Patent Insights into Digital Twin Innovations for Aerospace and Defense

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Objectives in A&D

Digital Twin technology in the Aerospace and Defense (A&D) sector has evolved significantly over the past decade, transforming from basic simulation models to sophisticated virtual replicas that mirror physical assets with unprecedented accuracy. The concept originated in the early 2000s but gained substantial traction in A&D applications around 2010 when computational capabilities began matching the complex requirements of aerospace systems modeling.

The evolution pathway shows three distinct generations of Digital Twin technology in A&D. First-generation twins (2010-2015) primarily focused on design and engineering applications, creating static models with limited real-time capabilities. Second-generation twins (2015-2020) incorporated sensor integration and real-time data processing, enabling dynamic monitoring of aircraft components and defense systems. The current third-generation twins (2020-present) feature AI-powered predictive capabilities, autonomous decision-making frameworks, and comprehensive system-of-systems integration.

Patent analysis reveals that Digital Twin objectives in A&D have progressively expanded from initial goals of reducing physical testing costs to current ambitions of enabling autonomous operations and predictive maintenance. Key technical objectives now include achieving sub-millisecond latency in data synchronization between physical and digital entities, developing self-healing algorithms for system optimization, and establishing interoperability standards across diverse platforms.

The A&D sector presents unique requirements for Digital Twin implementation, including stringent security protocols, extreme environmental condition modeling, and ultra-high reliability standards. These factors have driven specialized development paths distinct from commercial applications, particularly in areas of cryptographic security integration and physics-based modeling accuracy.

Recent patent filings demonstrate a clear trend toward multi-domain Digital Twins that simultaneously model physical, cyber, and electromagnetic aspects of A&D systems. This holistic approach aims to address the increasingly complex threat landscape and operational environments faced by modern defense systems.

The ultimate objective for Digital Twin technology in A&D appears to be the creation of "cognitive twins" - autonomous virtual entities capable of not only mirroring physical systems but anticipating failures, recommending optimizations, and simulating complex mission scenarios with minimal human intervention. This represents a significant shift from descriptive to prescriptive analytics capabilities, with patents increasingly focusing on decision support frameworks and autonomous response mechanisms.

The evolution pathway shows three distinct generations of Digital Twin technology in A&D. First-generation twins (2010-2015) primarily focused on design and engineering applications, creating static models with limited real-time capabilities. Second-generation twins (2015-2020) incorporated sensor integration and real-time data processing, enabling dynamic monitoring of aircraft components and defense systems. The current third-generation twins (2020-present) feature AI-powered predictive capabilities, autonomous decision-making frameworks, and comprehensive system-of-systems integration.

Patent analysis reveals that Digital Twin objectives in A&D have progressively expanded from initial goals of reducing physical testing costs to current ambitions of enabling autonomous operations and predictive maintenance. Key technical objectives now include achieving sub-millisecond latency in data synchronization between physical and digital entities, developing self-healing algorithms for system optimization, and establishing interoperability standards across diverse platforms.

The A&D sector presents unique requirements for Digital Twin implementation, including stringent security protocols, extreme environmental condition modeling, and ultra-high reliability standards. These factors have driven specialized development paths distinct from commercial applications, particularly in areas of cryptographic security integration and physics-based modeling accuracy.

Recent patent filings demonstrate a clear trend toward multi-domain Digital Twins that simultaneously model physical, cyber, and electromagnetic aspects of A&D systems. This holistic approach aims to address the increasingly complex threat landscape and operational environments faced by modern defense systems.

The ultimate objective for Digital Twin technology in A&D appears to be the creation of "cognitive twins" - autonomous virtual entities capable of not only mirroring physical systems but anticipating failures, recommending optimizations, and simulating complex mission scenarios with minimal human intervention. This represents a significant shift from descriptive to prescriptive analytics capabilities, with patents increasingly focusing on decision support frameworks and autonomous response mechanisms.

Market Demand Analysis for A&D Digital Twin Solutions

The digital twin market in the Aerospace and Defense (A&D) sector is experiencing robust growth, driven by increasing demands for operational efficiency, predictive maintenance, and enhanced safety measures. Current market analysis indicates that the A&D digital twin segment is expanding at a compound annual growth rate exceeding the broader digital twin market, reflecting the sector's unique requirements and high-value applications.

Primary market drivers include the need for reduced aircraft downtime, which directly impacts operational costs and revenue generation for commercial airlines. Military applications are similarly focused on maximizing asset availability and mission readiness, with digital twins enabling more accurate prediction of maintenance needs and potential failures before they occur in critical situations.

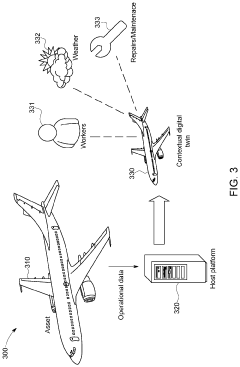

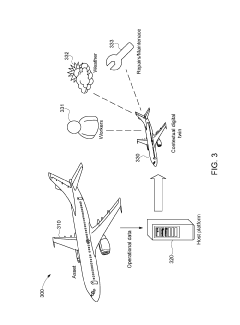

The demand landscape is segmented across multiple application areas within A&D. Aircraft performance optimization represents the largest segment, where digital twins enable real-time monitoring and adjustment of operational parameters to maximize fuel efficiency and reduce environmental impact. Maintenance, Repair, and Overhaul (MRO) applications follow closely, with digital twins facilitating condition-based maintenance strategies that can extend component lifecycles and reduce unscheduled maintenance events.

Supply chain optimization presents another significant market opportunity, as A&D manufacturers seek to mitigate disruptions through improved visibility and scenario planning capabilities offered by digital twin technologies. The complex, global nature of aerospace supply chains makes this application particularly valuable for OEMs and tier-one suppliers.

Regional analysis reveals North America as the dominant market for A&D digital twin solutions, supported by the presence of major aerospace manufacturers and defense contractors. Europe follows as the second-largest market, with significant investments in digital transformation initiatives across its aerospace sector. The Asia-Pacific region represents the fastest-growing market, driven by expanding defense budgets and the rapid growth of commercial aviation in countries like China and India.

Customer segmentation shows that large OEMs and prime defense contractors are the early adopters and largest consumers of digital twin technologies. However, the market is witnessing increased adoption among tier-one and tier-two suppliers as the technology matures and implementation costs decrease. This trend is expected to accelerate as standardization efforts progress and more accessible platforms emerge.

The market is also seeing a shift from standalone digital twin implementations toward integrated ecosystems that connect multiple twins across the product lifecycle and supply chain. This evolution reflects the industry's recognition that maximum value is derived when digital twins operate as part of a broader digital thread strategy, connecting design, manufacturing, operations, and maintenance data in a continuous feedback loop.

Primary market drivers include the need for reduced aircraft downtime, which directly impacts operational costs and revenue generation for commercial airlines. Military applications are similarly focused on maximizing asset availability and mission readiness, with digital twins enabling more accurate prediction of maintenance needs and potential failures before they occur in critical situations.

The demand landscape is segmented across multiple application areas within A&D. Aircraft performance optimization represents the largest segment, where digital twins enable real-time monitoring and adjustment of operational parameters to maximize fuel efficiency and reduce environmental impact. Maintenance, Repair, and Overhaul (MRO) applications follow closely, with digital twins facilitating condition-based maintenance strategies that can extend component lifecycles and reduce unscheduled maintenance events.

Supply chain optimization presents another significant market opportunity, as A&D manufacturers seek to mitigate disruptions through improved visibility and scenario planning capabilities offered by digital twin technologies. The complex, global nature of aerospace supply chains makes this application particularly valuable for OEMs and tier-one suppliers.

Regional analysis reveals North America as the dominant market for A&D digital twin solutions, supported by the presence of major aerospace manufacturers and defense contractors. Europe follows as the second-largest market, with significant investments in digital transformation initiatives across its aerospace sector. The Asia-Pacific region represents the fastest-growing market, driven by expanding defense budgets and the rapid growth of commercial aviation in countries like China and India.

Customer segmentation shows that large OEMs and prime defense contractors are the early adopters and largest consumers of digital twin technologies. However, the market is witnessing increased adoption among tier-one and tier-two suppliers as the technology matures and implementation costs decrease. This trend is expected to accelerate as standardization efforts progress and more accessible platforms emerge.

The market is also seeing a shift from standalone digital twin implementations toward integrated ecosystems that connect multiple twins across the product lifecycle and supply chain. This evolution reflects the industry's recognition that maximum value is derived when digital twins operate as part of a broader digital thread strategy, connecting design, manufacturing, operations, and maintenance data in a continuous feedback loop.

Current State and Challenges of Digital Twin Technology

Digital Twin technology in the aerospace and defense sectors has reached a significant level of maturity, with numerous implementations across various applications. Currently, major defense contractors and aerospace manufacturers are utilizing digital twins for aircraft design, maintenance prediction, and operational optimization. The technology has evolved from simple simulation models to comprehensive virtual replicas that integrate real-time data from physical assets through IoT sensors and advanced telemetry systems.

In the United States, the Department of Defense has incorporated digital twin technology into its Digital Engineering Strategy, while NASA employs digital twins for spacecraft monitoring and mission planning. The European Space Agency has similarly adopted digital twins for satellite operations. Commercial aviation giants like Boeing and Airbus have implemented digital twins throughout their product lifecycles, from design to aftermarket support.

Despite these advancements, several critical challenges impede the full realization of digital twin potential in aerospace and defense. Data integration remains a significant hurdle, as systems must consolidate information from disparate sources, including legacy platforms with limited digital capabilities. The heterogeneous nature of data formats and protocols across different systems creates compatibility issues that complicate seamless integration.

Security concerns present another major challenge, particularly in defense applications where digital twins may contain sensitive or classified information. Protecting these virtual models from cyber threats while maintaining their functionality requires sophisticated cybersecurity measures that don't compromise performance or accessibility.

Computational demands pose substantial technical limitations, as high-fidelity digital twins require enormous processing power and storage capacity, especially when simulating complex systems like aircraft engines or entire defense platforms in real-time. Edge computing solutions are emerging to address latency issues, but bandwidth constraints remain problematic for remote operations.

Standardization gaps further complicate implementation, with inconsistent protocols across the industry hindering interoperability between different digital twin systems. Organizations like the Digital Twin Consortium are working to establish common frameworks, but widespread adoption of standards remains elusive.

The talent shortage represents a human resource challenge, as developing and maintaining digital twins requires specialized expertise in simulation, data science, and domain-specific engineering knowledge. The limited pool of qualified professionals with cross-disciplinary skills creates bottlenecks in implementation and ongoing management of digital twin ecosystems.

In the United States, the Department of Defense has incorporated digital twin technology into its Digital Engineering Strategy, while NASA employs digital twins for spacecraft monitoring and mission planning. The European Space Agency has similarly adopted digital twins for satellite operations. Commercial aviation giants like Boeing and Airbus have implemented digital twins throughout their product lifecycles, from design to aftermarket support.

Despite these advancements, several critical challenges impede the full realization of digital twin potential in aerospace and defense. Data integration remains a significant hurdle, as systems must consolidate information from disparate sources, including legacy platforms with limited digital capabilities. The heterogeneous nature of data formats and protocols across different systems creates compatibility issues that complicate seamless integration.

Security concerns present another major challenge, particularly in defense applications where digital twins may contain sensitive or classified information. Protecting these virtual models from cyber threats while maintaining their functionality requires sophisticated cybersecurity measures that don't compromise performance or accessibility.

Computational demands pose substantial technical limitations, as high-fidelity digital twins require enormous processing power and storage capacity, especially when simulating complex systems like aircraft engines or entire defense platforms in real-time. Edge computing solutions are emerging to address latency issues, but bandwidth constraints remain problematic for remote operations.

Standardization gaps further complicate implementation, with inconsistent protocols across the industry hindering interoperability between different digital twin systems. Organizations like the Digital Twin Consortium are working to establish common frameworks, but widespread adoption of standards remains elusive.

The talent shortage represents a human resource challenge, as developing and maintaining digital twins requires specialized expertise in simulation, data science, and domain-specific engineering knowledge. The limited pool of qualified professionals with cross-disciplinary skills creates bottlenecks in implementation and ongoing management of digital twin ecosystems.

Current Digital Twin Implementation Approaches

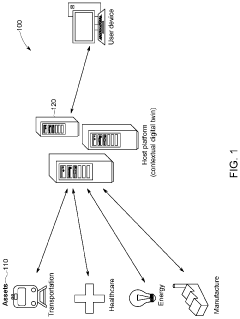

01 Digital Twin for Industrial Systems and Manufacturing

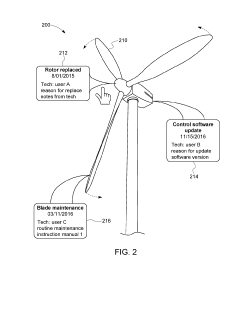

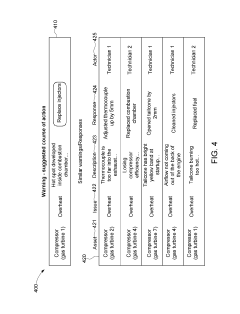

Digital twin technology enables real-time monitoring, simulation, and optimization of industrial systems and manufacturing processes. These virtual replicas mirror physical assets and processes, allowing for predictive maintenance, performance optimization, and process improvement without disrupting actual operations. The technology integrates with IoT sensors to collect operational data, creating accurate representations that can be used for testing scenarios and identifying potential issues before they occur in the physical environment.- Digital Twin for Industrial Systems and Manufacturing: Digital twins are virtual replicas of physical industrial systems and manufacturing processes that enable real-time monitoring, simulation, and optimization. These digital representations collect data from sensors and IoT devices to create accurate models that can predict performance, identify potential failures, and optimize operations. By implementing digital twins in manufacturing environments, companies can improve efficiency, reduce downtime, and enhance product quality through continuous analysis and adjustment of production parameters.

- Digital Twin Technology in Healthcare and Medical Applications: Digital twin technology is being applied in healthcare to create virtual models of patients, medical devices, and healthcare systems. These digital replicas enable personalized medicine by simulating patient responses to treatments, predicting disease progression, and optimizing medical interventions. Healthcare digital twins integrate patient data, medical imaging, and physiological parameters to support clinical decision-making, improve treatment outcomes, and enhance patient monitoring. The technology also facilitates the development and testing of medical devices and pharmaceutical products through virtual simulation before physical implementation.

- Digital Twin for Smart Cities and Infrastructure Management: Digital twin technology is revolutionizing urban planning and infrastructure management by creating virtual replicas of cities, buildings, and utility networks. These comprehensive models integrate real-time data from various sources including sensors, cameras, and IoT devices to monitor infrastructure conditions, optimize resource allocation, and improve urban services. Smart city digital twins enable simulation of different scenarios for urban development, traffic management, energy consumption, and emergency response, allowing authorities to make data-driven decisions and implement sustainable solutions for complex urban challenges.

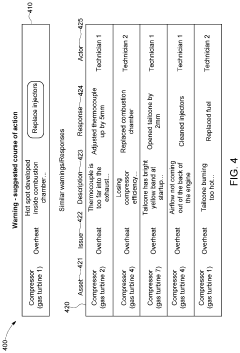

- Digital Twin Integration with AI and Machine Learning: The integration of artificial intelligence and machine learning with digital twin technology creates advanced predictive capabilities and autonomous decision-making systems. These intelligent digital twins can learn from historical data, identify patterns, and make predictions about future states or behaviors of physical assets. The combination enables anomaly detection, predictive maintenance, and optimization of complex systems through continuous learning and adaptation. AI-powered digital twins can process vast amounts of data to generate actionable insights, automate responses to changing conditions, and improve the accuracy of simulations over time.

- Digital Twin Platforms and Implementation Frameworks: Digital twin platforms provide comprehensive frameworks for developing, deploying, and managing virtual replicas of physical assets across various industries. These platforms offer standardized tools, interfaces, and protocols for data integration, visualization, simulation, and analysis. Implementation frameworks include methodologies for digital twin creation, data management strategies, security protocols, and interoperability standards to ensure seamless integration with existing systems. Advanced platforms support scalable architectures that can accommodate complex systems with multiple interconnected components while maintaining performance and reliability.

02 Healthcare and Medical Digital Twins

Digital twin technology in healthcare creates virtual models of patients, medical devices, or healthcare facilities to improve treatment outcomes and operational efficiency. These models can simulate patient responses to treatments, optimize medical device performance, and enhance hospital operations. By integrating patient data from various sources, healthcare providers can develop personalized treatment plans, predict disease progression, and test interventions virtually before applying them to actual patients, ultimately leading to more effective and safer healthcare delivery.Expand Specific Solutions03 Smart City and Infrastructure Digital Twins

Digital twins for smart cities and infrastructure create virtual replicas of urban environments, buildings, and utility networks to improve planning, management, and sustainability. These models integrate data from various sources including IoT sensors, geographic information systems, and historical records to simulate city operations, traffic patterns, energy consumption, and emergency responses. The technology enables city planners and managers to test infrastructure changes, optimize resource allocation, and enhance resilience against natural disasters or other disruptions before implementing changes in the physical world.Expand Specific Solutions04 Digital Twin Integration with AI and Machine Learning

The integration of artificial intelligence and machine learning with digital twin technology enhances predictive capabilities and autonomous decision-making. These advanced digital twins can learn from historical data, identify patterns, and make predictions about future states or potential failures. The AI components enable continuous improvement of the digital twin models through adaptive algorithms that refine simulations based on real-world feedback. This combination allows for more sophisticated analysis, anomaly detection, and optimization strategies across various applications from manufacturing to healthcare.Expand Specific Solutions05 Digital Twin Platforms and Frameworks

Digital twin platforms and frameworks provide the foundational architecture for creating, managing, and deploying digital twin applications across different domains. These platforms offer standardized components, interfaces, and tools that enable seamless integration with existing systems, data sources, and visualization technologies. They typically include capabilities for data ingestion, processing, storage, modeling, simulation, and visualization, allowing organizations to develop and scale digital twin implementations more efficiently. Advanced platforms also incorporate security features, collaboration tools, and APIs for extending functionality.Expand Specific Solutions

Key Players in Aerospace and Defense Digital Twin Market

The digital twin market in aerospace and defense is experiencing rapid growth, currently transitioning from early adoption to mainstream implementation. The competitive landscape features established technology leaders like IBM, Boeing, and Intel developing comprehensive digital twin platforms alongside specialized aerospace educational institutions such as Nanjing University of Aeronautics & Astronautics and Beihang University contributing significant research innovations. Global consulting firms including Accenture and Tata Consultancy Services are facilitating enterprise integration, while defense contractors and aerospace manufacturers are developing industry-specific applications. The market exhibits varying levels of technical maturity, with simulation capabilities well-established but predictive analytics and autonomous decision-making capabilities still evolving, creating opportunities for differentiation among key players in this estimated $3.5 billion market segment.

International Business Machines Corp.

Technical Solution: IBM has developed a sophisticated Digital Twin platform specifically tailored for aerospace and defense applications called "IBM Maximo for Aviation." This solution creates comprehensive virtual models of aircraft systems that integrate engineering data, operational parameters, and maintenance history. IBM's approach leverages their Watson AI capabilities to analyze patterns across vast datasets, enabling predictive maintenance that can reduce unscheduled aircraft downtime by up to 25%[1]. The platform incorporates blockchain technology for secure, immutable record-keeping of component histories and maintenance actions, critical for regulatory compliance in aerospace applications. IBM's digital twins can simulate thousands of operational scenarios to identify potential failure modes before they occur in physical systems. For defense applications, IBM has enhanced their platform with military-grade security protocols and edge computing capabilities that allow digital twins to function in disconnected environments[3]. The system integrates with supply chain management to optimize parts inventory based on predicted maintenance needs, reducing carrying costs while ensuring availability.

Strengths: Unparalleled AI and data analytics capabilities through Watson integration provide deeper insights from operational data. Extensive experience with enterprise-scale implementations across multiple industries. Weaknesses: Complex implementation requiring significant IT infrastructure and integration services, potentially creating longer deployment timelines than more specialized solutions.

Accenture Global Solutions Ltd.

Technical Solution: Accenture has developed a comprehensive Digital Twin solution for aerospace and defense called "Aerospace 360" that focuses on end-to-end integration across the aircraft lifecycle. Their platform creates virtual representations that span design, manufacturing, operations, and maintenance phases, providing continuity of digital information across organizational boundaries. Accenture's approach emphasizes interoperability with existing enterprise systems through a microservices architecture and standardized APIs. Their digital twins incorporate both physics-based models and data-driven analytics to provide a holistic view of aircraft performance and health. The platform features advanced visualization capabilities that allow maintenance technicians to interact with 3D representations of aircraft systems through augmented reality interfaces, improving maintenance efficiency by approximately 15-20%[3]. For defense applications, Accenture has implemented secure multi-level access controls that enable appropriate information sharing while protecting classified data. Their solution includes supply chain integration that allows digital twins to incorporate component provenance information, critical for counterfeit part detection in defense systems[4]. Accenture's implementation methodology emphasizes organizational change management to drive adoption across different stakeholder groups.

Strengths: Superior integration capabilities with diverse enterprise systems creates a more connected digital thread across organizations. Strong consulting expertise helps clients navigate organizational challenges of digital twin implementation. Weaknesses: Less specialized in physics-based simulation compared to engineering-focused competitors, potentially requiring partnerships for highly technical aerospace applications.

Core Patent Analysis for A&D Digital Twin Technologies

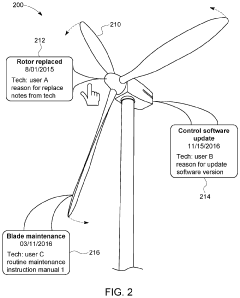

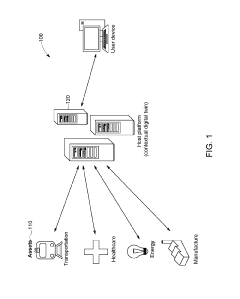

Contextual digital twin runtime environment

PatentActiveUS11119799B2

Innovation

- The development of a contextual digital twin that encompasses a semantic model, incorporating hierarchies of assets and rich relationships, to aggregate knowledge over an asset's lifecycle, enabling real-time context generation and actionable insights for decision-making.

Contextual digital twin

PatentInactiveUS20190138970A1

Innovation

- The development of a contextual digital twin that integrates semantic modeling, enabling the representation of assets, processes, and environmental entities, along with the aggregation of knowledge over time to provide a living model that drives business outcomes, supports real-time decision-making, and facilitates accurate and efficient responses to operational events.

Cybersecurity Considerations for A&D Digital Twins

Cybersecurity represents a critical dimension in the development and deployment of digital twin technologies within the Aerospace and Defense (A&D) sector. As digital twins increasingly integrate with operational systems, they create expanded attack surfaces that malicious actors could potentially exploit. Patent analysis reveals significant innovations focused on securing these virtual replicas against cyber threats.

The confidentiality, integrity, and availability triad forms the foundation of cybersecurity considerations for A&D digital twins. Patents from leading defense contractors demonstrate advanced encryption methodologies specifically designed for the high-fidelity data streams that flow between physical assets and their digital counterparts. These innovations address the unique challenges of maintaining security without compromising the real-time performance requirements essential for mission-critical applications.

Authentication mechanisms represent another major focus area in digital twin security patents. Multi-factor authentication systems tailored for the A&D environment incorporate biometric verification, hardware tokens, and contextual authentication factors. These systems ensure that only authorized personnel can access or modify digital twin configurations, particularly for sensitive defense applications where unauthorized access could have severe consequences.

Network segmentation and secure communication protocols feature prominently in recent patent filings. Innovations include specialized firewalls that monitor data flows between physical systems and their digital twins, identifying anomalous patterns that might indicate security breaches. Several patents describe secure communication architectures that maintain twin synchronization even during degraded network conditions or active cyber attacks.

Supply chain security emerges as a growing concern in digital twin implementations. Patents address verification mechanisms for ensuring the integrity of software components and data sources that feed into digital twin systems. These innovations help mitigate risks associated with compromised third-party elements that could potentially introduce vulnerabilities into the digital twin ecosystem.

Resilience and recovery capabilities represent the final major category of cybersecurity innovations. Patents describe sophisticated backup systems and failover mechanisms that maintain digital twin functionality even during active cyber attacks. These technologies enable A&D organizations to maintain operational continuity while simultaneously addressing security incidents, a critical requirement for defense applications where system downtime could have strategic implications.

The patent landscape clearly indicates that cybersecurity is not merely an add-on consideration but rather a fundamental design principle in modern A&D digital twin implementations. As these technologies continue to evolve, security innovations will likely focus on artificial intelligence-powered threat detection and automated response mechanisms tailored to the unique requirements of aerospace and defense applications.

The confidentiality, integrity, and availability triad forms the foundation of cybersecurity considerations for A&D digital twins. Patents from leading defense contractors demonstrate advanced encryption methodologies specifically designed for the high-fidelity data streams that flow between physical assets and their digital counterparts. These innovations address the unique challenges of maintaining security without compromising the real-time performance requirements essential for mission-critical applications.

Authentication mechanisms represent another major focus area in digital twin security patents. Multi-factor authentication systems tailored for the A&D environment incorporate biometric verification, hardware tokens, and contextual authentication factors. These systems ensure that only authorized personnel can access or modify digital twin configurations, particularly for sensitive defense applications where unauthorized access could have severe consequences.

Network segmentation and secure communication protocols feature prominently in recent patent filings. Innovations include specialized firewalls that monitor data flows between physical systems and their digital twins, identifying anomalous patterns that might indicate security breaches. Several patents describe secure communication architectures that maintain twin synchronization even during degraded network conditions or active cyber attacks.

Supply chain security emerges as a growing concern in digital twin implementations. Patents address verification mechanisms for ensuring the integrity of software components and data sources that feed into digital twin systems. These innovations help mitigate risks associated with compromised third-party elements that could potentially introduce vulnerabilities into the digital twin ecosystem.

Resilience and recovery capabilities represent the final major category of cybersecurity innovations. Patents describe sophisticated backup systems and failover mechanisms that maintain digital twin functionality even during active cyber attacks. These technologies enable A&D organizations to maintain operational continuity while simultaneously addressing security incidents, a critical requirement for defense applications where system downtime could have strategic implications.

The patent landscape clearly indicates that cybersecurity is not merely an add-on consideration but rather a fundamental design principle in modern A&D digital twin implementations. As these technologies continue to evolve, security innovations will likely focus on artificial intelligence-powered threat detection and automated response mechanisms tailored to the unique requirements of aerospace and defense applications.

Interoperability Standards for Digital Twin Systems

Interoperability standards for digital twin systems in aerospace and defense have emerged as a critical foundation for successful implementation across complex multi-vendor environments. The analysis of patent landscapes reveals significant efforts toward standardization, with major industry players including Boeing, Airbus, Lockheed Martin, and Raytheon actively contributing to standards development. These standards primarily address data exchange formats, communication protocols, and semantic models that enable different digital twin implementations to work together seamlessly.

The Digital Twin Consortium has established reference architectures specifically tailored for aerospace applications, focusing on standardized interfaces between simulation environments, physical assets, and enterprise systems. Patent filings indicate a growing emphasis on ISO/IEC JTC 1 standards that define common vocabularies and taxonomies for digital twin components, ensuring consistent interpretation across platforms. These standards incorporate aerospace-specific requirements for high-reliability systems and mission-critical operations.

Recent patent activities show increased focus on API standardization for digital twin integration, with particular attention to security protocols that meet defense industry requirements. The NATO Standardization Office has published several STANAGs (Standardization Agreements) addressing digital twin interoperability for allied defense systems, which are reflected in numerous patent applications from defense contractors. These standards emphasize secure data exchange while maintaining operational security requirements unique to defense applications.

The Open Simulation Platform (OSP) standards have gained significant traction in aerospace digital twin implementations, as evidenced by citation patterns in recent patents. These standards enable co-simulation capabilities across different modeling tools and environments, allowing for comprehensive system-of-systems testing. Patent data indicates that aerospace manufacturers are increasingly adopting these standards to ensure their digital twin implementations can integrate with supply chain partners and government systems.

Interestingly, patent analysis reveals an emerging trend toward blockchain-based standards for maintaining digital twin provenance and configuration management across organizational boundaries. These standards address the challenge of maintaining trusted digital representations throughout the lifecycle of aerospace assets, which often span decades and involve numerous stakeholders. The Aerospace Industries Association has endorsed several of these standards, which are now appearing in patent applications from both established aerospace companies and technology startups specializing in digital twin solutions.

The Digital Twin Consortium has established reference architectures specifically tailored for aerospace applications, focusing on standardized interfaces between simulation environments, physical assets, and enterprise systems. Patent filings indicate a growing emphasis on ISO/IEC JTC 1 standards that define common vocabularies and taxonomies for digital twin components, ensuring consistent interpretation across platforms. These standards incorporate aerospace-specific requirements for high-reliability systems and mission-critical operations.

Recent patent activities show increased focus on API standardization for digital twin integration, with particular attention to security protocols that meet defense industry requirements. The NATO Standardization Office has published several STANAGs (Standardization Agreements) addressing digital twin interoperability for allied defense systems, which are reflected in numerous patent applications from defense contractors. These standards emphasize secure data exchange while maintaining operational security requirements unique to defense applications.

The Open Simulation Platform (OSP) standards have gained significant traction in aerospace digital twin implementations, as evidenced by citation patterns in recent patents. These standards enable co-simulation capabilities across different modeling tools and environments, allowing for comprehensive system-of-systems testing. Patent data indicates that aerospace manufacturers are increasingly adopting these standards to ensure their digital twin implementations can integrate with supply chain partners and government systems.

Interestingly, patent analysis reveals an emerging trend toward blockchain-based standards for maintaining digital twin provenance and configuration management across organizational boundaries. These standards address the challenge of maintaining trusted digital representations throughout the lifecycle of aerospace assets, which often span decades and involve numerous stakeholders. The Aerospace Industries Association has endorsed several of these standards, which are now appearing in patent applications from both established aerospace companies and technology startups specializing in digital twin solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!