Comparison of Digital Twin and Traditional Simulation for Manufacturing

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Objectives

The concept of Digital Twin has evolved significantly over the past two decades, transforming from a theoretical framework into a practical manufacturing technology. Initially proposed by Dr. Michael Grieves at the University of Michigan in 2002, Digital Twin was conceptualized as a virtual representation of physical assets. The early iterations were primarily focused on product lifecycle management, with limited real-time capabilities and minimal integration with physical systems.

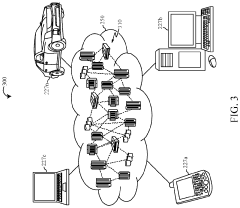

By 2010, as sensor technology and Internet of Things (IoT) infrastructure matured, Digital Twin implementations began incorporating real-time data streams, enabling more dynamic representations of physical assets. This marked a crucial transition from static simulation models to responsive digital counterparts that could reflect the current state of physical equipment.

The evolution accelerated between 2015-2020 with the integration of artificial intelligence and machine learning algorithms, allowing Digital Twins to not only mirror physical systems but also predict future states and recommend optimizations. This predictive capability represents a fundamental departure from traditional simulation approaches, which typically operate on historical or hypothetical data sets.

Today's Digital Twins incorporate multi-physics modeling, real-time data synchronization, and AI-driven predictive analytics, creating comprehensive virtual replicas that can simulate, predict, and optimize manufacturing processes with unprecedented accuracy. The technology has progressed from simple 3D models to complex ecosystems that integrate with enterprise systems and span entire production facilities.

The primary objectives of Digital Twin technology in manufacturing contexts are multifaceted. First, it aims to enable real-time monitoring and control of production processes, allowing operators to visualize operations and make informed decisions based on current conditions. Second, it seeks to facilitate predictive maintenance by identifying potential equipment failures before they occur, thereby reducing downtime and maintenance costs.

Additionally, Digital Twin technology strives to optimize production processes through scenario testing and simulation without disrupting physical operations. This capability allows manufacturers to experiment with process modifications virtually before implementing changes in the physical environment. Furthermore, Digital Twins aim to enhance product quality by providing insights into how manufacturing variations affect final product performance.

Looking forward, the evolution of Digital Twin technology is expected to continue toward greater autonomy, with self-optimizing systems that can automatically adjust manufacturing parameters based on changing conditions and objectives. The ultimate goal is to create fully integrated digital-physical systems that seamlessly bridge the gap between virtual simulation and physical reality in manufacturing environments.

By 2010, as sensor technology and Internet of Things (IoT) infrastructure matured, Digital Twin implementations began incorporating real-time data streams, enabling more dynamic representations of physical assets. This marked a crucial transition from static simulation models to responsive digital counterparts that could reflect the current state of physical equipment.

The evolution accelerated between 2015-2020 with the integration of artificial intelligence and machine learning algorithms, allowing Digital Twins to not only mirror physical systems but also predict future states and recommend optimizations. This predictive capability represents a fundamental departure from traditional simulation approaches, which typically operate on historical or hypothetical data sets.

Today's Digital Twins incorporate multi-physics modeling, real-time data synchronization, and AI-driven predictive analytics, creating comprehensive virtual replicas that can simulate, predict, and optimize manufacturing processes with unprecedented accuracy. The technology has progressed from simple 3D models to complex ecosystems that integrate with enterprise systems and span entire production facilities.

The primary objectives of Digital Twin technology in manufacturing contexts are multifaceted. First, it aims to enable real-time monitoring and control of production processes, allowing operators to visualize operations and make informed decisions based on current conditions. Second, it seeks to facilitate predictive maintenance by identifying potential equipment failures before they occur, thereby reducing downtime and maintenance costs.

Additionally, Digital Twin technology strives to optimize production processes through scenario testing and simulation without disrupting physical operations. This capability allows manufacturers to experiment with process modifications virtually before implementing changes in the physical environment. Furthermore, Digital Twins aim to enhance product quality by providing insights into how manufacturing variations affect final product performance.

Looking forward, the evolution of Digital Twin technology is expected to continue toward greater autonomy, with self-optimizing systems that can automatically adjust manufacturing parameters based on changing conditions and objectives. The ultimate goal is to create fully integrated digital-physical systems that seamlessly bridge the gap between virtual simulation and physical reality in manufacturing environments.

Manufacturing Market Demand Analysis

The manufacturing industry is experiencing a significant shift towards digital transformation, creating a robust market demand for advanced simulation technologies. Recent market research indicates that the global digital twin market in manufacturing is projected to grow at a CAGR of 38% between 2021 and 2026, reaching a valuation of 26 billion USD. This exceptional growth rate significantly outpaces traditional simulation software markets, which maintain a steady but more modest growth rate of 11-13% annually.

Manufacturing enterprises across various sectors are increasingly seeking solutions that provide real-time operational insights and predictive capabilities. A survey conducted among 500 manufacturing executives revealed that 67% consider digital twin technology as a strategic priority for their digital transformation initiatives, compared to 43% who prioritized traditional simulation approaches three years ago. This shift reflects the growing recognition of digital twin's superior capabilities in addressing complex manufacturing challenges.

The automotive and aerospace sectors currently lead digital twin adoption, with implementation rates of 38% and 42% respectively. These industries require high-precision manufacturing processes where the enhanced accuracy of digital twins delivers significant competitive advantages. However, adoption is rapidly expanding into other manufacturing segments including consumer electronics, industrial equipment, and medical devices manufacturing.

Cost reduction remains the primary market driver, with manufacturers reporting average operational cost savings of 25% following digital twin implementation, compared to 12% with traditional simulation approaches. Additionally, the ability to reduce time-to-market has become increasingly critical, with digital twin technologies enabling average development cycle reductions of 30% versus 15% for traditional simulation methods.

The market demand is further segmented by enterprise size. Large manufacturers with complex supply chains and production systems show the highest adoption rates at 56%, while mid-sized manufacturers follow at 37%. Small manufacturers, traditionally constrained by implementation costs, are showing increased interest as more scalable and affordable solutions enter the market, with adoption rates growing from 8% to 19% over the past two years.

Geographically, North America and Europe currently lead in digital twin adoption with market shares of 35% and 28% respectively. However, the Asia-Pacific region is experiencing the fastest growth rate at 42% annually, driven by rapid industrial modernization in China, Japan, South Korea, and emerging manufacturing hubs in Southeast Asia.

Manufacturing enterprises across various sectors are increasingly seeking solutions that provide real-time operational insights and predictive capabilities. A survey conducted among 500 manufacturing executives revealed that 67% consider digital twin technology as a strategic priority for their digital transformation initiatives, compared to 43% who prioritized traditional simulation approaches three years ago. This shift reflects the growing recognition of digital twin's superior capabilities in addressing complex manufacturing challenges.

The automotive and aerospace sectors currently lead digital twin adoption, with implementation rates of 38% and 42% respectively. These industries require high-precision manufacturing processes where the enhanced accuracy of digital twins delivers significant competitive advantages. However, adoption is rapidly expanding into other manufacturing segments including consumer electronics, industrial equipment, and medical devices manufacturing.

Cost reduction remains the primary market driver, with manufacturers reporting average operational cost savings of 25% following digital twin implementation, compared to 12% with traditional simulation approaches. Additionally, the ability to reduce time-to-market has become increasingly critical, with digital twin technologies enabling average development cycle reductions of 30% versus 15% for traditional simulation methods.

The market demand is further segmented by enterprise size. Large manufacturers with complex supply chains and production systems show the highest adoption rates at 56%, while mid-sized manufacturers follow at 37%. Small manufacturers, traditionally constrained by implementation costs, are showing increased interest as more scalable and affordable solutions enter the market, with adoption rates growing from 8% to 19% over the past two years.

Geographically, North America and Europe currently lead in digital twin adoption with market shares of 35% and 28% respectively. However, the Asia-Pacific region is experiencing the fastest growth rate at 42% annually, driven by rapid industrial modernization in China, Japan, South Korea, and emerging manufacturing hubs in Southeast Asia.

Technical Challenges in Digital Twin Implementation

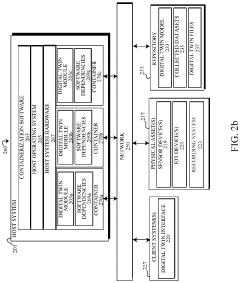

Despite the promising potential of digital twins in manufacturing, their implementation faces significant technical challenges that distinguish them from traditional simulation approaches. The primary challenge lies in achieving real-time data integration and synchronization between physical assets and their digital counterparts. Unlike traditional simulations that operate with historical or static data, digital twins require continuous data streams from multiple sensors, which demands robust communication infrastructure and protocols to handle large volumes of heterogeneous data with minimal latency.

Data quality and reliability present another substantial hurdle. Manufacturing environments are often noisy, with sensors subject to interference, calibration drift, and occasional failures. These issues can compromise the fidelity of digital twin models, whereas traditional simulations typically work with cleaner, pre-processed datasets. Developing effective data validation mechanisms and fault-tolerant architectures becomes essential for maintaining digital twin accuracy.

The complexity of multi-physics modeling also poses significant challenges. Digital twins must simultaneously represent mechanical, electrical, thermal, and sometimes chemical processes in an integrated manner. Traditional simulations often focus on single physics domains or use simplified coupling approaches. Creating comprehensive models that accurately capture these interdependencies while maintaining computational efficiency requires sophisticated mathematical frameworks and modeling techniques.

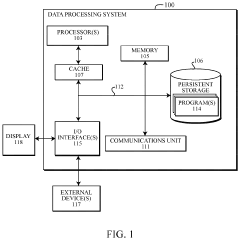

Computational resource management represents a critical technical barrier. Digital twins demand substantial processing power for real-time analysis and visualization, often necessitating edge computing solutions to reduce latency. Traditional simulations can typically be scheduled as batch processes with predetermined computational resources. The dynamic nature of digital twins requires adaptive resource allocation strategies and potentially cloud-edge hybrid architectures.

Interoperability between different systems and platforms creates additional complexity. Manufacturing environments typically contain equipment from multiple vendors with proprietary interfaces and data formats. Digital twins must integrate with these diverse systems, legacy equipment, and enterprise software, requiring standardized communication protocols and semantic data models that exceed the integration needs of traditional simulations.

Security and privacy concerns are amplified in digital twin implementations. The continuous data exchange between physical assets and digital models creates potential vulnerabilities that must be addressed through comprehensive cybersecurity measures. Traditional simulations, operating in more isolated environments with controlled data access, generally present lower security risks and privacy concerns.

Human-AI collaboration frameworks represent an emerging challenge. As digital twins evolve to incorporate predictive capabilities and autonomous decision-making, developing intuitive interfaces and trust-building mechanisms becomes essential for effective human oversight and intervention, a dimension largely absent in traditional simulation approaches.

Data quality and reliability present another substantial hurdle. Manufacturing environments are often noisy, with sensors subject to interference, calibration drift, and occasional failures. These issues can compromise the fidelity of digital twin models, whereas traditional simulations typically work with cleaner, pre-processed datasets. Developing effective data validation mechanisms and fault-tolerant architectures becomes essential for maintaining digital twin accuracy.

The complexity of multi-physics modeling also poses significant challenges. Digital twins must simultaneously represent mechanical, electrical, thermal, and sometimes chemical processes in an integrated manner. Traditional simulations often focus on single physics domains or use simplified coupling approaches. Creating comprehensive models that accurately capture these interdependencies while maintaining computational efficiency requires sophisticated mathematical frameworks and modeling techniques.

Computational resource management represents a critical technical barrier. Digital twins demand substantial processing power for real-time analysis and visualization, often necessitating edge computing solutions to reduce latency. Traditional simulations can typically be scheduled as batch processes with predetermined computational resources. The dynamic nature of digital twins requires adaptive resource allocation strategies and potentially cloud-edge hybrid architectures.

Interoperability between different systems and platforms creates additional complexity. Manufacturing environments typically contain equipment from multiple vendors with proprietary interfaces and data formats. Digital twins must integrate with these diverse systems, legacy equipment, and enterprise software, requiring standardized communication protocols and semantic data models that exceed the integration needs of traditional simulations.

Security and privacy concerns are amplified in digital twin implementations. The continuous data exchange between physical assets and digital models creates potential vulnerabilities that must be addressed through comprehensive cybersecurity measures. Traditional simulations, operating in more isolated environments with controlled data access, generally present lower security risks and privacy concerns.

Human-AI collaboration frameworks represent an emerging challenge. As digital twins evolve to incorporate predictive capabilities and autonomous decision-making, developing intuitive interfaces and trust-building mechanisms becomes essential for effective human oversight and intervention, a dimension largely absent in traditional simulation approaches.

Current Digital Twin vs Traditional Simulation Approaches

01 Real-time data integration and monitoring capabilities

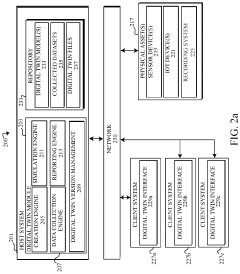

Digital twins offer superior real-time data integration compared to traditional simulation methods. They continuously update with actual operational data from physical assets through IoT sensors, enabling dynamic monitoring and immediate response to changing conditions. Traditional simulations typically rely on static or historical data sets, making them less responsive to real-world variations and limiting their ability to reflect current operational states accurately.- Real-time data integration and monitoring capabilities: Digital twins offer superior real-time data integration compared to traditional simulation methods. They continuously incorporate data from IoT sensors and operational systems to create dynamic, living models that reflect current conditions. This enables more accurate monitoring, predictive maintenance, and immediate response to changing conditions. Traditional simulations typically rely on static or historical data sets, making them less responsive to real-world changes and limiting their ability to provide up-to-date insights.

- Accuracy and fidelity comparison: Digital twins generally provide higher fidelity representations of physical assets or systems than traditional simulations. By incorporating multi-physics modeling, AI algorithms, and continuous calibration with real-world data, digital twins can achieve greater accuracy in predicting system behavior across various conditions. Traditional simulations often rely on simplified models with assumptions and approximations that may not capture complex interactions or emergent behaviors, particularly in dynamic or highly variable environments.

- Implementation complexity and resource requirements: Digital twin implementation typically requires more extensive infrastructure and resources compared to traditional simulation approaches. They demand robust data collection systems, high-performance computing capabilities, specialized software platforms, and cross-disciplinary expertise. Traditional simulations generally have lower entry barriers, requiring less complex infrastructure and fewer ongoing operational resources. The cost-benefit analysis between these approaches depends on the application complexity, required accuracy, and available organizational capabilities.

- Application scope and industry adoption: Digital twins are increasingly adopted in industries requiring comprehensive system understanding and optimization, such as manufacturing, healthcare, smart cities, and aerospace. They excel in scenarios demanding continuous monitoring, predictive maintenance, and complex system optimization. Traditional simulations remain prevalent in design validation, training, and scenarios where real-time data integration is less critical. The adoption pattern shows traditional simulations serving as entry points, with organizations progressively moving toward digital twin implementations as their digital maturity increases.

- Integration with emerging technologies: Digital twins demonstrate superior integration capabilities with emerging technologies compared to traditional simulations. They effectively incorporate artificial intelligence, machine learning, extended reality (XR), and blockchain to enhance functionality and user experience. This integration enables advanced predictive analytics, immersive visualization, and autonomous decision-making capabilities. Traditional simulations typically have more limited integration capabilities, focusing primarily on specific modeling aspects rather than creating comprehensive, interconnected digital ecosystems that can evolve alongside technological advancements.

02 Predictive maintenance and failure analysis

Digital twins excel in predictive maintenance applications by creating virtual replicas that can forecast potential failures before they occur in physical systems. They analyze real-time performance data against expected parameters to identify anomalies and maintenance needs. Traditional simulations are more limited in this aspect, typically offering scenario-based predictions without the continuous feedback loop that digital twins provide, resulting in less accurate failure predictions and maintenance scheduling.Expand Specific Solutions03 Computational efficiency and resource requirements

Traditional simulations often require less computational infrastructure for initial implementation compared to digital twins, making them more accessible for simpler applications or organizations with limited resources. Digital twins typically demand more substantial computing power, data storage, and specialized software to maintain real-time synchronization between physical and virtual environments. However, digital twins can provide more efficient long-term resource utilization through targeted interventions based on precise virtual testing.Expand Specific Solutions04 Integration with AI and machine learning capabilities

Digital twins leverage artificial intelligence and machine learning algorithms to continuously improve their accuracy and predictive capabilities over time. They can autonomously identify patterns, optimize operations, and adapt to changing conditions without human intervention. Traditional simulations typically lack this self-improving capability, requiring manual updates to models and parameters. The AI integration in digital twins enables more sophisticated scenario planning and decision support than conventional simulation approaches.Expand Specific Solutions05 Lifecycle management and historical data utilization

Digital twins maintain a complete historical record of an asset's performance throughout its lifecycle, creating a valuable knowledge base for future designs and operations. They enable comprehensive what-if analyses by combining historical data with real-time inputs. Traditional simulations typically focus on specific time periods or scenarios without maintaining the continuous historical context. This difference makes digital twins particularly valuable for long-term asset management and iterative design improvements across multiple generations of products or systems.Expand Specific Solutions

Key Digital Twin Solution Providers

The digital twin technology market is rapidly evolving, currently transitioning from early adoption to growth phase, with an estimated market size exceeding $10 billion and projected CAGR of 35% through 2026. Unlike traditional simulation, digital twins offer real-time data integration and predictive capabilities, creating a significant competitive advantage in manufacturing. Industry leaders like Siemens AG have established comprehensive digital twin platforms, while IBM, ABB Group, and Rockwell Automation are developing specialized solutions. Academic institutions including Zhengzhou University of Light Industry and Shandong University are contributing research advancements. The ecosystem shows varying levels of technological maturity, with established players focusing on integration while newer entrants target niche applications across automotive, electronics, and heavy machinery sectors.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive Digital Twin platform called Xcelerator that integrates multiple dimensions of digital representation across the entire product and production lifecycle. Their approach combines mechanical, electrical, and software components with real-time operational data to create high-fidelity virtual models. Unlike traditional simulation that typically focuses on isolated aspects of manufacturing processes, Siemens' Digital Twin technology creates a continuous digital thread that connects design, engineering, production, and service phases. The platform incorporates physics-based simulation with real-time IoT data feedback loops, enabling predictive maintenance and optimization. Siemens has implemented this technology in various manufacturing sectors, demonstrating up to 30% reduction in commissioning time and 20% improvement in overall equipment effectiveness compared to traditional simulation approaches[1]. Their Digital Twin framework also supports virtual commissioning, allowing engineers to validate automation systems before physical implementation, significantly reducing downtime and integration issues.

Strengths: Comprehensive integration across entire product lifecycle; robust IoT connectivity for real-time data integration; extensive industry-specific templates and libraries. Weaknesses: Higher implementation complexity requiring significant organizational change; substantial initial investment in both technology and expertise; requires comprehensive data infrastructure.

International Business Machines Corp.

Technical Solution: IBM has developed a sophisticated Digital Twin platform that leverages their Watson AI capabilities to transform manufacturing simulation. Their approach moves beyond traditional simulation's static modeling by creating dynamic, AI-enhanced virtual replicas that continuously learn and adapt. IBM's Digital Twin technology integrates real-time operational data with AI analytics to enable predictive maintenance, process optimization, and quality control. The platform incorporates IBM's Maximo Application Suite which provides asset performance management capabilities enhanced by Digital Twin visualizations. Unlike traditional simulations that typically operate in isolation from operational systems, IBM's solution creates a bidirectional flow of information between physical assets and their digital counterparts. This enables not only monitoring but also autonomous optimization through AI-driven insights. IBM has reported that their Digital Twin implementations have reduced unplanned downtime by up to 50% and maintenance costs by 10-40% compared to traditional simulation-based approaches[2]. Their platform also supports scenario planning capabilities that allow manufacturers to test process changes virtually before implementation.

Strengths: Advanced AI and machine learning integration for predictive capabilities; strong cloud infrastructure supporting global deployment; extensive analytics capabilities for complex manufacturing environments. Weaknesses: May require significant customization for specialized manufacturing processes; potential complexity in integration with legacy systems; ongoing subscription costs for cloud-based services.

Core Technologies Enabling Digital Twin Advancement

Digital twin workflow simulation

PatentActiveUS11556449B2

Innovation

- A computer-implemented method for simulating digital twin performance that allows users to selectively bypass certain input parameters and components, using customizable configurations to focus on specific parts, substitute alternative components, and provide overriding values for intermediate simulation results, enabling more targeted analysis and optimization.

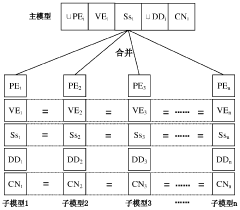

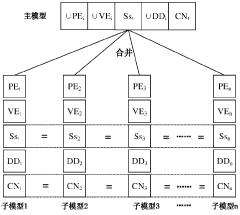

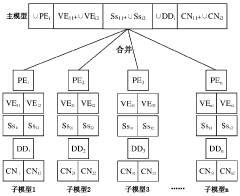

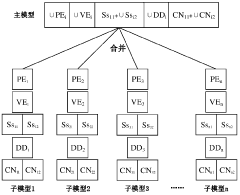

Digital twin model merging method

PatentWO2024045415A1

Innovation

- This paper proposes a digital twin model merging method that reduces duplication of work and improves efficiency by defining basic application scenarios and similarity differentiation strategies, and adopting merging strategies of identical, homogeneous and mixed similarity models, including divide-and-conquer modeling and similar merging strategies.

ROI Analysis for Digital Twin Adoption

When evaluating the return on investment (ROI) for digital twin adoption in manufacturing environments, organizations must consider both quantitative financial metrics and qualitative operational benefits that may be harder to monetize directly.

Initial implementation costs for digital twin technology typically exceed those of traditional simulation approaches by 30-50%. These costs include specialized software licenses, hardware infrastructure, sensor networks, integration services, and staff training. However, the ongoing operational costs often decrease over time as the digital twin system matures and becomes more integrated with existing processes.

The payback period for digital twin investments ranges from 12-36 months depending on implementation scope and industry sector. Manufacturing organizations implementing comprehensive digital twin solutions report an average ROI of 25-40% over a five-year period, significantly outperforming the 15-20% typical for traditional simulation investments.

Cost reduction benefits materialize through multiple channels. Predictive maintenance capabilities reduce unplanned downtime by 30-45%, while energy consumption optimization typically yields 10-15% savings. Material waste reduction of 5-8% further contributes to operational savings. These efficiency gains translate to measurable financial returns that accelerate over time as the digital twin accumulates more operational data.

Revenue enhancement opportunities represent another critical ROI component. Digital twins enable faster product development cycles, reducing time-to-market by 20-30% compared to traditional simulation approaches. The ability to rapidly test design modifications virtually before physical implementation provides competitive advantages that directly impact top-line growth.

Risk mitigation benefits, while more challenging to quantify precisely, contribute significantly to overall ROI. Digital twins reduce costly production errors by enabling comprehensive virtual testing before physical implementation. They also enhance regulatory compliance by providing detailed documentation of production processes and product specifications.

Long-term strategic value must be factored into ROI calculations. Digital twins create organizational knowledge assets that appreciate over time as more operational data is incorporated. This growing digital representation of physical assets becomes increasingly valuable for future decision-making, representing an appreciating asset rather than a depreciating technology investment.

When calculating ROI, organizations should establish clear baseline metrics before implementation and track performance improvements systematically. A phased implementation approach often yields better financial returns by allowing organizations to demonstrate value incrementally while refining their digital twin strategy based on early results.

Initial implementation costs for digital twin technology typically exceed those of traditional simulation approaches by 30-50%. These costs include specialized software licenses, hardware infrastructure, sensor networks, integration services, and staff training. However, the ongoing operational costs often decrease over time as the digital twin system matures and becomes more integrated with existing processes.

The payback period for digital twin investments ranges from 12-36 months depending on implementation scope and industry sector. Manufacturing organizations implementing comprehensive digital twin solutions report an average ROI of 25-40% over a five-year period, significantly outperforming the 15-20% typical for traditional simulation investments.

Cost reduction benefits materialize through multiple channels. Predictive maintenance capabilities reduce unplanned downtime by 30-45%, while energy consumption optimization typically yields 10-15% savings. Material waste reduction of 5-8% further contributes to operational savings. These efficiency gains translate to measurable financial returns that accelerate over time as the digital twin accumulates more operational data.

Revenue enhancement opportunities represent another critical ROI component. Digital twins enable faster product development cycles, reducing time-to-market by 20-30% compared to traditional simulation approaches. The ability to rapidly test design modifications virtually before physical implementation provides competitive advantages that directly impact top-line growth.

Risk mitigation benefits, while more challenging to quantify precisely, contribute significantly to overall ROI. Digital twins reduce costly production errors by enabling comprehensive virtual testing before physical implementation. They also enhance regulatory compliance by providing detailed documentation of production processes and product specifications.

Long-term strategic value must be factored into ROI calculations. Digital twins create organizational knowledge assets that appreciate over time as more operational data is incorporated. This growing digital representation of physical assets becomes increasingly valuable for future decision-making, representing an appreciating asset rather than a depreciating technology investment.

When calculating ROI, organizations should establish clear baseline metrics before implementation and track performance improvements systematically. A phased implementation approach often yields better financial returns by allowing organizations to demonstrate value incrementally while refining their digital twin strategy based on early results.

Cybersecurity Considerations in Connected Manufacturing Systems

The integration of digital twins and connected manufacturing systems introduces significant cybersecurity vulnerabilities that traditional simulation environments typically do not face. Connected manufacturing systems utilizing digital twins create an expanded attack surface through the continuous data exchange between physical assets and their virtual counterparts. This bidirectional flow of operational data presents multiple entry points for malicious actors seeking to compromise manufacturing operations.

Primary security threats include unauthorized access to sensitive production data, manipulation of digital twin parameters that could affect physical operations, and potential disruption of manufacturing processes through denial-of-service attacks targeting the connectivity infrastructure. Unlike traditional simulation models that operate in isolated environments, digital twins require robust network security protocols to protect their real-time connections to physical assets.

Data integrity becomes particularly critical in digital twin implementations, as corrupted or manipulated data could lead to incorrect operational decisions or faulty product designs. Manufacturing organizations must implement comprehensive encryption standards for data in transit and at rest, alongside strong authentication mechanisms to verify the legitimacy of data sources feeding into the digital twin environment.

Supply chain vulnerabilities represent another significant concern, as digital twins often integrate data from multiple vendors and third-party systems. Each connection point introduces potential security weaknesses that must be assessed and mitigated through rigorous vendor security evaluations and contractual security requirements.

The regulatory landscape surrounding manufacturing cybersecurity continues to evolve, with frameworks such as IEC 62443 for industrial automation and NIST Cybersecurity Framework providing guidance for securing connected manufacturing environments. Organizations implementing digital twin technology must ensure compliance with these standards while maintaining operational efficiency.

Effective security strategies for digital twin implementations should include network segmentation to isolate critical manufacturing systems, continuous monitoring for anomalous behavior patterns, and regular security assessments to identify emerging vulnerabilities. Additionally, organizations should develop incident response plans specifically addressing scenarios involving compromised digital twin environments.

As manufacturing systems become increasingly interconnected through digital twin technology, security-by-design principles must be incorporated from the earliest stages of implementation. This approach ensures that cybersecurity considerations are integrated into the architecture rather than added as afterthoughts, significantly reducing potential vulnerabilities in the connected manufacturing ecosystem.

Primary security threats include unauthorized access to sensitive production data, manipulation of digital twin parameters that could affect physical operations, and potential disruption of manufacturing processes through denial-of-service attacks targeting the connectivity infrastructure. Unlike traditional simulation models that operate in isolated environments, digital twins require robust network security protocols to protect their real-time connections to physical assets.

Data integrity becomes particularly critical in digital twin implementations, as corrupted or manipulated data could lead to incorrect operational decisions or faulty product designs. Manufacturing organizations must implement comprehensive encryption standards for data in transit and at rest, alongside strong authentication mechanisms to verify the legitimacy of data sources feeding into the digital twin environment.

Supply chain vulnerabilities represent another significant concern, as digital twins often integrate data from multiple vendors and third-party systems. Each connection point introduces potential security weaknesses that must be assessed and mitigated through rigorous vendor security evaluations and contractual security requirements.

The regulatory landscape surrounding manufacturing cybersecurity continues to evolve, with frameworks such as IEC 62443 for industrial automation and NIST Cybersecurity Framework providing guidance for securing connected manufacturing environments. Organizations implementing digital twin technology must ensure compliance with these standards while maintaining operational efficiency.

Effective security strategies for digital twin implementations should include network segmentation to isolate critical manufacturing systems, continuous monitoring for anomalous behavior patterns, and regular security assessments to identify emerging vulnerabilities. Additionally, organizations should develop incident response plans specifically addressing scenarios involving compromised digital twin environments.

As manufacturing systems become increasingly interconnected through digital twin technology, security-by-design principles must be incorporated from the earliest stages of implementation. This approach ensures that cybersecurity considerations are integrated into the architecture rather than added as afterthoughts, significantly reducing potential vulnerabilities in the connected manufacturing ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!