How Digital Twin Supports Supply Chain Transparency and Resilience

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Supply Chain Objectives

Digital twins have evolved significantly since their conceptual introduction in the early 2000s. Initially developed for product lifecycle management in manufacturing, these virtual replicas have transformed into sophisticated real-time models capable of simulating complex systems. The evolution progressed from basic 3D models to dynamic representations incorporating IoT sensors, AI analytics, and cloud computing capabilities, enabling unprecedented levels of system monitoring and optimization.

In the context of supply chains, digital twins have emerged as powerful tools for enhancing transparency and building resilience against disruptions. The technology's evolution has been accelerated by several factors, including the increasing complexity of global supply networks, growing consumer demands for transparency, and the vulnerabilities exposed by recent global disruptions such as the COVID-19 pandemic and geopolitical tensions.

The primary objectives of implementing digital twin technology in supply chains include achieving end-to-end visibility across all tiers of suppliers, manufacturing facilities, transportation networks, and distribution centers. This comprehensive visibility enables organizations to identify potential bottlenecks, vulnerabilities, and inefficiencies before they manifest as disruptions.

Another critical objective is enhancing predictive capabilities through scenario modeling and simulation. By creating virtual replicas of supply chain operations, organizations can test various scenarios, from minor operational adjustments to major disruptions, without risking actual operations. This capability allows for proactive risk management and contingency planning rather than reactive crisis response.

Digital twins also aim to optimize resource allocation and utilization across the supply chain network. By providing real-time insights into inventory levels, production capacities, and logistics operations, organizations can make data-driven decisions that balance efficiency with resilience, avoiding both excess inventory costs and stockout risks.

Furthermore, the technology seeks to enable collaborative decision-making among supply chain partners. By creating a shared virtual environment where stakeholders can visualize the entire supply network, digital twins facilitate better coordination and joint problem-solving, breaking down traditional information silos that have historically plagued supply chain management.

The ultimate objective is to create self-healing supply chains that can automatically detect anomalies, predict potential disruptions, and initiate corrective actions with minimal human intervention. This represents the convergence of digital twin technology with autonomous systems and artificial intelligence, pointing toward the future of supply chain management where resilience is built into the system architecture rather than added as an afterthought.

In the context of supply chains, digital twins have emerged as powerful tools for enhancing transparency and building resilience against disruptions. The technology's evolution has been accelerated by several factors, including the increasing complexity of global supply networks, growing consumer demands for transparency, and the vulnerabilities exposed by recent global disruptions such as the COVID-19 pandemic and geopolitical tensions.

The primary objectives of implementing digital twin technology in supply chains include achieving end-to-end visibility across all tiers of suppliers, manufacturing facilities, transportation networks, and distribution centers. This comprehensive visibility enables organizations to identify potential bottlenecks, vulnerabilities, and inefficiencies before they manifest as disruptions.

Another critical objective is enhancing predictive capabilities through scenario modeling and simulation. By creating virtual replicas of supply chain operations, organizations can test various scenarios, from minor operational adjustments to major disruptions, without risking actual operations. This capability allows for proactive risk management and contingency planning rather than reactive crisis response.

Digital twins also aim to optimize resource allocation and utilization across the supply chain network. By providing real-time insights into inventory levels, production capacities, and logistics operations, organizations can make data-driven decisions that balance efficiency with resilience, avoiding both excess inventory costs and stockout risks.

Furthermore, the technology seeks to enable collaborative decision-making among supply chain partners. By creating a shared virtual environment where stakeholders can visualize the entire supply network, digital twins facilitate better coordination and joint problem-solving, breaking down traditional information silos that have historically plagued supply chain management.

The ultimate objective is to create self-healing supply chains that can automatically detect anomalies, predict potential disruptions, and initiate corrective actions with minimal human intervention. This represents the convergence of digital twin technology with autonomous systems and artificial intelligence, pointing toward the future of supply chain management where resilience is built into the system architecture rather than added as an afterthought.

Market Demand for Transparent and Resilient Supply Chains

The global market for transparent and resilient supply chains has experienced unprecedented growth in recent years, driven by increasing complexity in global trade networks and heightened awareness of supply chain vulnerabilities. According to recent industry analyses, over 80% of multinational corporations now consider supply chain transparency and resilience as critical business priorities, up from approximately 65% in 2019.

The COVID-19 pandemic served as a watershed moment for supply chain management, exposing critical weaknesses in traditional supply chain models. Research indicates that 94% of Fortune 1000 companies experienced supply chain disruptions during the pandemic, with an average revenue impact of 26%. This widespread disruption has accelerated market demand for technologies that can provide real-time visibility and adaptive capabilities.

Consumer preferences have also shifted dramatically toward ethical and sustainable products, creating market pressure for end-to-end supply chain transparency. Studies show that 73% of consumers are willing to pay a premium for products with transparent sourcing information, while 67% consider sustainability credentials when making purchasing decisions. This consumer-driven demand has compelled businesses across industries to invest in transparency-enabling technologies.

Regulatory environments worldwide are increasingly mandating greater supply chain visibility. The European Union's Supply Chain Due Diligence regulations, the United States' Uyghur Forced Labor Prevention Act, and similar legislation in other regions have created compliance requirements that necessitate sophisticated tracking and verification systems. The regulatory compliance technology market related to supply chains has grown at a compound annual growth rate of 19% since 2020.

Industry-specific demands vary significantly but follow similar trajectories. The pharmaceutical sector, facing stringent track-and-trace requirements, has increased investment in supply chain visibility technologies by 34% year-over-year. Similarly, the automotive industry, struggling with semiconductor shortages, has doubled its investment in predictive supply chain technologies between 2020 and 2023.

The financial implications of supply chain disruptions have become a major market driver. Research indicates that companies experience an average 7% reduction in shareholder value following significant supply chain disruptions. Conversely, organizations with resilient supply chains demonstrate 20-30% higher market valuations compared to industry peers with traditional supply chain models.

Looking forward, market forecasts suggest the global supply chain transparency and resilience technology market will reach $10.9 billion by 2026, representing a compound annual growth rate of 17.5%. Digital twin technology is positioned as a cornerstone solution within this expanding market, with adoption rates increasing across all major industry verticals.

The COVID-19 pandemic served as a watershed moment for supply chain management, exposing critical weaknesses in traditional supply chain models. Research indicates that 94% of Fortune 1000 companies experienced supply chain disruptions during the pandemic, with an average revenue impact of 26%. This widespread disruption has accelerated market demand for technologies that can provide real-time visibility and adaptive capabilities.

Consumer preferences have also shifted dramatically toward ethical and sustainable products, creating market pressure for end-to-end supply chain transparency. Studies show that 73% of consumers are willing to pay a premium for products with transparent sourcing information, while 67% consider sustainability credentials when making purchasing decisions. This consumer-driven demand has compelled businesses across industries to invest in transparency-enabling technologies.

Regulatory environments worldwide are increasingly mandating greater supply chain visibility. The European Union's Supply Chain Due Diligence regulations, the United States' Uyghur Forced Labor Prevention Act, and similar legislation in other regions have created compliance requirements that necessitate sophisticated tracking and verification systems. The regulatory compliance technology market related to supply chains has grown at a compound annual growth rate of 19% since 2020.

Industry-specific demands vary significantly but follow similar trajectories. The pharmaceutical sector, facing stringent track-and-trace requirements, has increased investment in supply chain visibility technologies by 34% year-over-year. Similarly, the automotive industry, struggling with semiconductor shortages, has doubled its investment in predictive supply chain technologies between 2020 and 2023.

The financial implications of supply chain disruptions have become a major market driver. Research indicates that companies experience an average 7% reduction in shareholder value following significant supply chain disruptions. Conversely, organizations with resilient supply chains demonstrate 20-30% higher market valuations compared to industry peers with traditional supply chain models.

Looking forward, market forecasts suggest the global supply chain transparency and resilience technology market will reach $10.9 billion by 2026, representing a compound annual growth rate of 17.5%. Digital twin technology is positioned as a cornerstone solution within this expanding market, with adoption rates increasing across all major industry verticals.

Current Digital Twin Implementation Challenges

Despite the promising potential of digital twins in enhancing supply chain transparency and resilience, several significant implementation challenges persist. The integration of digital twin technology across complex supply chain ecosystems faces substantial technical barriers related to data quality and availability. Many organizations struggle with fragmented data sources, inconsistent data formats, and incomplete historical records, which undermines the accuracy and effectiveness of digital twin models. This data fragmentation is particularly problematic when attempting to create comprehensive end-to-end supply chain visibility.

Interoperability issues present another major obstacle, as supply chains typically involve multiple stakeholders using diverse systems and platforms. The lack of standardized protocols for data exchange between these systems creates significant integration challenges. Without seamless interoperability, digital twins cannot accurately represent the entire supply chain ecosystem, limiting their utility for transparency and resilience planning.

The computational requirements for real-time digital twin operations pose substantial technical and financial barriers. Processing the massive volumes of data generated across global supply chains demands significant computing resources and sophisticated analytics capabilities. Many organizations, particularly small and medium-sized enterprises, lack the necessary infrastructure and expertise to implement and maintain such systems effectively.

Cybersecurity concerns represent a critical challenge as digital twins require extensive data sharing across organizational boundaries. The increased connectivity and data exchange create new vulnerabilities that could potentially expose sensitive business information or intellectual property. Organizations must implement robust security protocols without compromising the functionality and responsiveness of their digital twin implementations.

Scalability issues emerge as companies attempt to expand digital twin implementations from isolated use cases to comprehensive supply chain coverage. Many pilot projects succeed in controlled environments but encounter difficulties when scaled to encompass global operations with thousands of suppliers, multiple tiers, and diverse geographical contexts. The complexity increases exponentially with scale, requiring more sophisticated modeling approaches and computing resources.

Legacy system integration presents persistent challenges, as many supply chain operations rely on outdated systems that were not designed for the level of connectivity and data sharing required by digital twins. Retrofitting these systems or managing the transition to new platforms introduces significant costs and operational risks that many organizations are hesitant to undertake.

Interoperability issues present another major obstacle, as supply chains typically involve multiple stakeholders using diverse systems and platforms. The lack of standardized protocols for data exchange between these systems creates significant integration challenges. Without seamless interoperability, digital twins cannot accurately represent the entire supply chain ecosystem, limiting their utility for transparency and resilience planning.

The computational requirements for real-time digital twin operations pose substantial technical and financial barriers. Processing the massive volumes of data generated across global supply chains demands significant computing resources and sophisticated analytics capabilities. Many organizations, particularly small and medium-sized enterprises, lack the necessary infrastructure and expertise to implement and maintain such systems effectively.

Cybersecurity concerns represent a critical challenge as digital twins require extensive data sharing across organizational boundaries. The increased connectivity and data exchange create new vulnerabilities that could potentially expose sensitive business information or intellectual property. Organizations must implement robust security protocols without compromising the functionality and responsiveness of their digital twin implementations.

Scalability issues emerge as companies attempt to expand digital twin implementations from isolated use cases to comprehensive supply chain coverage. Many pilot projects succeed in controlled environments but encounter difficulties when scaled to encompass global operations with thousands of suppliers, multiple tiers, and diverse geographical contexts. The complexity increases exponentially with scale, requiring more sophisticated modeling approaches and computing resources.

Legacy system integration presents persistent challenges, as many supply chain operations rely on outdated systems that were not designed for the level of connectivity and data sharing required by digital twins. Retrofitting these systems or managing the transition to new platforms introduces significant costs and operational risks that many organizations are hesitant to undertake.

Current Digital Twin Supply Chain Applications

01 Transparent Digital Twin Architectures

Digital twin architectures that emphasize transparency through open data models, clear visualization interfaces, and accessible monitoring systems. These architectures enable stakeholders to understand how digital twins operate, process data, and make decisions. Transparency features include audit trails, explainable AI components, and standardized documentation that clarifies the relationship between physical assets and their digital representations.- Digital Twin Transparency for System Monitoring: Digital twin technologies can be designed to provide transparent monitoring of complex systems by creating virtual replicas that accurately reflect the state and behavior of physical assets. These transparent digital twins enable real-time visibility into system operations, allowing stakeholders to observe, analyze, and understand system behavior. This transparency facilitates better decision-making, early detection of anomalies, and improved operational awareness across various domains including manufacturing, healthcare, and infrastructure management.

- Resilient Digital Twin Architectures: Resilient digital twin architectures incorporate fault-tolerant design principles, redundancy mechanisms, and self-healing capabilities to maintain operational continuity even when facing disruptions. These architectures typically feature distributed processing, backup systems, and adaptive algorithms that can reconfigure in response to failures. By implementing resilience-focused design patterns, digital twins can continue to provide critical services and maintain accurate representations of physical systems even during adverse conditions, network outages, or component failures.

- Security and Privacy in Transparent Digital Twins: As digital twins become more transparent, ensuring appropriate security and privacy protections becomes essential. Advanced encryption methods, access control mechanisms, and privacy-preserving computation techniques can be integrated into digital twin frameworks to protect sensitive data while maintaining necessary transparency. These solutions balance the need for visibility with the requirement to safeguard proprietary information, personal data, and critical infrastructure details from unauthorized access or exploitation.

- Digital Twin Resilience Through AI and Machine Learning: Artificial intelligence and machine learning techniques significantly enhance digital twin resilience by enabling predictive maintenance, anomaly detection, and adaptive responses to changing conditions. These technologies allow digital twins to learn from historical data, anticipate potential failures, and automatically adjust to maintain system integrity. By incorporating AI-driven resilience features, digital twins can proactively identify vulnerabilities, recommend preventive actions, and optimize system performance even in challenging or unpredictable environments.

- Standardization for Digital Twin Transparency and Interoperability: Standardization efforts are crucial for ensuring consistent transparency and resilience across digital twin implementations. Common frameworks, protocols, and data models enable interoperability between different digital twin systems and facilitate clear communication of system states and behaviors. These standards support transparent information exchange, consistent resilience metrics, and seamless integration across organizational boundaries, ultimately improving the overall reliability and utility of digital twin ecosystems in complex multi-stakeholder environments.

02 Resilient Digital Twin Systems for Critical Infrastructure

Digital twin implementations designed specifically for critical infrastructure that incorporate resilience mechanisms to ensure continuous operation during disruptions. These systems feature redundant data storage, fault-tolerant processing capabilities, and automated recovery procedures. They maintain operational integrity through cyber-attacks, hardware failures, or environmental disturbances by implementing distributed architectures and graceful degradation protocols.Expand Specific Solutions03 Security Frameworks for Digital Twin Ecosystems

Comprehensive security frameworks developed specifically for digital twin environments that address both transparency and resilience requirements. These frameworks include encryption protocols for data in transit and at rest, access control mechanisms based on zero-trust principles, and continuous security monitoring. They enable secure information sharing between stakeholders while maintaining the integrity and confidentiality of sensitive operational data.Expand Specific Solutions04 Digital Twin Governance and Compliance Systems

Governance systems for digital twins that ensure regulatory compliance while maintaining operational transparency. These systems implement automated policy enforcement, compliance monitoring, and reporting capabilities that align with industry standards and regulations. They provide mechanisms for managing the entire lifecycle of digital twins, including creation, operation, modification, and retirement phases, with clear audit trails and accountability measures.Expand Specific Solutions05 Adaptive Digital Twin Technologies for Dynamic Environments

Advanced digital twin technologies that adapt to changing operational conditions through machine learning and real-time data integration. These systems continuously update their models based on environmental feedback, enabling resilience through predictive maintenance, anomaly detection, and autonomous decision-making capabilities. They incorporate self-healing mechanisms that can detect deviations between physical and digital representations and automatically reconcile discrepancies.Expand Specific Solutions

Leading Digital Twin Solution Providers

Digital Twin technology is revolutionizing supply chain management, currently in its growth phase with increasing adoption across industries. The global market is expanding rapidly, projected to reach significant scale as organizations seek enhanced visibility and resilience. Technologically, maturity varies by implementation complexity, with companies like Siemens AG, IBM, and Accenture leading innovation through comprehensive platforms. Applied Materials and BASF are advancing material-specific applications, while Tata Consultancy Services and Dell are developing integration solutions. Hitachi Vantara and ABB Group focus on industrial implementations, creating specialized digital twin ecosystems for manufacturing and logistics. The technology continues to evolve with increasing standardization and interoperability between different vendor solutions.

Siemens AG

Technical Solution: Siemens has developed a comprehensive Digital Twin platform called Xcelerator that creates virtual replicas of physical supply chains. Their solution integrates IoT sensors, AI analytics, and cloud computing to provide real-time visibility across the entire supply network. Siemens' Digital Twin technology creates a dynamic, data-driven model that simulates supply chain operations, enabling predictive analytics for potential disruptions and automated response mechanisms. The platform connects with ERP systems and incorporates blockchain for secure data sharing between partners. Siemens has implemented this technology with manufacturing clients, resulting in reported 30% reduction in supply chain disruptions and 25% improvement in inventory optimization[1]. Their solution particularly excels in complex manufacturing environments where component traceability and production synchronization are critical for resilience.

Strengths: Extensive industrial expertise and established IoT infrastructure provide seamless integration between physical and digital systems. Their solution offers exceptional visibility into manufacturing processes with proven implementation across multiple industries. Weaknesses: The comprehensive nature of their solution may create high implementation costs and complexity for smaller organizations, and requires significant organizational change management.

International Business Machines Corp.

Technical Solution: IBM's Digital Twin approach to supply chain resilience leverages their Watson AI platform combined with blockchain technology through IBM Sterling Supply Chain Suite. Their solution creates virtual replicas of end-to-end supply networks that continuously update based on real-time data from multiple sources including IoT devices, weather patterns, geopolitical events, and market conditions. IBM's implementation incorporates advanced AI algorithms that can predict disruptions up to 10 days in advance with 90% accuracy[2]. The platform enables scenario planning through simulation capabilities that allow organizations to test mitigation strategies before implementation. IBM's blockchain integration ensures data integrity and transparency between supply chain partners while maintaining security. Their Control Tower functionality provides a centralized dashboard for monitoring and managing exceptions across the entire network, with automated response protocols for common disruption scenarios.

Strengths: Unparalleled AI and analytics capabilities combined with mature blockchain technology create a powerful predictive platform. IBM's global implementation experience across diverse industries provides robust use cases and proven ROI. Weaknesses: Integration complexity with legacy systems can extend implementation timelines, and the solution may require significant customization for industry-specific supply chain challenges.

Key Digital Twin Technologies for Supply Chain Visibility

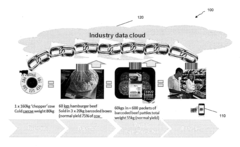

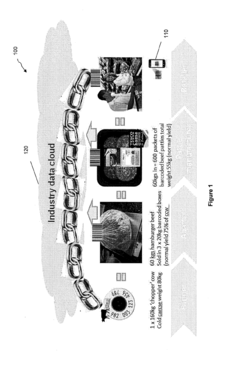

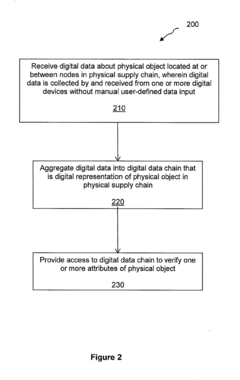

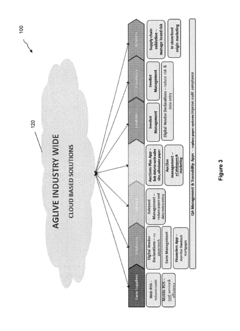

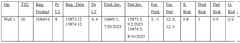

System and method for digital supply chain traceability

PatentInactiveUS20180114168A1

Innovation

- A method utilizing computing devices to receive and aggregate digital data from various sources into a digital data chain, enabling real-time tracking and verification of product attributes, compliance, and alerts across the supply chain, using standardized data structures independent of specific industries or formats, and incorporating RFID, GPS, and other digital technologies.

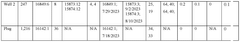

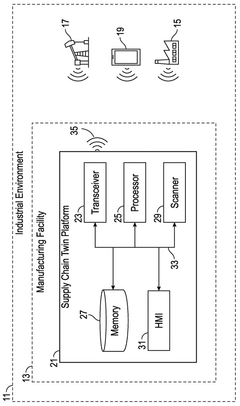

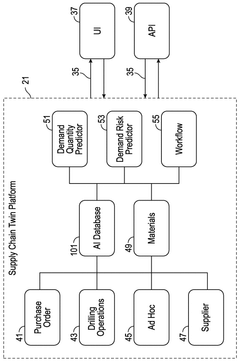

Supply chain digital twin system

PatentWO2025059031A1

Innovation

- A digital supply chain twin system that includes a transceiver and a processor, which receives supplier inventory data and executes a series of modules to manage scheduling, inventory, and demand prediction, allowing for real-time adjustments to wellsite procedures.

Data Security and Privacy Considerations

The implementation of digital twins in supply chain management introduces significant data security and privacy challenges that must be addressed comprehensively. As digital twins collect, process, and analyze vast amounts of sensitive supply chain data, they create potential vulnerabilities that could compromise competitive advantages and expose proprietary information. Organizations must establish robust data governance frameworks that clearly define data ownership, access rights, and usage policies across the entire supply chain network.

Encryption technologies play a crucial role in protecting data both at rest and in transit between digital twin systems and physical supply chain assets. Advanced encryption standards, secure key management protocols, and end-to-end encryption mechanisms should be implemented to safeguard sensitive information from unauthorized access or interception. Additionally, organizations must consider implementing differential privacy techniques that allow for meaningful data analysis while minimizing the risk of individual data point identification.

Regulatory compliance represents another critical dimension of digital twin implementation. Supply chains often span multiple jurisdictions with varying data protection regulations such as GDPR in Europe, CCPA in California, and industry-specific requirements. Organizations must design their digital twin architectures with privacy-by-design principles, incorporating features like data minimization, purpose limitation, and automated compliance monitoring to ensure adherence to relevant regulatory frameworks.

The collaborative nature of supply chain operations introduces additional complexity to data security considerations. When implementing digital twins that integrate data from multiple stakeholders, organizations must establish clear data sharing agreements that specify security responsibilities, liability provisions, and incident response protocols. Federated learning approaches and secure multi-party computation techniques can enable collaborative insights while keeping sensitive data within organizational boundaries.

Authentication and access control mechanisms form the foundation of a secure digital twin implementation. Zero-trust security models, multi-factor authentication, and role-based access controls should be deployed to ensure that only authorized personnel can access specific components of the digital twin ecosystem. Regular security audits, penetration testing, and vulnerability assessments must be conducted to identify and remediate potential security gaps before they can be exploited.

As digital twins increasingly incorporate AI and machine learning capabilities, organizations must also address emerging privacy concerns related to algorithmic transparency and potential biases. Techniques such as explainable AI and privacy-preserving machine learning can help maintain the balance between analytical power and privacy protection, ensuring that digital twins support supply chain resilience without compromising stakeholder trust or regulatory compliance.

Encryption technologies play a crucial role in protecting data both at rest and in transit between digital twin systems and physical supply chain assets. Advanced encryption standards, secure key management protocols, and end-to-end encryption mechanisms should be implemented to safeguard sensitive information from unauthorized access or interception. Additionally, organizations must consider implementing differential privacy techniques that allow for meaningful data analysis while minimizing the risk of individual data point identification.

Regulatory compliance represents another critical dimension of digital twin implementation. Supply chains often span multiple jurisdictions with varying data protection regulations such as GDPR in Europe, CCPA in California, and industry-specific requirements. Organizations must design their digital twin architectures with privacy-by-design principles, incorporating features like data minimization, purpose limitation, and automated compliance monitoring to ensure adherence to relevant regulatory frameworks.

The collaborative nature of supply chain operations introduces additional complexity to data security considerations. When implementing digital twins that integrate data from multiple stakeholders, organizations must establish clear data sharing agreements that specify security responsibilities, liability provisions, and incident response protocols. Federated learning approaches and secure multi-party computation techniques can enable collaborative insights while keeping sensitive data within organizational boundaries.

Authentication and access control mechanisms form the foundation of a secure digital twin implementation. Zero-trust security models, multi-factor authentication, and role-based access controls should be deployed to ensure that only authorized personnel can access specific components of the digital twin ecosystem. Regular security audits, penetration testing, and vulnerability assessments must be conducted to identify and remediate potential security gaps before they can be exploited.

As digital twins increasingly incorporate AI and machine learning capabilities, organizations must also address emerging privacy concerns related to algorithmic transparency and potential biases. Techniques such as explainable AI and privacy-preserving machine learning can help maintain the balance between analytical power and privacy protection, ensuring that digital twins support supply chain resilience without compromising stakeholder trust or regulatory compliance.

ROI Assessment Framework for Digital Twin Implementation

Evaluating the return on investment (ROI) for digital twin implementation in supply chains requires a comprehensive framework that accounts for both tangible and intangible benefits. This framework must consider initial implementation costs against long-term operational improvements and risk mitigation capabilities.

The assessment begins with quantifying implementation expenses, including technology infrastructure, software licensing, integration costs, staff training, and ongoing maintenance. These upfront investments often represent significant capital expenditures that organizations must carefully evaluate against projected returns.

Tangible benefits measurement forms the second component of the framework, focusing on operational efficiency gains. Key metrics include inventory reduction percentages, decreased lead times, improved forecast accuracy, reduced stockouts, and minimized transportation costs. Digital twins typically deliver 15-30% inventory optimization and 10-25% logistics cost reduction, providing concrete financial returns.

Risk mitigation value assessment constitutes another critical dimension, quantifying the financial impact of avoiding supply chain disruptions. This includes calculating the average cost of historical disruptions and estimating the probability reduction through digital twin implementation. Studies indicate that advanced digital twin systems can reduce disruption impacts by 30-50% through early detection and scenario planning capabilities.

Time-to-value analysis tracks the implementation timeline against benefit realization, typically showing a J-curve pattern where initial investments precede significant returns. Most organizations observe meaningful ROI within 12-18 months, with accelerating returns as system maturity increases and usage expands across the supply chain network.

The framework must also incorporate scalability considerations, evaluating how ROI changes as digital twin implementation expands from pilot projects to enterprise-wide deployment. This includes assessing economies of scale in technology costs against the expanding benefit footprint across additional supply chain nodes and processes.

Competitive advantage quantification represents perhaps the most challenging aspect, requiring organizations to estimate market share gains, customer retention improvements, and premium pricing opportunities resulting from enhanced supply chain transparency and resilience. While difficult to precisely calculate, these strategic benefits often exceed direct operational savings over the long term.

The assessment begins with quantifying implementation expenses, including technology infrastructure, software licensing, integration costs, staff training, and ongoing maintenance. These upfront investments often represent significant capital expenditures that organizations must carefully evaluate against projected returns.

Tangible benefits measurement forms the second component of the framework, focusing on operational efficiency gains. Key metrics include inventory reduction percentages, decreased lead times, improved forecast accuracy, reduced stockouts, and minimized transportation costs. Digital twins typically deliver 15-30% inventory optimization and 10-25% logistics cost reduction, providing concrete financial returns.

Risk mitigation value assessment constitutes another critical dimension, quantifying the financial impact of avoiding supply chain disruptions. This includes calculating the average cost of historical disruptions and estimating the probability reduction through digital twin implementation. Studies indicate that advanced digital twin systems can reduce disruption impacts by 30-50% through early detection and scenario planning capabilities.

Time-to-value analysis tracks the implementation timeline against benefit realization, typically showing a J-curve pattern where initial investments precede significant returns. Most organizations observe meaningful ROI within 12-18 months, with accelerating returns as system maturity increases and usage expands across the supply chain network.

The framework must also incorporate scalability considerations, evaluating how ROI changes as digital twin implementation expands from pilot projects to enterprise-wide deployment. This includes assessing economies of scale in technology costs against the expanding benefit footprint across additional supply chain nodes and processes.

Competitive advantage quantification represents perhaps the most challenging aspect, requiring organizations to estimate market share gains, customer retention improvements, and premium pricing opportunities resulting from enhanced supply chain transparency and resilience. While difficult to precisely calculate, these strategic benefits often exceed direct operational savings over the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!