Comparative Study of Digital Twin Use in Aviation vs Automotive Sectors

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Objectives in Transportation

Digital twins have evolved significantly in the transportation sector over the past decade, transforming from simple virtual representations to sophisticated real-time simulation models. Initially, digital twin technology emerged in manufacturing around 2002 when Dr. Michael Grieves introduced the concept at the University of Michigan. However, its application in transportation began to gain traction only after 2010, when advances in IoT, cloud computing, and big data analytics made comprehensive digital modeling more feasible.

In aviation, digital twins first appeared as maintenance tools for aircraft engines, with companies like GE Aviation pioneering their implementation to monitor performance and predict maintenance needs. The technology gradually expanded to encompass entire aircraft systems, enabling manufacturers to simulate flight conditions and component interactions with unprecedented accuracy.

The automotive sector adopted digital twins slightly later but has since accelerated implementation across vehicle development cycles. Initially focused on design and prototyping phases, automotive digital twins now extend through manufacturing, testing, and after-sales service, creating a continuous feedback loop throughout the product lifecycle.

Both sectors have witnessed a parallel evolution from static models to dynamic, real-time systems capable of processing vast amounts of sensor data. This progression has been marked by three distinct generations: descriptive twins (virtual representations), analytical twins (incorporating analytics), and predictive twins (featuring AI-driven forecasting capabilities).

The primary objectives of digital twin technology in transportation revolve around enhancing safety, reliability, efficiency, and sustainability. In aviation, digital twins aim to improve flight safety through predictive maintenance, optimize fuel consumption, and reduce aircraft downtime. The technology also supports certification processes by providing comprehensive simulation data that can supplement physical testing requirements.

For automotive applications, digital twins focus on accelerating vehicle development cycles, reducing prototype costs, improving manufacturing precision, and enabling advanced driver assistance systems. As autonomous vehicles advance, digital twins serve as critical testing environments for validating complex algorithms under diverse conditions without physical risk.

A convergent objective across both sectors is sustainability improvement through optimized design and operation. Digital twins enable engineers to model environmental impact factors and identify efficiency opportunities that might otherwise remain undiscovered through conventional methods.

Looking forward, the evolution trajectory points toward increasingly integrated digital twins that span entire transportation ecosystems rather than individual vehicles, potentially revolutionizing traffic management, infrastructure planning, and intermodal transportation coordination.

In aviation, digital twins first appeared as maintenance tools for aircraft engines, with companies like GE Aviation pioneering their implementation to monitor performance and predict maintenance needs. The technology gradually expanded to encompass entire aircraft systems, enabling manufacturers to simulate flight conditions and component interactions with unprecedented accuracy.

The automotive sector adopted digital twins slightly later but has since accelerated implementation across vehicle development cycles. Initially focused on design and prototyping phases, automotive digital twins now extend through manufacturing, testing, and after-sales service, creating a continuous feedback loop throughout the product lifecycle.

Both sectors have witnessed a parallel evolution from static models to dynamic, real-time systems capable of processing vast amounts of sensor data. This progression has been marked by three distinct generations: descriptive twins (virtual representations), analytical twins (incorporating analytics), and predictive twins (featuring AI-driven forecasting capabilities).

The primary objectives of digital twin technology in transportation revolve around enhancing safety, reliability, efficiency, and sustainability. In aviation, digital twins aim to improve flight safety through predictive maintenance, optimize fuel consumption, and reduce aircraft downtime. The technology also supports certification processes by providing comprehensive simulation data that can supplement physical testing requirements.

For automotive applications, digital twins focus on accelerating vehicle development cycles, reducing prototype costs, improving manufacturing precision, and enabling advanced driver assistance systems. As autonomous vehicles advance, digital twins serve as critical testing environments for validating complex algorithms under diverse conditions without physical risk.

A convergent objective across both sectors is sustainability improvement through optimized design and operation. Digital twins enable engineers to model environmental impact factors and identify efficiency opportunities that might otherwise remain undiscovered through conventional methods.

Looking forward, the evolution trajectory points toward increasingly integrated digital twins that span entire transportation ecosystems rather than individual vehicles, potentially revolutionizing traffic management, infrastructure planning, and intermodal transportation coordination.

Market Demand Analysis for Digital Twin Technologies

The digital twin market is experiencing significant growth across various industries, with particularly strong demand in aviation and automotive sectors. Current market analysis indicates that the global digital twin market is projected to reach $48.2 billion by 2026, growing at a CAGR of 58% from 2021. Within this broader market, aviation and automotive sectors represent key growth drivers, collectively accounting for approximately 30% of the total market share.

In the aviation sector, market demand for digital twin technologies is primarily driven by the need for predictive maintenance, operational efficiency improvements, and safety enhancement. Airlines and aircraft manufacturers are increasingly adopting digital twins to monitor aircraft health in real-time, optimize maintenance schedules, and extend the operational lifespan of critical components. Boeing and Airbus have reported maintenance cost reductions of up to 25% through digital twin implementation, creating a compelling business case for wider adoption.

The automotive industry demonstrates different market demand characteristics, focusing predominantly on production optimization, vehicle design enhancement, and supply chain management. Automotive manufacturers are leveraging digital twins to simulate production processes, test new vehicle designs virtually, and optimize assembly line operations. Market research indicates that automotive companies implementing digital twin technologies have achieved production efficiency improvements of 15-20% and reduced time-to-market for new vehicle models by up to 30%.

Consumer expectations are also shaping market demand differently across these sectors. In aviation, passengers prioritize safety and reliability, driving airlines to invest in digital twins for enhanced predictive maintenance. In contrast, automotive consumers increasingly demand personalization and connectivity features, pushing manufacturers to utilize digital twins for customized vehicle development and connected car services.

Regional market analysis reveals varying adoption rates, with North America leading in aviation digital twin implementation while Europe shows stronger demand in the automotive sector. Asia-Pacific represents the fastest-growing market for both sectors, with China and Japan making significant investments in digital twin technologies for their aviation and automotive industries.

Market forecasts suggest that by 2025, over 85% of major aviation companies and 70% of automotive manufacturers will have implemented some form of digital twin technology in their operations. This adoption is expected to be accelerated by decreasing implementation costs, increasing availability of IoT sensors, and advancements in AI and machine learning capabilities that enhance digital twin functionality and value proposition.

In the aviation sector, market demand for digital twin technologies is primarily driven by the need for predictive maintenance, operational efficiency improvements, and safety enhancement. Airlines and aircraft manufacturers are increasingly adopting digital twins to monitor aircraft health in real-time, optimize maintenance schedules, and extend the operational lifespan of critical components. Boeing and Airbus have reported maintenance cost reductions of up to 25% through digital twin implementation, creating a compelling business case for wider adoption.

The automotive industry demonstrates different market demand characteristics, focusing predominantly on production optimization, vehicle design enhancement, and supply chain management. Automotive manufacturers are leveraging digital twins to simulate production processes, test new vehicle designs virtually, and optimize assembly line operations. Market research indicates that automotive companies implementing digital twin technologies have achieved production efficiency improvements of 15-20% and reduced time-to-market for new vehicle models by up to 30%.

Consumer expectations are also shaping market demand differently across these sectors. In aviation, passengers prioritize safety and reliability, driving airlines to invest in digital twins for enhanced predictive maintenance. In contrast, automotive consumers increasingly demand personalization and connectivity features, pushing manufacturers to utilize digital twins for customized vehicle development and connected car services.

Regional market analysis reveals varying adoption rates, with North America leading in aviation digital twin implementation while Europe shows stronger demand in the automotive sector. Asia-Pacific represents the fastest-growing market for both sectors, with China and Japan making significant investments in digital twin technologies for their aviation and automotive industries.

Market forecasts suggest that by 2025, over 85% of major aviation companies and 70% of automotive manufacturers will have implemented some form of digital twin technology in their operations. This adoption is expected to be accelerated by decreasing implementation costs, increasing availability of IoT sensors, and advancements in AI and machine learning capabilities that enhance digital twin functionality and value proposition.

Current Digital Twin Implementation Challenges

Despite the promising potential of digital twins in both aviation and automotive sectors, several significant implementation challenges persist. The complexity of creating accurate virtual replicas of physical assets remains a primary obstacle. In aviation, the intricate nature of aircraft systems with thousands of components requires extensive computational resources and sophisticated modeling techniques that often exceed current capabilities. Similarly, automotive manufacturers struggle with the granularity required for comprehensive vehicle twins that can accurately simulate real-world performance across diverse operating conditions.

Data integration presents another formidable challenge. Both sectors generate massive volumes of heterogeneous data from multiple sources including sensors, maintenance records, and operational logs. Aviation companies face particular difficulties with legacy systems that weren't designed for real-time data sharing, while automotive manufacturers struggle with standardizing data formats across global supply chains. The absence of unified data architectures impedes the seamless flow of information necessary for dynamic digital twin updates.

Security and privacy concerns significantly impact implementation efforts. Aviation's stringent safety regulations require extensive validation of digital twin systems before deployment, creating lengthy approval processes. Meanwhile, automotive manufacturers must navigate complex data ownership questions, especially as vehicles increasingly collect driver behavior data that may have privacy implications. Both sectors face cybersecurity vulnerabilities as digital twins create new potential attack surfaces.

Cost justification remains problematic across both industries. The substantial initial investment required for digital twin infrastructure—including specialized software, hardware, and skilled personnel—often lacks clear ROI metrics. Aviation companies struggle to quantify benefits like improved maintenance scheduling against implementation costs, while automotive manufacturers face challenges demonstrating how digital twins translate to competitive advantages in consumer markets.

Technical expertise shortages further complicate implementation. Both sectors report difficulties recruiting and retaining specialists with the multidisciplinary skills required for digital twin development—combining domain knowledge with data science, simulation expertise, and systems integration capabilities. Aviation faces particular challenges finding personnel with both aeronautical engineering expertise and advanced digital modeling skills.

Interoperability issues between different systems and platforms create significant barriers. The lack of standardized protocols for digital twin development means that solutions often exist in isolated environments, limiting their utility across organizational boundaries. This challenge is particularly acute in automotive supply chains where tier suppliers and OEMs must collaborate on integrated systems without established digital twin standards.

Data integration presents another formidable challenge. Both sectors generate massive volumes of heterogeneous data from multiple sources including sensors, maintenance records, and operational logs. Aviation companies face particular difficulties with legacy systems that weren't designed for real-time data sharing, while automotive manufacturers struggle with standardizing data formats across global supply chains. The absence of unified data architectures impedes the seamless flow of information necessary for dynamic digital twin updates.

Security and privacy concerns significantly impact implementation efforts. Aviation's stringent safety regulations require extensive validation of digital twin systems before deployment, creating lengthy approval processes. Meanwhile, automotive manufacturers must navigate complex data ownership questions, especially as vehicles increasingly collect driver behavior data that may have privacy implications. Both sectors face cybersecurity vulnerabilities as digital twins create new potential attack surfaces.

Cost justification remains problematic across both industries. The substantial initial investment required for digital twin infrastructure—including specialized software, hardware, and skilled personnel—often lacks clear ROI metrics. Aviation companies struggle to quantify benefits like improved maintenance scheduling against implementation costs, while automotive manufacturers face challenges demonstrating how digital twins translate to competitive advantages in consumer markets.

Technical expertise shortages further complicate implementation. Both sectors report difficulties recruiting and retaining specialists with the multidisciplinary skills required for digital twin development—combining domain knowledge with data science, simulation expertise, and systems integration capabilities. Aviation faces particular challenges finding personnel with both aeronautical engineering expertise and advanced digital modeling skills.

Interoperability issues between different systems and platforms create significant barriers. The lack of standardized protocols for digital twin development means that solutions often exist in isolated environments, limiting their utility across organizational boundaries. This challenge is particularly acute in automotive supply chains where tier suppliers and OEMs must collaborate on integrated systems without established digital twin standards.

Current Digital Twin Architectures and Frameworks

01 Digital Twin for Industrial Systems and Manufacturing

Digital twins are virtual replicas of physical industrial systems and manufacturing processes that enable real-time monitoring, simulation, and optimization. These digital models collect data from sensors and IoT devices to create accurate representations of equipment, production lines, and facilities. By analyzing this data, manufacturers can predict maintenance needs, optimize production processes, and improve operational efficiency while reducing downtime and costs.- Digital Twin for Industrial Systems and Manufacturing: Digital twins are virtual replicas of physical industrial systems and manufacturing processes that enable real-time monitoring, simulation, and optimization. These digital models integrate IoT sensors, AI, and analytics to mirror the behavior of physical assets, allowing for predictive maintenance, process optimization, and enhanced operational efficiency. By creating a virtual representation of manufacturing equipment and production lines, companies can identify potential issues before they occur, optimize performance, and reduce downtime.

- Digital Twin in Healthcare and Medical Applications: Digital twin technology is being applied in healthcare to create virtual models of patients, medical devices, and healthcare systems. These digital replicas enable personalized medicine approaches, treatment optimization, and improved patient outcomes. By simulating physiological processes and responses to treatments, healthcare providers can develop tailored interventions, predict disease progression, and test medical devices virtually before physical implementation. Digital twins also facilitate remote patient monitoring and healthcare facility optimization.

- Digital Twin for Smart Cities and Infrastructure: Digital twin technology is revolutionizing urban planning and infrastructure management by creating virtual replicas of cities, buildings, and utility networks. These comprehensive models integrate real-time data from various sources including IoT sensors, traffic systems, and environmental monitors to simulate urban environments. This enables city planners and managers to optimize resource allocation, improve sustainability, enhance emergency response, and test infrastructure changes before physical implementation, ultimately creating more resilient and efficient urban environments.

- Digital Twin Integration with AI and Machine Learning: The integration of artificial intelligence and machine learning with digital twin technology creates intelligent virtual models that can learn, adapt, and make predictions based on data analysis. These AI-enhanced digital twins can identify patterns, anomalies, and optimization opportunities that might be missed by traditional analysis. The combination enables autonomous decision-making capabilities, continuous improvement through learning algorithms, and more accurate predictive modeling. This integration is particularly valuable for complex systems where traditional modeling approaches are insufficient.

- Digital Twin for Product Development and Lifecycle Management: Digital twin technology transforms product development and lifecycle management by creating virtual replicas of products from conception through retirement. These digital models enable designers and engineers to simulate product performance under various conditions, optimize designs before physical prototyping, and monitor products throughout their operational life. The approach reduces development costs, accelerates time-to-market, enables predictive maintenance, and facilitates continuous improvement through real-world performance feedback, ultimately extending product lifespan and improving sustainability.

02 Digital Twin for Healthcare and Medical Applications

Digital twin technology in healthcare creates virtual models of patients, medical devices, or biological systems to improve diagnosis, treatment planning, and personalized medicine. These virtual replicas use patient-specific data to simulate physiological responses, predict outcomes, and optimize treatment protocols. The technology enables healthcare providers to test interventions virtually before applying them to actual patients, reducing risks and improving outcomes while supporting medical research and development.Expand Specific Solutions03 Digital Twin for Smart Cities and Infrastructure

Digital twins for urban environments and infrastructure create comprehensive virtual models of cities, buildings, transportation networks, and utility systems. These models integrate data from various sources including IoT sensors, cameras, and existing databases to simulate urban dynamics and infrastructure performance. City planners and managers can use these digital replicas to optimize resource allocation, improve emergency response, enhance sustainability efforts, and test the impact of proposed changes before implementation.Expand Specific Solutions04 Digital Twin Integration with AI and Machine Learning

The integration of artificial intelligence and machine learning with digital twin technology enhances predictive capabilities and autonomous decision-making. AI algorithms analyze the vast amounts of data collected by digital twins to identify patterns, predict failures, and recommend optimizations. This combination enables more sophisticated simulations, real-time anomaly detection, and adaptive responses to changing conditions, creating increasingly intelligent and self-improving virtual models that can learn from historical data and ongoing operations.Expand Specific Solutions05 Digital Twin Security and Data Management

Security frameworks and data management systems for digital twin implementations address the challenges of protecting sensitive information while enabling effective data sharing and integration. These solutions include secure communication protocols, access control mechanisms, and data governance frameworks designed specifically for the complex ecosystems of digital twins. Advanced encryption methods and blockchain technology can be employed to maintain data integrity while enabling the necessary connectivity between physical assets and their virtual counterparts.Expand Specific Solutions

Key Industry Players in Aviation and Automotive Digital Twins

The digital twin technology landscape in aviation and automotive sectors is evolving at different rates, with aviation currently at a more mature implementation stage while automotive applications are rapidly expanding. The market for digital twin technology across both sectors is projected to grow significantly, reaching approximately $35-40 billion by 2025, driven by increasing demands for operational efficiency and predictive maintenance. In aviation, companies like Boeing, Airbus Operations, and GE have established sophisticated digital twin ecosystems for aircraft lifecycle management, while automotive players including Toyota, Ford, BYD, and Volvo are accelerating adoption for vehicle development and manufacturing optimization. Academic institutions such as Xi'an Jiaotong University and Northwestern Polytechnical University are contributing significant research to bridge implementation gaps between these sectors, focusing on standardization and interoperability challenges.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered automotive Digital Twin technology through their "Ford Integrated Vehicle Digital Twin" platform that creates virtual replicas of vehicles throughout the development and production cycles. Their approach combines CAD/CAM design data with real-world testing information to create high-fidelity simulations of vehicle performance. Ford's Digital Twin implementation incorporates manufacturing process simulation, allowing engineers to optimize assembly procedures before physical production begins. The company has integrated their Digital Twin platform with vehicle connectivity systems, enabling continuous data collection from vehicles in the field that feeds back into design improvements. Ford utilizes this technology extensively in their electric vehicle development, creating digital models that simulate battery performance, thermal management, and powertrain efficiency under various driving conditions. Their Digital Twin approach has reportedly accelerated product development cycles by approximately 20% while reducing physical prototype costs by up to 30%. Ford has also implemented Digital Twin technology in their manufacturing facilities, creating virtual representations of assembly lines to optimize production flow and identify potential bottlenecks before they impact operations.

Strengths: Ford's Digital Twin technology excels in production optimization and supply chain integration, allowing for rapid manufacturing adjustments and efficient resource allocation. Their system effectively bridges the gap between design and production phases. Weaknesses: The technology currently has limitations in capturing all real-world variables affecting vehicle performance, particularly in extreme environmental conditions or unusual driving scenarios.

The Boeing Co.

Technical Solution: Boeing has developed an advanced Digital Twin framework called the "Digital Thread" that creates comprehensive virtual representations of their aircraft throughout the entire lifecycle. Their approach integrates design data, manufacturing processes, and operational performance metrics into a unified digital ecosystem. Boeing's Digital Twin implementation enables real-time monitoring of aircraft components, predictive maintenance scheduling, and performance optimization. The company utilizes sensor networks across critical aircraft systems that continuously feed data to their cloud-based analytics platform, allowing for comparison between actual performance and digital simulations. This technology has been particularly valuable for the 777X program, where Boeing created complete digital representations before physical manufacturing, enabling virtual testing of aerodynamics, structural integrity, and systems integration. Boeing's Digital Twin technology has reportedly reduced design-to-production time by approximately 25% and maintenance-related downtime by up to 30% for airline operators.

Strengths: Boeing's Digital Twin technology excels in comprehensive lifecycle management, from design through retirement, providing exceptional visibility into aircraft performance. Their integration with IoT sensor networks enables real-time monitoring capabilities that enhance safety and reliability. Weaknesses: The system requires substantial computing infrastructure and specialized expertise to maintain, creating high implementation costs and potential barriers to adoption for smaller aviation entities.

Critical Technologies Enabling Digital Twin Applications

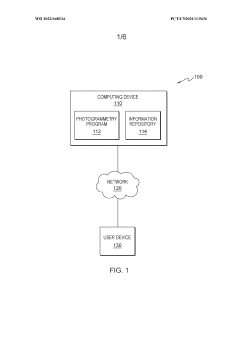

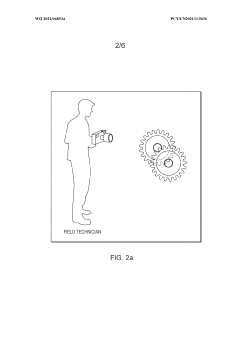

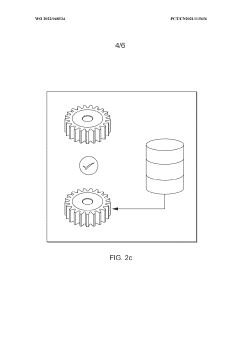

Digital twin multi-dimensional model record using photogrammetry

PatentWO2022048534A1

Innovation

- Integration of photogrammetry techniques with digital twin technology to create multi-dimensional model records, enabling more accurate virtual representations of physical assets.

- Creation of a comprehensive life-cycle tracking system that uses photogrammetric data to dynamically update digital twin models, allowing for improved decision making and system optimization.

- Development of a cross-sector digital twin framework that adapts photogrammetry techniques to the specific requirements of both aviation and automotive industries, facilitating knowledge transfer between domains.

Digital twin and a method for a heavy-duty vehicle

PatentPendingUS20230306156A1

Innovation

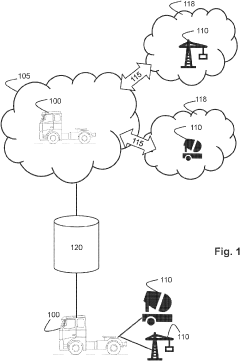

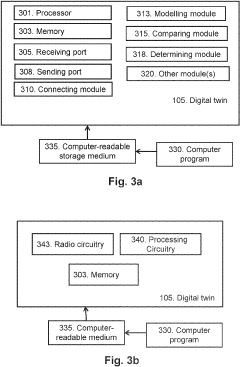

- A digital twin system that includes interfaces to connect with replaceable digital modules for auxiliary devices, allowing real-time data transfer and modeling of power consumption based on the operating state, vehicle state, and environmental conditions, enabling accurate assessment of power requirements and optimization of auxiliary device usage.

ROI and Business Value Assessment

The ROI and business value assessment of digital twin technology reveals significant differences between aviation and automotive sectors. In aviation, digital twins deliver exceptional long-term value with ROI typically realized over 3-5 years, reflecting the industry's longer development cycles and asset lifespans. Airlines and manufacturers report 15-20% maintenance cost reductions and 25-30% decreases in unscheduled downtime through predictive maintenance capabilities, translating to millions in savings for high-value assets like commercial aircraft.

Aviation digital twins demonstrate particular strength in lifecycle management, with Boeing and Airbus reporting 7-12% reductions in total lifecycle costs. The technology's ability to simulate complex systems has reduced development time for new aircraft components by up to 18%, while enhancing safety compliance—a critical value driver unique to aviation.

By contrast, automotive implementations show faster ROI realization, typically within 1-3 years, aligned with the industry's shorter product cycles. Manufacturing efficiency improvements dominate the value proposition, with production optimization yielding 8-15% efficiency gains and 10-20% reductions in quality-related costs. Tesla and BMW have documented 12-18% reductions in time-to-market for new vehicle models through digital twin integration.

The business value assessment reveals sector-specific priorities. Aviation emphasizes safety, reliability, and regulatory compliance, with digital twins providing substantial risk mitigation value estimated at $2-5 million per major incident avoided. Automotive manufacturers prioritize production scale and consumer-facing innovations, with digital twins enabling flexible manufacturing systems that adapt to market demands 30-40% faster than traditional approaches.

Cost structures also differ significantly. Aviation implementations require higher initial investments ($5-15 million for comprehensive enterprise solutions) but deliver proportionally larger long-term returns. Automotive implementations typically start smaller ($1-5 million) with more incremental scaling. Both sectors report challenges in quantifying indirect benefits, particularly regarding knowledge management and organizational learning.

Future value projections indicate convergence in some areas, with both sectors increasingly leveraging digital twins for sustainability optimization. Aviation leads in using twins for emissions modeling and fuel efficiency (3-7% improvements), while automotive manufacturers are rapidly adopting similar approaches for electric vehicle battery optimization and manufacturing carbon footprint reduction (5-10% improvements in resource utilization).

Aviation digital twins demonstrate particular strength in lifecycle management, with Boeing and Airbus reporting 7-12% reductions in total lifecycle costs. The technology's ability to simulate complex systems has reduced development time for new aircraft components by up to 18%, while enhancing safety compliance—a critical value driver unique to aviation.

By contrast, automotive implementations show faster ROI realization, typically within 1-3 years, aligned with the industry's shorter product cycles. Manufacturing efficiency improvements dominate the value proposition, with production optimization yielding 8-15% efficiency gains and 10-20% reductions in quality-related costs. Tesla and BMW have documented 12-18% reductions in time-to-market for new vehicle models through digital twin integration.

The business value assessment reveals sector-specific priorities. Aviation emphasizes safety, reliability, and regulatory compliance, with digital twins providing substantial risk mitigation value estimated at $2-5 million per major incident avoided. Automotive manufacturers prioritize production scale and consumer-facing innovations, with digital twins enabling flexible manufacturing systems that adapt to market demands 30-40% faster than traditional approaches.

Cost structures also differ significantly. Aviation implementations require higher initial investments ($5-15 million for comprehensive enterprise solutions) but deliver proportionally larger long-term returns. Automotive implementations typically start smaller ($1-5 million) with more incremental scaling. Both sectors report challenges in quantifying indirect benefits, particularly regarding knowledge management and organizational learning.

Future value projections indicate convergence in some areas, with both sectors increasingly leveraging digital twins for sustainability optimization. Aviation leads in using twins for emissions modeling and fuel efficiency (3-7% improvements), while automotive manufacturers are rapidly adopting similar approaches for electric vehicle battery optimization and manufacturing carbon footprint reduction (5-10% improvements in resource utilization).

Data Security and Interoperability Standards

In the digital twin ecosystems of aviation and automotive sectors, data security and interoperability standards represent critical infrastructure components with distinct implementation approaches. Aviation's digital twin implementations typically adhere to more stringent security protocols due to the safety-critical nature of aircraft operations. The industry has developed comprehensive frameworks like the Aerospace Industries Association (AIA) cybersecurity standards and RTCA DO-326A for airworthiness security process specifications, which establish robust protection mechanisms for digital twin data.

Contrastingly, the automotive sector operates under less centralized regulatory oversight, though standards like ISO/SAE 21434 for automotive cybersecurity engineering are gaining traction. This sector faces unique challenges in balancing security requirements with the need for rapid innovation cycles and cost-effective implementations across diverse vehicle platforms.

Interoperability standards show similar divergence patterns. Aviation relies heavily on established standards like ARINC 429/629 for avionics data exchange and the more recent FACE (Future Airborne Capability Environment) technical standard, which promotes common interfaces for avionics systems. These standards facilitate seamless integration between digital twin components while maintaining strict certification requirements.

The automotive industry has embraced more flexible approaches, with standards like AUTOSAR (Automotive Open System Architecture) providing a foundation for software component integration. However, proprietary systems remain prevalent, creating interoperability challenges across manufacturer ecosystems. The emergence of OPC UA (Open Platform Communications Unified Architecture) as a cross-industry standard shows promise for bridging these gaps.

Data ownership and access control frameworks differ significantly between sectors. Aviation digital twins typically implement hierarchical access models with clearly defined roles and responsibilities, often extending to regulatory authorities. Automotive implementations tend toward more compartmentalized approaches, with stronger emphasis on protecting proprietary manufacturing processes and competitive advantages.

Cross-sector convergence is emerging through initiatives like the Digital Twin Consortium, which aims to establish common taxonomies and reference architectures. Both industries are increasingly adopting zero-trust security models and blockchain technologies for data integrity verification, though aviation maintains more conservative implementation timelines due to certification requirements.

The maturity gap between these sectors presents valuable learning opportunities, with automotive manufacturers potentially benefiting from aviation's robust security frameworks, while aviation could adopt more agile development approaches from automotive digital twin implementations.

Contrastingly, the automotive sector operates under less centralized regulatory oversight, though standards like ISO/SAE 21434 for automotive cybersecurity engineering are gaining traction. This sector faces unique challenges in balancing security requirements with the need for rapid innovation cycles and cost-effective implementations across diverse vehicle platforms.

Interoperability standards show similar divergence patterns. Aviation relies heavily on established standards like ARINC 429/629 for avionics data exchange and the more recent FACE (Future Airborne Capability Environment) technical standard, which promotes common interfaces for avionics systems. These standards facilitate seamless integration between digital twin components while maintaining strict certification requirements.

The automotive industry has embraced more flexible approaches, with standards like AUTOSAR (Automotive Open System Architecture) providing a foundation for software component integration. However, proprietary systems remain prevalent, creating interoperability challenges across manufacturer ecosystems. The emergence of OPC UA (Open Platform Communications Unified Architecture) as a cross-industry standard shows promise for bridging these gaps.

Data ownership and access control frameworks differ significantly between sectors. Aviation digital twins typically implement hierarchical access models with clearly defined roles and responsibilities, often extending to regulatory authorities. Automotive implementations tend toward more compartmentalized approaches, with stronger emphasis on protecting proprietary manufacturing processes and competitive advantages.

Cross-sector convergence is emerging through initiatives like the Digital Twin Consortium, which aims to establish common taxonomies and reference architectures. Both industries are increasingly adopting zero-trust security models and blockchain technologies for data integrity verification, though aviation maintains more conservative implementation timelines due to certification requirements.

The maturity gap between these sectors presents valuable learning opportunities, with automotive manufacturers potentially benefiting from aviation's robust security frameworks, while aviation could adopt more agile development approaches from automotive digital twin implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!