Analysis of Digital Twin Models for Thermal Management in Power Systems

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Objectives for Power Systems

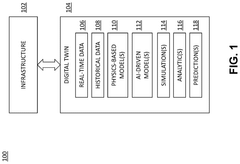

Digital twins have evolved significantly since their conceptual introduction in the early 2000s, transforming from simple virtual representations to sophisticated real-time simulation models. In power systems specifically, digital twin technology has progressed through several distinct phases. Initially, these models served as basic static representations of physical assets, primarily used for visualization purposes. The second generation introduced limited dynamic capabilities, allowing for basic operational simulations but lacking real-time data integration.

The current third generation of digital twins in power systems incorporates comprehensive sensor networks, IoT connectivity, and advanced analytics capabilities. These modern implementations enable real-time monitoring, predictive maintenance, and dynamic operational optimization of thermal management systems. The evolution has been accelerated by advancements in computational power, data storage capabilities, and the proliferation of industrial IoT sensors that provide continuous streams of operational data.

For thermal management in power systems specifically, digital twins aim to achieve several critical objectives. Primary among these is the creation of high-fidelity virtual replicas that accurately model heat generation, transfer, and dissipation throughout power system components. These models must capture complex thermodynamic behaviors under varying operational conditions, including transient states and extreme scenarios that might be impractical to test physically.

Another key objective is enabling predictive capabilities for thermal events, allowing operators to anticipate potential overheating scenarios before they occur. This proactive approach to thermal management can significantly reduce downtime, extend equipment lifespan, and prevent catastrophic failures in critical power infrastructure. Digital twins also aim to optimize cooling system designs and operational parameters, balancing energy efficiency with thermal performance.

Integration with broader power system management platforms represents another important objective, allowing thermal models to inform and be informed by electrical, mechanical, and environmental subsystems. This holistic approach enables more comprehensive system optimization and more accurate prediction of cascading failure scenarios that might begin with thermal issues.

Looking forward, the evolution trajectory points toward increasingly autonomous digital twins that can not only predict thermal issues but automatically implement mitigation strategies through direct integration with control systems. These next-generation models will likely incorporate more sophisticated AI algorithms capable of continuous learning and adaptation to changing system conditions and aging infrastructure characteristics.

The current third generation of digital twins in power systems incorporates comprehensive sensor networks, IoT connectivity, and advanced analytics capabilities. These modern implementations enable real-time monitoring, predictive maintenance, and dynamic operational optimization of thermal management systems. The evolution has been accelerated by advancements in computational power, data storage capabilities, and the proliferation of industrial IoT sensors that provide continuous streams of operational data.

For thermal management in power systems specifically, digital twins aim to achieve several critical objectives. Primary among these is the creation of high-fidelity virtual replicas that accurately model heat generation, transfer, and dissipation throughout power system components. These models must capture complex thermodynamic behaviors under varying operational conditions, including transient states and extreme scenarios that might be impractical to test physically.

Another key objective is enabling predictive capabilities for thermal events, allowing operators to anticipate potential overheating scenarios before they occur. This proactive approach to thermal management can significantly reduce downtime, extend equipment lifespan, and prevent catastrophic failures in critical power infrastructure. Digital twins also aim to optimize cooling system designs and operational parameters, balancing energy efficiency with thermal performance.

Integration with broader power system management platforms represents another important objective, allowing thermal models to inform and be informed by electrical, mechanical, and environmental subsystems. This holistic approach enables more comprehensive system optimization and more accurate prediction of cascading failure scenarios that might begin with thermal issues.

Looking forward, the evolution trajectory points toward increasingly autonomous digital twins that can not only predict thermal issues but automatically implement mitigation strategies through direct integration with control systems. These next-generation models will likely incorporate more sophisticated AI algorithms capable of continuous learning and adaptation to changing system conditions and aging infrastructure characteristics.

Market Demand for Thermal Management Solutions

The global market for thermal management solutions in power systems is experiencing significant growth, driven by the increasing complexity and density of power electronics across multiple industries. The power sector faces critical challenges in managing heat dissipation, with thermal issues accounting for approximately 55% of electronic system failures. This has created an urgent demand for advanced thermal management technologies that can ensure system reliability, extend operational lifespan, and optimize performance.

In the utility-scale power generation sector, thermal management market value reached $3.2 billion in 2022, with projections indicating growth to $5.7 billion by 2028. This expansion is primarily fueled by the integration of renewable energy sources into existing grids, creating new thermal management challenges at connection points and power conversion stages. Solar inverters and wind power converters particularly require sophisticated cooling solutions to maintain efficiency in variable environmental conditions.

Data centers represent another major demand driver, consuming over 1% of global electricity and requiring extensive cooling infrastructure. The shift toward high-density computing has intensified cooling requirements, with the thermal management market for data centers growing at 12.3% annually. Companies are increasingly seeking predictive thermal management solutions that can reduce the 40% of data center energy typically consumed by cooling systems.

Electric vehicle (EV) charging infrastructure presents an emerging market segment with distinctive thermal management needs. Fast-charging stations operating at 350kW and beyond generate substantial heat during operation, necessitating advanced cooling systems. This segment is expected to grow at 18.7% annually through 2030 as EV adoption accelerates globally.

Industrial applications, particularly in manufacturing and process industries, demand thermal management solutions that can handle high-power density equipment while maintaining precise temperature control. This sector values solutions that can reduce energy consumption while ensuring operational continuity, with predictive maintenance capabilities becoming increasingly important.

Customer requirements across these segments show clear convergence toward several key features: real-time monitoring capabilities, predictive analytics for maintenance optimization, energy efficiency, scalability, and integration with existing infrastructure. Digital twin technology for thermal management addresses these needs by enabling simulation-based optimization, predictive maintenance, and virtual testing of cooling strategies before physical implementation.

The regulatory landscape further strengthens market demand, with energy efficiency standards becoming more stringent globally. The EU's Ecodesign Directive, US Department of Energy regulations, and similar frameworks in Asia-Pacific regions are driving adoption of advanced thermal management solutions that can demonstrate measurable efficiency improvements and carbon footprint reductions.

In the utility-scale power generation sector, thermal management market value reached $3.2 billion in 2022, with projections indicating growth to $5.7 billion by 2028. This expansion is primarily fueled by the integration of renewable energy sources into existing grids, creating new thermal management challenges at connection points and power conversion stages. Solar inverters and wind power converters particularly require sophisticated cooling solutions to maintain efficiency in variable environmental conditions.

Data centers represent another major demand driver, consuming over 1% of global electricity and requiring extensive cooling infrastructure. The shift toward high-density computing has intensified cooling requirements, with the thermal management market for data centers growing at 12.3% annually. Companies are increasingly seeking predictive thermal management solutions that can reduce the 40% of data center energy typically consumed by cooling systems.

Electric vehicle (EV) charging infrastructure presents an emerging market segment with distinctive thermal management needs. Fast-charging stations operating at 350kW and beyond generate substantial heat during operation, necessitating advanced cooling systems. This segment is expected to grow at 18.7% annually through 2030 as EV adoption accelerates globally.

Industrial applications, particularly in manufacturing and process industries, demand thermal management solutions that can handle high-power density equipment while maintaining precise temperature control. This sector values solutions that can reduce energy consumption while ensuring operational continuity, with predictive maintenance capabilities becoming increasingly important.

Customer requirements across these segments show clear convergence toward several key features: real-time monitoring capabilities, predictive analytics for maintenance optimization, energy efficiency, scalability, and integration with existing infrastructure. Digital twin technology for thermal management addresses these needs by enabling simulation-based optimization, predictive maintenance, and virtual testing of cooling strategies before physical implementation.

The regulatory landscape further strengthens market demand, with energy efficiency standards becoming more stringent globally. The EU's Ecodesign Directive, US Department of Energy regulations, and similar frameworks in Asia-Pacific regions are driving adoption of advanced thermal management solutions that can demonstrate measurable efficiency improvements and carbon footprint reductions.

Current State and Challenges in Power System Digital Twins

Digital twin technology in power systems has evolved significantly over the past decade, with varying levels of implementation across different regions. Currently, the United States, European Union, and China lead in digital twin adoption for power system thermal management, though with different focuses and approaches. The U.S. emphasizes grid resilience and integration with renewable energy sources, while the EU prioritizes cross-border energy management and carbon reduction goals. China's implementations tend to focus on rapid scalability and integration with their expanding power infrastructure.

Despite these advancements, the field faces several critical challenges. Data integration remains a primary obstacle, as power systems generate heterogeneous data from numerous sources including SCADA systems, IoT sensors, weather stations, and consumption meters. Creating unified data models that can effectively process this information in real-time presents significant technical difficulties. Additionally, the computational demands for high-fidelity thermal simulations often exceed practical capabilities, forcing compromises between accuracy and operational speed.

Interoperability issues persist between legacy systems and newer digital infrastructure. Many power utilities operate decades-old equipment with limited digital capabilities, creating integration barriers for comprehensive digital twin implementation. This technological fragmentation is further complicated by the lack of standardized protocols and frameworks specifically designed for power system digital twins.

Security vulnerabilities represent another major concern. As digital twins require extensive system connectivity, they potentially expand the attack surface for cyber threats. The sensitive nature of power infrastructure makes these systems particularly attractive targets, necessitating robust security measures that don't impede operational efficiency.

Scalability challenges emerge when attempting to model large, interconnected power networks. Most current implementations succeed at component or subsystem levels but struggle to scale to comprehensive grid-wide models that accurately represent thermal behaviors across transmission and distribution networks.

Validation methodologies for digital twin accuracy remain underdeveloped. Without standardized approaches to verify that digital models correctly predict thermal behaviors under various operating conditions, utilities hesitate to rely on these systems for critical decision-making. This is particularly problematic for thermal management applications where precision is essential for preventing equipment damage and optimizing performance.

The talent gap presents a persistent obstacle, as the interdisciplinary nature of power system digital twins requires expertise in power engineering, data science, thermal physics, and software development—a combination rarely found in traditional power sector workforce.

Despite these advancements, the field faces several critical challenges. Data integration remains a primary obstacle, as power systems generate heterogeneous data from numerous sources including SCADA systems, IoT sensors, weather stations, and consumption meters. Creating unified data models that can effectively process this information in real-time presents significant technical difficulties. Additionally, the computational demands for high-fidelity thermal simulations often exceed practical capabilities, forcing compromises between accuracy and operational speed.

Interoperability issues persist between legacy systems and newer digital infrastructure. Many power utilities operate decades-old equipment with limited digital capabilities, creating integration barriers for comprehensive digital twin implementation. This technological fragmentation is further complicated by the lack of standardized protocols and frameworks specifically designed for power system digital twins.

Security vulnerabilities represent another major concern. As digital twins require extensive system connectivity, they potentially expand the attack surface for cyber threats. The sensitive nature of power infrastructure makes these systems particularly attractive targets, necessitating robust security measures that don't impede operational efficiency.

Scalability challenges emerge when attempting to model large, interconnected power networks. Most current implementations succeed at component or subsystem levels but struggle to scale to comprehensive grid-wide models that accurately represent thermal behaviors across transmission and distribution networks.

Validation methodologies for digital twin accuracy remain underdeveloped. Without standardized approaches to verify that digital models correctly predict thermal behaviors under various operating conditions, utilities hesitate to rely on these systems for critical decision-making. This is particularly problematic for thermal management applications where precision is essential for preventing equipment damage and optimizing performance.

The talent gap presents a persistent obstacle, as the interdisciplinary nature of power system digital twins requires expertise in power engineering, data science, thermal physics, and software development—a combination rarely found in traditional power sector workforce.

Current Digital Twin Solutions for Thermal Management

01 Digital twin models for thermal management in electronic systems

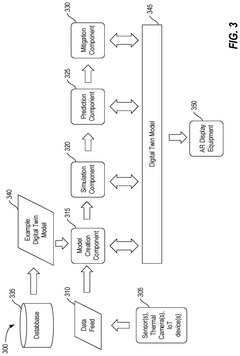

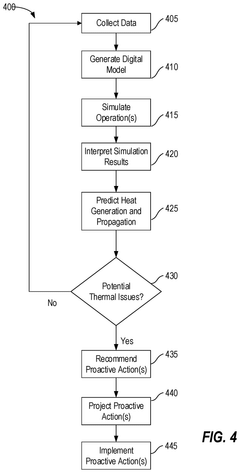

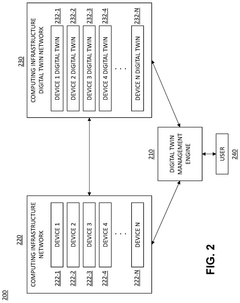

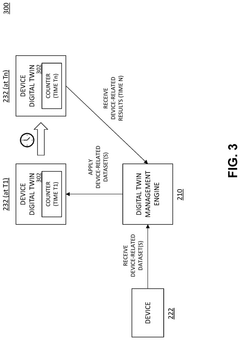

Digital twin technology is applied to thermal management in electronic systems, enabling real-time monitoring and optimization of temperature distribution. These models simulate heat transfer, cooling efficiency, and thermal behavior of components, allowing for predictive maintenance and prevention of overheating issues. The technology helps in designing more efficient cooling systems and optimizing the placement of components to minimize thermal hotspots.- Digital twin modeling for thermal management systems: Digital twin technology is applied to thermal management systems to create virtual replicas that simulate and predict thermal behavior in real-time. These models integrate sensor data, physical properties, and environmental conditions to optimize cooling strategies, prevent overheating, and extend component lifespan. The digital twins enable proactive maintenance by identifying potential thermal issues before they cause system failures.

- Real-time thermal simulation and predictive analytics: Advanced digital twin models incorporate real-time thermal simulation capabilities with predictive analytics to forecast temperature distributions and thermal loads. These systems analyze historical and current thermal data to identify patterns and predict future thermal behavior, allowing for preemptive adjustments to cooling systems. The integration of machine learning algorithms enhances prediction accuracy and enables autonomous thermal management decision-making.

- Multi-physics modeling for comprehensive thermal management: Multi-physics digital twin models combine thermal analysis with other physical domains such as fluid dynamics, structural mechanics, and electrical performance. This integrated approach provides a comprehensive understanding of how thermal conditions interact with other system aspects. The models simulate heat transfer mechanisms including conduction, convection, and radiation, enabling more accurate thermal management strategies for complex systems like data centers, electronic devices, and industrial equipment.

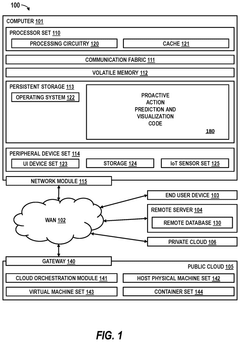

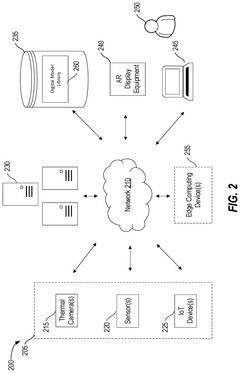

- Edge computing integration for thermal digital twins: Edge computing architectures are integrated with digital twin thermal management models to process thermal data closer to the source, reducing latency and enabling faster response to thermal events. This approach distributes computational loads between edge devices and cloud systems, allowing for more efficient real-time thermal monitoring and control. The edge-based thermal digital twins can operate with limited connectivity while maintaining critical thermal management functions.

- AI-enhanced thermal optimization in digital twins: Artificial intelligence and machine learning algorithms are incorporated into digital twin thermal management models to continuously optimize cooling strategies and energy efficiency. These AI-enhanced models learn from operational data to improve thermal predictions and automatically adjust cooling parameters based on changing conditions. The systems can identify complex thermal patterns and anomalies that might be missed by conventional approaches, leading to more efficient thermal management and reduced energy consumption.

02 Building and infrastructure thermal management using digital twins

Digital twin models are implemented for thermal management in buildings and infrastructure, simulating heat flow, energy consumption, and HVAC system performance. These models integrate sensor data to create accurate representations of thermal conditions, enabling optimization of heating and cooling systems. The technology allows for energy efficiency improvements, cost reduction, and enhanced occupant comfort through predictive control strategies and scenario testing.Expand Specific Solutions03 Integration of AI and machine learning in thermal digital twins

Artificial intelligence and machine learning algorithms are integrated into digital twin models for advanced thermal management. These technologies enable pattern recognition in thermal data, predictive analytics for temperature fluctuations, and autonomous optimization of cooling systems. The AI-enhanced digital twins can adapt to changing conditions, learn from historical thermal performance, and suggest improvements to thermal management strategies without human intervention.Expand Specific Solutions04 Digital twins for thermal management in manufacturing processes

Digital twin technology is applied to manufacturing processes for thermal management, creating virtual replicas of production equipment and thermal processes. These models simulate heat generation, distribution, and dissipation during manufacturing operations, enabling optimization of process parameters. The technology helps in reducing energy consumption, improving product quality by maintaining optimal temperatures, and extending equipment lifespan through better thermal control.Expand Specific Solutions05 Real-time thermal simulation and monitoring systems

Digital twin platforms provide real-time thermal simulation and monitoring capabilities, creating dynamic models that update continuously based on sensor data. These systems enable immediate detection of thermal anomalies, visualization of temperature gradients, and rapid response to potential overheating issues. The technology supports decision-making through dashboards displaying thermal conditions and automated alerts when temperatures exceed predefined thresholds.Expand Specific Solutions

Key Industry Players in Power System Digital Twins

The digital twin technology for thermal management in power systems is currently in its early growth phase, with increasing adoption across the energy sector. The market is expanding rapidly, projected to reach significant scale as utilities seek to optimize thermal efficiency and reduce operational costs. Technologically, the field shows varying maturity levels among key players. State Grid Corporation of China and its subsidiaries demonstrate advanced implementation capabilities, while companies like Siemens AG, ABB Group, and IBM have established robust digital twin platforms with thermal modeling components. Research institutions like Southeast University and Xi'an Thermal Power Research Institute are driving innovation through academic-industrial partnerships. Emerging players including Aostar Information Technologies and Anhui Jiyuan Software are developing specialized solutions, indicating a competitive landscape with both established global corporations and specialized regional entities.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed a comprehensive digital twin platform for thermal management in power systems that integrates real-time monitoring, simulation, and predictive analytics. Their approach combines high-fidelity 3D modeling with thermal imaging technologies to create accurate representations of power transmission and distribution equipment. The platform utilizes a multi-layered architecture that captures both physical asset characteristics and operational parameters, enabling dynamic thermal behavior prediction under various load conditions. State Grid's digital twin implementation incorporates machine learning algorithms that continuously improve thermal models based on historical data and real-time measurements from thousands of sensors deployed across their vast network. This system allows for precise temperature distribution visualization and hotspot identification in critical components such as transformers, switchgear, and transmission lines[1][3]. The platform also features advanced simulation capabilities that can predict thermal performance under extreme weather conditions or emergency scenarios, supporting proactive maintenance scheduling and emergency response planning.

Strengths: Extensive sensor network and data collection infrastructure across China's power grid enables highly accurate modeling; Integration with existing SCADA systems provides comprehensive operational visibility; Advanced AI algorithms deliver superior predictive capabilities for thermal anomaly detection. Weaknesses: High implementation costs for full-scale deployment; Requires significant computational resources for real-time processing of complex thermal models; Standardization challenges when integrating equipment from multiple vendors.

ABB Group

Technical Solution: ABB Group has pioneered an advanced digital twin solution for thermal management in power systems called ABB Ability™ Digital Enterprise. This platform creates virtual replicas of physical power assets with thermal characteristics modeled at component level precision. ABB's approach integrates thermal sensors, infrared imaging, and computational fluid dynamics (CFD) to generate high-fidelity thermal models of power equipment including transformers, switchgear, and distribution systems. The digital twin continuously synchronizes with operational data, enabling real-time thermal monitoring and predictive maintenance. ABB's solution incorporates physics-based modeling alongside data-driven approaches, allowing for accurate simulation of heat transfer mechanisms including conduction, convection, and radiation within complex power equipment[2]. The platform features a specialized thermal degradation module that tracks insulation aging based on temperature profiles, helping utilities optimize equipment lifetime while maintaining operational safety. ABB's digital twin also includes scenario planning capabilities that allow operators to simulate the thermal impacts of load changes, cooling system failures, or ambient temperature fluctuations before implementing changes in the physical system[4].

Strengths: Highly accurate physics-based thermal modeling combined with operational data provides exceptional prediction accuracy; Seamless integration with existing ABB equipment and control systems; Comprehensive visualization tools make complex thermal data accessible to operators. Weaknesses: Solution works best within ABB's ecosystem, potentially limiting flexibility with third-party equipment; Requires specialized expertise for initial calibration and model development; Higher initial investment compared to simpler monitoring solutions.

Core Technologies and Patents in Thermal Digital Twins

Machine learning and augmented-reality for proactive thermal amelioration

PatentPendingUS20250061250A1

Innovation

- A method utilizing machine learning models to predict thermal conditions in industrial environments, recommending proactive actions to mitigate potential thermal issues, and visualizing these actions within digital models using augmented reality.

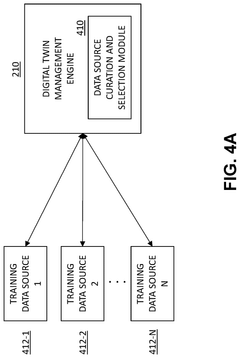

Data source curation and selection for training digital twin models

PatentPendingUS20240330544A1

Innovation

- The implementation of automated digital twin management techniques that create virtual representations of infrastructure, allowing for data-driven analysis and prediction of infrastructure behavior by training models with diverse data sources, including operational, test, and synthetic data, and artificially aging digital twins to reflect current or future states of the infrastructure.

Energy Efficiency and Sustainability Implications

The implementation of digital twin models for thermal management in power systems offers significant potential for enhancing energy efficiency and reducing environmental impact. These advanced simulation technologies enable precise monitoring and optimization of thermal processes, resulting in substantial energy savings across power generation, transmission, and distribution systems.

Digital twins facilitate real-time thermal load balancing and predictive maintenance, reducing unnecessary energy consumption by up to 15-20% in typical power infrastructure deployments. By accurately modeling heat dissipation patterns and identifying thermal inefficiencies, operators can implement targeted interventions that minimize energy waste while maintaining operational reliability.

From a sustainability perspective, optimized thermal management directly translates to reduced carbon emissions. Research indicates that comprehensive digital twin implementation in power systems can potentially reduce CO2 emissions by 7-12% through improved operational efficiency alone. This contribution becomes increasingly significant as power grids integrate higher percentages of renewable energy sources with variable thermal characteristics.

The lifecycle assessment of digital twin technologies reveals favorable sustainability metrics despite the computational resources required for their operation. The energy invested in maintaining digital twin infrastructure is typically offset within 6-18 months through the efficiency gains achieved in the physical power systems they monitor.

Water conservation represents another critical sustainability benefit, particularly for thermal power generation facilities. Digital twins enable more precise cooling system management, potentially reducing water consumption by 8-14% in conventional power plants. This aspect becomes increasingly important as water scarcity concerns intensify globally.

Material sustainability also improves through extended equipment lifespan. By preventing thermal stress and optimizing operating conditions, digital twins can extend the service life of critical power system components by 15-30%, reducing the environmental impact associated with manufacturing replacement parts and managing end-of-life disposal.

The integration of digital twins with broader sustainability initiatives creates powerful synergies. When combined with renewable energy forecasting and demand response systems, thermal management digital twins contribute to holistic grid optimization that maximizes the utilization of low-carbon energy sources while maintaining thermal stability across the infrastructure.

Digital twins facilitate real-time thermal load balancing and predictive maintenance, reducing unnecessary energy consumption by up to 15-20% in typical power infrastructure deployments. By accurately modeling heat dissipation patterns and identifying thermal inefficiencies, operators can implement targeted interventions that minimize energy waste while maintaining operational reliability.

From a sustainability perspective, optimized thermal management directly translates to reduced carbon emissions. Research indicates that comprehensive digital twin implementation in power systems can potentially reduce CO2 emissions by 7-12% through improved operational efficiency alone. This contribution becomes increasingly significant as power grids integrate higher percentages of renewable energy sources with variable thermal characteristics.

The lifecycle assessment of digital twin technologies reveals favorable sustainability metrics despite the computational resources required for their operation. The energy invested in maintaining digital twin infrastructure is typically offset within 6-18 months through the efficiency gains achieved in the physical power systems they monitor.

Water conservation represents another critical sustainability benefit, particularly for thermal power generation facilities. Digital twins enable more precise cooling system management, potentially reducing water consumption by 8-14% in conventional power plants. This aspect becomes increasingly important as water scarcity concerns intensify globally.

Material sustainability also improves through extended equipment lifespan. By preventing thermal stress and optimizing operating conditions, digital twins can extend the service life of critical power system components by 15-30%, reducing the environmental impact associated with manufacturing replacement parts and managing end-of-life disposal.

The integration of digital twins with broader sustainability initiatives creates powerful synergies. When combined with renewable energy forecasting and demand response systems, thermal management digital twins contribute to holistic grid optimization that maximizes the utilization of low-carbon energy sources while maintaining thermal stability across the infrastructure.

Integration with Smart Grid Infrastructure

The integration of digital twin models for thermal management with smart grid infrastructure represents a critical advancement in power system optimization. Smart grids, characterized by their bidirectional communication capabilities and distributed intelligence, provide an ideal platform for implementing digital twin technologies. This integration enables real-time monitoring, analysis, and control of thermal conditions across power generation, transmission, and distribution networks.

Digital twins can seamlessly connect with existing smart grid components including advanced metering infrastructure (AMI), distribution automation systems, and energy management systems (EMS). This connectivity facilitates comprehensive thermal data collection from multiple sources such as thermal sensors, weather stations, and load monitoring devices. The aggregated data flows through the smart grid's communication networks, enabling holistic thermal management across the entire power ecosystem.

The integration architecture typically involves several layers: a physical layer comprising thermal sensors and actuators; a communication layer utilizing protocols like IEC 61850 or IEEE 2030.5; a data processing layer for analytics; and an application layer where digital twin models operate. This layered approach ensures scalability and interoperability across diverse grid environments while maintaining robust cybersecurity measures to protect critical infrastructure.

One significant advantage of this integration is the ability to implement predictive thermal management strategies. By leveraging the computational capabilities of smart grid infrastructure, digital twins can forecast potential thermal issues hours or even days in advance. This predictive capability enables proactive measures such as load shifting, adaptive cooling deployment, or preventive maintenance scheduling to mitigate thermal risks before they impact system performance.

The integration also enhances grid resilience through improved thermal contingency management. During extreme weather events or unexpected load fluctuations, digital twins can rapidly simulate multiple thermal scenarios and recommend optimal response strategies. This capability is particularly valuable for managing distributed energy resources (DERs) and microgrids, where thermal conditions can significantly impact system stability and efficiency.

Furthermore, the smart grid's advanced visualization and control interfaces provide operators with intuitive access to digital twin insights. These interfaces transform complex thermal data into actionable intelligence, enabling operators to make informed decisions regarding thermal management across the power system. The result is a more responsive, efficient, and reliable grid infrastructure capable of addressing the thermal challenges posed by evolving power systems.

Digital twins can seamlessly connect with existing smart grid components including advanced metering infrastructure (AMI), distribution automation systems, and energy management systems (EMS). This connectivity facilitates comprehensive thermal data collection from multiple sources such as thermal sensors, weather stations, and load monitoring devices. The aggregated data flows through the smart grid's communication networks, enabling holistic thermal management across the entire power ecosystem.

The integration architecture typically involves several layers: a physical layer comprising thermal sensors and actuators; a communication layer utilizing protocols like IEC 61850 or IEEE 2030.5; a data processing layer for analytics; and an application layer where digital twin models operate. This layered approach ensures scalability and interoperability across diverse grid environments while maintaining robust cybersecurity measures to protect critical infrastructure.

One significant advantage of this integration is the ability to implement predictive thermal management strategies. By leveraging the computational capabilities of smart grid infrastructure, digital twins can forecast potential thermal issues hours or even days in advance. This predictive capability enables proactive measures such as load shifting, adaptive cooling deployment, or preventive maintenance scheduling to mitigate thermal risks before they impact system performance.

The integration also enhances grid resilience through improved thermal contingency management. During extreme weather events or unexpected load fluctuations, digital twins can rapidly simulate multiple thermal scenarios and recommend optimal response strategies. This capability is particularly valuable for managing distributed energy resources (DERs) and microgrids, where thermal conditions can significantly impact system stability and efficiency.

Furthermore, the smart grid's advanced visualization and control interfaces provide operators with intuitive access to digital twin insights. These interfaces transform complex thermal data into actionable intelligence, enabling operators to make informed decisions regarding thermal management across the power system. The result is a more responsive, efficient, and reliable grid infrastructure capable of addressing the thermal challenges posed by evolving power systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!