How Sodium Alginate Supports Cell Encapsulation Techniques?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate in Cell Encapsulation: Background and Objectives

Sodium alginate has emerged as a pivotal biomaterial in cell encapsulation techniques, revolutionizing various fields including tissue engineering, regenerative medicine, and drug delivery systems. This natural polysaccharide, derived from brown algae, has gained significant attention due to its unique properties that make it ideal for creating protective microenvironments for cells.

The journey of sodium alginate in cell encapsulation began in the 1960s when researchers first explored its potential for immobilizing enzymes and microorganisms. However, it wasn't until the 1980s that its application in mammalian cell encapsulation gained momentum, marking a significant milestone in biomedical research.

Over the past few decades, the use of sodium alginate in cell encapsulation has evolved dramatically, driven by advancements in polymer science, bioengineering, and cellular biology. This evolution has been characterized by improvements in alginate purification methods, modifications to enhance its biocompatibility, and the development of more sophisticated encapsulation techniques.

The primary objective of using sodium alginate in cell encapsulation is to create a protective, three-dimensional matrix that mimics the natural extracellular environment. This matrix serves multiple purposes: it shields encapsulated cells from mechanical stress and immune responses, allows for the diffusion of nutrients and oxygen, and enables the controlled release of therapeutic molecules produced by the encapsulated cells.

Recent technological advancements have expanded the potential applications of alginate-based cell encapsulation. These include the development of hybrid alginate systems, incorporating other biomaterials to enhance functionality, and the use of 3D bioprinting techniques to create more complex, tissue-like structures.

The growing interest in personalized medicine and cell-based therapies has further propelled research into sodium alginate encapsulation. Scientists are now exploring its use in creating artificial organs, developing novel drug delivery systems, and enhancing cell-based cancer treatments.

As we look towards the future, the objectives for sodium alginate in cell encapsulation are multifaceted. Researchers aim to improve the long-term stability of alginate capsules, enhance their biocompatibility, and develop methods for precise control over capsule properties. There is also a focus on scaling up production processes to meet clinical demands and regulatory standards.

Understanding the fundamental mechanisms by which sodium alginate supports cell encapsulation is crucial for achieving these objectives. This includes investigating the interactions between alginate and cellular components, optimizing gelation processes, and exploring ways to functionalize alginate matrices for specific applications.

The journey of sodium alginate in cell encapsulation began in the 1960s when researchers first explored its potential for immobilizing enzymes and microorganisms. However, it wasn't until the 1980s that its application in mammalian cell encapsulation gained momentum, marking a significant milestone in biomedical research.

Over the past few decades, the use of sodium alginate in cell encapsulation has evolved dramatically, driven by advancements in polymer science, bioengineering, and cellular biology. This evolution has been characterized by improvements in alginate purification methods, modifications to enhance its biocompatibility, and the development of more sophisticated encapsulation techniques.

The primary objective of using sodium alginate in cell encapsulation is to create a protective, three-dimensional matrix that mimics the natural extracellular environment. This matrix serves multiple purposes: it shields encapsulated cells from mechanical stress and immune responses, allows for the diffusion of nutrients and oxygen, and enables the controlled release of therapeutic molecules produced by the encapsulated cells.

Recent technological advancements have expanded the potential applications of alginate-based cell encapsulation. These include the development of hybrid alginate systems, incorporating other biomaterials to enhance functionality, and the use of 3D bioprinting techniques to create more complex, tissue-like structures.

The growing interest in personalized medicine and cell-based therapies has further propelled research into sodium alginate encapsulation. Scientists are now exploring its use in creating artificial organs, developing novel drug delivery systems, and enhancing cell-based cancer treatments.

As we look towards the future, the objectives for sodium alginate in cell encapsulation are multifaceted. Researchers aim to improve the long-term stability of alginate capsules, enhance their biocompatibility, and develop methods for precise control over capsule properties. There is also a focus on scaling up production processes to meet clinical demands and regulatory standards.

Understanding the fundamental mechanisms by which sodium alginate supports cell encapsulation is crucial for achieving these objectives. This includes investigating the interactions between alginate and cellular components, optimizing gelation processes, and exploring ways to functionalize alginate matrices for specific applications.

Market Analysis for Cell Encapsulation Technologies

The cell encapsulation technology market has been experiencing significant growth in recent years, driven by the increasing demand for advanced cell-based therapies and regenerative medicine applications. This market segment is expected to continue its upward trajectory due to the rising prevalence of chronic diseases, advancements in biotechnology, and the growing focus on personalized medicine.

Cell encapsulation technologies, particularly those utilizing sodium alginate, have gained traction across various sectors of the healthcare industry. The pharmaceutical and biotechnology sectors are the primary drivers of market growth, as these technologies offer promising solutions for drug delivery systems, tissue engineering, and cell-based therapies. The ability of sodium alginate to create a protective barrier around cells while allowing for nutrient exchange and waste removal has made it a preferred choice for many applications.

In the field of regenerative medicine, cell encapsulation technologies are being extensively explored for treating conditions such as diabetes, neurodegenerative disorders, and cardiovascular diseases. The potential to deliver therapeutic cells to specific sites in the body while protecting them from immune rejection has sparked considerable interest among researchers and clinicians alike.

The global market for cell encapsulation technologies is characterized by a diverse range of players, including large pharmaceutical companies, biotechnology firms, and specialized research institutions. North America currently holds the largest market share, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in healthcare infrastructure and rising awareness of advanced therapies.

Key factors influencing market growth include technological advancements in encapsulation materials and techniques, increasing research and development activities, and growing collaborations between academic institutions and industry players. However, challenges such as regulatory hurdles, high development costs, and concerns regarding long-term efficacy and safety of encapsulated cells may impact market expansion.

The market for sodium alginate-based cell encapsulation technologies is particularly promising, as this natural polymer offers several advantages over synthetic alternatives. Its biocompatibility, ease of manipulation, and cost-effectiveness have contributed to its widespread adoption in research and clinical applications. As a result, companies specializing in sodium alginate-based encapsulation solutions are likely to see increased demand and market opportunities in the near future.

Cell encapsulation technologies, particularly those utilizing sodium alginate, have gained traction across various sectors of the healthcare industry. The pharmaceutical and biotechnology sectors are the primary drivers of market growth, as these technologies offer promising solutions for drug delivery systems, tissue engineering, and cell-based therapies. The ability of sodium alginate to create a protective barrier around cells while allowing for nutrient exchange and waste removal has made it a preferred choice for many applications.

In the field of regenerative medicine, cell encapsulation technologies are being extensively explored for treating conditions such as diabetes, neurodegenerative disorders, and cardiovascular diseases. The potential to deliver therapeutic cells to specific sites in the body while protecting them from immune rejection has sparked considerable interest among researchers and clinicians alike.

The global market for cell encapsulation technologies is characterized by a diverse range of players, including large pharmaceutical companies, biotechnology firms, and specialized research institutions. North America currently holds the largest market share, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in healthcare infrastructure and rising awareness of advanced therapies.

Key factors influencing market growth include technological advancements in encapsulation materials and techniques, increasing research and development activities, and growing collaborations between academic institutions and industry players. However, challenges such as regulatory hurdles, high development costs, and concerns regarding long-term efficacy and safety of encapsulated cells may impact market expansion.

The market for sodium alginate-based cell encapsulation technologies is particularly promising, as this natural polymer offers several advantages over synthetic alternatives. Its biocompatibility, ease of manipulation, and cost-effectiveness have contributed to its widespread adoption in research and clinical applications. As a result, companies specializing in sodium alginate-based encapsulation solutions are likely to see increased demand and market opportunities in the near future.

Current Challenges in Sodium Alginate-Based Cell Encapsulation

Despite the promising potential of sodium alginate in cell encapsulation techniques, several challenges persist that hinder its widespread adoption and optimal performance. One of the primary issues is the variability in alginate composition and purity, which can significantly affect the mechanical properties and biocompatibility of the resulting hydrogels. This inconsistency makes it difficult to achieve reproducible results across different batches and studies, potentially impacting the reliability of cell encapsulation processes.

Another critical challenge is the limited control over the porosity and degradation rate of alginate-based hydrogels. The pore size and distribution within the hydrogel matrix play a crucial role in nutrient diffusion and waste removal for encapsulated cells. However, achieving precise control over these parameters remains challenging, often resulting in suboptimal cell viability and functionality over extended periods.

The mechanical stability of alginate hydrogels poses another significant hurdle. While alginate forms stable gels through ionic crosslinking, these structures can be susceptible to gradual dissolution in physiological conditions, particularly in the presence of chelating agents or monovalent ions. This instability can lead to premature release of encapsulated cells or compromise the integrity of the encapsulation system, limiting its long-term effectiveness in both in vitro and in vivo applications.

Immunogenicity and biocompatibility concerns also persist with sodium alginate-based encapsulation systems. Although alginate is generally considered biocompatible, some studies have reported inflammatory responses and fibrotic overgrowth around alginate capsules when implanted in vivo. This immune reaction can interfere with the function of encapsulated cells and potentially lead to graft failure in therapeutic applications.

The scalability of alginate-based cell encapsulation techniques presents another challenge, particularly for large-scale production and clinical applications. Current methods often struggle to maintain uniform capsule size and shape when scaling up, which can affect the overall performance and reproducibility of the encapsulation system.

Lastly, the limited functionalization options for alginate hydrogels restrict their ability to mimic complex extracellular matrix environments. While alginate provides a suitable 3D structure for cell encapsulation, it lacks the biological cues and cell-adhesion motifs found in natural tissues. This limitation can impact cell behavior, differentiation, and long-term viability within the encapsulation system.

Addressing these challenges requires interdisciplinary approaches, combining materials science, bioengineering, and cell biology to develop more robust and versatile sodium alginate-based cell encapsulation techniques. Ongoing research efforts focus on enhancing alginate purity, developing novel crosslinking strategies, and incorporating bioactive molecules to overcome these limitations and expand the potential applications of this promising biomaterial in regenerative medicine and tissue engineering.

Another critical challenge is the limited control over the porosity and degradation rate of alginate-based hydrogels. The pore size and distribution within the hydrogel matrix play a crucial role in nutrient diffusion and waste removal for encapsulated cells. However, achieving precise control over these parameters remains challenging, often resulting in suboptimal cell viability and functionality over extended periods.

The mechanical stability of alginate hydrogels poses another significant hurdle. While alginate forms stable gels through ionic crosslinking, these structures can be susceptible to gradual dissolution in physiological conditions, particularly in the presence of chelating agents or monovalent ions. This instability can lead to premature release of encapsulated cells or compromise the integrity of the encapsulation system, limiting its long-term effectiveness in both in vitro and in vivo applications.

Immunogenicity and biocompatibility concerns also persist with sodium alginate-based encapsulation systems. Although alginate is generally considered biocompatible, some studies have reported inflammatory responses and fibrotic overgrowth around alginate capsules when implanted in vivo. This immune reaction can interfere with the function of encapsulated cells and potentially lead to graft failure in therapeutic applications.

The scalability of alginate-based cell encapsulation techniques presents another challenge, particularly for large-scale production and clinical applications. Current methods often struggle to maintain uniform capsule size and shape when scaling up, which can affect the overall performance and reproducibility of the encapsulation system.

Lastly, the limited functionalization options for alginate hydrogels restrict their ability to mimic complex extracellular matrix environments. While alginate provides a suitable 3D structure for cell encapsulation, it lacks the biological cues and cell-adhesion motifs found in natural tissues. This limitation can impact cell behavior, differentiation, and long-term viability within the encapsulation system.

Addressing these challenges requires interdisciplinary approaches, combining materials science, bioengineering, and cell biology to develop more robust and versatile sodium alginate-based cell encapsulation techniques. Ongoing research efforts focus on enhancing alginate purity, developing novel crosslinking strategies, and incorporating bioactive molecules to overcome these limitations and expand the potential applications of this promising biomaterial in regenerative medicine and tissue engineering.

Existing Sodium Alginate Encapsulation Methodologies

01 Sodium alginate-based cell encapsulation methods

Sodium alginate is widely used for cell encapsulation due to its biocompatibility and ability to form hydrogels. Various techniques are employed to create alginate-based microspheres or beads for encapsulating cells, including droplet generation, microfluidic devices, and electrospraying. These methods allow for the controlled formation of uniform capsules that protect cells while allowing nutrient and waste exchange.- Sodium alginate as a cell encapsulation material: Sodium alginate is widely used as a biocompatible material for cell encapsulation due to its ability to form hydrogels. It provides a suitable environment for cell survival and function while protecting cells from external factors. The encapsulation process typically involves mixing cells with a sodium alginate solution and then crosslinking it to form a gel matrix.

- Optimization of alginate composition for cell encapsulation: The composition of sodium alginate can be optimized to enhance cell viability and functionality. This includes adjusting the molecular weight, viscosity, and concentration of alginate, as well as incorporating additives or modifying the crosslinking process. These optimizations aim to improve the mechanical properties, porosity, and biocompatibility of the encapsulation matrix.

- Encapsulation techniques for specific cell types: Different cell types may require specialized encapsulation techniques using sodium alginate. This includes adjusting the encapsulation parameters for stem cells, islet cells, or genetically modified cells. The techniques may involve co-encapsulation with supporting cells or biomolecules, or creating multi-layered capsules to enhance cell function and survival.

- Functionalization of alginate capsules: Sodium alginate capsules can be functionalized to enhance their properties for specific applications. This may include incorporating growth factors, drugs, or nanoparticles into the alginate matrix. Functionalization can improve cell growth, differentiation, or provide controlled release of therapeutic agents from the encapsulated cells.

- Applications of alginate-encapsulated cells: Cells encapsulated in sodium alginate have various applications in biotechnology and medicine. These include tissue engineering, cell therapy, drug screening, and biosensors. The encapsulated cells can be used for treating diseases, producing biopharmaceuticals, or as in vitro models for research and drug development.

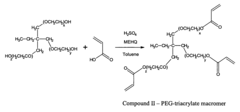

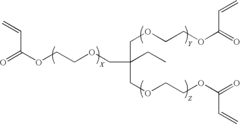

02 Modifications to sodium alginate for improved cell encapsulation

Researchers have developed modifications to sodium alginate to enhance its properties for cell encapsulation. These include combining alginate with other polymers, incorporating growth factors or bioactive molecules, and chemically modifying the alginate structure. Such modifications can improve cell viability, proliferation, and functionality within the encapsulated environment.Expand Specific Solutions03 Applications of sodium alginate cell encapsulation in tissue engineering

Sodium alginate cell encapsulation has found numerous applications in tissue engineering. It is used for creating 3D cell cultures, developing artificial organs, and producing scaffolds for tissue regeneration. This technology has been applied to various cell types, including stem cells, pancreatic islets, and hepatocytes, for potential therapeutic applications.Expand Specific Solutions04 Controlled release systems using sodium alginate encapsulation

Sodium alginate encapsulation is utilized in developing controlled release systems for drugs, proteins, and other bioactive compounds. By encapsulating these substances along with cells, it is possible to create localized delivery systems that can provide sustained release of therapeutic agents. This approach has potential applications in cancer treatment, wound healing, and other medical fields.Expand Specific Solutions05 Optimization of sodium alginate encapsulation conditions

Research focuses on optimizing various parameters of sodium alginate cell encapsulation to improve outcomes. This includes studying the effects of alginate concentration, crosslinking conditions, capsule size, and environmental factors on cell viability and functionality. Advanced characterization techniques are employed to assess the properties of the encapsulated cells and the alginate matrix.Expand Specific Solutions

Key Players in Cell Encapsulation Industry

The cell encapsulation techniques supported by sodium alginate are in a growth phase, with increasing market size and technological advancements. The industry is characterized by a mix of academic institutions, research organizations, and commercial entities driving innovation. Key players like Agency for Science, Technology & Research, Surmodics, Inc., and Brown University are contributing to the field's development. The technology's maturity is progressing, with universities such as Zhejiang University, National University of Singapore, and University of Miami conducting research to enhance its applications. Companies like NovaThera Ltd. and IP2IPO Innovations Ltd. are working on commercializing these techniques, indicating a growing interest in translating academic research into practical solutions.

Surmodics, Inc.

Technical Solution: Surmodics, Inc. has developed proprietary technologies for cell encapsulation using sodium alginate-based hydrogels. Their approach focuses on creating biocompatible coatings and matrices that enhance the performance of medical devices and cell-based therapies[17]. Surmodics has engineered alginate derivatives with improved stability and reduced immunogenicity, addressing key challenges in long-term cell encapsulation[18]. They've also developed methods for incorporating bioactive molecules into alginate matrices to promote cell survival and function[19]. Surmodics' technology has been applied to encapsulate pancreatic islets for diabetes treatment and has shown promise in drug delivery applications[20].

Strengths: Strong intellectual property portfolio, established manufacturing capabilities, and experience in regulatory approval processes. Weaknesses: Limited public information on specific technical details due to proprietary nature of their technologies.

National University of Singapore

Technical Solution: The National University of Singapore (NUS) has made significant contributions to sodium alginate-based cell encapsulation techniques. Their research focuses on developing novel alginate derivatives with improved biocompatibility and functionality[12]. NUS scientists have created alginate-based hydrogels with tunable degradation rates, allowing for controlled release of encapsulated cells over time[13]. They've also explored the use of alginate-chitosan complexes to enhance cell adhesion and proliferation within the capsules[14]. NUS has demonstrated success in encapsulating a wide range of cell types, including pancreatic islets for diabetes treatment and neural stem cells for brain injury repair[15]. Additionally, they've developed microfluidic platforms for high-throughput production of uniform alginate microcapsules[16].

Strengths: Strong interdisciplinary collaboration, focus on translational research, and expertise in biomaterials engineering. Weaknesses: Potential regulatory challenges in bringing novel alginate derivatives to clinical applications.

Innovations in Sodium Alginate Formulations for Cell Encapsulation

The manner of production of alginate cellular spheres and the manner of encapsulation of live cells or immobilization of biologically active substances in these spheres

PatentInactivePL381727A1

Innovation

- Incorporation of a surfactant, preferably a protein, into the sodium alginate solution to enhance foaming and stability of the cellular spheres.

- Mechanical foaming or gas-induced foaming (using CO2 or air) of the alginate mixture to create porous structures within the spheres.

- Submerging the foamed alginate droplets beneath the surface of the cross-linking solution for at least 1 second to ensure complete gelation.

Encapsulated cells using positively-charged initiator polymer

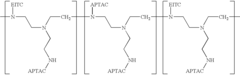

PatentInactiveUS8143043B2

Innovation

- Development of positively-charged polymerization initiator polymers with cationic portions that are soluble in aqueous solutions and specifically interact with biological surfaces, promoting polymerization of macromers using visible light activation, thereby forming a biocompatible polymeric matrix around cells.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in cell encapsulation techniques using sodium alginate. The primary concern is ensuring that the encapsulation process and the resulting alginate-based constructs do not adversely affect cell viability, function, or the surrounding host tissue upon implantation.

Sodium alginate, derived from brown seaweed, is generally recognized as safe (GRAS) by the FDA, which contributes to its widespread use in biomedical applications. However, the purity of the alginate is crucial, as contaminants can potentially trigger immune responses or affect cell behavior. High-grade, ultra-pure sodium alginate is typically used for cell encapsulation to minimize these risks.

The porosity of the alginate matrix plays a vital role in biocompatibility. It must allow for sufficient diffusion of nutrients, oxygen, and waste products while protecting encapsulated cells from immune attack. The molecular weight and guluronic acid content of the alginate influence this porosity and, consequently, the overall biocompatibility of the construct.

Cross-linking agents used in the gelation process, such as calcium chloride, must also be carefully considered. While calcium ions are physiologically compatible, the concentration and exposure time during cross-linking can impact cell viability. Optimizing these parameters is essential to maintain cell function without compromising the structural integrity of the alginate capsules.

Long-term stability of alginate capsules in physiological conditions is another critical factor. Gradual degradation of the alginate matrix can lead to the release of encapsulated cells, potentially triggering an immune response. Strategies to enhance stability, such as coating with poly-L-lysine or using alginate derivatives, must be evaluated for their impact on biocompatibility and cell function.

The immune response to alginate-encapsulated cells is a complex issue. While alginate itself is relatively inert, the presence of impurities or the release of cellular components can elicit an inflammatory response. This can lead to fibrosis around the implanted capsules, impeding nutrient diffusion and compromising cell viability. Techniques to mitigate this response, such as co-encapsulation with immunomodulatory molecules or surface modification of alginate, are active areas of research.

Safety considerations extend to the potential for uncontrolled cell growth or differentiation within the alginate matrix. This is particularly relevant when encapsulating stem cells or genetically modified cells. Careful characterization of cell behavior within the 3D alginate environment is necessary to ensure that the encapsulated cells maintain their desired phenotype and function over time.

Sodium alginate, derived from brown seaweed, is generally recognized as safe (GRAS) by the FDA, which contributes to its widespread use in biomedical applications. However, the purity of the alginate is crucial, as contaminants can potentially trigger immune responses or affect cell behavior. High-grade, ultra-pure sodium alginate is typically used for cell encapsulation to minimize these risks.

The porosity of the alginate matrix plays a vital role in biocompatibility. It must allow for sufficient diffusion of nutrients, oxygen, and waste products while protecting encapsulated cells from immune attack. The molecular weight and guluronic acid content of the alginate influence this porosity and, consequently, the overall biocompatibility of the construct.

Cross-linking agents used in the gelation process, such as calcium chloride, must also be carefully considered. While calcium ions are physiologically compatible, the concentration and exposure time during cross-linking can impact cell viability. Optimizing these parameters is essential to maintain cell function without compromising the structural integrity of the alginate capsules.

Long-term stability of alginate capsules in physiological conditions is another critical factor. Gradual degradation of the alginate matrix can lead to the release of encapsulated cells, potentially triggering an immune response. Strategies to enhance stability, such as coating with poly-L-lysine or using alginate derivatives, must be evaluated for their impact on biocompatibility and cell function.

The immune response to alginate-encapsulated cells is a complex issue. While alginate itself is relatively inert, the presence of impurities or the release of cellular components can elicit an inflammatory response. This can lead to fibrosis around the implanted capsules, impeding nutrient diffusion and compromising cell viability. Techniques to mitigate this response, such as co-encapsulation with immunomodulatory molecules or surface modification of alginate, are active areas of research.

Safety considerations extend to the potential for uncontrolled cell growth or differentiation within the alginate matrix. This is particularly relevant when encapsulating stem cells or genetically modified cells. Careful characterization of cell behavior within the 3D alginate environment is necessary to ensure that the encapsulated cells maintain their desired phenotype and function over time.

Scalability and Manufacturing Challenges

Scaling up cell encapsulation techniques using sodium alginate presents several significant challenges in manufacturing and production processes. One of the primary obstacles is maintaining consistent bead size and shape during large-scale production. As the volume of encapsulated cells increases, it becomes increasingly difficult to control the uniformity of alginate droplets, which can lead to variations in cell distribution and viability within the beads.

Another major challenge is the sterility and aseptic processing requirements for cell encapsulation. Maintaining a sterile environment throughout the entire production process is crucial for preventing contamination and ensuring the quality of the final product. This becomes more complex as production scales up, requiring specialized equipment and stringent quality control measures.

The gelation process of sodium alginate also poses scalability issues. In large-scale production, achieving uniform cross-linking of alginate chains can be problematic, potentially resulting in inconsistent bead properties. This can affect the mechanical strength, permeability, and overall functionality of the encapsulated cells.

Furthermore, the time-sensitive nature of the encapsulation process presents logistical challenges in large-scale manufacturing. The rapid gelation of alginate upon exposure to calcium ions necessitates precise timing and coordination in production workflows, which becomes increasingly complex as batch sizes grow.

The choice of equipment for large-scale cell encapsulation is another critical consideration. Traditional methods such as droplet extrusion may not be suitable for high-throughput production, necessitating the development of specialized equipment capable of handling larger volumes while maintaining precision and sterility.

Quality control and characterization of encapsulated cells also become more challenging at scale. Developing efficient methods for assessing bead integrity, cell viability, and functionality across large batches is essential for ensuring consistent product quality.

Lastly, the storage and transportation of large quantities of encapsulated cells present additional hurdles. Maintaining the stability and viability of encapsulated cells during extended storage periods and distribution requires careful consideration of preservation techniques and packaging solutions.

Addressing these scalability and manufacturing challenges is crucial for the widespread adoption of sodium alginate-based cell encapsulation techniques in industrial and clinical applications. Ongoing research and development efforts are focused on optimizing production processes, developing novel equipment, and improving quality control methods to overcome these obstacles and enable large-scale implementation of this promising technology.

Another major challenge is the sterility and aseptic processing requirements for cell encapsulation. Maintaining a sterile environment throughout the entire production process is crucial for preventing contamination and ensuring the quality of the final product. This becomes more complex as production scales up, requiring specialized equipment and stringent quality control measures.

The gelation process of sodium alginate also poses scalability issues. In large-scale production, achieving uniform cross-linking of alginate chains can be problematic, potentially resulting in inconsistent bead properties. This can affect the mechanical strength, permeability, and overall functionality of the encapsulated cells.

Furthermore, the time-sensitive nature of the encapsulation process presents logistical challenges in large-scale manufacturing. The rapid gelation of alginate upon exposure to calcium ions necessitates precise timing and coordination in production workflows, which becomes increasingly complex as batch sizes grow.

The choice of equipment for large-scale cell encapsulation is another critical consideration. Traditional methods such as droplet extrusion may not be suitable for high-throughput production, necessitating the development of specialized equipment capable of handling larger volumes while maintaining precision and sterility.

Quality control and characterization of encapsulated cells also become more challenging at scale. Developing efficient methods for assessing bead integrity, cell viability, and functionality across large batches is essential for ensuring consistent product quality.

Lastly, the storage and transportation of large quantities of encapsulated cells present additional hurdles. Maintaining the stability and viability of encapsulated cells during extended storage periods and distribution requires careful consideration of preservation techniques and packaging solutions.

Addressing these scalability and manufacturing challenges is crucial for the widespread adoption of sodium alginate-based cell encapsulation techniques in industrial and clinical applications. Ongoing research and development efforts are focused on optimizing production processes, developing novel equipment, and improving quality control methods to overcome these obstacles and enable large-scale implementation of this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!