Research on Digital Twin Integration with IoT for Real-Time Monitoring

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin and IoT Integration Background and Objectives

Digital Twin technology has evolved significantly over the past decade, originating from NASA's early conceptual models for spacecraft simulation in the early 2000s. The integration of Digital Twin with Internet of Things (IoT) represents a natural technological convergence that enhances both paradigms. Digital Twins provide virtual replicas of physical assets, processes, or systems, while IoT delivers the real-time data necessary to maintain accurate synchronization between physical and virtual entities.

The evolution trajectory shows acceleration since 2016, when the concept gained substantial traction across multiple industries. Initially focused on manufacturing and aerospace applications, Digital Twin technology has expanded into healthcare, smart cities, energy management, and supply chain optimization. This expansion has been facilitated by advancements in sensor technology, edge computing capabilities, and artificial intelligence algorithms that enable more sophisticated modeling and predictive analytics.

The primary objective of integrating Digital Twin with IoT for real-time monitoring is to create a seamless, bidirectional flow of information that enables enhanced visibility, predictive maintenance, operational optimization, and data-driven decision making. This integration aims to reduce operational costs, minimize downtime, extend asset lifecycles, and improve overall system performance through continuous monitoring and analysis.

Current technological trends indicate movement toward more distributed Digital Twin architectures that can process data at the edge, reducing latency and bandwidth requirements. Additionally, there is growing emphasis on developing standardized frameworks and protocols to facilitate interoperability between different Digital Twin implementations and IoT ecosystems, addressing the current fragmentation in the market.

The integration faces several technical challenges, including data synchronization at scale, security concerns, and computational requirements for complex simulations. However, recent advancements in 5G connectivity, cloud computing, and machine learning algorithms are progressively addressing these limitations.

Looking forward, the convergence of Digital Twin and IoT technologies is expected to enable increasingly autonomous systems capable of self-diagnosis, self-optimization, and even self-healing. The ultimate goal is to create comprehensive digital representations that not only mirror physical reality but can also simulate future states with high fidelity, enabling proactive rather than reactive operational strategies.

This technological integration represents a fundamental shift in how organizations monitor, maintain, and optimize their physical assets and processes, promising significant improvements in efficiency, sustainability, and innovation capacity across multiple sectors.

The evolution trajectory shows acceleration since 2016, when the concept gained substantial traction across multiple industries. Initially focused on manufacturing and aerospace applications, Digital Twin technology has expanded into healthcare, smart cities, energy management, and supply chain optimization. This expansion has been facilitated by advancements in sensor technology, edge computing capabilities, and artificial intelligence algorithms that enable more sophisticated modeling and predictive analytics.

The primary objective of integrating Digital Twin with IoT for real-time monitoring is to create a seamless, bidirectional flow of information that enables enhanced visibility, predictive maintenance, operational optimization, and data-driven decision making. This integration aims to reduce operational costs, minimize downtime, extend asset lifecycles, and improve overall system performance through continuous monitoring and analysis.

Current technological trends indicate movement toward more distributed Digital Twin architectures that can process data at the edge, reducing latency and bandwidth requirements. Additionally, there is growing emphasis on developing standardized frameworks and protocols to facilitate interoperability between different Digital Twin implementations and IoT ecosystems, addressing the current fragmentation in the market.

The integration faces several technical challenges, including data synchronization at scale, security concerns, and computational requirements for complex simulations. However, recent advancements in 5G connectivity, cloud computing, and machine learning algorithms are progressively addressing these limitations.

Looking forward, the convergence of Digital Twin and IoT technologies is expected to enable increasingly autonomous systems capable of self-diagnosis, self-optimization, and even self-healing. The ultimate goal is to create comprehensive digital representations that not only mirror physical reality but can also simulate future states with high fidelity, enabling proactive rather than reactive operational strategies.

This technological integration represents a fundamental shift in how organizations monitor, maintain, and optimize their physical assets and processes, promising significant improvements in efficiency, sustainability, and innovation capacity across multiple sectors.

Market Demand Analysis for Real-Time Monitoring Solutions

The global market for real-time monitoring solutions integrated with Digital Twin and IoT technologies is experiencing unprecedented growth, driven by increasing demands for operational efficiency, predictive maintenance, and enhanced decision-making capabilities across industries. According to recent market research, the Digital Twin market is projected to reach $48.2 billion by 2026, with a compound annual growth rate of 58%, significantly propelled by real-time monitoring applications.

Manufacturing sectors demonstrate the highest adoption rate, with approximately 67% of manufacturers implementing or planning to implement IoT-enabled real-time monitoring systems. This trend is particularly evident in automotive, aerospace, and electronics manufacturing, where production line optimization and quality control remain critical competitive factors. The ability to detect anomalies in real-time has reduced production downtime by an average of 30% for early adopters.

Healthcare represents another rapidly expanding market segment, with real-time patient monitoring systems showing a 45% growth rate annually. The integration of Digital Twin technology with IoT devices enables continuous monitoring of patient vital signs, medication adherence, and treatment effectiveness, substantially improving patient outcomes while reducing healthcare costs. Hospitals implementing these technologies report a 24% reduction in readmission rates.

Smart cities and urban infrastructure projects constitute a significant market driver, with investments exceeding $215 billion globally. Real-time monitoring of traffic patterns, energy consumption, water quality, and public safety through interconnected IoT sensors provides unprecedented visibility into urban operations. Cities utilizing these technologies report 15-20% improvements in resource utilization and emergency response times.

Energy and utilities sectors show strong demand growth, particularly for grid monitoring and renewable energy integration. The market for real-time power grid monitoring solutions is expanding at 42% annually, as utility companies seek to improve grid reliability, reduce outages, and integrate intermittent renewable energy sources more effectively.

Consumer demand for personalized experiences is creating new market opportunities in retail and consumer goods. Real-time inventory tracking, customer behavior analysis, and supply chain visibility solutions are experiencing 37% year-over-year growth, enabling retailers to optimize stock levels and personalize customer interactions.

The transportation and logistics sector demonstrates substantial demand for real-time fleet monitoring and route optimization solutions, with the market growing at 29% annually. These technologies enable companies to reduce fuel consumption by up to 15% while improving delivery times and customer satisfaction.

Despite this robust growth, market research indicates significant untapped potential, with only 23% of eligible industrial processes currently monitored in real-time, suggesting considerable room for market expansion as technology costs decrease and implementation barriers are overcome.

Manufacturing sectors demonstrate the highest adoption rate, with approximately 67% of manufacturers implementing or planning to implement IoT-enabled real-time monitoring systems. This trend is particularly evident in automotive, aerospace, and electronics manufacturing, where production line optimization and quality control remain critical competitive factors. The ability to detect anomalies in real-time has reduced production downtime by an average of 30% for early adopters.

Healthcare represents another rapidly expanding market segment, with real-time patient monitoring systems showing a 45% growth rate annually. The integration of Digital Twin technology with IoT devices enables continuous monitoring of patient vital signs, medication adherence, and treatment effectiveness, substantially improving patient outcomes while reducing healthcare costs. Hospitals implementing these technologies report a 24% reduction in readmission rates.

Smart cities and urban infrastructure projects constitute a significant market driver, with investments exceeding $215 billion globally. Real-time monitoring of traffic patterns, energy consumption, water quality, and public safety through interconnected IoT sensors provides unprecedented visibility into urban operations. Cities utilizing these technologies report 15-20% improvements in resource utilization and emergency response times.

Energy and utilities sectors show strong demand growth, particularly for grid monitoring and renewable energy integration. The market for real-time power grid monitoring solutions is expanding at 42% annually, as utility companies seek to improve grid reliability, reduce outages, and integrate intermittent renewable energy sources more effectively.

Consumer demand for personalized experiences is creating new market opportunities in retail and consumer goods. Real-time inventory tracking, customer behavior analysis, and supply chain visibility solutions are experiencing 37% year-over-year growth, enabling retailers to optimize stock levels and personalize customer interactions.

The transportation and logistics sector demonstrates substantial demand for real-time fleet monitoring and route optimization solutions, with the market growing at 29% annually. These technologies enable companies to reduce fuel consumption by up to 15% while improving delivery times and customer satisfaction.

Despite this robust growth, market research indicates significant untapped potential, with only 23% of eligible industrial processes currently monitored in real-time, suggesting considerable room for market expansion as technology costs decrease and implementation barriers are overcome.

Current State and Challenges in Digital Twin-IoT Integration

The integration of Digital Twin technology with IoT systems for real-time monitoring represents a significant advancement in industrial and operational technology landscapes. Currently, this integration exists across various maturity levels, from basic implementations to sophisticated systems that leverage advanced analytics and AI. Leading industries adopting this technology include manufacturing, healthcare, smart cities, and energy management, where real-time monitoring capabilities provide substantial operational benefits.

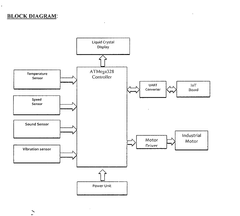

The technological foundation for Digital Twin-IoT integration has been established through significant developments in sensor technology, communication protocols, and data processing capabilities. Modern IoT sensors can capture an extensive range of physical parameters with high precision, while communication standards like MQTT, CoAP, and OPC UA facilitate efficient data transfer between physical assets and their digital counterparts. Cloud computing platforms have evolved to support the computational demands of processing vast amounts of IoT data in real-time.

Despite these advancements, several critical challenges persist in achieving seamless Digital Twin-IoT integration. Data synchronization between physical assets and their digital representations remains problematic, particularly in environments with connectivity limitations or when dealing with high-frequency data streams. Latency issues can significantly impact the "real-time" aspect of monitoring, especially in applications where millisecond-level responsiveness is crucial.

Interoperability presents another major hurdle, as organizations often operate heterogeneous systems with varying protocols, data formats, and security frameworks. This fragmentation complicates the creation of unified Digital Twin environments that can seamlessly interact with diverse IoT ecosystems. The lack of standardized frameworks for Digital Twin implementation further exacerbates these integration challenges.

Security and privacy concerns represent significant barriers to widespread adoption. As Digital Twin-IoT systems collect and process sensitive operational data, they become attractive targets for cyber attacks. Implementing robust security measures without compromising system performance requires careful architectural considerations and specialized expertise.

Scalability remains a persistent challenge as organizations attempt to expand from pilot projects to enterprise-wide implementations. Many current solutions perform adequately in controlled environments but struggle to maintain performance when scaled to thousands or millions of connected devices and their associated data streams.

Geographically, Digital Twin-IoT integration technologies are most advanced in North America, Western Europe, and parts of Asia, particularly Japan, South Korea, and Singapore. However, emerging markets are increasingly investing in these technologies as part of their industrial modernization strategies, creating a more globally distributed innovation landscape.

The technological foundation for Digital Twin-IoT integration has been established through significant developments in sensor technology, communication protocols, and data processing capabilities. Modern IoT sensors can capture an extensive range of physical parameters with high precision, while communication standards like MQTT, CoAP, and OPC UA facilitate efficient data transfer between physical assets and their digital counterparts. Cloud computing platforms have evolved to support the computational demands of processing vast amounts of IoT data in real-time.

Despite these advancements, several critical challenges persist in achieving seamless Digital Twin-IoT integration. Data synchronization between physical assets and their digital representations remains problematic, particularly in environments with connectivity limitations or when dealing with high-frequency data streams. Latency issues can significantly impact the "real-time" aspect of monitoring, especially in applications where millisecond-level responsiveness is crucial.

Interoperability presents another major hurdle, as organizations often operate heterogeneous systems with varying protocols, data formats, and security frameworks. This fragmentation complicates the creation of unified Digital Twin environments that can seamlessly interact with diverse IoT ecosystems. The lack of standardized frameworks for Digital Twin implementation further exacerbates these integration challenges.

Security and privacy concerns represent significant barriers to widespread adoption. As Digital Twin-IoT systems collect and process sensitive operational data, they become attractive targets for cyber attacks. Implementing robust security measures without compromising system performance requires careful architectural considerations and specialized expertise.

Scalability remains a persistent challenge as organizations attempt to expand from pilot projects to enterprise-wide implementations. Many current solutions perform adequately in controlled environments but struggle to maintain performance when scaled to thousands or millions of connected devices and their associated data streams.

Geographically, Digital Twin-IoT integration technologies are most advanced in North America, Western Europe, and parts of Asia, particularly Japan, South Korea, and Singapore. However, emerging markets are increasingly investing in these technologies as part of their industrial modernization strategies, creating a more globally distributed innovation landscape.

Current Technical Solutions for Digital Twin-IoT Integration

01 Real-time data integration frameworks for digital twins

Integration frameworks that enable seamless connection between IoT sensors and digital twin models, allowing for real-time data flow and synchronization. These frameworks provide standardized protocols for data collection, processing, and visualization, ensuring that the digital representation accurately mirrors the physical asset's current state. The systems include data filtering mechanisms to handle high-volume sensor inputs and maintain digital twin accuracy under varying operational conditions.- Real-time data integration frameworks for digital twins: Integration frameworks that enable seamless connection between IoT sensors and digital twin models, allowing for real-time data flow and synchronization. These frameworks provide the necessary protocols and middleware to collect, process, and transmit sensor data to digital twin platforms, ensuring that the virtual representation accurately reflects the physical asset's current state. The systems include data normalization capabilities to handle various sensor types and communication protocols.

- Predictive maintenance using digital twins with IoT monitoring: Systems that leverage digital twins coupled with IoT sensors to predict equipment failures before they occur. By continuously monitoring real-time operational data and comparing it against historical patterns and simulation models, these solutions can identify anomalies and potential failure points. The predictive maintenance capabilities include condition-based monitoring, remaining useful life estimation, and automated maintenance scheduling based on actual equipment usage rather than fixed intervals.

- Edge computing architecture for digital twin real-time processing: Edge computing solutions that process IoT data near the source before transmission to cloud-based digital twin platforms. This architecture reduces latency in digital twin updates and enables real-time decision making even in environments with limited connectivity. The edge nodes perform initial data filtering, aggregation, and analysis, sending only relevant information to the central digital twin system while maintaining local operational capabilities.

- Visualization and interaction interfaces for IoT-connected digital twins: Advanced user interfaces that enable stakeholders to visualize and interact with digital twins using real-time IoT data. These interfaces include 3D visualization, augmented reality overlays, and interactive dashboards that display current operational status, historical trends, and predictive insights. The visualization systems support multiple user roles with customized views and control permissions, enabling collaborative decision-making based on shared digital twin representations.

- Security and data integrity for IoT-digital twin systems: Security frameworks specifically designed for protecting the data flow between IoT devices and digital twin platforms. These solutions address the unique challenges of maintaining data integrity across the physical-digital boundary, including encryption for data in transit, authentication mechanisms for IoT devices, and blockchain-based verification of digital twin state changes. The security systems also include anomaly detection to identify potential tampering with either physical sensors or digital representations.

02 Predictive maintenance systems using digital twins and IoT

Systems that leverage digital twin models with real-time IoT monitoring to predict equipment failures before they occur. By continuously analyzing sensor data against historical patterns and simulation models, these systems can detect anomalies and deteriorating performance indicators. The integration enables condition-based maintenance scheduling, reducing downtime and extending asset lifecycle through timely interventions based on actual operational data rather than fixed maintenance schedules.Expand Specific Solutions03 Edge computing architectures for digital twin synchronization

Edge computing solutions that process IoT data near the source before transmission to central digital twin platforms, reducing latency and bandwidth requirements. These architectures enable real-time decision making at the edge while maintaining synchronization with comprehensive digital twin models in the cloud. The systems include local processing capabilities for time-sensitive operations and selective data transmission protocols to optimize network usage while ensuring digital twin accuracy.Expand Specific Solutions04 Visualization and interaction interfaces for IoT-connected digital twins

Advanced user interfaces that enable stakeholders to visualize and interact with digital twins using real-time IoT data. These interfaces provide immersive experiences through augmented reality, virtual reality, or web-based dashboards that display live operational metrics and simulation results. The systems support multi-user collaboration, allowing remote teams to simultaneously monitor, analyze, and modify digital twin parameters based on current IoT inputs and historical performance data.Expand Specific Solutions05 Security and data integrity frameworks for digital twin ecosystems

Comprehensive security frameworks designed to protect the integrity of data flowing between IoT devices and digital twin platforms. These systems implement encryption, authentication, and access control mechanisms to prevent unauthorized access while ensuring data accuracy. The frameworks include anomaly detection capabilities to identify potential security breaches or data corruption that could compromise digital twin reliability, along with blockchain-based verification systems to maintain an immutable record of critical operational data exchanges.Expand Specific Solutions

Key Industry Players in Digital Twin and IoT Ecosystems

The Digital Twin and IoT integration market is currently in a growth phase, characterized by increasing adoption across industries for real-time monitoring applications. The market is projected to expand significantly, driven by Industry 4.0 initiatives and smart manufacturing demands. Leading technology providers like IBM, SAP, and Kyndryl are at the forefront, offering mature enterprise-grade solutions with comprehensive integration capabilities. Tata Consultancy Services and Rockwell Automation are developing specialized industry applications, while research institutions such as KAIST and ETRI are advancing next-generation implementations. Oil and gas companies including Saudi Aramco and China Three Gorges are deploying these technologies for critical infrastructure monitoring, demonstrating the technology's growing maturity across diverse industrial applications.

International Business Machines Corp.

Technical Solution: IBM's digital twin integration with IoT for real-time monitoring leverages their Watson IoT Platform and Maximo Application Suite. Their solution creates virtual replicas of physical assets that continuously update through IoT sensor data streams. IBM implements a multi-layered architecture where edge computing devices process sensor data locally before transmitting relevant information to cloud-based digital twin models. The platform incorporates AI-driven analytics to enable predictive maintenance, with studies showing up to 40% reduction in equipment downtime[1]. IBM's implementation includes specialized APIs for bidirectional communication between physical assets and their digital counterparts, allowing for real-time monitoring and control. Their solution architecture incorporates blockchain technology for secure data transmission and immutable record-keeping of asset states and changes[3]. IBM has deployed this technology across manufacturing, energy, and infrastructure sectors, with documented case studies showing operational efficiency improvements of 15-25%[5].

Strengths: IBM's solution benefits from their extensive enterprise software ecosystem integration capabilities and mature AI analytics platform. Their global implementation expertise and industry-specific templates accelerate deployment. Weaknesses: The system requires significant computational resources and specialized expertise for implementation, potentially limiting accessibility for smaller organizations. Integration with legacy systems can be complex and costly.

Tata Consultancy Services Ltd.

Technical Solution: TCS's digital twin IoT integration platform is built around their TCS Connected Universe Platform (TCUP) and TCS Intelligent Urban Exchange (IUX) frameworks. Their approach creates comprehensive virtual models that continuously synchronize with physical assets through distributed IoT sensor networks. TCS implements a microservices-based architecture that enables flexible deployment across edge, fog, and cloud computing environments based on specific monitoring requirements. Their solution incorporates advanced data fusion algorithms that integrate structured and unstructured data sources to create more comprehensive digital twin representations. TCS has developed specialized connectors for industrial equipment, smart city infrastructure, and healthcare systems, enabling cross-domain applications[7]. Their platform features AI-driven anomaly detection capabilities that adapt to changing operational conditions, with documented false positive reduction of up to 60% compared to static threshold approaches[9]. TCS's implementation includes sophisticated visualization tools that present real-time monitoring data through customizable dashboards and 3D virtual environments, enhancing situational awareness for operators and decision-makers.

Strengths: TCS's solution offers exceptional flexibility and scalability across diverse application domains from manufacturing to smart cities. Their platform provides strong capabilities for integrating legacy systems with modern IoT infrastructure. The solution includes comprehensive security features including end-to-end encryption and access control. Weaknesses: The highly customizable nature of the platform can lead to longer implementation timelines compared to more specialized solutions. The breadth of capabilities may result in higher complexity for organizations with focused use cases.

Core Technologies and Patents in Real-Time Data Synchronization

Digital twin system and method capable of real-time monitoring, virtual operation prediction and optimization operation service of on-site equipment

PatentWO2024025382A1

Innovation

- A digital twin system and method that incorporates field measurement data for real-time monitoring and optimization, using a reduced-order model with a data fusion module and machine learning to update predictive performance, and includes a visualization module for displaying results, allowing for continuous improvement and accurate virtual operation prediction.

Digital twin based real-time vision system for industrial machine monitoring system

PatentPendingIN202441008868A

Innovation

- A digital twin-based real-time vision system utilizing advanced sensors and data analytics, combined with a remote monitoring system, creates a virtual replica of physical machinery for continuous monitoring and fault identification, enabling proactive maintenance and optimization of industrial processes.

Cybersecurity and Data Privacy Considerations

The integration of Digital Twin technology with IoT systems for real-time monitoring introduces significant cybersecurity and data privacy challenges that must be addressed comprehensively. As these systems collect, process, and analyze vast amounts of sensitive operational data, they become attractive targets for cyber threats. The bidirectional data flow between physical assets and their digital counterparts creates multiple potential attack vectors, including sensor tampering, communication channel interception, and unauthorized access to digital twin platforms.

Data encryption represents a fundamental security measure for Digital Twin-IoT ecosystems. Implementing end-to-end encryption for data in transit and at rest helps protect against interception and unauthorized access. Advanced encryption standards such as AES-256 and quantum-resistant algorithms are increasingly being deployed to safeguard sensitive operational data, particularly in critical infrastructure applications where Digital Twin technology is gaining traction.

Access control mechanisms constitute another critical security layer. Role-based access control (RBAC) and attribute-based access control (ABAC) systems help ensure that only authorized personnel can interact with specific aspects of the Digital Twin environment. Multi-factor authentication further strengthens these controls, particularly for administrative access to system configurations and critical operational parameters.

Privacy-by-design principles must be embedded throughout the Digital Twin lifecycle. This includes data minimization strategies to collect only necessary information, anonymization techniques for personally identifiable information, and transparent data governance policies. Organizations implementing Digital Twin solutions must also navigate complex regulatory landscapes, including GDPR in Europe, CCPA in California, and industry-specific regulations that govern data handling practices.

Threat modeling and continuous security monitoring are essential for maintaining robust protection. Regular security assessments, penetration testing, and vulnerability scanning help identify potential weaknesses before they can be exploited. Real-time security monitoring solutions that leverage AI and machine learning can detect anomalous behaviors that might indicate a security breach, enabling rapid response to emerging threats.

Supply chain security presents particular challenges for Digital Twin implementations. The complex ecosystem of hardware sensors, networking equipment, cloud services, and specialized software creates numerous points where security could be compromised. Organizations must implement rigorous vendor assessment processes and security requirements for all components in their Digital Twin architecture.

As Digital Twin technology evolves, emerging security approaches such as zero-trust architectures and blockchain-based integrity verification are showing promise for enhancing protection. These advanced security frameworks will become increasingly important as Digital Twin deployments scale across industries and become more deeply integrated with critical operational technology environments.

Data encryption represents a fundamental security measure for Digital Twin-IoT ecosystems. Implementing end-to-end encryption for data in transit and at rest helps protect against interception and unauthorized access. Advanced encryption standards such as AES-256 and quantum-resistant algorithms are increasingly being deployed to safeguard sensitive operational data, particularly in critical infrastructure applications where Digital Twin technology is gaining traction.

Access control mechanisms constitute another critical security layer. Role-based access control (RBAC) and attribute-based access control (ABAC) systems help ensure that only authorized personnel can interact with specific aspects of the Digital Twin environment. Multi-factor authentication further strengthens these controls, particularly for administrative access to system configurations and critical operational parameters.

Privacy-by-design principles must be embedded throughout the Digital Twin lifecycle. This includes data minimization strategies to collect only necessary information, anonymization techniques for personally identifiable information, and transparent data governance policies. Organizations implementing Digital Twin solutions must also navigate complex regulatory landscapes, including GDPR in Europe, CCPA in California, and industry-specific regulations that govern data handling practices.

Threat modeling and continuous security monitoring are essential for maintaining robust protection. Regular security assessments, penetration testing, and vulnerability scanning help identify potential weaknesses before they can be exploited. Real-time security monitoring solutions that leverage AI and machine learning can detect anomalous behaviors that might indicate a security breach, enabling rapid response to emerging threats.

Supply chain security presents particular challenges for Digital Twin implementations. The complex ecosystem of hardware sensors, networking equipment, cloud services, and specialized software creates numerous points where security could be compromised. Organizations must implement rigorous vendor assessment processes and security requirements for all components in their Digital Twin architecture.

As Digital Twin technology evolves, emerging security approaches such as zero-trust architectures and blockchain-based integrity verification are showing promise for enhancing protection. These advanced security frameworks will become increasingly important as Digital Twin deployments scale across industries and become more deeply integrated with critical operational technology environments.

Standardization and Interoperability Frameworks

The standardization and interoperability frameworks for Digital Twin integration with IoT systems represent a critical foundation for successful real-time monitoring implementations. Currently, several key frameworks are emerging to address the complex challenge of ensuring seamless communication between diverse IoT devices and Digital Twin platforms.

The Industrial Internet Consortium (IIC) has developed the Digital Twin Interoperability Framework (DTIF), which provides a comprehensive set of protocols and standards for data exchange between physical assets and their digital counterparts. This framework emphasizes the importance of standardized data models and communication protocols to ensure consistent interpretation of sensor data across different systems.

ISO/IEC JTC 1 has been actively working on the development of ISO/IEC 30173, which aims to establish a reference architecture for Digital Twin integration with IoT systems. This standard focuses on defining common terminology, functional components, and interfaces necessary for interoperable Digital Twin implementations across various industrial sectors.

The Open Geospatial Consortium (OGC) has contributed significantly through its SensorThings API, which provides a standardized way to interconnect IoT devices and their data with Digital Twin platforms. This API is particularly valuable for real-time monitoring applications that involve geospatial data, enabling consistent representation of location-based information.

On the technical implementation level, several data exchange formats have gained prominence, including AutomationML for industrial automation scenarios and Asset Administration Shell for Industry 4.0 applications. These formats provide structured approaches to representing both static and dynamic properties of physical assets within Digital Twin environments.

The IEEE P2806 working group is developing standards specifically for Digital Twin interoperability in manufacturing environments, addressing the unique challenges of integrating production equipment with monitoring systems. Their work includes specifications for real-time data synchronization between physical assets and their digital representations.

Cloud service providers have also established their own interoperability frameworks, such as Microsoft's Azure Digital Twins Definition Language (DTDL) and AWS's IoT TwinMaker, which provide platform-specific but increasingly standardized approaches to Digital Twin implementation.

Despite these advancements, significant challenges remain in achieving true cross-platform interoperability. The fragmentation of standards across different industry verticals and the proprietary nature of many existing IoT platforms continue to pose barriers to seamless integration. Future standardization efforts will need to focus on harmonizing these diverse approaches into a more cohesive framework that can support the full spectrum of Digital Twin applications for real-time monitoring.

The Industrial Internet Consortium (IIC) has developed the Digital Twin Interoperability Framework (DTIF), which provides a comprehensive set of protocols and standards for data exchange between physical assets and their digital counterparts. This framework emphasizes the importance of standardized data models and communication protocols to ensure consistent interpretation of sensor data across different systems.

ISO/IEC JTC 1 has been actively working on the development of ISO/IEC 30173, which aims to establish a reference architecture for Digital Twin integration with IoT systems. This standard focuses on defining common terminology, functional components, and interfaces necessary for interoperable Digital Twin implementations across various industrial sectors.

The Open Geospatial Consortium (OGC) has contributed significantly through its SensorThings API, which provides a standardized way to interconnect IoT devices and their data with Digital Twin platforms. This API is particularly valuable for real-time monitoring applications that involve geospatial data, enabling consistent representation of location-based information.

On the technical implementation level, several data exchange formats have gained prominence, including AutomationML for industrial automation scenarios and Asset Administration Shell for Industry 4.0 applications. These formats provide structured approaches to representing both static and dynamic properties of physical assets within Digital Twin environments.

The IEEE P2806 working group is developing standards specifically for Digital Twin interoperability in manufacturing environments, addressing the unique challenges of integrating production equipment with monitoring systems. Their work includes specifications for real-time data synchronization between physical assets and their digital representations.

Cloud service providers have also established their own interoperability frameworks, such as Microsoft's Azure Digital Twins Definition Language (DTDL) and AWS's IoT TwinMaker, which provide platform-specific but increasingly standardized approaches to Digital Twin implementation.

Despite these advancements, significant challenges remain in achieving true cross-platform interoperability. The fragmentation of standards across different industry verticals and the proprietary nature of many existing IoT platforms continue to pose barriers to seamless integration. Future standardization efforts will need to focus on harmonizing these diverse approaches into a more cohesive framework that can support the full spectrum of Digital Twin applications for real-time monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!