Sodium Alginate in Extraction Processes for Nutrient Preservation

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Extraction Background and Objectives

Sodium alginate, a versatile polysaccharide derived from brown seaweed, has gained significant attention in various industries, particularly in food processing and biotechnology. The extraction and application of sodium alginate in nutrient preservation processes have become a focal point of research due to its unique properties and potential benefits.

The history of alginate extraction dates back to the early 20th century when it was first isolated from kelp. Since then, the technology has evolved considerably, with researchers and industries continuously refining extraction methods to improve yield, purity, and functionality. The growing demand for natural, sustainable, and biocompatible materials has further propelled the interest in sodium alginate research.

In recent years, the focus has shifted towards optimizing extraction processes to enhance the preservation of nutrients. This is particularly crucial in the food industry, where maintaining the nutritional value of products during processing and storage is of paramount importance. Sodium alginate's ability to form gels and act as a stabilizer makes it an ideal candidate for encapsulation and controlled release of nutrients.

The primary objective of current research on sodium alginate extraction for nutrient preservation is to develop efficient and cost-effective methods that maximize the retention of essential nutrients while maintaining the desired functional properties of the alginate. This involves exploring various extraction parameters, such as temperature, pH, and solvent composition, to identify optimal conditions that minimize nutrient degradation during the extraction process.

Another key goal is to investigate the potential of sodium alginate as a protective matrix for sensitive nutrients. This includes studying its interaction with different types of nutrients, such as vitamins, minerals, and bioactive compounds, and assessing its effectiveness in shielding these components from environmental factors that could lead to degradation.

Furthermore, researchers aim to elucidate the mechanisms by which sodium alginate contributes to nutrient preservation. This involves examining its molecular structure, gel-forming properties, and interactions with other food components to understand how it can be tailored for specific nutrient preservation applications.

The development of novel extraction techniques that combine efficiency with sustainability is also a priority. This includes exploring green extraction methods, such as enzyme-assisted extraction or supercritical fluid extraction, which could potentially reduce the environmental impact of alginate production while maintaining or improving its nutrient preservation capabilities.

As the field progresses, there is a growing emphasis on interdisciplinary approaches, combining expertise from food science, chemistry, materials science, and biotechnology to address the complex challenges associated with sodium alginate extraction and its application in nutrient preservation. This collaborative effort aims to bridge the gap between fundamental research and practical industrial applications, ultimately leading to innovative solutions for enhancing food quality and nutritional value.

The history of alginate extraction dates back to the early 20th century when it was first isolated from kelp. Since then, the technology has evolved considerably, with researchers and industries continuously refining extraction methods to improve yield, purity, and functionality. The growing demand for natural, sustainable, and biocompatible materials has further propelled the interest in sodium alginate research.

In recent years, the focus has shifted towards optimizing extraction processes to enhance the preservation of nutrients. This is particularly crucial in the food industry, where maintaining the nutritional value of products during processing and storage is of paramount importance. Sodium alginate's ability to form gels and act as a stabilizer makes it an ideal candidate for encapsulation and controlled release of nutrients.

The primary objective of current research on sodium alginate extraction for nutrient preservation is to develop efficient and cost-effective methods that maximize the retention of essential nutrients while maintaining the desired functional properties of the alginate. This involves exploring various extraction parameters, such as temperature, pH, and solvent composition, to identify optimal conditions that minimize nutrient degradation during the extraction process.

Another key goal is to investigate the potential of sodium alginate as a protective matrix for sensitive nutrients. This includes studying its interaction with different types of nutrients, such as vitamins, minerals, and bioactive compounds, and assessing its effectiveness in shielding these components from environmental factors that could lead to degradation.

Furthermore, researchers aim to elucidate the mechanisms by which sodium alginate contributes to nutrient preservation. This involves examining its molecular structure, gel-forming properties, and interactions with other food components to understand how it can be tailored for specific nutrient preservation applications.

The development of novel extraction techniques that combine efficiency with sustainability is also a priority. This includes exploring green extraction methods, such as enzyme-assisted extraction or supercritical fluid extraction, which could potentially reduce the environmental impact of alginate production while maintaining or improving its nutrient preservation capabilities.

As the field progresses, there is a growing emphasis on interdisciplinary approaches, combining expertise from food science, chemistry, materials science, and biotechnology to address the complex challenges associated with sodium alginate extraction and its application in nutrient preservation. This collaborative effort aims to bridge the gap between fundamental research and practical industrial applications, ultimately leading to innovative solutions for enhancing food quality and nutritional value.

Market Analysis for Nutrient-Preserved Extracts

The market for nutrient-preserved extracts has shown significant growth in recent years, driven by increasing consumer demand for natural and healthy food products. This trend is particularly evident in the functional food and beverage sector, where consumers are seeking products with enhanced nutritional profiles and health benefits. The use of sodium alginate in extraction processes for nutrient preservation has emerged as a key technology in meeting this market demand.

The global market for functional foods and beverages, which heavily relies on nutrient-preserved extracts, was valued at $177.7 billion in 2019 and is projected to reach $267.9 billion by 2027, growing at a CAGR of 6.7% from 2020 to 2027. This growth is largely attributed to the rising health consciousness among consumers and the increasing prevalence of lifestyle-related diseases.

Within this market, the demand for plant-based extracts preserved using sodium alginate technology is particularly strong. These extracts are widely used in the production of functional beverages, dietary supplements, and fortified foods. The plant-based food market, which extensively utilizes these extracts, is expected to grow at a CAGR of 11.9% from 2020 to 2027, reaching a value of $74.2 billion by the end of the forecast period.

The pharmaceutical and nutraceutical industries are also significant consumers of nutrient-preserved extracts. The global nutraceutical market, which heavily relies on these extracts, was valued at $382.5 billion in 2019 and is projected to reach $722.5 billion by 2027, growing at a CAGR of 8.3% during the forecast period.

Geographically, North America and Europe currently dominate the market for nutrient-preserved extracts, owing to the high consumer awareness and stringent food safety regulations in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by the increasing disposable income, changing dietary habits, and growing health consciousness among consumers in countries like China and India.

The market is characterized by intense competition among key players, including major food and beverage companies, ingredient suppliers, and biotechnology firms. These companies are investing heavily in research and development to improve extraction technologies and develop new applications for nutrient-preserved extracts. The use of sodium alginate in extraction processes has become a key differentiator in this competitive landscape, as it allows for better nutrient retention and improved product quality.

In conclusion, the market for nutrient-preserved extracts, particularly those utilizing sodium alginate technology, shows strong growth potential across various industries. The increasing consumer demand for natural, healthy, and functional food products is expected to drive continued innovation and market expansion in the coming years.

The global market for functional foods and beverages, which heavily relies on nutrient-preserved extracts, was valued at $177.7 billion in 2019 and is projected to reach $267.9 billion by 2027, growing at a CAGR of 6.7% from 2020 to 2027. This growth is largely attributed to the rising health consciousness among consumers and the increasing prevalence of lifestyle-related diseases.

Within this market, the demand for plant-based extracts preserved using sodium alginate technology is particularly strong. These extracts are widely used in the production of functional beverages, dietary supplements, and fortified foods. The plant-based food market, which extensively utilizes these extracts, is expected to grow at a CAGR of 11.9% from 2020 to 2027, reaching a value of $74.2 billion by the end of the forecast period.

The pharmaceutical and nutraceutical industries are also significant consumers of nutrient-preserved extracts. The global nutraceutical market, which heavily relies on these extracts, was valued at $382.5 billion in 2019 and is projected to reach $722.5 billion by 2027, growing at a CAGR of 8.3% during the forecast period.

Geographically, North America and Europe currently dominate the market for nutrient-preserved extracts, owing to the high consumer awareness and stringent food safety regulations in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by the increasing disposable income, changing dietary habits, and growing health consciousness among consumers in countries like China and India.

The market is characterized by intense competition among key players, including major food and beverage companies, ingredient suppliers, and biotechnology firms. These companies are investing heavily in research and development to improve extraction technologies and develop new applications for nutrient-preserved extracts. The use of sodium alginate in extraction processes has become a key differentiator in this competitive landscape, as it allows for better nutrient retention and improved product quality.

In conclusion, the market for nutrient-preserved extracts, particularly those utilizing sodium alginate technology, shows strong growth potential across various industries. The increasing consumer demand for natural, healthy, and functional food products is expected to drive continued innovation and market expansion in the coming years.

Current Challenges in Nutrient Preservation Techniques

The field of nutrient preservation faces several significant challenges that hinder the effective extraction and retention of valuable compounds from natural sources. One of the primary issues is the degradation of nutrients during the extraction process. Traditional methods often expose sensitive compounds to harsh conditions, such as high temperatures or extreme pH levels, leading to the breakdown or alteration of essential nutrients. This degradation not only reduces the nutritional value of the final product but also affects its organoleptic properties and shelf life.

Another critical challenge is the selectivity of extraction techniques. Many current methods struggle to isolate specific nutrients without co-extracting undesirable compounds. This lack of precision can result in impure extracts that require additional purification steps, increasing processing time and costs while potentially further compromising nutrient integrity.

The use of organic solvents in conventional extraction methods poses environmental and health concerns. These solvents can leave residues in the final product, necessitating extensive purification processes. Moreover, the disposal of these solvents contributes to environmental pollution, making the development of greener extraction technologies a pressing need in the industry.

Scalability remains a significant hurdle in nutrient preservation techniques. Many promising methods developed in laboratory settings face difficulties when scaled up to industrial levels. Issues such as increased processing times, reduced efficiency, and higher energy consumption often arise, making it challenging to maintain the quality and cost-effectiveness of nutrient extraction at larger scales.

The preservation of thermolabile nutrients presents a particular challenge. Heat-sensitive compounds, such as certain vitamins and antioxidants, are prone to degradation during thermal processing. This limitation necessitates the development of novel, low-temperature extraction and preservation methods that can maintain the integrity of these delicate nutrients throughout the production process.

Water-soluble nutrients pose another set of challenges. These compounds are often difficult to extract and concentrate without significant loss. Current techniques struggle to efficiently separate these nutrients from aqueous solutions while maintaining their bioavailability and stability.

Lastly, the industry faces challenges in developing universal preservation techniques. Different nutrients require specific extraction and preservation conditions, making it difficult to create a one-size-fits-all approach. This variability necessitates the development of versatile, adaptable technologies that can be fine-tuned for various nutrient profiles and source materials.

Another critical challenge is the selectivity of extraction techniques. Many current methods struggle to isolate specific nutrients without co-extracting undesirable compounds. This lack of precision can result in impure extracts that require additional purification steps, increasing processing time and costs while potentially further compromising nutrient integrity.

The use of organic solvents in conventional extraction methods poses environmental and health concerns. These solvents can leave residues in the final product, necessitating extensive purification processes. Moreover, the disposal of these solvents contributes to environmental pollution, making the development of greener extraction technologies a pressing need in the industry.

Scalability remains a significant hurdle in nutrient preservation techniques. Many promising methods developed in laboratory settings face difficulties when scaled up to industrial levels. Issues such as increased processing times, reduced efficiency, and higher energy consumption often arise, making it challenging to maintain the quality and cost-effectiveness of nutrient extraction at larger scales.

The preservation of thermolabile nutrients presents a particular challenge. Heat-sensitive compounds, such as certain vitamins and antioxidants, are prone to degradation during thermal processing. This limitation necessitates the development of novel, low-temperature extraction and preservation methods that can maintain the integrity of these delicate nutrients throughout the production process.

Water-soluble nutrients pose another set of challenges. These compounds are often difficult to extract and concentrate without significant loss. Current techniques struggle to efficiently separate these nutrients from aqueous solutions while maintaining their bioavailability and stability.

Lastly, the industry faces challenges in developing universal preservation techniques. Different nutrients require specific extraction and preservation conditions, making it difficult to create a one-size-fits-all approach. This variability necessitates the development of versatile, adaptable technologies that can be fine-tuned for various nutrient profiles and source materials.

Existing Sodium Alginate-based Extraction Methods

01 Encapsulation techniques for nutrient preservation

Sodium alginate is used in encapsulation techniques to protect and preserve nutrients. This method involves creating a protective barrier around sensitive compounds, enhancing their stability and bioavailability. The encapsulation process can be optimized for various types of nutrients, improving their shelf life and efficacy in food and pharmaceutical applications.- Encapsulation techniques for nutrient preservation: Sodium alginate is used in encapsulation techniques to protect and preserve nutrients. This method involves creating a protective barrier around sensitive compounds, enhancing their stability and prolonging their shelf life. The encapsulation process can be optimized for various types of nutrients, improving their bioavailability and controlled release properties.

- Sodium alginate as a coating material: Sodium alginate serves as an effective coating material for food products and supplements. When applied as a thin film or layer, it helps preserve nutrients by creating a barrier against moisture, oxygen, and other environmental factors that can degrade sensitive compounds. This coating technique can be particularly useful for extending the shelf life of fruits, vegetables, and other perishable items.

- Hydrogel formation for controlled release: Sodium alginate can form hydrogels that enable controlled release of nutrients. These hydrogels can be designed to respond to specific environmental conditions, such as pH or temperature, allowing for targeted delivery of nutrients. This approach is particularly useful in applications where sustained release of nutrients is desired, such as in agriculture or in the development of functional foods.

- Combination with other preservatives: Sodium alginate can be combined with other natural or synthetic preservatives to enhance its nutrient preservation capabilities. These synergistic combinations can provide improved protection against microbial growth, oxidation, and other degradation processes. The selection of complementary preservatives depends on the specific nutrients being protected and the intended application.

- Nanocomposite systems for nutrient stabilization: Sodium alginate can be incorporated into nanocomposite systems to enhance nutrient stability and preservation. These systems often involve the combination of sodium alginate with nanoparticles or other nanomaterials to create advanced delivery vehicles for nutrients. The nanocomposite structure can provide improved protection against environmental stressors and enable more efficient nutrient absorption.

02 Controlled release systems for nutrients

Sodium alginate-based matrices are employed in controlled release systems for nutrients. These systems allow for the gradual and sustained release of nutrients over time, maintaining their effectiveness and reducing the need for frequent administration. The release rate can be tailored by adjusting the composition and structure of the alginate matrix.Expand Specific Solutions03 Stabilization of probiotics and enzymes

Sodium alginate is utilized to stabilize probiotics and enzymes, preserving their activity during storage and gastrointestinal transit. This application is particularly valuable in the development of functional foods and dietary supplements. The alginate coating protects these sensitive microorganisms and biomolecules from harsh environmental conditions.Expand Specific Solutions04 Edible coatings for fresh produce

Sodium alginate-based edible coatings are applied to fresh fruits and vegetables to extend their shelf life and preserve nutritional quality. These coatings act as a barrier against moisture loss and gas exchange, slowing down the ripening process and maintaining the nutrient content of the produce. Additionally, they can be fortified with additional nutrients or antimicrobial agents.Expand Specific Solutions05 Nutrient-fortified hydrogels

Sodium alginate is used to create nutrient-fortified hydrogels for various applications in food and agriculture. These hydrogels can incorporate and slowly release essential nutrients, providing a sustained source of nourishment. This technology is particularly useful in plant cultivation, soil amendment, and the development of functional food products.Expand Specific Solutions

Key Players in Sodium Alginate Extraction Industry

The research on sodium alginate in extraction processes for nutrient preservation is in a growth phase, with increasing market demand and technological advancements. The global market for alginate-based products is expanding, driven by applications in food, pharmaceuticals, and biotechnology. While the technology is relatively mature, ongoing research focuses on optimizing extraction methods and enhancing nutrient preservation efficiency. Key players like Qingdao Bright Moon Seaweed Group, Alginor ASA, and Beijing Leili Marine Bioindustry are investing in R&D to improve product quality and expand applications. Universities such as Shandong University and Xiamen University are contributing to fundamental research, fostering industry-academia collaborations to drive innovation in this field.

Alginor ASA

Technical Solution: Alginor ASA has pioneered a biorefinery approach to sodium alginate extraction that maximizes nutrient preservation. Their process, known as AORTA (Alginor's Ocean Refining Total Utilization Application), utilizes a cascading extraction method that sequentially isolates various compounds from seaweed biomass[7]. This approach allows for the extraction of sodium alginate while simultaneously preserving other valuable nutrients and bioactive compounds. The process involves a series of gentle extraction steps using green solvents and enzymatic treatments, each optimized for specific compound classes. Alginor has also developed a novel fractionation technology that separates different alginate types based on their molecular structure, enabling the production of high-purity, nutrient-rich alginate fractions[9]. Furthermore, they have implemented a closed-loop system that recycles solvents and minimizes waste, contributing to both nutrient preservation and environmental sustainability[11].

Strengths: Comprehensive utilization of seaweed biomass, high-purity alginate fractions, and environmentally friendly process. Weaknesses: Complex multi-step process may lead to higher operational costs and require specialized expertise.

Qingdao Bright Moon Seaweed Group Co., Ltd.

Technical Solution: Qingdao Bright Moon Seaweed Group Co., Ltd. has developed an innovative extraction process for sodium alginate that focuses on nutrient preservation. Their method utilizes a low-temperature, enzymatic extraction technique that maintains the integrity of bioactive compounds. This process involves controlled pH conditions and the use of specific enzymes to break down cell walls, allowing for efficient extraction of sodium alginate while preserving valuable nutrients[1]. The company has also implemented a purification step using membrane technology, which helps in removing impurities without compromising the nutritional value of the final product[3]. Additionally, they have incorporated a spray-drying technique that minimizes thermal degradation of heat-sensitive nutrients during the drying phase[5].

Strengths: High nutrient retention, improved product quality, and increased yield. Weaknesses: Potentially higher production costs due to specialized enzymes and equipment, and longer processing time compared to traditional methods.

Innovative Approaches in Nutrient Preservation

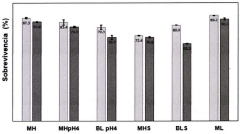

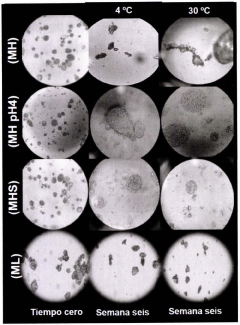

Method for microencapsulation of probiotic bacteria using sodium alginate and extrusion.

PatentActiveMX2020014178A

Innovation

- A combination of extrusion and ionic gelation using calcium alginate to form microcapsules with sizes between 15 to 116 microns, achieving encapsulation efficiencies greater than 85% and maintaining probiotic viability for at least 6 weeks, suitable for use in food, pharmaceutical, and cosmetic products.

Simultaneous extraction process of sodium alginate, fucoidan, and biostimulant derived from sargassum.

PatentPendingMX2023007721A

Innovation

- A circular economy-based process is implemented to extract sodium alginate, fucoidan, and a biostimulant from sargassum, utilizing a three-stage conversion process that includes grinding, alkaline extraction, spray drying, and fermentation to maximize material use and minimize environmental impact.

Environmental Impact of Sodium Alginate Extraction

The extraction of sodium alginate from seaweed has significant environmental implications that warrant careful consideration. The process typically involves harvesting large quantities of brown algae, which can impact marine ecosystems if not managed sustainably. Overharvesting can lead to habitat destruction and disrupt the balance of coastal ecosystems, affecting marine biodiversity and the livelihoods of coastal communities.

The extraction process itself also raises environmental concerns. Traditional methods often involve the use of strong acids and bases, which can generate hazardous waste and contribute to water pollution if not properly treated. The disposal of these chemical byproducts requires stringent environmental controls to prevent contamination of soil and water resources.

Energy consumption is another critical factor in the environmental footprint of sodium alginate extraction. The process typically involves multiple stages of heating, filtering, and drying, all of which require substantial energy inputs. This energy demand contributes to greenhouse gas emissions, particularly if fossil fuels are the primary energy source.

Water usage is also a significant consideration. Large volumes of water are required for washing and processing the seaweed, as well as for the extraction and purification stages. In regions where water scarcity is a concern, this high water demand can strain local resources and compete with other essential uses.

On the positive side, sodium alginate extraction can potentially contribute to the development of sustainable bio-based industries. As a renewable resource, seaweed cultivation for alginate production could offer an alternative to petroleum-based products in various applications. This shift towards bio-based materials aligns with global efforts to reduce dependence on fossil fuels and mitigate climate change.

Furthermore, responsible seaweed farming practices can have beneficial environmental effects. Seaweed cultivation can help sequester carbon dioxide, reduce ocean acidification, and provide habitats for marine life. When integrated into multi-trophic aquaculture systems, seaweed farming can also help mitigate the environmental impacts of fish farming by absorbing excess nutrients.

To minimize the negative environmental impacts of sodium alginate extraction, research is ongoing to develop more sustainable practices. This includes exploring alternative extraction methods that use less harmful chemicals, improving energy efficiency in processing, and implementing water recycling systems. Additionally, efforts are being made to establish sustainable harvesting quotas and cultivation practices to ensure the long-term viability of seaweed resources.

The extraction process itself also raises environmental concerns. Traditional methods often involve the use of strong acids and bases, which can generate hazardous waste and contribute to water pollution if not properly treated. The disposal of these chemical byproducts requires stringent environmental controls to prevent contamination of soil and water resources.

Energy consumption is another critical factor in the environmental footprint of sodium alginate extraction. The process typically involves multiple stages of heating, filtering, and drying, all of which require substantial energy inputs. This energy demand contributes to greenhouse gas emissions, particularly if fossil fuels are the primary energy source.

Water usage is also a significant consideration. Large volumes of water are required for washing and processing the seaweed, as well as for the extraction and purification stages. In regions where water scarcity is a concern, this high water demand can strain local resources and compete with other essential uses.

On the positive side, sodium alginate extraction can potentially contribute to the development of sustainable bio-based industries. As a renewable resource, seaweed cultivation for alginate production could offer an alternative to petroleum-based products in various applications. This shift towards bio-based materials aligns with global efforts to reduce dependence on fossil fuels and mitigate climate change.

Furthermore, responsible seaweed farming practices can have beneficial environmental effects. Seaweed cultivation can help sequester carbon dioxide, reduce ocean acidification, and provide habitats for marine life. When integrated into multi-trophic aquaculture systems, seaweed farming can also help mitigate the environmental impacts of fish farming by absorbing excess nutrients.

To minimize the negative environmental impacts of sodium alginate extraction, research is ongoing to develop more sustainable practices. This includes exploring alternative extraction methods that use less harmful chemicals, improving energy efficiency in processing, and implementing water recycling systems. Additionally, efforts are being made to establish sustainable harvesting quotas and cultivation practices to ensure the long-term viability of seaweed resources.

Regulatory Framework for Food-grade Extracts

The regulatory framework for food-grade extracts plays a crucial role in ensuring the safety and quality of products containing sodium alginate used in extraction processes for nutrient preservation. This framework encompasses a complex set of regulations, guidelines, and standards established by various national and international regulatory bodies.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory agency overseeing food-grade extracts. The FDA has classified sodium alginate as Generally Recognized as Safe (GRAS) for use in food products. However, manufacturers must adhere to Good Manufacturing Practices (GMPs) and ensure that the use of sodium alginate in extraction processes does not compromise the safety or nutritional value of the final product.

The European Food Safety Authority (EFSA) regulates the use of sodium alginate in food products within the European Union. EFSA has established specific purity criteria and maximum levels for the use of sodium alginate as a food additive. Manufacturers must comply with these regulations when using sodium alginate in extraction processes for nutrient preservation in products intended for the European market.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards and guidelines. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in various food categories, which serves as a reference for many countries developing their national regulations.

Regulatory bodies often require manufacturers to demonstrate the safety and efficacy of their extraction processes using sodium alginate. This may involve submitting scientific data, toxicological studies, and analytical methods to support the use of sodium alginate in specific applications. Additionally, labeling requirements for products containing sodium alginate may vary depending on the jurisdiction and intended use of the product.

As research on sodium alginate in extraction processes for nutrient preservation continues to advance, regulatory frameworks may evolve to address new findings and applications. Manufacturers and researchers must stay informed about updates to regulations and guidelines to ensure compliance and maintain product safety.

It is important to note that while sodium alginate is generally considered safe for food use, regulatory bodies may impose specific restrictions or requirements based on the intended application, target consumer group, or potential interactions with other ingredients. Manufacturers must conduct thorough risk assessments and ensure that their use of sodium alginate in extraction processes aligns with all applicable regulatory standards.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory agency overseeing food-grade extracts. The FDA has classified sodium alginate as Generally Recognized as Safe (GRAS) for use in food products. However, manufacturers must adhere to Good Manufacturing Practices (GMPs) and ensure that the use of sodium alginate in extraction processes does not compromise the safety or nutritional value of the final product.

The European Food Safety Authority (EFSA) regulates the use of sodium alginate in food products within the European Union. EFSA has established specific purity criteria and maximum levels for the use of sodium alginate as a food additive. Manufacturers must comply with these regulations when using sodium alginate in extraction processes for nutrient preservation in products intended for the European market.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards and guidelines. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in various food categories, which serves as a reference for many countries developing their national regulations.

Regulatory bodies often require manufacturers to demonstrate the safety and efficacy of their extraction processes using sodium alginate. This may involve submitting scientific data, toxicological studies, and analytical methods to support the use of sodium alginate in specific applications. Additionally, labeling requirements for products containing sodium alginate may vary depending on the jurisdiction and intended use of the product.

As research on sodium alginate in extraction processes for nutrient preservation continues to advance, regulatory frameworks may evolve to address new findings and applications. Manufacturers and researchers must stay informed about updates to regulations and guidelines to ensure compliance and maintain product safety.

It is important to note that while sodium alginate is generally considered safe for food use, regulatory bodies may impose specific restrictions or requirements based on the intended application, target consumer group, or potential interactions with other ingredients. Manufacturers must conduct thorough risk assessments and ensure that their use of sodium alginate in extraction processes aligns with all applicable regulatory standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!