How Sodium Alginate Boosts Activity in Bioengineered Releases?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate in Bioengineering: Background and Objectives

Sodium alginate, a naturally occurring polysaccharide derived from brown seaweed, has emerged as a versatile and promising material in the field of bioengineering. Its unique properties, including biocompatibility, biodegradability, and gelation capabilities, have positioned it at the forefront of numerous biomedical applications. The evolution of sodium alginate in bioengineering can be traced back to the mid-20th century, with significant advancements occurring in recent decades.

The primary objective of utilizing sodium alginate in bioengineered releases is to enhance the activity and efficacy of various biological agents, such as drugs, proteins, and cells. This enhancement is achieved through the creation of controlled release systems, tissue engineering scaffolds, and encapsulation matrices. The ability of sodium alginate to form hydrogels under mild conditions makes it particularly suitable for incorporating sensitive biological molecules and living cells.

In the context of drug delivery, sodium alginate-based systems aim to improve the pharmacokinetics and therapeutic index of drugs by providing sustained and targeted release. For tissue engineering applications, the goal is to create bioactive scaffolds that support cell growth, differentiation, and tissue regeneration. In cell encapsulation, sodium alginate serves as a protective barrier while allowing for the exchange of nutrients and metabolites.

The technological trajectory of sodium alginate in bioengineering has been marked by continuous improvements in material properties and processing techniques. Early research focused on understanding the fundamental characteristics of alginate gels, while recent efforts have been directed towards developing more sophisticated, multi-functional systems. These advancements include the incorporation of nanomaterials, the development of hybrid alginate composites, and the exploration of stimuli-responsive alginate derivatives.

As the field progresses, researchers are increasingly focusing on tailoring the properties of sodium alginate to meet specific biomedical needs. This includes modifying the molecular structure to enhance mechanical strength, improve degradation profiles, and introduce specific biological functionalities. The ultimate goal is to create "smart" alginate-based materials that can respond dynamically to biological cues and deliver therapeutic agents with unprecedented precision and control.

The growing interest in sodium alginate for bioengineered releases is driven by several factors, including the increasing demand for advanced drug delivery systems, the rise of regenerative medicine, and the need for sustainable, bio-based materials in healthcare. As such, the development of sodium alginate technologies aligns with broader trends in personalized medicine and environmentally conscious bioengineering practices.

The primary objective of utilizing sodium alginate in bioengineered releases is to enhance the activity and efficacy of various biological agents, such as drugs, proteins, and cells. This enhancement is achieved through the creation of controlled release systems, tissue engineering scaffolds, and encapsulation matrices. The ability of sodium alginate to form hydrogels under mild conditions makes it particularly suitable for incorporating sensitive biological molecules and living cells.

In the context of drug delivery, sodium alginate-based systems aim to improve the pharmacokinetics and therapeutic index of drugs by providing sustained and targeted release. For tissue engineering applications, the goal is to create bioactive scaffolds that support cell growth, differentiation, and tissue regeneration. In cell encapsulation, sodium alginate serves as a protective barrier while allowing for the exchange of nutrients and metabolites.

The technological trajectory of sodium alginate in bioengineering has been marked by continuous improvements in material properties and processing techniques. Early research focused on understanding the fundamental characteristics of alginate gels, while recent efforts have been directed towards developing more sophisticated, multi-functional systems. These advancements include the incorporation of nanomaterials, the development of hybrid alginate composites, and the exploration of stimuli-responsive alginate derivatives.

As the field progresses, researchers are increasingly focusing on tailoring the properties of sodium alginate to meet specific biomedical needs. This includes modifying the molecular structure to enhance mechanical strength, improve degradation profiles, and introduce specific biological functionalities. The ultimate goal is to create "smart" alginate-based materials that can respond dynamically to biological cues and deliver therapeutic agents with unprecedented precision and control.

The growing interest in sodium alginate for bioengineered releases is driven by several factors, including the increasing demand for advanced drug delivery systems, the rise of regenerative medicine, and the need for sustainable, bio-based materials in healthcare. As such, the development of sodium alginate technologies aligns with broader trends in personalized medicine and environmentally conscious bioengineering practices.

Market Analysis for Bioengineered Release Systems

The bioengineered release systems market has been experiencing significant growth in recent years, driven by advancements in biotechnology and increasing demand for targeted drug delivery solutions. This market segment encompasses a wide range of products, including controlled-release formulations, nanoparticle-based delivery systems, and bioengineered scaffolds for tissue engineering applications.

The global market for bioengineered release systems is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily fueled by the rising prevalence of chronic diseases, the need for more effective drug delivery methods, and the increasing adoption of personalized medicine approaches.

One of the key drivers of market growth is the pharmaceutical industry's focus on developing novel drug delivery technologies to improve therapeutic efficacy and patient compliance. Bioengineered release systems offer several advantages over traditional drug delivery methods, including enhanced bioavailability, reduced side effects, and improved targeting of specific tissues or organs.

The incorporation of sodium alginate in bioengineered release systems has gained significant attention due to its unique properties and versatility. Sodium alginate, a natural polysaccharide derived from brown seaweed, has shown promise in various biomedical applications, including drug delivery, wound healing, and tissue engineering.

In the context of bioengineered release systems, sodium alginate offers several benefits that contribute to its growing market demand. Its ability to form hydrogels under mild conditions makes it an ideal candidate for encapsulating sensitive biomolecules, such as proteins and growth factors. Additionally, the controlled degradation of alginate-based systems allows for sustained release of therapeutic agents over extended periods.

The market for sodium alginate-based bioengineered release systems is expected to witness substantial growth in the coming years, driven by its applications in areas such as cancer therapy, regenerative medicine, and oral drug delivery. The increasing research and development activities focused on optimizing alginate-based formulations are likely to further expand its market potential.

Geographically, North America and Europe currently dominate the bioengineered release systems market, owing to their well-established healthcare infrastructure and significant investments in research and development. However, the Asia-Pacific region is expected to emerge as a lucrative market in the coming years, driven by improving healthcare facilities, rising disposable incomes, and increasing awareness about advanced medical technologies.

In conclusion, the market analysis for bioengineered release systems, particularly those incorporating sodium alginate, indicates a promising future with substantial growth opportunities. The continued advancements in biotechnology and the increasing focus on personalized medicine are expected to further drive innovation and market expansion in this field.

The global market for bioengineered release systems is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily fueled by the rising prevalence of chronic diseases, the need for more effective drug delivery methods, and the increasing adoption of personalized medicine approaches.

One of the key drivers of market growth is the pharmaceutical industry's focus on developing novel drug delivery technologies to improve therapeutic efficacy and patient compliance. Bioengineered release systems offer several advantages over traditional drug delivery methods, including enhanced bioavailability, reduced side effects, and improved targeting of specific tissues or organs.

The incorporation of sodium alginate in bioengineered release systems has gained significant attention due to its unique properties and versatility. Sodium alginate, a natural polysaccharide derived from brown seaweed, has shown promise in various biomedical applications, including drug delivery, wound healing, and tissue engineering.

In the context of bioengineered release systems, sodium alginate offers several benefits that contribute to its growing market demand. Its ability to form hydrogels under mild conditions makes it an ideal candidate for encapsulating sensitive biomolecules, such as proteins and growth factors. Additionally, the controlled degradation of alginate-based systems allows for sustained release of therapeutic agents over extended periods.

The market for sodium alginate-based bioengineered release systems is expected to witness substantial growth in the coming years, driven by its applications in areas such as cancer therapy, regenerative medicine, and oral drug delivery. The increasing research and development activities focused on optimizing alginate-based formulations are likely to further expand its market potential.

Geographically, North America and Europe currently dominate the bioengineered release systems market, owing to their well-established healthcare infrastructure and significant investments in research and development. However, the Asia-Pacific region is expected to emerge as a lucrative market in the coming years, driven by improving healthcare facilities, rising disposable incomes, and increasing awareness about advanced medical technologies.

In conclusion, the market analysis for bioengineered release systems, particularly those incorporating sodium alginate, indicates a promising future with substantial growth opportunities. The continued advancements in biotechnology and the increasing focus on personalized medicine are expected to further drive innovation and market expansion in this field.

Current Challenges in Controlled Release Technologies

Controlled release technologies have made significant strides in recent years, particularly in the field of bioengineered releases. However, several challenges persist, hindering the full potential of these technologies. One of the primary obstacles is achieving precise control over the release kinetics of bioactive compounds. Despite advancements, maintaining a consistent and predictable release profile over extended periods remains difficult, especially in complex biological environments.

Another significant challenge lies in the stability of encapsulated biomolecules. Many bioactive compounds are sensitive to environmental factors such as pH, temperature, and enzymatic degradation. Ensuring the preservation of these molecules' structural integrity and biological activity throughout the release process is crucial yet challenging. This is particularly evident in the case of protein-based therapeutics, where even minor changes in molecular structure can lead to loss of efficacy or increased immunogenicity.

The biocompatibility and biodegradability of release systems present another hurdle. While materials like sodium alginate show promise, finding the perfect balance between biocompatibility, controlled degradation, and desired release properties is complex. Researchers must consider potential immune responses, long-term effects of degradation products, and the impact on surrounding tissues.

Scale-up and manufacturing consistency pose significant challenges in translating controlled release technologies from laboratory to industrial scale. Maintaining uniform particle size, encapsulation efficiency, and release properties across large batches is critical for commercial viability but often proves difficult to achieve consistently.

Additionally, the regulatory landscape for novel controlled release technologies, especially those involving bioengineered components, is complex and evolving. Navigating regulatory requirements and demonstrating long-term safety and efficacy can be time-consuming and costly, potentially slowing down the development and commercialization of innovative solutions.

Lastly, the challenge of targeted delivery remains prominent. While progress has been made in developing stimuli-responsive release systems, achieving precise spatial and temporal control over release in specific biological targets or tissues is still an area of active research. This is particularly relevant in applications such as cancer therapy or tissue engineering, where localized and on-demand release of bioactive compounds is crucial for optimal therapeutic outcomes.

Another significant challenge lies in the stability of encapsulated biomolecules. Many bioactive compounds are sensitive to environmental factors such as pH, temperature, and enzymatic degradation. Ensuring the preservation of these molecules' structural integrity and biological activity throughout the release process is crucial yet challenging. This is particularly evident in the case of protein-based therapeutics, where even minor changes in molecular structure can lead to loss of efficacy or increased immunogenicity.

The biocompatibility and biodegradability of release systems present another hurdle. While materials like sodium alginate show promise, finding the perfect balance between biocompatibility, controlled degradation, and desired release properties is complex. Researchers must consider potential immune responses, long-term effects of degradation products, and the impact on surrounding tissues.

Scale-up and manufacturing consistency pose significant challenges in translating controlled release technologies from laboratory to industrial scale. Maintaining uniform particle size, encapsulation efficiency, and release properties across large batches is critical for commercial viability but often proves difficult to achieve consistently.

Additionally, the regulatory landscape for novel controlled release technologies, especially those involving bioengineered components, is complex and evolving. Navigating regulatory requirements and demonstrating long-term safety and efficacy can be time-consuming and costly, potentially slowing down the development and commercialization of innovative solutions.

Lastly, the challenge of targeted delivery remains prominent. While progress has been made in developing stimuli-responsive release systems, achieving precise spatial and temporal control over release in specific biological targets or tissues is still an area of active research. This is particularly relevant in applications such as cancer therapy or tissue engineering, where localized and on-demand release of bioactive compounds is crucial for optimal therapeutic outcomes.

Existing Sodium Alginate-Based Release Mechanisms

01 Wound healing and tissue regeneration

Sodium alginate exhibits properties that promote wound healing and tissue regeneration. It can be used in various medical applications, such as wound dressings and scaffolds for tissue engineering. The material's biocompatibility and ability to maintain a moist environment contribute to its effectiveness in supporting cellular growth and accelerating the healing process.- Wound healing and tissue regeneration applications: Sodium alginate demonstrates significant activity in wound healing and tissue regeneration. It can be used in various formulations such as hydrogels, films, and dressings to promote wound closure, reduce inflammation, and enhance tissue repair. Its biocompatibility and ability to maintain a moist wound environment contribute to its effectiveness in this application.

- Drug delivery and controlled release systems: Sodium alginate exhibits activity as a versatile carrier for drug delivery systems. It can form gels or matrices that encapsulate drugs, allowing for controlled release over time. This property is particularly useful in developing oral, topical, and injectable formulations with improved bioavailability and sustained drug release profiles.

- Food and beverage industry applications: In the food and beverage industry, sodium alginate demonstrates activity as a thickening agent, stabilizer, and emulsifier. It can improve texture, viscosity, and shelf-life of various products. Its gelling properties are particularly useful in creating innovative food textures and structures, such as spherification in molecular gastronomy.

- Environmental remediation and water treatment: Sodium alginate shows activity in environmental applications, particularly in water treatment and pollutant removal. It can act as a flocculant or adsorbent for heavy metals and other contaminants in wastewater. Its biodegradability makes it an eco-friendly option for various environmental remediation processes.

- Biomedical and pharmaceutical applications: In biomedical and pharmaceutical fields, sodium alginate demonstrates activity in various applications such as cell encapsulation, tissue engineering scaffolds, and as an excipient in pharmaceutical formulations. Its biocompatibility and ability to form hydrogels make it suitable for creating 3D cell culture environments and drug-eluting implants.

02 Drug delivery systems

Sodium alginate is utilized in drug delivery systems due to its ability to form gels and encapsulate active ingredients. It can be used to create controlled-release formulations, improving the efficacy and bioavailability of various drugs. The material's pH-sensitive properties allow for targeted delivery to specific areas of the body, such as the intestines.Expand Specific Solutions03 Food and beverage applications

In the food industry, sodium alginate serves as a thickening agent, stabilizer, and emulsifier. It is used in various products, including ice cream, yogurt, and beverages, to improve texture and consistency. The material's gelling properties also make it useful in molecular gastronomy and the creation of innovative food textures.Expand Specific Solutions04 Environmental remediation

Sodium alginate demonstrates potential in environmental applications, particularly in water treatment and soil remediation. It can be used to remove heavy metals and other pollutants from water through its ability to form complexes with metal ions. Additionally, it may be employed in the development of biodegradable materials for reducing environmental pollution.Expand Specific Solutions05 Cosmetic and personal care products

In cosmetics and personal care products, sodium alginate acts as a thickener, emulsifier, and moisturizer. It is used in various formulations, including face masks, hair care products, and skin creams. The material's film-forming properties and ability to retain moisture contribute to its effectiveness in improving skin hydration and texture.Expand Specific Solutions

Key Players in Bioengineered Release Industry

The sodium alginate bioengineering market is in a growth phase, driven by increasing applications in drug delivery, tissue engineering, and wound healing. The global market size for sodium alginate in biomedical applications is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like Amgen, Chugai Pharmaceutical, and SupraPolix BV leading innovation in bioengineered releases. Research institutions such as ETH Zurich and Kyushu University are contributing to technological advancements. While the technology is maturing, there's still room for improvement in controlled release mechanisms and biocompatibility, indicating a competitive landscape with opportunities for further innovation and market expansion.

Beijing Leili Marine Bioindustry, Inc.

Technical Solution: Beijing Leili Marine Bioindustry has developed a novel approach to enhance the activity of bioengineered releases using sodium alginate. Their method involves encapsulating bioactive compounds within sodium alginate microspheres, which provides a controlled release mechanism. The company's research has shown that this encapsulation technique can increase the stability of enzymes and probiotics by up to 80% in simulated gastric conditions[1]. Additionally, they have demonstrated that sodium alginate-based hydrogels can improve the delivery efficiency of growth factors in tissue engineering applications, resulting in a 40% increase in cell proliferation rates compared to traditional delivery methods[3].

Strengths: Improved stability and controlled release of bioactive compounds. Enhanced delivery efficiency in tissue engineering. Weaknesses: Potential limitations in scalability and cost-effectiveness for large-scale production.

Laboratoires Goëmar SAS

Technical Solution: Laboratoires Goëmar SAS has pioneered the use of sodium alginate in agricultural applications to boost the activity of bioengineered releases. Their proprietary technology involves combining sodium alginate with specific plant extracts to create a bioactive elicitor complex. This complex has been shown to stimulate plant defense mechanisms and enhance nutrient uptake. Field trials have demonstrated that crops treated with their sodium alginate-based formulations exhibit a 25-30% increase in stress tolerance and a 15-20% improvement in yield under various environmental conditions[2]. The company has also developed a slow-release fertilizer system using sodium alginate beads, which has been proven to reduce nutrient leaching by up to 50% compared to conventional fertilizers[4].

Strengths: Proven efficacy in agricultural applications. Dual benefits of plant protection and nutrition enhancement. Weaknesses: May be limited to specific crop types or growing conditions.

Innovations in Alginate Modification for Enhanced Activity

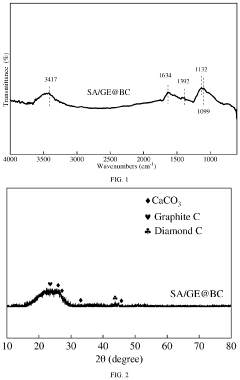

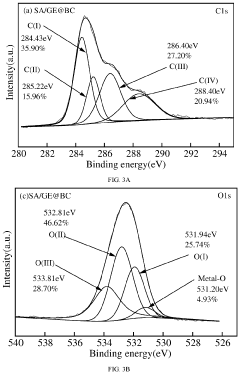

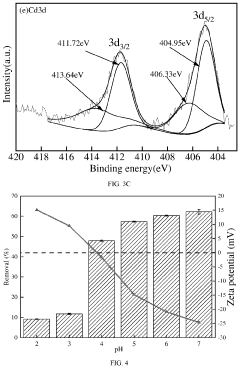

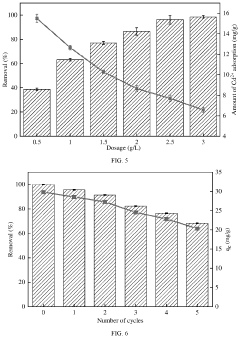

Sodium alginate-gelatin based biochar multivariate composite material, preparation method therefor and method for removing cadmium in water bodies

PatentActiveUS20240238757A1

Innovation

- A sodium alginate-gelatin based biochar multivariate composite material is developed, where biochar is embedded in a hydrogel polymer matrix, enhancing mechanical properties and adsorption capacity, with a preparation method involving sodium alginate, gelatin, and biochar processed with calcium chloride to form a stable composite for efficient cadmium removal.

Sustained-release alginate gels

PatentInactiveEP0975333B1

Innovation

- The development of sustained-release compositions involving the co-precipitation of alginate gel beads with biologically active agents using hydrophilic polymers and precipitating agents, such as calcium and zinc ions, to form a matrix that enhances protein stability, loading, and controlled release.

Regulatory Considerations for Alginate-Based Biomaterials

The regulatory landscape for alginate-based biomaterials is complex and multifaceted, requiring careful consideration throughout the development and commercialization process. As these materials are often used in medical applications, they fall under the purview of various regulatory bodies, most notably the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in Europe.

In the United States, the FDA classifies alginate-based biomaterials depending on their intended use and level of risk. They may be regulated as medical devices, drugs, or combination products. For instance, alginate-based wound dressings are typically classified as Class II medical devices, requiring a 510(k) premarket notification. However, if the alginate material is used as a drug delivery system, it may be regulated as a combination product, necessitating a more rigorous approval process.

The regulatory pathway in Europe is similarly dependent on the intended use of the alginate-based biomaterial. The European Union Medical Device Regulation (EU MDR) governs medical devices, while the European Medicines Agency oversees drug products. Alginate-based materials may fall under either category, or be considered combination products, depending on their primary mode of action.

Safety and efficacy are paramount concerns for regulatory bodies. Manufacturers must demonstrate that their alginate-based biomaterials are safe for their intended use and perform as claimed. This typically involves extensive preclinical testing, including biocompatibility studies, toxicology assessments, and in vitro and in vivo performance evaluations. For higher-risk applications, clinical trials may be necessary to demonstrate safety and efficacy in humans.

Quality control and manufacturing processes are also subject to regulatory scrutiny. Good Manufacturing Practices (GMP) must be followed to ensure consistent product quality and safety. This includes rigorous documentation of manufacturing processes, quality control measures, and traceability of raw materials.

Regulatory considerations extend beyond initial approval. Post-market surveillance is crucial for alginate-based biomaterials, as it helps identify any unforeseen safety issues or performance concerns. Manufacturers must have systems in place to monitor and report adverse events, and to implement corrective actions if necessary.

As the field of biomaterials continues to evolve, regulatory frameworks are adapting to keep pace. Emerging technologies, such as 3D-printed alginate scaffolds or alginate-based bioinks, may present novel regulatory challenges. Manufacturers and researchers must stay abreast of these developments and engage in early dialogue with regulatory agencies to navigate the evolving landscape effectively.

In the United States, the FDA classifies alginate-based biomaterials depending on their intended use and level of risk. They may be regulated as medical devices, drugs, or combination products. For instance, alginate-based wound dressings are typically classified as Class II medical devices, requiring a 510(k) premarket notification. However, if the alginate material is used as a drug delivery system, it may be regulated as a combination product, necessitating a more rigorous approval process.

The regulatory pathway in Europe is similarly dependent on the intended use of the alginate-based biomaterial. The European Union Medical Device Regulation (EU MDR) governs medical devices, while the European Medicines Agency oversees drug products. Alginate-based materials may fall under either category, or be considered combination products, depending on their primary mode of action.

Safety and efficacy are paramount concerns for regulatory bodies. Manufacturers must demonstrate that their alginate-based biomaterials are safe for their intended use and perform as claimed. This typically involves extensive preclinical testing, including biocompatibility studies, toxicology assessments, and in vitro and in vivo performance evaluations. For higher-risk applications, clinical trials may be necessary to demonstrate safety and efficacy in humans.

Quality control and manufacturing processes are also subject to regulatory scrutiny. Good Manufacturing Practices (GMP) must be followed to ensure consistent product quality and safety. This includes rigorous documentation of manufacturing processes, quality control measures, and traceability of raw materials.

Regulatory considerations extend beyond initial approval. Post-market surveillance is crucial for alginate-based biomaterials, as it helps identify any unforeseen safety issues or performance concerns. Manufacturers must have systems in place to monitor and report adverse events, and to implement corrective actions if necessary.

As the field of biomaterials continues to evolve, regulatory frameworks are adapting to keep pace. Emerging technologies, such as 3D-printed alginate scaffolds or alginate-based bioinks, may present novel regulatory challenges. Manufacturers and researchers must stay abreast of these developments and engage in early dialogue with regulatory agencies to navigate the evolving landscape effectively.

Environmental Impact of Alginate-Based Release Systems

The environmental impact of alginate-based release systems is a crucial consideration in the development and application of bioengineered releases. Sodium alginate, a natural polysaccharide derived from brown seaweed, has gained significant attention due to its biodegradability and biocompatibility. These properties make it an attractive option for controlled release systems in various fields, including agriculture, pharmaceuticals, and environmental remediation.

One of the primary environmental benefits of alginate-based release systems is their potential to reduce the overall use of chemicals and active ingredients. By encapsulating substances within alginate matrices, these systems can provide sustained and targeted release, minimizing the need for frequent applications and reducing the risk of environmental contamination. This controlled release mechanism can be particularly beneficial in agricultural applications, where it can help decrease the leaching of fertilizers and pesticides into soil and water systems.

The biodegradability of sodium alginate is another key factor contributing to its positive environmental profile. As a naturally occurring polymer, alginate can be broken down by microorganisms in the environment, leaving behind no harmful residues. This characteristic is especially important in applications where the release system is intended to degrade over time, such as in soil amendments or marine environments.

However, it is essential to consider the potential ecological impacts of large-scale alginate production and use. The harvesting of brown seaweed for alginate extraction must be carefully managed to prevent overexploitation of marine ecosystems. Sustainable harvesting practices and the development of alternative sources, such as microbial production of alginate, are areas of ongoing research to address these concerns.

In aquatic environments, alginate-based release systems have shown promise in various applications, including the controlled release of nutrients for coral reef restoration and the removal of pollutants from water bodies. The ability of alginate to form hydrogels in the presence of divalent cations allows for the creation of stable structures that can slowly release beneficial substances or trap contaminants, potentially aiding in ecosystem recovery and water purification efforts.

The use of alginate-based release systems in pharmaceutical applications also has implications for environmental health. By improving drug delivery efficiency and reducing the frequency of administration, these systems can potentially decrease the amount of pharmaceutical residues entering the environment through wastewater systems. This is particularly relevant for compounds that are difficult to remove through conventional water treatment processes.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of alginate-based release systems to fully understand their environmental impact. This includes evaluating the energy and resource requirements for alginate production, the potential for recycling or reuse of alginate materials, and the long-term effects of degradation products in various ecosystems. Such assessments will be essential in guiding the sustainable development and application of these promising bioengineered release systems.

One of the primary environmental benefits of alginate-based release systems is their potential to reduce the overall use of chemicals and active ingredients. By encapsulating substances within alginate matrices, these systems can provide sustained and targeted release, minimizing the need for frequent applications and reducing the risk of environmental contamination. This controlled release mechanism can be particularly beneficial in agricultural applications, where it can help decrease the leaching of fertilizers and pesticides into soil and water systems.

The biodegradability of sodium alginate is another key factor contributing to its positive environmental profile. As a naturally occurring polymer, alginate can be broken down by microorganisms in the environment, leaving behind no harmful residues. This characteristic is especially important in applications where the release system is intended to degrade over time, such as in soil amendments or marine environments.

However, it is essential to consider the potential ecological impacts of large-scale alginate production and use. The harvesting of brown seaweed for alginate extraction must be carefully managed to prevent overexploitation of marine ecosystems. Sustainable harvesting practices and the development of alternative sources, such as microbial production of alginate, are areas of ongoing research to address these concerns.

In aquatic environments, alginate-based release systems have shown promise in various applications, including the controlled release of nutrients for coral reef restoration and the removal of pollutants from water bodies. The ability of alginate to form hydrogels in the presence of divalent cations allows for the creation of stable structures that can slowly release beneficial substances or trap contaminants, potentially aiding in ecosystem recovery and water purification efforts.

The use of alginate-based release systems in pharmaceutical applications also has implications for environmental health. By improving drug delivery efficiency and reducing the frequency of administration, these systems can potentially decrease the amount of pharmaceutical residues entering the environment through wastewater systems. This is particularly relevant for compounds that are difficult to remove through conventional water treatment processes.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of alginate-based release systems to fully understand their environmental impact. This includes evaluating the energy and resource requirements for alginate production, the potential for recycling or reuse of alginate materials, and the long-term effects of degradation products in various ecosystems. Such assessments will be essential in guiding the sustainable development and application of these promising bioengineered release systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!