift towards more sustainable food choices. The extended shelf life provided by sodium alginate in certain applications also contributes to reducing food waste, a significant sustainability concern in the food industry.

Furthermore, the biodegradability of sodium alginate aligns with sustainability goals in packaging and food service applications. As a natural polymer, it can be used to develop eco-friendly food packaging solutions, potentially replacing some petroleum-based plastics.

Looking ahead, research into optimizing seaweed cultivation methods and improving alginate extraction processes continues to enhance the sustainability profile of sodium alginate. The development of new applications that leverage its unique properties may further contribute to sustainable food systems and circular economy initiatives in the food industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!