How Digital Twin Enhances Predictive Maintenance in Industrial Systems

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Maintenance Objectives

Digital Twin technology has evolved significantly since its conceptual introduction by Michael Grieves at the University of Michigan in 2002. Initially conceived as a virtual representation of physical assets, the technology has transformed through several distinct phases. The early 2000s marked the conceptual phase, where Digital Twins existed primarily as theoretical models. By 2010-2015, with advances in IoT sensors and cloud computing, practical implementations began emerging in aerospace and manufacturing sectors, focusing on basic monitoring capabilities.

The period from 2016 to 2020 witnessed rapid maturation, characterized by integration with AI and machine learning algorithms, enabling more sophisticated simulation and predictive capabilities. Currently, Digital Twins have evolved into comprehensive cyber-physical systems that can simulate, predict, and optimize industrial operations in real-time, representing a significant leap from their initial conceptualization.

In the context of predictive maintenance, Digital Twin technology aims to achieve several critical objectives. Primarily, it seeks to create high-fidelity virtual replicas of physical assets that accurately mirror real-world conditions and behaviors. These virtual models continuously synchronize with their physical counterparts through real-time data streams from embedded sensors, creating a dynamic feedback loop.

A fundamental objective is to enable proactive maintenance strategies by identifying potential failures before they occur. This involves analyzing historical performance data, current operating conditions, and simulated future states to predict component degradation and system failures with increasing accuracy. The technology aims to optimize maintenance scheduling by determining the optimal time for intervention—neither too early (wasting useful component life) nor too late (risking catastrophic failure).

Cost reduction represents another key objective, achieved through minimizing unplanned downtime, extending equipment lifespan, and optimizing spare parts inventory. Digital Twins also aim to enhance safety by identifying potential failure modes that could lead to hazardous conditions, particularly critical in high-risk industries like oil and gas or nuclear power.

Looking forward, the evolution trajectory points toward increasingly autonomous maintenance systems where Digital Twins not only predict failures but also automatically initiate maintenance workflows, order replacement parts, and even execute certain maintenance procedures through connected robotic systems. The ultimate goal is to create self-healing industrial systems that can anticipate, diagnose, and resolve potential issues with minimal human intervention, fundamentally transforming traditional maintenance paradigms.

The period from 2016 to 2020 witnessed rapid maturation, characterized by integration with AI and machine learning algorithms, enabling more sophisticated simulation and predictive capabilities. Currently, Digital Twins have evolved into comprehensive cyber-physical systems that can simulate, predict, and optimize industrial operations in real-time, representing a significant leap from their initial conceptualization.

In the context of predictive maintenance, Digital Twin technology aims to achieve several critical objectives. Primarily, it seeks to create high-fidelity virtual replicas of physical assets that accurately mirror real-world conditions and behaviors. These virtual models continuously synchronize with their physical counterparts through real-time data streams from embedded sensors, creating a dynamic feedback loop.

A fundamental objective is to enable proactive maintenance strategies by identifying potential failures before they occur. This involves analyzing historical performance data, current operating conditions, and simulated future states to predict component degradation and system failures with increasing accuracy. The technology aims to optimize maintenance scheduling by determining the optimal time for intervention—neither too early (wasting useful component life) nor too late (risking catastrophic failure).

Cost reduction represents another key objective, achieved through minimizing unplanned downtime, extending equipment lifespan, and optimizing spare parts inventory. Digital Twins also aim to enhance safety by identifying potential failure modes that could lead to hazardous conditions, particularly critical in high-risk industries like oil and gas or nuclear power.

Looking forward, the evolution trajectory points toward increasingly autonomous maintenance systems where Digital Twins not only predict failures but also automatically initiate maintenance workflows, order replacement parts, and even execute certain maintenance procedures through connected robotic systems. The ultimate goal is to create self-healing industrial systems that can anticipate, diagnose, and resolve potential issues with minimal human intervention, fundamentally transforming traditional maintenance paradigms.

Industrial Market Demand for Predictive Maintenance

The industrial sector is witnessing a significant shift towards predictive maintenance solutions, driven by the need to minimize downtime, optimize operational efficiency, and extend equipment lifespan. Market research indicates that the global predictive maintenance market is projected to grow from $4.0 billion in 2020 to $12.3 billion by 2025, representing a compound annual growth rate of 25.2%. This substantial growth reflects the increasing recognition of predictive maintenance as a critical component in modern industrial operations.

Manufacturing industries, particularly automotive, aerospace, and heavy machinery sectors, demonstrate the highest demand for advanced predictive maintenance solutions. These industries operate with high-value equipment where unplanned downtime can cost between $10,000 and $250,000 per hour, creating a compelling business case for predictive maintenance implementation. According to recent surveys, over 70% of manufacturing companies consider predictive maintenance a strategic priority for their digital transformation initiatives.

The energy sector follows closely, with power generation and distribution companies investing heavily in predictive maintenance technologies to ensure grid reliability and optimize asset performance. Oil and gas companies are similarly adopting these solutions to monitor critical infrastructure across remote locations, with implementation rates increasing by approximately 30% annually since 2018.

Transportation and logistics industries are emerging as significant adopters, focusing on fleet management and critical infrastructure maintenance. Railways, commercial aviation, and shipping companies report maintenance cost reductions of 15-25% following implementation of predictive maintenance systems enhanced by digital twin technology.

Market analysis reveals that the primary drivers for this growing demand include aging industrial infrastructure in developed economies, increasing complexity of modern equipment, rising labor costs for skilled maintenance personnel, and stringent regulatory requirements regarding operational safety and environmental impact. Additionally, the COVID-19 pandemic has accelerated adoption as companies seek to reduce on-site personnel while maintaining operational integrity.

Regional analysis shows North America and Europe leading in adoption rates, while Asia-Pacific represents the fastest-growing market with China, Japan, and South Korea making substantial investments in smart manufacturing initiatives that incorporate predictive maintenance capabilities. Industry surveys indicate that approximately 65% of large industrial enterprises have either implemented or are planning to implement predictive maintenance solutions within the next three years.

The market is further stimulated by the convergence of predictive maintenance with other Industry 4.0 technologies, particularly IoT sensors, cloud computing, and artificial intelligence. This technological integration is creating demand for comprehensive solutions that not only predict failures but also automate maintenance scheduling and resource allocation.

Manufacturing industries, particularly automotive, aerospace, and heavy machinery sectors, demonstrate the highest demand for advanced predictive maintenance solutions. These industries operate with high-value equipment where unplanned downtime can cost between $10,000 and $250,000 per hour, creating a compelling business case for predictive maintenance implementation. According to recent surveys, over 70% of manufacturing companies consider predictive maintenance a strategic priority for their digital transformation initiatives.

The energy sector follows closely, with power generation and distribution companies investing heavily in predictive maintenance technologies to ensure grid reliability and optimize asset performance. Oil and gas companies are similarly adopting these solutions to monitor critical infrastructure across remote locations, with implementation rates increasing by approximately 30% annually since 2018.

Transportation and logistics industries are emerging as significant adopters, focusing on fleet management and critical infrastructure maintenance. Railways, commercial aviation, and shipping companies report maintenance cost reductions of 15-25% following implementation of predictive maintenance systems enhanced by digital twin technology.

Market analysis reveals that the primary drivers for this growing demand include aging industrial infrastructure in developed economies, increasing complexity of modern equipment, rising labor costs for skilled maintenance personnel, and stringent regulatory requirements regarding operational safety and environmental impact. Additionally, the COVID-19 pandemic has accelerated adoption as companies seek to reduce on-site personnel while maintaining operational integrity.

Regional analysis shows North America and Europe leading in adoption rates, while Asia-Pacific represents the fastest-growing market with China, Japan, and South Korea making substantial investments in smart manufacturing initiatives that incorporate predictive maintenance capabilities. Industry surveys indicate that approximately 65% of large industrial enterprises have either implemented or are planning to implement predictive maintenance solutions within the next three years.

The market is further stimulated by the convergence of predictive maintenance with other Industry 4.0 technologies, particularly IoT sensors, cloud computing, and artificial intelligence. This technological integration is creating demand for comprehensive solutions that not only predict failures but also automate maintenance scheduling and resource allocation.

Current Digital Twin Implementation Challenges

Despite the promising potential of digital twins in predictive maintenance, several significant implementation challenges persist in industrial environments. The integration of comprehensive digital twin systems faces substantial technical barriers related to data acquisition and management. Many industrial facilities operate with legacy equipment lacking built-in sensors or standardized data outputs, creating fundamental obstacles to establishing the real-time data streams necessary for accurate twin modeling. This heterogeneity in equipment age and capabilities complicates the creation of unified digital representations.

Data quality and integration issues represent another major hurdle. Industrial environments generate vast quantities of data from diverse sources with varying formats, sampling rates, and reliability levels. Synchronizing and harmonizing these disparate data streams to create coherent digital models requires sophisticated data engineering capabilities that many organizations currently lack. Furthermore, the absence of standardized protocols for digital twin implementation across industries creates interoperability challenges between systems and components.

Computational requirements present significant technical constraints. High-fidelity digital twins, particularly those modeling complex physical processes or entire production lines, demand substantial computing resources for real-time simulation and analysis. The balance between model complexity and computational efficiency remains difficult to optimize, especially when attempting to deploy digital twins at scale across multiple assets or facilities.

Security concerns also impede widespread adoption. Digital twins require extensive data sharing between operational technology (OT) and information technology (IT) systems, creating potential cybersecurity vulnerabilities. As industrial systems become increasingly connected, the attack surface expands, raising legitimate concerns about unauthorized access to critical infrastructure control systems through digital twin interfaces.

Organizational challenges compound these technical issues. Many companies lack the cross-functional expertise required to implement digital twins effectively. The technology demands collaboration between domain experts, data scientists, IT specialists, and operational staff—a level of integration that traditional organizational structures often impede. Additionally, the substantial upfront investment required for digital twin implementation, coupled with uncertain ROI timelines, creates financial barriers to adoption.

Validation and verification of digital twin accuracy represents another significant challenge. Establishing confidence in digital twin predictions requires extensive testing and calibration against real-world performance data. For predictive maintenance applications, this validation process is particularly critical yet methodologically complex, as it must account for rare failure events and evolving equipment conditions.

Data quality and integration issues represent another major hurdle. Industrial environments generate vast quantities of data from diverse sources with varying formats, sampling rates, and reliability levels. Synchronizing and harmonizing these disparate data streams to create coherent digital models requires sophisticated data engineering capabilities that many organizations currently lack. Furthermore, the absence of standardized protocols for digital twin implementation across industries creates interoperability challenges between systems and components.

Computational requirements present significant technical constraints. High-fidelity digital twins, particularly those modeling complex physical processes or entire production lines, demand substantial computing resources for real-time simulation and analysis. The balance between model complexity and computational efficiency remains difficult to optimize, especially when attempting to deploy digital twins at scale across multiple assets or facilities.

Security concerns also impede widespread adoption. Digital twins require extensive data sharing between operational technology (OT) and information technology (IT) systems, creating potential cybersecurity vulnerabilities. As industrial systems become increasingly connected, the attack surface expands, raising legitimate concerns about unauthorized access to critical infrastructure control systems through digital twin interfaces.

Organizational challenges compound these technical issues. Many companies lack the cross-functional expertise required to implement digital twins effectively. The technology demands collaboration between domain experts, data scientists, IT specialists, and operational staff—a level of integration that traditional organizational structures often impede. Additionally, the substantial upfront investment required for digital twin implementation, coupled with uncertain ROI timelines, creates financial barriers to adoption.

Validation and verification of digital twin accuracy represents another significant challenge. Establishing confidence in digital twin predictions requires extensive testing and calibration against real-world performance data. For predictive maintenance applications, this validation process is particularly critical yet methodologically complex, as it must account for rare failure events and evolving equipment conditions.

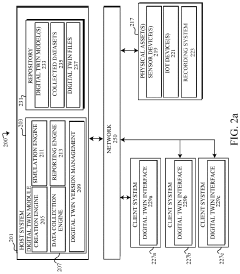

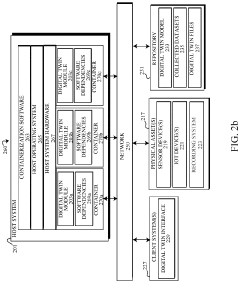

Current Digital Twin Architectures for Maintenance

01 Digital twin modeling for equipment health monitoring

Digital twin technology creates virtual replicas of physical assets to monitor equipment health in real-time. These models integrate sensor data with simulation capabilities to track operational parameters and detect anomalies before failures occur. The technology enables continuous assessment of equipment condition, providing insights into performance degradation patterns and supporting proactive maintenance decisions.- Digital twin modeling for equipment health monitoring: Digital twin technology creates virtual replicas of physical assets to monitor equipment health in real-time. These models integrate sensor data with simulation capabilities to track performance metrics, detect anomalies, and predict potential failures before they occur. By continuously comparing actual performance against expected behavior, the system can identify deviations that indicate maintenance needs, enabling proactive intervention and reducing unplanned downtime.

- AI-powered predictive analytics for maintenance optimization: Advanced artificial intelligence algorithms analyze historical and real-time data from digital twins to predict equipment failures and optimize maintenance schedules. Machine learning models identify patterns and correlations in operational data that human analysts might miss, enabling more accurate failure predictions. These AI systems continuously improve over time as they process more data, leading to increasingly precise maintenance forecasts and recommendations that reduce unnecessary maintenance while preventing critical failures.

- IoT sensor integration for real-time condition monitoring: Internet of Things (IoT) sensors collect real-time data on equipment parameters such as temperature, vibration, pressure, and acoustic emissions for digital twin models. This continuous stream of operational data enables the digital twin to maintain an accurate representation of the physical asset's current state. The integration of multiple sensor types provides a comprehensive view of equipment health, allowing for more nuanced analysis of potential failure modes and more effective predictive maintenance strategies.

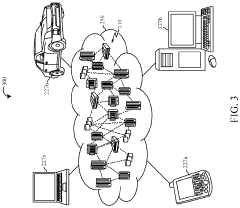

- Cloud-based digital twin platforms for distributed maintenance systems: Cloud computing platforms enable the deployment of digital twin solutions across distributed industrial environments, providing centralized monitoring and maintenance management. These platforms offer scalable computing resources for processing large volumes of sensor data and running complex simulation models. Cloud-based systems facilitate remote access to digital twin insights, allowing maintenance teams to monitor equipment health and coordinate maintenance activities across multiple locations, improving overall operational efficiency.

- Digital twin-enabled maintenance workflow automation: Digital twin systems automate maintenance workflows by triggering alerts, generating work orders, and providing detailed maintenance instructions based on predictive analytics. When potential issues are detected, the system can automatically schedule maintenance tasks, allocate resources, and provide technicians with relevant information about the problem and required repairs. This automation streamlines the maintenance process, reduces human error, and ensures that maintenance activities are performed at optimal times to minimize disruption to operations.

02 AI-powered predictive analytics for maintenance optimization

Artificial intelligence algorithms analyze data collected from digital twins to predict potential equipment failures. Machine learning models identify patterns in operational data, enabling accurate failure prediction and optimized maintenance scheduling. These systems continuously improve their predictive capabilities through feedback loops, reducing false alarms while increasing detection accuracy of impending failures.Expand Specific Solutions03 IoT sensor integration with digital twin platforms

Internet of Things (IoT) sensors collect real-time data from physical equipment and feed it into digital twin platforms. This integration enables comprehensive monitoring of various parameters including temperature, vibration, pressure, and electrical characteristics. The sensor networks provide continuous data streams that form the foundation for accurate digital representations and timely maintenance interventions.Expand Specific Solutions04 Cloud-based digital twin systems for remote monitoring

Cloud platforms host digital twin implementations to enable remote monitoring and maintenance management across distributed assets. These systems provide scalable infrastructure for processing large volumes of sensor data and running complex simulation models. Cloud-based architectures facilitate collaboration among maintenance teams, allowing experts to access digital twins from anywhere and provide timely maintenance recommendations.Expand Specific Solutions05 Lifecycle management through digital twin simulation

Digital twins enable simulation of equipment lifecycle scenarios to optimize maintenance strategies and extend asset lifespan. These simulations can test different operational conditions and maintenance approaches without risking physical equipment. By analyzing the impact of various factors on equipment degradation, maintenance teams can develop optimal intervention strategies that balance performance, reliability, and cost considerations.Expand Specific Solutions

Leading Digital Twin Solution Providers

Digital Twin technology in predictive maintenance is evolving rapidly, currently transitioning from early adoption to growth phase. The global market is expanding significantly, projected to reach $48.2 billion by 2026 with a CAGR of 58%. Technology maturity varies across players: industry leaders like Siemens AG, IBM, and ABB Group have developed comprehensive platforms with advanced AI integration, while companies like Tata Consultancy Services and Oracle are focusing on specialized industry applications. Applied Materials and Boeing are leveraging Digital Twins for complex manufacturing systems, while newer entrants like LG Energy Solution are developing niche solutions. Universities including Shanghai Jiao Tong and Northwestern Polytechnical are driving fundamental research, accelerating the technology's industrial implementation.

International Business Machines Corp.

Technical Solution: IBM has developed an advanced Digital Twin framework for predictive maintenance called IBM Maximo, which incorporates their Watson AI capabilities. This solution creates virtual replicas of industrial equipment and systems that continuously update based on real-time operational data collected through IoT sensors[2]. IBM's approach leverages cognitive analytics to process massive amounts of structured and unstructured data, identifying subtle patterns that might indicate impending failures. Their Digital Twin implementation incorporates multiple data sources including equipment specifications, maintenance histories, environmental conditions, and operational parameters to create comprehensive asset models[4]. The system employs sophisticated machine learning algorithms that improve over time, becoming increasingly accurate at predicting maintenance needs. IBM's solution also features augmented reality interfaces that allow maintenance technicians to visualize the Digital Twin overlaid on physical equipment, providing contextual information and step-by-step guidance for maintenance procedures[7]. The platform integrates with enterprise asset management systems to automatically generate work orders and optimize maintenance scheduling based on predictive insights.

Strengths: IBM's solution offers powerful AI and cognitive computing capabilities through Watson integration, enabling sophisticated pattern recognition and anomaly detection. Their platform provides excellent scalability for enterprise-level implementations across diverse industrial environments. Weaknesses: The solution may require significant computational resources and specialized expertise to implement and maintain effectively. Integration with legacy industrial systems can sometimes present challenges requiring custom development work.

ABB Group

Technical Solution: ABB Group has developed ABB Ability™, a comprehensive Digital Twin platform for industrial predictive maintenance that creates virtual replicas of physical assets and processes. Their solution integrates operational technology (OT) with information technology (IT) to enable real-time monitoring and predictive analytics across industrial systems[3]. ABB's Digital Twin implementation collects data from thousands of sensors embedded throughout industrial equipment, processing this information through edge computing devices before transmitting relevant insights to cloud platforms. Their system employs physics-based modeling combined with machine learning algorithms to detect anomalies and predict potential failures weeks or even months in advance[6]. ABB's platform includes specialized modules for different industrial sectors, including power generation, manufacturing, and process industries, with tailored algorithms for equipment-specific failure modes. The solution features a collaborative interface that allows maintenance teams, engineers, and operations personnel to interact with the Digital Twin, run simulations, and evaluate different maintenance scenarios before implementing them on physical assets[8]. ABB's predictive maintenance capabilities are enhanced by their extensive domain knowledge in industrial automation and electrical systems.

Strengths: ABB offers deep domain expertise across multiple industrial sectors, particularly in power systems and automation. Their solution provides excellent integration between operational technology and IT systems, bridging the traditional gap between these domains. The platform offers robust edge computing capabilities for environments with limited connectivity. Weaknesses: The solution may require significant customization for specialized industrial applications. Implementation complexity can be high for organizations without strong technical capabilities.

Key Innovations in Digital Twin Sensor Integration

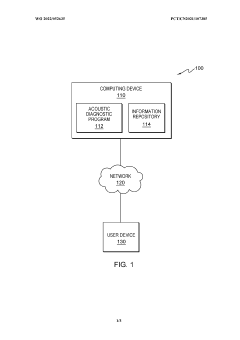

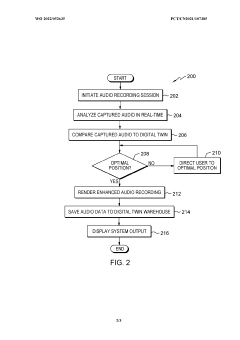

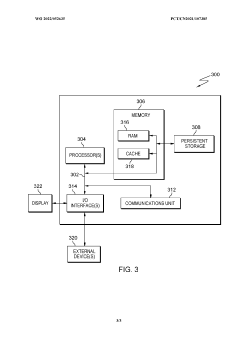

Digital twin enabled equipment diagnostics based on acoustic modeling

PatentWO2022052635A1

Innovation

- Integration of acoustic modeling with digital twin technology for enhanced equipment diagnostics, creating a more comprehensive virtual representation that includes sound patterns for fault detection.

- Real-time sound data collection and analysis through connected sensors that map acoustic information onto the virtual model, enabling immediate detection of abnormal operating conditions.

- Using sound recognition technology based on pattern recognition theories to identify equipment faults before they lead to failures, enhancing predictive maintenance capabilities.

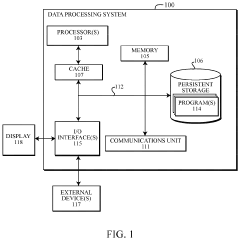

Digital twin workflow simulation

PatentActiveUS20210374032A1

Innovation

- A computer-implemented method for simulating digital twin performance that allows users to selectively bypass certain input parameters and components, using customizable configurations to focus on specific parts, substitute alternative components, and provide overriding values for intermediate simulation results, enabling more targeted analysis and optimization.

ROI Analysis of Digital Twin Maintenance Solutions

Implementing digital twin technology for predictive maintenance requires significant investment, making ROI analysis crucial for decision-makers. Initial implementation costs typically range from $100,000 to $1 million depending on system complexity, including hardware sensors, software platforms, integration services, and staff training. However, these investments yield substantial returns through multiple value streams.

Downtime reduction represents the most significant ROI factor, with studies indicating a 30-45% decrease in unplanned downtime. For manufacturing facilities where downtime costs average $22,000 per minute, this translates to millions in annual savings. A mid-sized automotive plant implementing digital twin maintenance solutions reported $3.2 million in avoided downtime costs within the first year of deployment.

Maintenance cost optimization delivers another substantial return, with organizations reporting 25-30% reductions in overall maintenance expenses. This stems from transitioning from reactive or scheduled maintenance to predictive approaches, reducing unnecessary part replacements and labor costs. Digital twins enable precise identification of when components require maintenance, extending asset lifecycles by 20-25% on average.

Energy efficiency improvements contribute additional ROI, with digital twin implementations yielding 10-15% reductions in energy consumption through optimized operations. For energy-intensive industries like steel manufacturing or chemical processing, these savings can exceed $500,000 annually for a single facility.

The payback period for digital twin maintenance solutions typically ranges from 12-24 months, with more complex implementations trending toward the longer end. However, organizations implementing these solutions across multiple facilities or production lines report accelerated ROI as implementation expertise increases and economies of scale emerge.

Risk mitigation benefits, while harder to quantify, provide significant value through reduced safety incidents, regulatory compliance improvements, and intellectual property protection. Companies report 15-20% reductions in safety incidents following digital twin implementation, with corresponding decreases in associated costs and liabilities.

When calculating comprehensive ROI, organizations should consider both tangible metrics (downtime reduction, maintenance savings, energy efficiency) and intangible benefits (improved decision-making, knowledge retention, competitive advantage) to capture the full value proposition of digital twin maintenance solutions.

Downtime reduction represents the most significant ROI factor, with studies indicating a 30-45% decrease in unplanned downtime. For manufacturing facilities where downtime costs average $22,000 per minute, this translates to millions in annual savings. A mid-sized automotive plant implementing digital twin maintenance solutions reported $3.2 million in avoided downtime costs within the first year of deployment.

Maintenance cost optimization delivers another substantial return, with organizations reporting 25-30% reductions in overall maintenance expenses. This stems from transitioning from reactive or scheduled maintenance to predictive approaches, reducing unnecessary part replacements and labor costs. Digital twins enable precise identification of when components require maintenance, extending asset lifecycles by 20-25% on average.

Energy efficiency improvements contribute additional ROI, with digital twin implementations yielding 10-15% reductions in energy consumption through optimized operations. For energy-intensive industries like steel manufacturing or chemical processing, these savings can exceed $500,000 annually for a single facility.

The payback period for digital twin maintenance solutions typically ranges from 12-24 months, with more complex implementations trending toward the longer end. However, organizations implementing these solutions across multiple facilities or production lines report accelerated ROI as implementation expertise increases and economies of scale emerge.

Risk mitigation benefits, while harder to quantify, provide significant value through reduced safety incidents, regulatory compliance improvements, and intellectual property protection. Companies report 15-20% reductions in safety incidents following digital twin implementation, with corresponding decreases in associated costs and liabilities.

When calculating comprehensive ROI, organizations should consider both tangible metrics (downtime reduction, maintenance savings, energy efficiency) and intangible benefits (improved decision-making, knowledge retention, competitive advantage) to capture the full value proposition of digital twin maintenance solutions.

Cybersecurity Considerations for Industrial Digital Twins

As digital twins become increasingly integrated into industrial systems for predictive maintenance, they simultaneously introduce significant cybersecurity vulnerabilities. The bidirectional data flow between physical assets and their digital counterparts creates multiple attack vectors that malicious actors can exploit. These vulnerabilities are particularly concerning as digital twins often contain sensitive operational data and intellectual property that could be valuable targets.

The interconnected nature of digital twin ecosystems presents unique security challenges. With numerous sensors, edge devices, cloud platforms, and analytics systems working in concert, each connection point represents a potential security breach. Compromised digital twins could lead to data theft, operational disruption, or even physical damage to industrial equipment if manipulated maintenance recommendations are implemented.

Authentication and access control mechanisms must be robust yet flexible enough to accommodate the dynamic nature of digital twin operations. Multi-factor authentication, role-based access controls, and principle of least privilege approaches are essential for protecting digital twin environments while maintaining operational efficiency. Regular security audits and penetration testing should be conducted to identify vulnerabilities before they can be exploited.

Data integrity is paramount in digital twin implementations for predictive maintenance. Corrupted or manipulated data could lead to incorrect maintenance decisions, potentially causing equipment failure or unnecessary downtime. Implementing data validation protocols, cryptographic verification, and blockchain technologies can help ensure that data remains authentic and unaltered throughout its lifecycle in the digital twin ecosystem.

Network segmentation and secure communication protocols are critical defensive measures. Industrial digital twins should operate within carefully designed network architectures that isolate critical systems and implement encrypted communications. Zero-trust security models, which verify every access request regardless of source, are increasingly recommended for digital twin implementations in industrial environments.

Supply chain security must also be considered, as digital twins often incorporate components from multiple vendors. Thorough vetting of third-party software and hardware, along with continuous monitoring for vulnerabilities, helps mitigate risks introduced through the supply chain. Security requirements should be explicitly defined in vendor contracts and regularly verified through compliance assessments.

Incident response planning specifically tailored to digital twin environments is essential. Organizations must develop protocols for detecting, containing, and remediating security breaches that affect their digital twin infrastructure. This includes procedures for safely reverting to backup systems while maintaining critical operations during security incidents.

The interconnected nature of digital twin ecosystems presents unique security challenges. With numerous sensors, edge devices, cloud platforms, and analytics systems working in concert, each connection point represents a potential security breach. Compromised digital twins could lead to data theft, operational disruption, or even physical damage to industrial equipment if manipulated maintenance recommendations are implemented.

Authentication and access control mechanisms must be robust yet flexible enough to accommodate the dynamic nature of digital twin operations. Multi-factor authentication, role-based access controls, and principle of least privilege approaches are essential for protecting digital twin environments while maintaining operational efficiency. Regular security audits and penetration testing should be conducted to identify vulnerabilities before they can be exploited.

Data integrity is paramount in digital twin implementations for predictive maintenance. Corrupted or manipulated data could lead to incorrect maintenance decisions, potentially causing equipment failure or unnecessary downtime. Implementing data validation protocols, cryptographic verification, and blockchain technologies can help ensure that data remains authentic and unaltered throughout its lifecycle in the digital twin ecosystem.

Network segmentation and secure communication protocols are critical defensive measures. Industrial digital twins should operate within carefully designed network architectures that isolate critical systems and implement encrypted communications. Zero-trust security models, which verify every access request regardless of source, are increasingly recommended for digital twin implementations in industrial environments.

Supply chain security must also be considered, as digital twins often incorporate components from multiple vendors. Thorough vetting of third-party software and hardware, along with continuous monitoring for vulnerabilities, helps mitigate risks introduced through the supply chain. Security requirements should be explicitly defined in vendor contracts and regularly verified through compliance assessments.

Incident response planning specifically tailored to digital twin environments is essential. Organizations must develop protocols for detecting, containing, and remediating security breaches that affect their digital twin infrastructure. This includes procedures for safely reverting to backup systems while maintaining critical operations during security incidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!