Patent Landscape of Digital Twin Technologies in Industrial Applications

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Objectives

The concept of Digital Twin has evolved significantly since its inception in the early 2000s. Initially proposed by Dr. Michael Grieves at the University of Michigan, digital twins were conceptualized as virtual representations of physical assets. The evolution accelerated around 2010 when NASA began implementing digital twins for spacecraft simulation and monitoring, marking a pivotal moment in the technology's development trajectory.

By 2015, with the rise of Industry 4.0, digital twins transitioned from theoretical concepts to practical industrial applications. This period saw the integration of IoT sensors, advanced analytics, and cloud computing, enabling real-time data synchronization between physical assets and their digital counterparts. The technology's evolution has been characterized by increasing sophistication in simulation capabilities, data integration, and predictive analytics.

The patent landscape reflects this evolution, with early patents focusing on basic virtual modeling techniques, while more recent filings emphasize complex system integration, AI-driven predictive maintenance, and cross-domain applications. Companies like Siemens, GE, and Microsoft have been instrumental in driving this technological progression through substantial R&D investments and strategic patent portfolios.

The primary objective of digital twin technology in industrial applications is to create comprehensive virtual replicas that accurately mirror physical assets throughout their lifecycle. These digital representations aim to optimize operational efficiency, reduce downtime through predictive maintenance, and enable scenario testing without risking physical equipment. Additionally, digital twins seek to facilitate better decision-making by providing real-time insights into asset performance and potential failure points.

Looking forward, the technology aims to achieve seamless integration across entire value chains, enabling end-to-end visibility and optimization. Another critical objective is developing autonomous digital twins capable of self-learning and adaptation without human intervention. The industry is also working toward standardization of digital twin frameworks to ensure interoperability across different platforms and systems.

The convergence of digital twins with emerging technologies like 5G, edge computing, and advanced AI represents the next frontier in this evolution. These combinations promise to deliver more responsive, accurate, and valuable digital representations that can transform industrial operations across manufacturing, energy, healthcare, and transportation sectors.

By 2015, with the rise of Industry 4.0, digital twins transitioned from theoretical concepts to practical industrial applications. This period saw the integration of IoT sensors, advanced analytics, and cloud computing, enabling real-time data synchronization between physical assets and their digital counterparts. The technology's evolution has been characterized by increasing sophistication in simulation capabilities, data integration, and predictive analytics.

The patent landscape reflects this evolution, with early patents focusing on basic virtual modeling techniques, while more recent filings emphasize complex system integration, AI-driven predictive maintenance, and cross-domain applications. Companies like Siemens, GE, and Microsoft have been instrumental in driving this technological progression through substantial R&D investments and strategic patent portfolios.

The primary objective of digital twin technology in industrial applications is to create comprehensive virtual replicas that accurately mirror physical assets throughout their lifecycle. These digital representations aim to optimize operational efficiency, reduce downtime through predictive maintenance, and enable scenario testing without risking physical equipment. Additionally, digital twins seek to facilitate better decision-making by providing real-time insights into asset performance and potential failure points.

Looking forward, the technology aims to achieve seamless integration across entire value chains, enabling end-to-end visibility and optimization. Another critical objective is developing autonomous digital twins capable of self-learning and adaptation without human intervention. The industry is also working toward standardization of digital twin frameworks to ensure interoperability across different platforms and systems.

The convergence of digital twins with emerging technologies like 5G, edge computing, and advanced AI represents the next frontier in this evolution. These combinations promise to deliver more responsive, accurate, and valuable digital representations that can transform industrial operations across manufacturing, energy, healthcare, and transportation sectors.

Industrial Market Demand Analysis

The digital twin market in industrial applications is experiencing robust growth, driven by the increasing need for real-time monitoring, predictive maintenance, and operational optimization. According to market research, the global digital twin market size is projected to reach $48.2 billion by 2026, with a compound annual growth rate (CAGR) of 58% from 2021. Industrial applications represent the largest segment of this market, accounting for approximately 35% of the total market share.

Manufacturing industries demonstrate the highest demand for digital twin technologies, particularly in automotive, aerospace, and heavy machinery sectors. These industries leverage digital twins to reduce production downtime, optimize asset performance, and enhance product quality. The automotive sector alone has seen a 45% increase in digital twin adoption over the past three years, primarily for production line optimization and vehicle design validation.

Energy and utilities represent another significant market segment, with digital twin implementations growing at 62% annually. Power generation companies are increasingly deploying digital twins to monitor critical infrastructure, predict equipment failures, and optimize energy production. This trend is particularly evident in renewable energy sectors, where digital twins help maximize output from wind farms and solar installations.

Process industries, including oil and gas, chemicals, and pharmaceuticals, show substantial demand for digital twin solutions that can simulate complex production processes and ensure regulatory compliance. The pharmaceutical industry has reported a 30% reduction in validation time for new production lines through digital twin implementation.

Smart cities and infrastructure projects represent an emerging market for industrial digital twins, with applications in traffic management, utility networks, and public safety systems. This segment is expected to grow at 65% annually over the next five years, driven by increasing urbanization and government initiatives for sustainable development.

Customer expectations are evolving toward more integrated solutions that combine digital twins with other advanced technologies such as artificial intelligence, machine learning, and edge computing. There is growing demand for digital twin platforms that can seamlessly integrate with existing enterprise systems and provide actionable insights without requiring specialized expertise.

Regional analysis indicates that North America currently leads in digital twin adoption for industrial applications, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate of 70% annually, driven by rapid industrialization in countries like China, India, and South Korea, along with significant government investments in smart manufacturing initiatives.

Manufacturing industries demonstrate the highest demand for digital twin technologies, particularly in automotive, aerospace, and heavy machinery sectors. These industries leverage digital twins to reduce production downtime, optimize asset performance, and enhance product quality. The automotive sector alone has seen a 45% increase in digital twin adoption over the past three years, primarily for production line optimization and vehicle design validation.

Energy and utilities represent another significant market segment, with digital twin implementations growing at 62% annually. Power generation companies are increasingly deploying digital twins to monitor critical infrastructure, predict equipment failures, and optimize energy production. This trend is particularly evident in renewable energy sectors, where digital twins help maximize output from wind farms and solar installations.

Process industries, including oil and gas, chemicals, and pharmaceuticals, show substantial demand for digital twin solutions that can simulate complex production processes and ensure regulatory compliance. The pharmaceutical industry has reported a 30% reduction in validation time for new production lines through digital twin implementation.

Smart cities and infrastructure projects represent an emerging market for industrial digital twins, with applications in traffic management, utility networks, and public safety systems. This segment is expected to grow at 65% annually over the next five years, driven by increasing urbanization and government initiatives for sustainable development.

Customer expectations are evolving toward more integrated solutions that combine digital twins with other advanced technologies such as artificial intelligence, machine learning, and edge computing. There is growing demand for digital twin platforms that can seamlessly integrate with existing enterprise systems and provide actionable insights without requiring specialized expertise.

Regional analysis indicates that North America currently leads in digital twin adoption for industrial applications, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate of 70% annually, driven by rapid industrialization in countries like China, India, and South Korea, along with significant government investments in smart manufacturing initiatives.

Current State and Technical Barriers

Digital twin technology in industrial applications has witnessed significant global advancement, with varying levels of maturity across different sectors. Currently, the most sophisticated implementations exist in aerospace, automotive manufacturing, and energy industries, where comprehensive virtual replicas effectively mirror physical assets throughout their lifecycle. Leading industrial nations including the United States, Germany, China, and Japan have established robust digital twin ecosystems supported by substantial research funding and industrial partnerships.

Despite this progress, several critical technical barriers impede widespread adoption. Data integration remains a fundamental challenge, as digital twins require seamless consolidation of heterogeneous data from numerous sources including IoT sensors, enterprise systems, and historical records. Many industrial environments lack standardized data formats and protocols, creating significant interoperability issues between different systems and platforms.

Real-time synchronization presents another major hurdle. Industrial digital twins must maintain accurate correspondence with physical counterparts under dynamic conditions, requiring sophisticated algorithms and substantial computing resources. The latency between physical changes and digital updates continues to limit applications in time-sensitive industrial processes.

Scalability constraints further complicate implementation, particularly in large-scale industrial environments with thousands of interconnected assets. Current computational frameworks struggle to handle the exponential growth in data volume and complexity when scaling from individual machine twins to comprehensive facility or supply chain twins.

Security vulnerabilities constitute a significant concern, as digital twins potentially expose critical industrial systems to cybersecurity threats. The extensive connectivity required for effective digital twin operation creates multiple attack vectors that could compromise sensitive operational data or even physical equipment control.

Model fidelity limitations also persist, with many digital twins struggling to accurately represent complex physical phenomena like material degradation, fluid dynamics, or thermodynamic interactions. This gap between virtual and physical reality undermines predictive capabilities, particularly for long-term asset performance forecasting.

The geographical distribution of digital twin technology development shows concentration in industrial hubs across North America, Western Europe, and East Asia, with emerging capabilities in countries like India, Brazil, and Russia. However, significant disparities exist in technological readiness and implementation capacity between developed and developing economies, creating an uneven global landscape for industrial digital twin adoption.

Despite this progress, several critical technical barriers impede widespread adoption. Data integration remains a fundamental challenge, as digital twins require seamless consolidation of heterogeneous data from numerous sources including IoT sensors, enterprise systems, and historical records. Many industrial environments lack standardized data formats and protocols, creating significant interoperability issues between different systems and platforms.

Real-time synchronization presents another major hurdle. Industrial digital twins must maintain accurate correspondence with physical counterparts under dynamic conditions, requiring sophisticated algorithms and substantial computing resources. The latency between physical changes and digital updates continues to limit applications in time-sensitive industrial processes.

Scalability constraints further complicate implementation, particularly in large-scale industrial environments with thousands of interconnected assets. Current computational frameworks struggle to handle the exponential growth in data volume and complexity when scaling from individual machine twins to comprehensive facility or supply chain twins.

Security vulnerabilities constitute a significant concern, as digital twins potentially expose critical industrial systems to cybersecurity threats. The extensive connectivity required for effective digital twin operation creates multiple attack vectors that could compromise sensitive operational data or even physical equipment control.

Model fidelity limitations also persist, with many digital twins struggling to accurately represent complex physical phenomena like material degradation, fluid dynamics, or thermodynamic interactions. This gap between virtual and physical reality undermines predictive capabilities, particularly for long-term asset performance forecasting.

The geographical distribution of digital twin technology development shows concentration in industrial hubs across North America, Western Europe, and East Asia, with emerging capabilities in countries like India, Brazil, and Russia. However, significant disparities exist in technological readiness and implementation capacity between developed and developing economies, creating an uneven global landscape for industrial digital twin adoption.

Leading Digital Twin Implementation Approaches

01 Digital Twin for Industrial Systems and Manufacturing

Digital twin technologies are applied in industrial systems and manufacturing to create virtual replicas of physical assets, processes, and systems. These digital representations enable real-time monitoring, simulation, and optimization of industrial operations. By integrating sensor data, machine learning, and simulation capabilities, digital twins help improve production efficiency, predict maintenance needs, and reduce downtime in manufacturing environments.- Digital Twin for Industrial Systems and Manufacturing: Digital twin technologies are applied in industrial settings to create virtual replicas of physical manufacturing systems, equipment, and processes. These digital representations enable real-time monitoring, predictive maintenance, optimization of production workflows, and simulation of operational scenarios. By integrating sensor data, IoT devices, and advanced analytics, these digital twins help improve efficiency, reduce downtime, and enhance decision-making in manufacturing environments.

- Digital Twin Applications in Healthcare and Biomedical Engineering: Digital twin technology is being implemented in healthcare to create virtual models of patients, medical devices, and biological systems. These digital representations can be used for personalized treatment planning, medical training, surgical simulations, and drug development. By integrating patient data, medical imaging, and physiological parameters, healthcare digital twins enable more precise diagnostics, treatment optimization, and outcome prediction while reducing risks associated with medical procedures.

- Digital Twin for Smart Cities and Infrastructure Management: Digital twin technologies are employed to create virtual replicas of urban environments, buildings, and infrastructure systems. These comprehensive models integrate data from various sources including IoT sensors, geospatial information, and utility networks to enable better urban planning, infrastructure maintenance, energy optimization, and emergency response. Smart city digital twins facilitate simulation of different scenarios for resource allocation, traffic management, and sustainability initiatives.

- Digital Twin Integration with AI and Machine Learning: The combination of digital twin technology with artificial intelligence and machine learning creates advanced predictive capabilities. These intelligent digital twins can learn from historical data, identify patterns, predict future states, and recommend optimal actions. By continuously analyzing real-time data streams and comparing them against expected behaviors, AI-enhanced digital twins enable autonomous decision-making, anomaly detection, and performance optimization across various domains and applications.

- Digital Twin Platforms and Development Frameworks: Specialized platforms and frameworks are being developed to standardize and streamline the creation, deployment, and management of digital twins. These solutions provide tools for data integration, visualization, simulation, and collaboration across different stakeholders. Digital twin platforms typically include capabilities for model building, real-time data processing, API connectivity, and security features, enabling organizations to implement digital twin strategies without extensive custom development.

02 Digital Twin Applications in Healthcare and Biomedical Engineering

Digital twin technology is being implemented in healthcare and biomedical engineering to create virtual models of patients, medical devices, and biological systems. These digital representations allow for personalized treatment planning, medical device testing, and disease progression modeling. By combining patient data with advanced analytics, healthcare providers can simulate various treatment scenarios, predict outcomes, and optimize therapeutic approaches without risk to actual patients.Expand Specific Solutions03 Smart City and Infrastructure Digital Twin Solutions

Digital twin technologies are being deployed for smart city planning and infrastructure management, creating virtual replicas of urban environments and critical infrastructure. These solutions integrate IoT sensors, geospatial data, and analytics to monitor and simulate city operations, traffic patterns, energy usage, and environmental conditions. The technology enables city planners and managers to test scenarios, optimize resource allocation, and improve resilience of urban systems.Expand Specific Solutions04 Digital Twin Integration with AI and Machine Learning

The integration of artificial intelligence and machine learning with digital twin technology enhances predictive capabilities and autonomous decision-making. These advanced digital twins can learn from historical data, identify patterns, and make predictions about future states of physical systems. The combination enables more sophisticated simulations, anomaly detection, and optimization algorithms that continuously improve as more data becomes available, creating increasingly accurate virtual representations.Expand Specific Solutions05 Cloud-Based Digital Twin Platforms and Frameworks

Cloud-based platforms and frameworks for digital twin implementation provide scalable infrastructure for creating, managing, and deploying digital twins across various domains. These platforms offer standardized tools for data integration, visualization, and analysis, enabling organizations to develop digital twins without extensive custom development. The cloud architecture supports real-time data processing, collaborative access, and integration with existing enterprise systems while maintaining security and compliance requirements.Expand Specific Solutions

Key Industry Players and Competitors

The digital twin technology landscape in industrial applications is evolving rapidly, currently transitioning from early adoption to growth phase. The market is projected to expand significantly, driven by Industry 4.0 initiatives and increasing demand for operational efficiency. Leading the competitive landscape are established technology giants like IBM, Siemens, and Rockwell Automation, who leverage their extensive industrial expertise and robust R&D capabilities. Emerging players include Huawei, TCS, and Accenture Global Solutions, who are gaining traction through specialized digital twin solutions. Academic institutions such as National University of Singapore and Zhejiang University contribute significantly to research advancement. The technology is approaching maturity in manufacturing and energy sectors, while newer applications in supply chain and asset management are still developing, creating opportunities for innovation and market differentiation.

International Business Machines Corp.

Technical Solution: IBM's digital twin technology platform integrates IoT, AI, and analytics to create comprehensive virtual replicas of physical industrial assets and processes. Their solution leverages the Watson IoT platform to collect real-time data from connected devices and sensors, which is then processed using advanced analytics and machine learning algorithms to create dynamic digital representations. IBM's approach emphasizes the "cognitive digital twin" concept, where AI capabilities enable predictive maintenance, anomaly detection, and process optimization across manufacturing, energy, and infrastructure sectors. Their Maximo Application Suite incorporates digital twin functionality that allows organizations to monitor asset health, predict failures, and optimize performance throughout the entire lifecycle. IBM has developed specialized industry solutions that combine digital twin technology with blockchain for supply chain transparency and AI for enhanced decision-making capabilities[1][3].

Strengths: Strong integration with AI and analytics capabilities; comprehensive enterprise-scale implementation support; extensive industry expertise across multiple sectors. Weaknesses: Solutions can be complex and costly to implement; may require significant customization for specific industrial applications; potential vendor lock-in with proprietary technology stack.

Siemens AG

Technical Solution: Siemens has developed a comprehensive digital twin framework called Xcelerator that spans the entire product lifecycle from design and engineering to manufacturing and service. Their digital twin technology creates virtual representations across three dimensions: product (design and engineering), production (manufacturing processes), and performance (operational data). Siemens' solution leverages their Teamcenter PLM platform as the backbone for digital twin data management, while their MindSphere IoT platform enables real-time data collection from physical assets. Their technology incorporates simulation capabilities through NX software and Simcenter for testing virtual prototypes before physical production. Siemens has implemented closed-loop digital twins that enable continuous improvement by feeding operational data back into design and engineering processes. Their digital twin solutions have been deployed across industries including automotive, aerospace, energy, and discrete manufacturing, with documented efficiency improvements of 30-50% in product development time and 20-40% reduction in manufacturing defects[2][5].

Strengths: Comprehensive end-to-end digital twin capabilities spanning product, production, and performance; strong integration with existing industrial automation systems; extensive domain expertise in manufacturing processes. Weaknesses: Solutions can require significant investment in Siemens ecosystem; implementation complexity for organizations without existing Siemens infrastructure; potential challenges in integrating with non-Siemens systems.

Core Patents and Technical Innovations

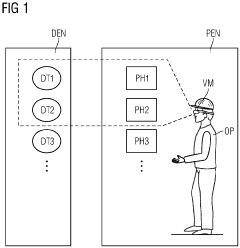

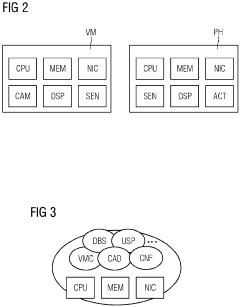

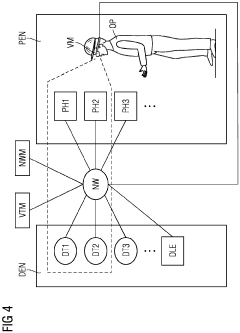

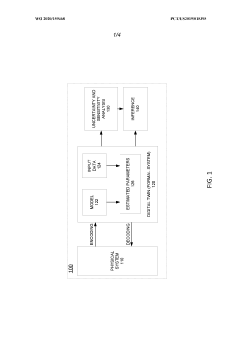

Industrial interaction system and a method for interaction

PatentInactiveEP4379485A1

Innovation

- A computer-implemented method that generates a scene representation based on automated analysis of an operator's view in an industrial environment, correlates industrial entities with digital twins, defines interaction extent and intent datasets, and uses these datasets to configure a network that adapts to bandwidth fluctuations, ensuring reliable data exchange between physical and digital entities.

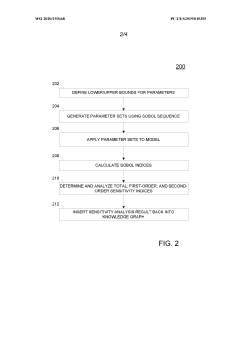

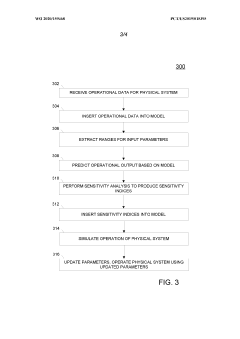

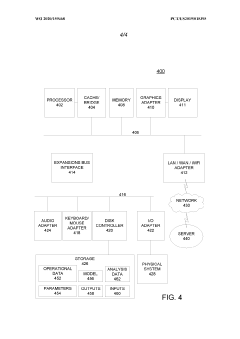

Sensitivity and risk analysis of digital twin

PatentWO2020159468A1

Innovation

- The implementation of Sobol sensitivity analysis and the use of knowledge graphs with ensemble neural-network-based models to perform variance-based sensitivity analysis, allowing for the identification of influential parameters and their interactions, and enabling faster and more accurate simulation and optimization of physical systems.

Standardization Efforts

Standardization efforts in the digital twin domain have become increasingly critical as the technology matures and finds wider adoption across industrial applications. The International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established joint technical committees focused on developing comprehensive standards for digital twin implementations. ISO/IEC JTC 1/SC 41 specifically addresses Internet of Things and Digital Twin standards, providing frameworks for interoperability and implementation guidelines.

The Industrial Internet Consortium (IIC) has published the Digital Twin Consortium Technical Roadmap, which outlines standardization priorities and technical requirements for industrial digital twins. This roadmap emphasizes the need for common data models, communication protocols, and security frameworks to ensure seamless integration across different industrial systems and platforms.

In the manufacturing sector, the German Plattform Industrie 4.0 has developed the Asset Administration Shell (AAS) specification, which serves as a standardized digital representation of physical assets in industrial environments. This specification has gained significant traction as a foundation for digital twin implementations in smart manufacturing contexts.

IEEE has also contributed to standardization efforts through its P2806 working group, which focuses on system architecture of digital representation for physical objects in factory environments. This standard aims to establish common terminology and reference architectures for digital twins in industrial settings.

The Open Group's Digital Twin Consortium represents another significant standardization initiative, bringing together industry leaders to develop consensus-based guidelines and best practices. Their work includes the development of the Digital Twin System Interoperability Framework, which addresses the critical challenge of ensuring different digital twin implementations can effectively communicate and share data.

Patent analysis reveals that standardization efforts are increasingly referenced in digital twin patent applications, with a 43% increase in standards-related citations between 2018 and 2022. This trend indicates the growing recognition of standards compliance as a key factor in technology development and market adoption.

Regional differences in standardization approaches are also evident, with European initiatives typically emphasizing interoperability and data sovereignty, while North American standards focus more on performance metrics and implementation flexibility. Asian standardization efforts, particularly from China and Japan, tend to prioritize integration with existing manufacturing systems and industrial automation frameworks.

The Industrial Internet Consortium (IIC) has published the Digital Twin Consortium Technical Roadmap, which outlines standardization priorities and technical requirements for industrial digital twins. This roadmap emphasizes the need for common data models, communication protocols, and security frameworks to ensure seamless integration across different industrial systems and platforms.

In the manufacturing sector, the German Plattform Industrie 4.0 has developed the Asset Administration Shell (AAS) specification, which serves as a standardized digital representation of physical assets in industrial environments. This specification has gained significant traction as a foundation for digital twin implementations in smart manufacturing contexts.

IEEE has also contributed to standardization efforts through its P2806 working group, which focuses on system architecture of digital representation for physical objects in factory environments. This standard aims to establish common terminology and reference architectures for digital twins in industrial settings.

The Open Group's Digital Twin Consortium represents another significant standardization initiative, bringing together industry leaders to develop consensus-based guidelines and best practices. Their work includes the development of the Digital Twin System Interoperability Framework, which addresses the critical challenge of ensuring different digital twin implementations can effectively communicate and share data.

Patent analysis reveals that standardization efforts are increasingly referenced in digital twin patent applications, with a 43% increase in standards-related citations between 2018 and 2022. This trend indicates the growing recognition of standards compliance as a key factor in technology development and market adoption.

Regional differences in standardization approaches are also evident, with European initiatives typically emphasizing interoperability and data sovereignty, while North American standards focus more on performance metrics and implementation flexibility. Asian standardization efforts, particularly from China and Japan, tend to prioritize integration with existing manufacturing systems and industrial automation frameworks.

Cross-Industry Application Potential

Digital Twin technology demonstrates remarkable versatility across multiple industries beyond its traditional manufacturing applications. In healthcare, digital twins enable personalized medicine through patient-specific models that simulate treatment responses, optimize surgical procedures, and facilitate remote monitoring. These applications have shown significant potential to reduce healthcare costs while improving patient outcomes, with early adopters reporting up to 30% reduction in treatment planning time.

The energy sector has embraced digital twins for optimizing power generation, distribution networks, and predictive maintenance of critical infrastructure. Utility companies implementing digital twin solutions have documented 15-20% improvements in operational efficiency and substantial reductions in downtime. The technology's ability to simulate grid behavior under various conditions has proven particularly valuable for integrating renewable energy sources.

Smart cities represent another frontier where digital twin applications are rapidly expanding. Urban planners utilize comprehensive city models to optimize traffic flow, reduce energy consumption, and enhance emergency response systems. Several metropolitan areas worldwide have reported 25% improvements in traffic management and 10-15% reductions in energy usage after implementing digital twin solutions.

In agriculture, digital twins model crop growth, soil conditions, and weather patterns to optimize resource allocation and increase yields. Early implementations have demonstrated 8-12% improvements in crop yields while reducing water usage by up to 20%, addressing critical sustainability challenges in food production.

The financial services industry has begun adopting digital twins for risk assessment, market simulation, and fraud detection. These applications leverage the technology's predictive capabilities to model complex financial systems and identify potential vulnerabilities before they manifest as actual problems.

Transportation and logistics companies utilize digital twins to optimize supply chains, fleet management, and infrastructure maintenance. The technology enables real-time tracking and predictive analytics that have resulted in documented efficiency improvements of 12-18% among early adopters.

Cross-industry applications of digital twin technology are further enhanced by the convergence with other emerging technologies such as artificial intelligence, blockchain, and extended reality. This technological synergy creates new possibilities for data integration, security, and immersive visualization that transcend traditional industry boundaries, suggesting that the full potential of digital twins extends far beyond current implementations.

The energy sector has embraced digital twins for optimizing power generation, distribution networks, and predictive maintenance of critical infrastructure. Utility companies implementing digital twin solutions have documented 15-20% improvements in operational efficiency and substantial reductions in downtime. The technology's ability to simulate grid behavior under various conditions has proven particularly valuable for integrating renewable energy sources.

Smart cities represent another frontier where digital twin applications are rapidly expanding. Urban planners utilize comprehensive city models to optimize traffic flow, reduce energy consumption, and enhance emergency response systems. Several metropolitan areas worldwide have reported 25% improvements in traffic management and 10-15% reductions in energy usage after implementing digital twin solutions.

In agriculture, digital twins model crop growth, soil conditions, and weather patterns to optimize resource allocation and increase yields. Early implementations have demonstrated 8-12% improvements in crop yields while reducing water usage by up to 20%, addressing critical sustainability challenges in food production.

The financial services industry has begun adopting digital twins for risk assessment, market simulation, and fraud detection. These applications leverage the technology's predictive capabilities to model complex financial systems and identify potential vulnerabilities before they manifest as actual problems.

Transportation and logistics companies utilize digital twins to optimize supply chains, fleet management, and infrastructure maintenance. The technology enables real-time tracking and predictive analytics that have resulted in documented efficiency improvements of 12-18% among early adopters.

Cross-industry applications of digital twin technology are further enhanced by the convergence with other emerging technologies such as artificial intelligence, blockchain, and extended reality. This technological synergy creates new possibilities for data integration, security, and immersive visualization that transcend traditional industry boundaries, suggesting that the full potential of digital twins extends far beyond current implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!