How Sodium Alginate Influences Polymer Network Evolution?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Background

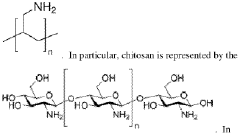

Sodium alginate, a naturally occurring polysaccharide derived from brown seaweed, has gained significant attention in the field of polymer science and materials engineering. This versatile biopolymer is composed of linear chains of (1-4)-linked β-D-mannuronate and α-L-guluronate residues, arranged in varying sequences and proportions. The unique chemical structure of sodium alginate contributes to its remarkable properties, including biocompatibility, biodegradability, and the ability to form hydrogels under specific conditions.

The history of sodium alginate can be traced back to the 19th century when it was first discovered and isolated from brown algae. However, its potential in polymer network evolution and materials science has only been fully recognized in recent decades. The growing interest in sustainable and eco-friendly materials has further propelled research into sodium alginate's applications across various industries, including biomedical, pharmaceutical, and food sectors.

One of the most notable characteristics of sodium alginate is its ability to form hydrogels through ionic crosslinking, particularly in the presence of divalent cations such as calcium. This gelation process, known as the "egg-box" model, occurs when calcium ions interact with the guluronate blocks of the alginate chains, creating a three-dimensional network structure. This unique property has made sodium alginate an attractive candidate for developing advanced materials with tunable mechanical and physical properties.

In the context of polymer network evolution, sodium alginate plays a crucial role in influencing the formation, structure, and properties of composite materials. Its incorporation into synthetic polymer systems can lead to the development of hybrid networks with enhanced functionality and performance. The interactions between sodium alginate and other polymer components can result in synergistic effects, altering the mechanical strength, swelling behavior, and degradation profiles of the resulting materials.

Furthermore, the presence of functional groups along the alginate backbone provides opportunities for chemical modifications and covalent crosslinking. These modifications can be exploited to tailor the properties of alginate-based materials for specific applications, such as controlled drug delivery systems, tissue engineering scaffolds, and smart materials responsive to external stimuli.

The growing body of research on sodium alginate has revealed its potential to address various challenges in materials science and engineering. Its ability to form reversible and stimuli-responsive gels has opened up new avenues for developing self-healing materials and adaptive structures. Additionally, the biocompatibility and biodegradability of sodium alginate make it an attractive option for creating environmentally friendly and sustainable materials, aligning with the global push towards greener technologies.

The history of sodium alginate can be traced back to the 19th century when it was first discovered and isolated from brown algae. However, its potential in polymer network evolution and materials science has only been fully recognized in recent decades. The growing interest in sustainable and eco-friendly materials has further propelled research into sodium alginate's applications across various industries, including biomedical, pharmaceutical, and food sectors.

One of the most notable characteristics of sodium alginate is its ability to form hydrogels through ionic crosslinking, particularly in the presence of divalent cations such as calcium. This gelation process, known as the "egg-box" model, occurs when calcium ions interact with the guluronate blocks of the alginate chains, creating a three-dimensional network structure. This unique property has made sodium alginate an attractive candidate for developing advanced materials with tunable mechanical and physical properties.

In the context of polymer network evolution, sodium alginate plays a crucial role in influencing the formation, structure, and properties of composite materials. Its incorporation into synthetic polymer systems can lead to the development of hybrid networks with enhanced functionality and performance. The interactions between sodium alginate and other polymer components can result in synergistic effects, altering the mechanical strength, swelling behavior, and degradation profiles of the resulting materials.

Furthermore, the presence of functional groups along the alginate backbone provides opportunities for chemical modifications and covalent crosslinking. These modifications can be exploited to tailor the properties of alginate-based materials for specific applications, such as controlled drug delivery systems, tissue engineering scaffolds, and smart materials responsive to external stimuli.

The growing body of research on sodium alginate has revealed its potential to address various challenges in materials science and engineering. Its ability to form reversible and stimuli-responsive gels has opened up new avenues for developing self-healing materials and adaptive structures. Additionally, the biocompatibility and biodegradability of sodium alginate make it an attractive option for creating environmentally friendly and sustainable materials, aligning with the global push towards greener technologies.

Market Applications Analysis

Sodium alginate's influence on polymer network evolution has significant implications across various market applications. In the biomedical field, this natural polysaccharide plays a crucial role in tissue engineering and drug delivery systems. Its ability to form hydrogels with controlled properties has led to the development of advanced wound dressings that promote healing and reduce scarring. These products have gained traction in the healthcare market, particularly for treating chronic wounds and burns.

The food industry has also embraced sodium alginate's network-forming capabilities. As a thickening and gelling agent, it enhances the texture and stability of various food products. The growing demand for plant-based alternatives has further boosted its use in creating meat-like textures in vegetarian and vegan products. This application has seen rapid growth in recent years, driven by consumer preferences for healthier and more sustainable food options.

In the pharmaceutical sector, sodium alginate's influence on polymer networks has revolutionized drug encapsulation and controlled release technologies. Its ability to form pH-sensitive gels allows for targeted drug delivery to specific areas of the gastrointestinal tract. This has led to the development of more effective oral medications with reduced side effects, addressing a significant market need for improved patient outcomes.

The cosmetics and personal care industry has leveraged sodium alginate's network-forming properties to create innovative skincare and haircare products. Its moisturizing and film-forming abilities have been utilized in anti-aging creams, face masks, and hair styling products. The natural and biodegradable nature of sodium alginate aligns well with the growing consumer demand for eco-friendly beauty solutions.

In the textile industry, sodium alginate's influence on polymer networks has found applications in fabric finishing and printing processes. It serves as a thickening agent in textile printing pastes, enabling precise and vibrant designs. Additionally, its use in creating antimicrobial and moisture-wicking fabrics has opened new market opportunities in sportswear and medical textiles.

The water treatment sector has also benefited from sodium alginate's network-forming capabilities. Its ability to form complexes with heavy metals has led to the development of efficient and eco-friendly water purification systems. This application addresses the growing global demand for clean water solutions, particularly in regions facing water scarcity and pollution challenges.

The food industry has also embraced sodium alginate's network-forming capabilities. As a thickening and gelling agent, it enhances the texture and stability of various food products. The growing demand for plant-based alternatives has further boosted its use in creating meat-like textures in vegetarian and vegan products. This application has seen rapid growth in recent years, driven by consumer preferences for healthier and more sustainable food options.

In the pharmaceutical sector, sodium alginate's influence on polymer networks has revolutionized drug encapsulation and controlled release technologies. Its ability to form pH-sensitive gels allows for targeted drug delivery to specific areas of the gastrointestinal tract. This has led to the development of more effective oral medications with reduced side effects, addressing a significant market need for improved patient outcomes.

The cosmetics and personal care industry has leveraged sodium alginate's network-forming properties to create innovative skincare and haircare products. Its moisturizing and film-forming abilities have been utilized in anti-aging creams, face masks, and hair styling products. The natural and biodegradable nature of sodium alginate aligns well with the growing consumer demand for eco-friendly beauty solutions.

In the textile industry, sodium alginate's influence on polymer networks has found applications in fabric finishing and printing processes. It serves as a thickening agent in textile printing pastes, enabling precise and vibrant designs. Additionally, its use in creating antimicrobial and moisture-wicking fabrics has opened new market opportunities in sportswear and medical textiles.

The water treatment sector has also benefited from sodium alginate's network-forming capabilities. Its ability to form complexes with heavy metals has led to the development of efficient and eco-friendly water purification systems. This application addresses the growing global demand for clean water solutions, particularly in regions facing water scarcity and pollution challenges.

Current Challenges in Polymer Networks

Polymer networks face several significant challenges that hinder their development and application in various fields. One of the primary issues is the lack of precise control over network formation and evolution. This limitation often results in heterogeneous structures with unpredictable properties, making it difficult to design materials with specific characteristics.

The complexity of polymer network systems poses another major challenge. These networks involve intricate interactions between multiple components, including crosslinkers, monomers, and additives. Understanding and predicting how these components influence network formation and properties remains a formidable task, often requiring advanced modeling techniques and experimental approaches.

Achieving uniform crosslinking density throughout the polymer network is another persistent challenge. Uneven distribution of crosslinks can lead to localized areas of high or low density, resulting in inconsistent mechanical properties and performance across the material. This heterogeneity can significantly impact the overall functionality and reliability of polymer network-based products.

The dynamic nature of polymer networks presents additional complications. Many networks undergo continuous reorganization and restructuring in response to external stimuli or environmental conditions. Controlling and harnessing these dynamic processes for desired applications, while maintaining network stability, remains a significant challenge for researchers and engineers.

Scalability and reproducibility of polymer network synthesis are also critical issues. Translating laboratory-scale successes to industrial production often encounters obstacles related to maintaining consistent network properties and performance. Variations in synthesis conditions, raw materials, and processing methods can lead to significant differences in the final product, making large-scale manufacturing challenging.

Furthermore, characterizing polymer networks at different length scales and time scales poses significant analytical challenges. Current techniques often struggle to provide comprehensive insights into network structure, dynamics, and properties simultaneously. This limitation hampers the development of structure-property relationships crucial for rational design and optimization of polymer network materials.

The integration of functional components, such as nanoparticles or biomolecules, into polymer networks while maintaining network integrity and desired properties is another area of ongoing research. Achieving uniform distribution and strong interactions between these components and the polymer matrix remains challenging, often limiting the performance of hybrid materials.

The complexity of polymer network systems poses another major challenge. These networks involve intricate interactions between multiple components, including crosslinkers, monomers, and additives. Understanding and predicting how these components influence network formation and properties remains a formidable task, often requiring advanced modeling techniques and experimental approaches.

Achieving uniform crosslinking density throughout the polymer network is another persistent challenge. Uneven distribution of crosslinks can lead to localized areas of high or low density, resulting in inconsistent mechanical properties and performance across the material. This heterogeneity can significantly impact the overall functionality and reliability of polymer network-based products.

The dynamic nature of polymer networks presents additional complications. Many networks undergo continuous reorganization and restructuring in response to external stimuli or environmental conditions. Controlling and harnessing these dynamic processes for desired applications, while maintaining network stability, remains a significant challenge for researchers and engineers.

Scalability and reproducibility of polymer network synthesis are also critical issues. Translating laboratory-scale successes to industrial production often encounters obstacles related to maintaining consistent network properties and performance. Variations in synthesis conditions, raw materials, and processing methods can lead to significant differences in the final product, making large-scale manufacturing challenging.

Furthermore, characterizing polymer networks at different length scales and time scales poses significant analytical challenges. Current techniques often struggle to provide comprehensive insights into network structure, dynamics, and properties simultaneously. This limitation hampers the development of structure-property relationships crucial for rational design and optimization of polymer network materials.

The integration of functional components, such as nanoparticles or biomolecules, into polymer networks while maintaining network integrity and desired properties is another area of ongoing research. Achieving uniform distribution and strong interactions between these components and the polymer matrix remains challenging, often limiting the performance of hybrid materials.

Sodium Alginate Integration Methods

01 Hydrogel formation and crosslinking

Sodium alginate polymer networks can be formed through various crosslinking methods, including ionic crosslinking with divalent cations and covalent crosslinking with chemical agents. These processes lead to the formation of hydrogels with tunable properties, such as mechanical strength and swelling behavior, which are crucial for applications in tissue engineering and drug delivery.- Hydrogel formation and crosslinking: Sodium alginate polymer networks can be formed through various crosslinking methods, including ionic crosslinking with divalent cations and covalent crosslinking with chemical agents. These processes lead to the formation of hydrogels with tunable properties, such as mechanical strength and swelling behavior, which are crucial for applications in tissue engineering and drug delivery.

- Composite materials and blends: Sodium alginate can be combined with other polymers or materials to create composite networks with enhanced properties. These composites often exhibit improved mechanical strength, biocompatibility, or functionality compared to pure sodium alginate networks. Examples include alginate-cellulose blends and alginate-nanoparticle composites.

- Stimuli-responsive behavior: Sodium alginate polymer networks can be designed to respond to various stimuli, such as pH, temperature, or light. This responsiveness allows for controlled release of encapsulated substances or changes in network properties, making them suitable for smart drug delivery systems and sensors.

- Biodegradation and controlled degradation: The biodegradability of sodium alginate polymer networks can be tailored through various methods, including oxidation, enzymatic degradation, or incorporation of degradable crosslinks. Controlled degradation is essential for applications in tissue engineering and drug delivery, where the network needs to break down over time.

- Functionalization and modification: Sodium alginate polymer networks can be functionalized or modified to introduce new properties or improve existing ones. This includes grafting of functional groups, incorporation of bioactive molecules, or chemical modifications to enhance cell adhesion, drug loading capacity, or mechanical properties.

02 Composite materials and blends

Sodium alginate can be combined with other polymers or materials to create composite networks with enhanced properties. These composites often exhibit improved mechanical strength, biocompatibility, or functionality compared to pure sodium alginate networks. Examples include alginate-cellulose blends and alginate-nanoparticle composites.Expand Specific Solutions03 Stimuli-responsive behavior

Sodium alginate polymer networks can be designed to respond to various stimuli, such as pH, temperature, or light. This responsiveness allows for controlled release of encapsulated substances or changes in network properties, making them suitable for smart drug delivery systems and environmental applications.Expand Specific Solutions04 Biodegradation and controlled release

The biodegradability of sodium alginate polymer networks can be tailored through various methods, including chemical modification and incorporation of enzymes. This allows for controlled degradation rates and release profiles of encapsulated drugs or bioactive compounds, which is essential for biomedical applications.Expand Specific Solutions05 3D printing and advanced fabrication

Sodium alginate polymer networks can be used in advanced fabrication techniques, such as 3D printing and electrospinning. These methods allow for the creation of complex structures with precise control over network architecture, enabling the development of customized scaffolds for tissue engineering and other biomedical applications.Expand Specific Solutions

Key Players in Alginate Research

The field of sodium alginate's influence on polymer network evolution is in a developing stage, with growing market potential due to its applications in biomaterials and drug delivery systems. The technology's maturity is advancing, as evidenced by research from prestigious institutions like Harvard College, MIT, and Columbia University. Companies such as Goodrich Corp. and research organizations like CNRS and A*STAR are also contributing to the field's progress. The market size is expanding as the technology finds applications in various industries, including healthcare and materials science. However, the technology is still evolving, with ongoing research focused on understanding and optimizing the interactions between sodium alginate and polymer networks.

President & Fellows of Harvard College

Technical Solution: Harvard's research on sodium alginate's influence on polymer network evolution focuses on developing biomimetic hydrogels for tissue engineering applications. Their approach combines sodium alginate with synthetic polymers to create hybrid networks with enhanced mechanical properties and biocompatibility[2]. Harvard researchers have developed a method to control the spatial distribution of alginate within the polymer network, allowing for the creation of gradient materials with tunable properties[4]. They utilize advanced imaging techniques, such as confocal microscopy and atomic force microscopy, to visualize the network evolution at multiple length scales. Additionally, Harvard has explored the use of enzymatic crosslinking methods to fine-tune the degradation kinetics of alginate-containing polymer networks, which is crucial for controlled drug delivery systems[6].

Strengths: Innovative biomimetic approaches, advanced imaging capabilities for network characterization. Weaknesses: Potential limitations in large-scale production, complexity in achieving precise control over degradation kinetics in vivo.

Centre National de la Recherche Scientifique

Technical Solution: CNRS's research on sodium alginate's influence on polymer network evolution focuses on developing sustainable and eco-friendly materials. Their approach involves combining sodium alginate with biodegradable synthetic polymers to create fully compostable hydrogels and films[13]. CNRS researchers have developed a method to enhance the mechanical properties of alginate-polymer blends through the incorporation of nanocellulose, resulting in high-strength, renewable materials[15]. They utilize advanced spectroscopic techniques, such as solid-state NMR and FTIR, to study the molecular interactions between alginate and synthetic polymers during network formation. CNRS has also explored the use of alginate as a natural flame retardant in polymer composites, leveraging its char-forming properties to enhance fire resistance[17].

Strengths: Focus on sustainable materials, expertise in polymer-nanocellulose composites. Weaknesses: Potential limitations in achieving properties comparable to non-biodegradable materials, challenges in controlling moisture sensitivity of alginate-containing networks.

Innovative Alginate-Polymer Interactions

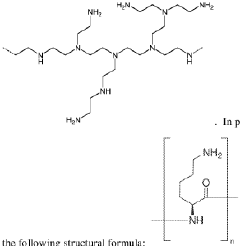

Biocompatible adhesives and methods of use thereof

PatentWO2017165490A1

Innovation

- A biocompatible adhesive system comprising a hydrogel with covalent and ionic polymer networks, a high-density primary amine polymer, and a coupling agent, which forms strong and selective adhesion on wet surfaces, sustains mechanical loads, and has tunable degradation properties, allowing for use in wet and dynamic environments.

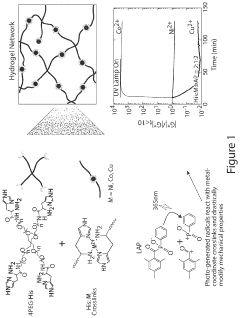

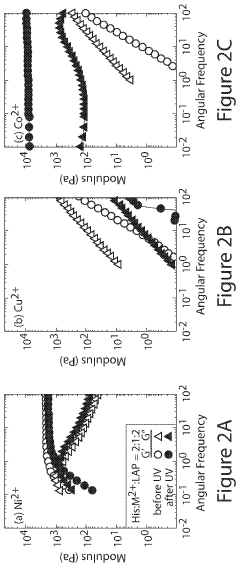

Materials with programmable properties controlled by light

PatentActiveUS20200199303A1

Innovation

- Development of metal-crosslinked hydrogels where the oxidation state of metal ions is controlled by external stimuli, such as light irradiation, to alter viscoelastic properties, using polymers like four-arm polyethylene glycol with histidine moieties and photoinitiators to generate free radicals for oxidation/reduction reactions, allowing independent modification of viscoelastic properties.

Environmental Impact Assessment

The environmental impact of sodium alginate's influence on polymer network evolution is a critical consideration in the development and application of these materials. Sodium alginate, derived from brown algae, is a biodegradable and renewable resource, which inherently contributes to its positive environmental profile. When incorporated into polymer networks, it can enhance the biodegradability of the resulting materials, potentially reducing their long-term environmental footprint.

The production process of sodium alginate involves extraction from seaweed, which generally has a lower environmental impact compared to synthetic polymer production. This can lead to reduced energy consumption and greenhouse gas emissions in the manufacturing stage. However, the harvesting of seaweed for alginate production must be carefully managed to prevent overexploitation of marine ecosystems and maintain biodiversity.

In terms of waste management, polymer networks influenced by sodium alginate often exhibit improved degradability in various environmental conditions. This characteristic can significantly reduce the persistence of plastic waste in landfills and marine environments, addressing one of the most pressing environmental concerns associated with conventional polymers. The degradation products of these materials are typically non-toxic and can be assimilated into natural biogeochemical cycles.

Water treatment applications represent a notable environmental benefit of sodium alginate-influenced polymer networks. These materials can be used in the development of advanced filtration systems and adsorbents for the removal of pollutants from water, contributing to improved water quality and ecosystem health. The ability of these networks to sequester heavy metals and organic contaminants offers a sustainable approach to environmental remediation.

However, it is essential to consider the potential release of sodium ions during the degradation of these materials, which could impact soil and aquatic ecosystems if not properly managed. Additionally, the production and use of crosslinking agents in the formation of these polymer networks may introduce additional environmental considerations, depending on the specific chemicals employed.

Life cycle assessments of products incorporating sodium alginate-influenced polymer networks are crucial to fully understand their environmental impact. These assessments should consider raw material sourcing, production processes, use phase, and end-of-life scenarios to provide a comprehensive view of the material's environmental footprint. Such analyses can guide the optimization of these materials for minimal environmental impact while maximizing their functional benefits.

The production process of sodium alginate involves extraction from seaweed, which generally has a lower environmental impact compared to synthetic polymer production. This can lead to reduced energy consumption and greenhouse gas emissions in the manufacturing stage. However, the harvesting of seaweed for alginate production must be carefully managed to prevent overexploitation of marine ecosystems and maintain biodiversity.

In terms of waste management, polymer networks influenced by sodium alginate often exhibit improved degradability in various environmental conditions. This characteristic can significantly reduce the persistence of plastic waste in landfills and marine environments, addressing one of the most pressing environmental concerns associated with conventional polymers. The degradation products of these materials are typically non-toxic and can be assimilated into natural biogeochemical cycles.

Water treatment applications represent a notable environmental benefit of sodium alginate-influenced polymer networks. These materials can be used in the development of advanced filtration systems and adsorbents for the removal of pollutants from water, contributing to improved water quality and ecosystem health. The ability of these networks to sequester heavy metals and organic contaminants offers a sustainable approach to environmental remediation.

However, it is essential to consider the potential release of sodium ions during the degradation of these materials, which could impact soil and aquatic ecosystems if not properly managed. Additionally, the production and use of crosslinking agents in the formation of these polymer networks may introduce additional environmental considerations, depending on the specific chemicals employed.

Life cycle assessments of products incorporating sodium alginate-influenced polymer networks are crucial to fully understand their environmental impact. These assessments should consider raw material sourcing, production processes, use phase, and end-of-life scenarios to provide a comprehensive view of the material's environmental footprint. Such analyses can guide the optimization of these materials for minimal environmental impact while maximizing their functional benefits.

Scalability and Industrial Adoption

The scalability and industrial adoption of sodium alginate in polymer network evolution present significant opportunities and challenges for various industries. As the demand for advanced materials with tailored properties continues to grow, the ability to scale up production processes involving sodium alginate becomes crucial. One of the primary advantages of sodium alginate in this context is its versatility and ease of manipulation, which allows for relatively straightforward scaling of production processes.

In industrial settings, the use of sodium alginate to influence polymer network evolution has shown promise in sectors such as biomedical engineering, food technology, and advanced materials manufacturing. The ability to control network formation and properties through the addition of sodium alginate has led to the development of novel hydrogels, drug delivery systems, and tissue engineering scaffolds. However, the transition from laboratory-scale experiments to large-scale industrial production requires careful consideration of several factors.

One key aspect of scalability is the consistency of sodium alginate's influence on polymer networks across different batch sizes. Maintaining uniform crosslinking density and mechanical properties in larger volumes can be challenging, as factors such as mixing efficiency and diffusion rates may vary. To address this, industries have been developing specialized equipment and protocols to ensure homogeneous distribution of sodium alginate and consistent network formation in large-scale production.

Another important consideration for industrial adoption is the cost-effectiveness of incorporating sodium alginate into existing manufacturing processes. While sodium alginate itself is relatively inexpensive and readily available, the additional processing steps and potential modifications to production lines may require significant initial investments. However, the long-term benefits of improved product performance and expanded application possibilities often justify these upfront costs.

The regulatory landscape also plays a crucial role in the industrial adoption of sodium alginate-influenced polymer networks. In sectors such as pharmaceuticals and food production, stringent regulations govern the use of additives and processing aids. The generally recognized as safe (GRAS) status of sodium alginate in many jurisdictions facilitates its adoption, but manufacturers must still navigate complex regulatory frameworks to ensure compliance.

As research continues to uncover new applications and benefits of sodium alginate in polymer network evolution, industries are increasingly investing in R&D to leverage these advancements. This has led to the development of specialized formulations and processing techniques tailored to specific industrial needs, further driving the scalability and adoption of this technology across various sectors.

In industrial settings, the use of sodium alginate to influence polymer network evolution has shown promise in sectors such as biomedical engineering, food technology, and advanced materials manufacturing. The ability to control network formation and properties through the addition of sodium alginate has led to the development of novel hydrogels, drug delivery systems, and tissue engineering scaffolds. However, the transition from laboratory-scale experiments to large-scale industrial production requires careful consideration of several factors.

One key aspect of scalability is the consistency of sodium alginate's influence on polymer networks across different batch sizes. Maintaining uniform crosslinking density and mechanical properties in larger volumes can be challenging, as factors such as mixing efficiency and diffusion rates may vary. To address this, industries have been developing specialized equipment and protocols to ensure homogeneous distribution of sodium alginate and consistent network formation in large-scale production.

Another important consideration for industrial adoption is the cost-effectiveness of incorporating sodium alginate into existing manufacturing processes. While sodium alginate itself is relatively inexpensive and readily available, the additional processing steps and potential modifications to production lines may require significant initial investments. However, the long-term benefits of improved product performance and expanded application possibilities often justify these upfront costs.

The regulatory landscape also plays a crucial role in the industrial adoption of sodium alginate-influenced polymer networks. In sectors such as pharmaceuticals and food production, stringent regulations govern the use of additives and processing aids. The generally recognized as safe (GRAS) status of sodium alginate in many jurisdictions facilitates its adoption, but manufacturers must still navigate complex regulatory frameworks to ensure compliance.

As research continues to uncover new applications and benefits of sodium alginate in polymer network evolution, industries are increasingly investing in R&D to leverage these advancements. This has led to the development of specialized formulations and processing techniques tailored to specific industrial needs, further driving the scalability and adoption of this technology across various sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!