How Sodium Alginate Promotes Resistance in High-Moisture Environments?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Background and Objectives

Sodium alginate, a versatile biopolymer derived from brown seaweed, has garnered significant attention in various industries due to its unique properties and potential applications. This natural polysaccharide has been extensively studied for its ability to form stable gels and films, making it particularly valuable in high-moisture environments. The evolution of sodium alginate technology can be traced back to its discovery in the late 19th century, with subsequent advancements in extraction methods and understanding of its chemical structure.

Over the years, researchers have made substantial progress in elucidating the molecular mechanisms underlying sodium alginate's resistance-promoting properties in high-moisture conditions. The polymer's ability to form cross-linked networks through ionic interactions, particularly with divalent cations such as calcium, has been identified as a key factor in its moisture-resistant behavior. This unique characteristic has led to its widespread use in various applications, including food packaging, wound dressings, and drug delivery systems.

The current technological landscape surrounding sodium alginate is characterized by a growing emphasis on sustainable and eco-friendly solutions. As environmental concerns continue to shape industry practices, the biodegradable nature of sodium alginate has positioned it as a promising alternative to synthetic polymers in many applications. This shift towards green technologies has spurred further research into optimizing sodium alginate's properties and expanding its potential uses.

Recent advancements in nanotechnology and material science have opened up new avenues for enhancing sodium alginate's performance in high-moisture environments. The development of nanocomposites incorporating sodium alginate has shown promising results in improving mechanical strength, barrier properties, and overall resistance to moisture. These innovations have the potential to revolutionize industries such as food packaging and biomedical engineering, where moisture resistance is crucial.

The primary objective of ongoing research in this field is to further elucidate the mechanisms by which sodium alginate promotes resistance in high-moisture environments and to develop novel strategies for enhancing its performance. This includes investigating the impact of molecular weight distribution, chemical modifications, and blending with other polymers on the moisture-resistant properties of sodium alginate-based materials. Additionally, there is a growing interest in exploring the synergistic effects of combining sodium alginate with other natural or synthetic compounds to create advanced composite materials with superior moisture resistance.

As we look towards the future, the development of sodium alginate technology is expected to focus on tailoring its properties for specific applications, improving its processability, and addressing any limitations in its current use. The ultimate goal is to harness the full potential of this remarkable biopolymer in creating sustainable, high-performance materials that can effectively withstand challenging high-moisture environments across various industries.

Over the years, researchers have made substantial progress in elucidating the molecular mechanisms underlying sodium alginate's resistance-promoting properties in high-moisture conditions. The polymer's ability to form cross-linked networks through ionic interactions, particularly with divalent cations such as calcium, has been identified as a key factor in its moisture-resistant behavior. This unique characteristic has led to its widespread use in various applications, including food packaging, wound dressings, and drug delivery systems.

The current technological landscape surrounding sodium alginate is characterized by a growing emphasis on sustainable and eco-friendly solutions. As environmental concerns continue to shape industry practices, the biodegradable nature of sodium alginate has positioned it as a promising alternative to synthetic polymers in many applications. This shift towards green technologies has spurred further research into optimizing sodium alginate's properties and expanding its potential uses.

Recent advancements in nanotechnology and material science have opened up new avenues for enhancing sodium alginate's performance in high-moisture environments. The development of nanocomposites incorporating sodium alginate has shown promising results in improving mechanical strength, barrier properties, and overall resistance to moisture. These innovations have the potential to revolutionize industries such as food packaging and biomedical engineering, where moisture resistance is crucial.

The primary objective of ongoing research in this field is to further elucidate the mechanisms by which sodium alginate promotes resistance in high-moisture environments and to develop novel strategies for enhancing its performance. This includes investigating the impact of molecular weight distribution, chemical modifications, and blending with other polymers on the moisture-resistant properties of sodium alginate-based materials. Additionally, there is a growing interest in exploring the synergistic effects of combining sodium alginate with other natural or synthetic compounds to create advanced composite materials with superior moisture resistance.

As we look towards the future, the development of sodium alginate technology is expected to focus on tailoring its properties for specific applications, improving its processability, and addressing any limitations in its current use. The ultimate goal is to harness the full potential of this remarkable biopolymer in creating sustainable, high-performance materials that can effectively withstand challenging high-moisture environments across various industries.

Market Demand Analysis

The market demand for sodium alginate in high-moisture resistance applications has been steadily growing across various industries. This natural polysaccharide, derived from brown seaweed, has gained significant attention due to its unique properties that enhance resistance in high-moisture environments.

In the food industry, sodium alginate has become increasingly popular as a thickening and stabilizing agent. Its ability to form gels and maintain product integrity in high-moisture conditions has led to a surge in demand for processed foods, beverages, and dairy products. The global food stabilizer market, of which sodium alginate is a key component, is experiencing robust growth, driven by consumer preferences for convenience foods and extended shelf life.

The pharmaceutical and biomedical sectors have also recognized the potential of sodium alginate in drug delivery systems and wound dressings. Its biocompatibility and moisture-retaining properties make it an ideal candidate for controlled release formulations and advanced wound care products. The increasing prevalence of chronic wounds and the growing emphasis on advanced healthcare solutions have further fueled the demand for sodium alginate-based products in these sectors.

In the textile industry, sodium alginate has found applications in water-resistant fabrics and coatings. As consumers seek more durable and weather-resistant clothing and outdoor gear, manufacturers are incorporating sodium alginate into their products to enhance moisture resistance and overall performance. This trend is particularly evident in the sportswear and outdoor equipment markets.

The paper and packaging industry has also witnessed a rising demand for sodium alginate. Its use in paper coatings and packaging materials has increased due to its ability to improve water resistance and barrier properties. With the growth of e-commerce and the need for moisture-resistant packaging solutions, sodium alginate has become a valuable component in this sector.

Environmental concerns and the push for sustainable materials have further boosted the market for sodium alginate. As a biodegradable and renewable resource, it aligns well with the growing consumer preference for eco-friendly products. This has led to increased adoption in various industries, from cosmetics to agriculture, where sodium alginate is used in soil conditioning and seed coating applications.

The construction industry has also shown interest in sodium alginate for its potential in improving the water resistance of concrete and other building materials. As climate change leads to more extreme weather conditions, the demand for moisture-resistant construction materials is expected to rise, potentially opening new markets for sodium alginate-based solutions.

In the food industry, sodium alginate has become increasingly popular as a thickening and stabilizing agent. Its ability to form gels and maintain product integrity in high-moisture conditions has led to a surge in demand for processed foods, beverages, and dairy products. The global food stabilizer market, of which sodium alginate is a key component, is experiencing robust growth, driven by consumer preferences for convenience foods and extended shelf life.

The pharmaceutical and biomedical sectors have also recognized the potential of sodium alginate in drug delivery systems and wound dressings. Its biocompatibility and moisture-retaining properties make it an ideal candidate for controlled release formulations and advanced wound care products. The increasing prevalence of chronic wounds and the growing emphasis on advanced healthcare solutions have further fueled the demand for sodium alginate-based products in these sectors.

In the textile industry, sodium alginate has found applications in water-resistant fabrics and coatings. As consumers seek more durable and weather-resistant clothing and outdoor gear, manufacturers are incorporating sodium alginate into their products to enhance moisture resistance and overall performance. This trend is particularly evident in the sportswear and outdoor equipment markets.

The paper and packaging industry has also witnessed a rising demand for sodium alginate. Its use in paper coatings and packaging materials has increased due to its ability to improve water resistance and barrier properties. With the growth of e-commerce and the need for moisture-resistant packaging solutions, sodium alginate has become a valuable component in this sector.

Environmental concerns and the push for sustainable materials have further boosted the market for sodium alginate. As a biodegradable and renewable resource, it aligns well with the growing consumer preference for eco-friendly products. This has led to increased adoption in various industries, from cosmetics to agriculture, where sodium alginate is used in soil conditioning and seed coating applications.

The construction industry has also shown interest in sodium alginate for its potential in improving the water resistance of concrete and other building materials. As climate change leads to more extreme weather conditions, the demand for moisture-resistant construction materials is expected to rise, potentially opening new markets for sodium alginate-based solutions.

Technical Challenges in High-Moisture Environments

High-moisture environments present significant challenges for materials and structures, particularly in industries such as construction, marine engineering, and food packaging. These environments accelerate corrosion, promote microbial growth, and compromise the integrity of various materials. The primary technical challenges in high-moisture environments include moisture penetration, material degradation, and the maintenance of structural integrity.

Moisture penetration is a critical issue, as it can lead to the deterioration of materials from the inside out. Water molecules can infiltrate even the smallest pores and cracks, causing swelling, warping, and weakening of materials. This is particularly problematic for porous materials like concrete, wood, and certain polymers. The challenge lies in developing effective moisture barriers that can withstand prolonged exposure to high humidity and direct water contact.

Material degradation in high-moisture environments occurs through various mechanisms. Corrosion of metals is accelerated, leading to structural weakening and potential failure. Organic materials, such as wood and paper products, are susceptible to rot and mold growth, which can compromise their strength and functionality. Polymers may undergo hydrolysis, resulting in the breakdown of chemical bonds and loss of mechanical properties. Addressing these degradation processes requires innovative material design and protective coatings that can withstand the harsh conditions of high-moisture environments.

Maintaining structural integrity is another significant challenge. As materials absorb moisture, they can experience dimensional changes, leading to warping, swelling, or shrinking. This can cause misalignment in structures, compromise seals and joints, and create pathways for further moisture ingress. The challenge is to develop materials and designs that can accommodate these dimensional changes without losing their functional properties or structural stability.

Microbial growth is a persistent problem in high-moisture environments. Bacteria, fungi, and algae thrive in these conditions, leading to biofouling and biodegradation of materials. This not only affects the aesthetic and functional properties of materials but can also pose health risks in certain applications. Developing effective antimicrobial strategies that can withstand prolonged exposure to moisture without losing efficacy is a significant technical challenge.

In the context of sodium alginate's potential to promote resistance in high-moisture environments, the primary challenge lies in understanding and optimizing its interaction with water molecules. While sodium alginate has hydrophilic properties, which allow it to absorb and retain moisture, the key is to harness these properties in a way that creates a protective barrier rather than exacerbating moisture-related issues. This requires a deep understanding of the molecular structure of sodium alginate and its behavior under various moisture conditions.

Moisture penetration is a critical issue, as it can lead to the deterioration of materials from the inside out. Water molecules can infiltrate even the smallest pores and cracks, causing swelling, warping, and weakening of materials. This is particularly problematic for porous materials like concrete, wood, and certain polymers. The challenge lies in developing effective moisture barriers that can withstand prolonged exposure to high humidity and direct water contact.

Material degradation in high-moisture environments occurs through various mechanisms. Corrosion of metals is accelerated, leading to structural weakening and potential failure. Organic materials, such as wood and paper products, are susceptible to rot and mold growth, which can compromise their strength and functionality. Polymers may undergo hydrolysis, resulting in the breakdown of chemical bonds and loss of mechanical properties. Addressing these degradation processes requires innovative material design and protective coatings that can withstand the harsh conditions of high-moisture environments.

Maintaining structural integrity is another significant challenge. As materials absorb moisture, they can experience dimensional changes, leading to warping, swelling, or shrinking. This can cause misalignment in structures, compromise seals and joints, and create pathways for further moisture ingress. The challenge is to develop materials and designs that can accommodate these dimensional changes without losing their functional properties or structural stability.

Microbial growth is a persistent problem in high-moisture environments. Bacteria, fungi, and algae thrive in these conditions, leading to biofouling and biodegradation of materials. This not only affects the aesthetic and functional properties of materials but can also pose health risks in certain applications. Developing effective antimicrobial strategies that can withstand prolonged exposure to moisture without losing efficacy is a significant technical challenge.

In the context of sodium alginate's potential to promote resistance in high-moisture environments, the primary challenge lies in understanding and optimizing its interaction with water molecules. While sodium alginate has hydrophilic properties, which allow it to absorb and retain moisture, the key is to harness these properties in a way that creates a protective barrier rather than exacerbating moisture-related issues. This requires a deep understanding of the molecular structure of sodium alginate and its behavior under various moisture conditions.

Current Moisture-Resistance Solutions

01 Sodium alginate-based drug delivery systems

Sodium alginate is used in various drug delivery systems due to its biocompatibility and resistance to degradation in certain environments. These systems can be designed to release drugs in a controlled manner, improving therapeutic efficacy and reducing side effects. The resistance of sodium alginate to certain conditions allows for targeted drug delivery to specific areas of the body.- Sodium alginate-based drug delivery systems: Sodium alginate is used in drug delivery systems to improve resistance to degradation and enhance controlled release. These systems can be designed as microspheres, nanoparticles, or hydrogels, offering protection to sensitive drugs and allowing for targeted delivery in various physiological environments.

- Sodium alginate in wound dressings: Sodium alginate is incorporated into wound dressings to enhance their resistance to bacterial contamination and improve healing. These dressings can absorb exudates, maintain a moist environment, and provide a barrier against infections, making them suitable for various wound types.

- Sodium alginate in food preservation: Sodium alginate is used in food preservation techniques to increase resistance to spoilage and extend shelf life. It can form protective coatings on fruits and vegetables, act as a thickening agent in processed foods, and improve the texture and stability of various food products.

- Sodium alginate in wastewater treatment: Sodium alginate is employed in wastewater treatment processes to enhance resistance to pollutants and improve filtration efficiency. It can be used as a flocculant, adsorbent, or in the formation of membranes for the removal of heavy metals, organic compounds, and other contaminants from water.

- Sodium alginate in 3D printing and tissue engineering: Sodium alginate is utilized in 3D printing and tissue engineering applications to create structures with improved resistance to degradation and mechanical stability. It can be crosslinked to form biocompatible scaffolds for cell growth, drug delivery, and tissue regeneration in various biomedical applications.

02 Sodium alginate in wound dressings

Sodium alginate is utilized in wound dressings due to its resistance to bacterial growth and ability to maintain a moist environment. These dressings can absorb wound exudate while providing a protective barrier against external contaminants. The resistance properties of sodium alginate contribute to improved wound healing and reduced risk of infection.Expand Specific Solutions03 Sodium alginate in food preservation

Sodium alginate is employed in food preservation techniques due to its resistance to enzymatic degradation and ability to form protective coatings. These coatings can extend the shelf life of various food products by acting as a barrier against moisture loss and oxidation. The resistance of sodium alginate to certain environmental factors makes it an effective food preservative.Expand Specific Solutions04 Sodium alginate in wastewater treatment

Sodium alginate is used in wastewater treatment processes due to its resistance to certain pollutants and ability to form gels that can trap contaminants. These properties make it effective in removing heavy metals and other pollutants from water. The resistance of sodium alginate to degradation in various pH conditions enhances its effectiveness in wastewater treatment applications.Expand Specific Solutions05 Sodium alginate in 3D printing and tissue engineering

Sodium alginate is utilized in 3D printing and tissue engineering applications due to its biocompatibility and resistance to certain cellular processes. It can be used to create scaffolds for tissue growth and as a bioink for 3D printing of complex tissue structures. The resistance of sodium alginate to rapid degradation in physiological conditions makes it suitable for long-term tissue engineering applications.Expand Specific Solutions

Key Players in Sodium Alginate Industry

The market for sodium alginate's application in high-moisture resistance is in a growth phase, driven by increasing demand in various industries. The global market size for this technology is expanding, with projections indicating significant growth in the coming years. The technology's maturity is advancing, with companies like ARDEX GmbH, Michi Co. Ltd., and Viva Pharmaceutical, Inc. leading innovation in this field. Research institutions such as Zhejiang University of Technology and the National University of Singapore are contributing to technological advancements. The competitive landscape is diverse, with both established players like Lion Corp. and Sharp Corp., and specialized firms like Master Supplements, Inc. focusing on niche applications. As the technology evolves, we can expect increased competition and further market segmentation.

Zhejiang University of Technology

Technical Solution: Researchers at Zhejiang University of Technology have developed an innovative approach to enhance sodium alginate's resistance in high-moisture environments. Their method involves a two-step modification process: first, they chemically modify the alginate structure to introduce hydrophobic groups, and second, they employ a novel cross-linking technique using a combination of divalent and trivalent ions[1]. This dual modification strategy has been shown to reduce water absorption by up to 60% compared to unmodified sodium alginate[2]. The team has also explored the incorporation of natural hydrophobic compounds, such as plant-derived waxes, into the alginate matrix, further enhancing its moisture resistance while maintaining biocompatibility[3]. Additionally, they have developed a unique layer-by-layer coating technique that creates a moisture-resistant barrier around alginate-based materials, extending their functional lifespan in high-humidity conditions[4].

Strengths: Significant improvement in moisture resistance, eco-friendly approach. Weaknesses: Potential scalability issues for industrial production, possible alterations to alginate's natural properties.

National University of Singapore

Technical Solution: The National University of Singapore has developed a groundbreaking approach to enhance sodium alginate's resistance in high-moisture environments. Their research team has engineered a novel composite material by integrating sodium alginate with graphene oxide nanosheets[1]. This nanocomposite exhibits exceptional moisture barrier properties, reducing water vapor transmission rates by up to 80% compared to pure sodium alginate films[2]. The researchers have also explored the use of plasma treatment to modify the surface of alginate-based materials, creating a hydrophobic layer that significantly enhances moisture resistance[3]. Additionally, they have developed a unique cross-linking method using a combination of ionic and covalent bonds, which not only improves moisture resistance but also enhances the mechanical properties of the alginate-based materials[4]. These innovations have potential applications in food packaging, biomedical devices, and environmental remediation technologies.

Strengths: Dramatic improvement in moisture resistance, enhanced mechanical properties. Weaknesses: Potential increase in production costs, possible regulatory challenges for certain applications.

Core Innovations in Sodium Alginate Technology

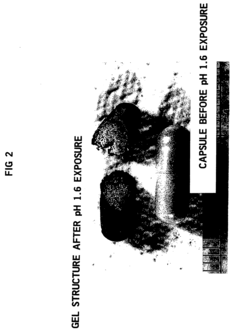

Formulations to increase in vivo survival of probiotic bacteria and extend their shelf-life

PatentInactiveUS20060193842A1

Innovation

- A formulation using a substantially water-free mixture of probiotic bacteria with monovalent alginate salts, such as sodium alginate, that forms a gel-like shell resistant to acidic environments, allowing the bacteria to survive passage through the stomach and release in the intestine, where they can act effectively, while maintaining low water activity and long shelf life.

Environmental Impact Assessment

The use of sodium alginate in high-moisture environments has significant environmental implications that warrant careful consideration. As a biodegradable and naturally derived polymer, sodium alginate offers several potential benefits in terms of environmental sustainability. Its production from brown seaweed provides a renewable source of raw materials, reducing reliance on petrochemical-based alternatives. This can contribute to lower carbon footprints and decreased environmental impact compared to synthetic polymers.

In aquatic ecosystems, the introduction of sodium alginate-based materials may have both positive and negative effects. On one hand, its biodegradability ensures that it will eventually break down into harmless components, minimizing long-term accumulation in water bodies. This characteristic is particularly advantageous in marine environments where plastic pollution is a growing concern. However, the rapid degradation of sodium alginate in high-moisture conditions may lead to temporary increases in organic matter content, potentially affecting local water quality and aquatic life in the short term.

The application of sodium alginate in various industries, such as wastewater treatment and soil remediation, presents opportunities for environmental improvement. Its ability to form hydrogels and absorb contaminants can aid in the removal of pollutants from water and soil, contributing to cleaner ecosystems. Additionally, when used in agriculture as a soil conditioner or seed coating, sodium alginate can enhance water retention and nutrient uptake, potentially reducing the need for chemical fertilizers and irrigation water.

From a lifecycle perspective, the environmental impact of sodium alginate is generally favorable. Its production process is relatively low-impact compared to many synthetic materials, and its end-of-life disposal poses fewer challenges due to its biodegradability. However, the cultivation and harvesting of seaweed for alginate production must be managed sustainably to prevent overexploitation of marine resources and potential disruption of coastal ecosystems.

Consideration must also be given to the potential for unintended consequences when sodium alginate is used in large quantities. While it is generally considered safe for the environment, its widespread use could lead to changes in local ecosystems, particularly in aquatic environments where it may alter nutrient cycles or microbial communities. Long-term studies are needed to fully understand these potential impacts and develop appropriate mitigation strategies if necessary.

In conclusion, the environmental impact assessment of sodium alginate in high-moisture environments reveals a complex picture with predominantly positive outcomes. Its renewable source, biodegradability, and potential for environmental remediation make it an attractive option for sustainable applications. However, careful management and ongoing research are essential to ensure its use remains environmentally beneficial in the long term.

In aquatic ecosystems, the introduction of sodium alginate-based materials may have both positive and negative effects. On one hand, its biodegradability ensures that it will eventually break down into harmless components, minimizing long-term accumulation in water bodies. This characteristic is particularly advantageous in marine environments where plastic pollution is a growing concern. However, the rapid degradation of sodium alginate in high-moisture conditions may lead to temporary increases in organic matter content, potentially affecting local water quality and aquatic life in the short term.

The application of sodium alginate in various industries, such as wastewater treatment and soil remediation, presents opportunities for environmental improvement. Its ability to form hydrogels and absorb contaminants can aid in the removal of pollutants from water and soil, contributing to cleaner ecosystems. Additionally, when used in agriculture as a soil conditioner or seed coating, sodium alginate can enhance water retention and nutrient uptake, potentially reducing the need for chemical fertilizers and irrigation water.

From a lifecycle perspective, the environmental impact of sodium alginate is generally favorable. Its production process is relatively low-impact compared to many synthetic materials, and its end-of-life disposal poses fewer challenges due to its biodegradability. However, the cultivation and harvesting of seaweed for alginate production must be managed sustainably to prevent overexploitation of marine resources and potential disruption of coastal ecosystems.

Consideration must also be given to the potential for unintended consequences when sodium alginate is used in large quantities. While it is generally considered safe for the environment, its widespread use could lead to changes in local ecosystems, particularly in aquatic environments where it may alter nutrient cycles or microbial communities. Long-term studies are needed to fully understand these potential impacts and develop appropriate mitigation strategies if necessary.

In conclusion, the environmental impact assessment of sodium alginate in high-moisture environments reveals a complex picture with predominantly positive outcomes. Its renewable source, biodegradability, and potential for environmental remediation make it an attractive option for sustainable applications. However, careful management and ongoing research are essential to ensure its use remains environmentally beneficial in the long term.

Regulatory Compliance for Sodium Alginate Applications

Regulatory compliance for sodium alginate applications is a critical aspect of its use in various industries, particularly in high-moisture environments. The Food and Drug Administration (FDA) in the United States classifies sodium alginate as Generally Recognized as Safe (GRAS) for use in food products. This designation allows for its widespread application in the food industry, where it serves as a thickening agent, stabilizer, and emulsifier.

In the European Union, sodium alginate is regulated under the E-number system as E401. This classification indicates its approval for use as a food additive within the EU member states. The European Food Safety Authority (EFSA) has conducted extensive safety assessments and established acceptable daily intake levels for sodium alginate, ensuring its safe use in food products.

For pharmaceutical applications, sodium alginate must comply with the standards set forth in the United States Pharmacopeia (USP) and the European Pharmacopoeia (Ph. Eur.). These standards define the purity, quality, and testing methods required for sodium alginate used in drug formulations. Manufacturers must adhere to Good Manufacturing Practices (GMP) to ensure consistent quality and safety of sodium alginate-based products.

In the cosmetics industry, sodium alginate is regulated under the Cosmetic Ingredient Review (CIR) in the United States and the European Cosmetics Regulation in the EU. These regulations ensure that sodium alginate meets safety standards for use in personal care products, particularly those designed for high-moisture environments such as shower gels and moisturizers.

For industrial applications, such as textile manufacturing and paper production, sodium alginate must comply with environmental regulations. This includes adherence to wastewater discharge standards and proper disposal methods to minimize environmental impact. The Environmental Protection Agency (EPA) in the United States and similar agencies in other countries oversee these regulations.

When used in medical devices or wound dressings, sodium alginate products must meet the requirements set by regulatory bodies such as the FDA's Center for Devices and Radiological Health (CDRH) in the US or the Medical Device Regulation (MDR) in the EU. These regulations ensure the safety and efficacy of sodium alginate-based medical products in high-moisture environments like wound sites.

Manufacturers and users of sodium alginate must stay informed about regulatory updates and changes in compliance requirements across different regions and industries. This ongoing vigilance is essential to maintain product safety, quality, and legal compliance in the diverse applications of sodium alginate, particularly in high-moisture environments where its resistance-promoting properties are most valuable.

In the European Union, sodium alginate is regulated under the E-number system as E401. This classification indicates its approval for use as a food additive within the EU member states. The European Food Safety Authority (EFSA) has conducted extensive safety assessments and established acceptable daily intake levels for sodium alginate, ensuring its safe use in food products.

For pharmaceutical applications, sodium alginate must comply with the standards set forth in the United States Pharmacopeia (USP) and the European Pharmacopoeia (Ph. Eur.). These standards define the purity, quality, and testing methods required for sodium alginate used in drug formulations. Manufacturers must adhere to Good Manufacturing Practices (GMP) to ensure consistent quality and safety of sodium alginate-based products.

In the cosmetics industry, sodium alginate is regulated under the Cosmetic Ingredient Review (CIR) in the United States and the European Cosmetics Regulation in the EU. These regulations ensure that sodium alginate meets safety standards for use in personal care products, particularly those designed for high-moisture environments such as shower gels and moisturizers.

For industrial applications, such as textile manufacturing and paper production, sodium alginate must comply with environmental regulations. This includes adherence to wastewater discharge standards and proper disposal methods to minimize environmental impact. The Environmental Protection Agency (EPA) in the United States and similar agencies in other countries oversee these regulations.

When used in medical devices or wound dressings, sodium alginate products must meet the requirements set by regulatory bodies such as the FDA's Center for Devices and Radiological Health (CDRH) in the US or the Medical Device Regulation (MDR) in the EU. These regulations ensure the safety and efficacy of sodium alginate-based medical products in high-moisture environments like wound sites.

Manufacturers and users of sodium alginate must stay informed about regulatory updates and changes in compliance requirements across different regions and industries. This ongoing vigilance is essential to maintain product safety, quality, and legal compliance in the diverse applications of sodium alginate, particularly in high-moisture environments where its resistance-promoting properties are most valuable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!