Market Outlook for Digital Twin in Global Industrial Digitalization

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Strategic Objectives

The concept of Digital Twin has evolved significantly since its inception in the early 2000s, transforming from a simple virtual representation to a sophisticated ecosystem of interconnected models. Initially conceptualized by Michael Grieves at the University of Michigan, digital twins were primarily used for product lifecycle management. The technology has since expanded beyond manufacturing to encompass entire industrial systems, smart cities, and even biological processes.

The evolution trajectory shows three distinct phases: descriptive twins (2000-2010) that simply mirrored physical assets; predictive twins (2010-2018) that incorporated simulation capabilities; and prescriptive twins (2018-present) that leverage AI and machine learning to enable autonomous decision-making. This progression reflects the increasing integration of IoT sensors, big data analytics, and cloud computing technologies that have collectively enhanced the fidelity and utility of digital twin implementations.

Current technological advancements are pushing digital twins toward real-time synchronization with physical counterparts, enabling unprecedented levels of monitoring, prediction, and optimization. The convergence with technologies like 5G, edge computing, and blockchain is further accelerating this evolution, creating more robust and secure digital twin ecosystems.

The strategic objectives for digital twin technology in global industrial digitalization are multifaceted. Primary among these is operational excellence through continuous optimization of industrial processes. By creating virtual replicas that can simulate various scenarios, organizations aim to identify inefficiencies, predict failures, and optimize resource allocation without disrupting physical operations.

Another critical objective is innovation acceleration. Digital twins provide safe environments for testing new product designs, manufacturing processes, and business models, significantly reducing time-to-market and development costs. This capability is particularly valuable in industries with high safety requirements or expensive testing procedures.

Sustainability represents an increasingly important strategic goal. Digital twins enable more precise energy management, waste reduction, and environmental impact assessment through detailed modeling of resource consumption and emissions. This aligns with global sustainability initiatives and regulatory requirements facing industrial sectors.

Risk mitigation constitutes the fourth major objective, with digital twins offering sophisticated predictive maintenance capabilities, supply chain resilience modeling, and cybersecurity scenario planning. These applications help organizations anticipate and prepare for potential disruptions, enhancing overall business continuity.

The evolution trajectory shows three distinct phases: descriptive twins (2000-2010) that simply mirrored physical assets; predictive twins (2010-2018) that incorporated simulation capabilities; and prescriptive twins (2018-present) that leverage AI and machine learning to enable autonomous decision-making. This progression reflects the increasing integration of IoT sensors, big data analytics, and cloud computing technologies that have collectively enhanced the fidelity and utility of digital twin implementations.

Current technological advancements are pushing digital twins toward real-time synchronization with physical counterparts, enabling unprecedented levels of monitoring, prediction, and optimization. The convergence with technologies like 5G, edge computing, and blockchain is further accelerating this evolution, creating more robust and secure digital twin ecosystems.

The strategic objectives for digital twin technology in global industrial digitalization are multifaceted. Primary among these is operational excellence through continuous optimization of industrial processes. By creating virtual replicas that can simulate various scenarios, organizations aim to identify inefficiencies, predict failures, and optimize resource allocation without disrupting physical operations.

Another critical objective is innovation acceleration. Digital twins provide safe environments for testing new product designs, manufacturing processes, and business models, significantly reducing time-to-market and development costs. This capability is particularly valuable in industries with high safety requirements or expensive testing procedures.

Sustainability represents an increasingly important strategic goal. Digital twins enable more precise energy management, waste reduction, and environmental impact assessment through detailed modeling of resource consumption and emissions. This aligns with global sustainability initiatives and regulatory requirements facing industrial sectors.

Risk mitigation constitutes the fourth major objective, with digital twins offering sophisticated predictive maintenance capabilities, supply chain resilience modeling, and cybersecurity scenario planning. These applications help organizations anticipate and prepare for potential disruptions, enhancing overall business continuity.

Industrial Market Demand Analysis for Digital Twin

The global digital twin market is experiencing unprecedented growth, driven by the accelerating pace of industrial digitalization across sectors. Current market analysis indicates that the digital twin technology market is expanding at a compound annual growth rate of approximately 35% and is projected to reach $48 billion by 2026. This remarkable growth trajectory is underpinned by increasing demand for real-time monitoring, predictive maintenance, and operational optimization across manufacturing, energy, healthcare, and infrastructure sectors.

Manufacturing industries represent the largest segment of digital twin adoption, accounting for nearly 40% of the total market share. This dominance stems from the critical need to optimize production processes, reduce downtime, and enhance product quality through virtual simulation and real-time monitoring capabilities. The automotive and aerospace sectors are particularly aggressive in implementing digital twin solutions to streamline complex assembly operations and enhance product development cycles.

Energy and utilities sectors follow closely, with substantial investments in digital twin technologies for asset management, grid optimization, and predictive maintenance. The ability to create virtual replicas of power plants, transmission networks, and renewable energy installations enables operators to simulate various operational scenarios, identify potential failures before they occur, and optimize energy distribution systems.

Healthcare and pharmaceutical industries are emerging as rapidly growing markets for digital twin applications. The technology enables virtual modeling of medical devices, pharmaceutical manufacturing processes, and even patient-specific anatomical structures. This capability significantly reduces development time, enhances product safety, and enables personalized treatment approaches.

Market demand analysis reveals several key drivers accelerating digital twin adoption across industries. First, the increasing complexity of industrial systems necessitates advanced simulation capabilities to understand interdependencies and optimize performance. Second, the proliferation of IoT sensors and connectivity solutions provides the data foundation required for creating accurate digital representations. Third, advancements in computing power and cloud infrastructure enable the processing of massive datasets required for real-time digital twin operations.

Regional analysis indicates that North America currently leads in digital twin adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization in China, India, and Southeast Asian countries, coupled with substantial government initiatives supporting digital transformation.

Customer requirements are evolving beyond basic simulation capabilities toward integrated platforms that combine digital twins with advanced analytics, artificial intelligence, and machine learning capabilities. This evolution reflects the growing sophistication of industrial applications and the increasing strategic importance of digital twin technology in driving competitive advantage and operational excellence.

Manufacturing industries represent the largest segment of digital twin adoption, accounting for nearly 40% of the total market share. This dominance stems from the critical need to optimize production processes, reduce downtime, and enhance product quality through virtual simulation and real-time monitoring capabilities. The automotive and aerospace sectors are particularly aggressive in implementing digital twin solutions to streamline complex assembly operations and enhance product development cycles.

Energy and utilities sectors follow closely, with substantial investments in digital twin technologies for asset management, grid optimization, and predictive maintenance. The ability to create virtual replicas of power plants, transmission networks, and renewable energy installations enables operators to simulate various operational scenarios, identify potential failures before they occur, and optimize energy distribution systems.

Healthcare and pharmaceutical industries are emerging as rapidly growing markets for digital twin applications. The technology enables virtual modeling of medical devices, pharmaceutical manufacturing processes, and even patient-specific anatomical structures. This capability significantly reduces development time, enhances product safety, and enables personalized treatment approaches.

Market demand analysis reveals several key drivers accelerating digital twin adoption across industries. First, the increasing complexity of industrial systems necessitates advanced simulation capabilities to understand interdependencies and optimize performance. Second, the proliferation of IoT sensors and connectivity solutions provides the data foundation required for creating accurate digital representations. Third, advancements in computing power and cloud infrastructure enable the processing of massive datasets required for real-time digital twin operations.

Regional analysis indicates that North America currently leads in digital twin adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization in China, India, and Southeast Asian countries, coupled with substantial government initiatives supporting digital transformation.

Customer requirements are evolving beyond basic simulation capabilities toward integrated platforms that combine digital twins with advanced analytics, artificial intelligence, and machine learning capabilities. This evolution reflects the growing sophistication of industrial applications and the increasing strategic importance of digital twin technology in driving competitive advantage and operational excellence.

Current Digital Twin Technology Landscape and Barriers

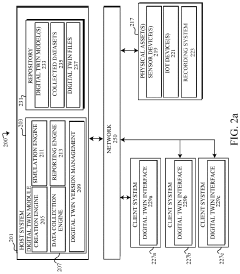

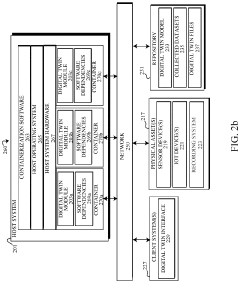

Digital twin technology has evolved significantly over the past decade, transforming from conceptual frameworks to practical implementations across various industrial sectors. Currently, the global digital twin landscape is characterized by a multi-tiered ecosystem comprising software platforms, hardware infrastructure, and integration services. Leading technology providers have developed comprehensive platforms that enable the creation, deployment, and management of digital twins across manufacturing, energy, healthcare, and urban planning sectors. These platforms typically incorporate real-time data processing capabilities, physics-based simulation engines, and advanced visualization tools that collectively facilitate the virtual replication of physical assets and processes.

Despite substantial progress, the digital twin technology landscape faces several critical barriers to widespread adoption. Interoperability remains a significant challenge, as digital twin implementations often require seamless integration with diverse legacy systems, IoT devices, and enterprise applications. The absence of standardized protocols and data formats impedes cross-platform compatibility and limits the potential for ecosystem expansion. This fragmentation necessitates costly custom integration efforts that can undermine the economic viability of digital twin initiatives, particularly for small and medium enterprises.

Data management presents another formidable barrier, with digital twin systems generating and processing enormous volumes of heterogeneous data. Organizations struggle with issues related to data quality, consistency, and governance, which directly impact the accuracy and reliability of digital twin models. The real-time synchronization between physical assets and their digital counterparts demands robust data pipelines and processing capabilities that many organizations lack. Furthermore, concerns regarding data security and intellectual property protection have emerged as digital twins often contain sensitive operational information and proprietary design specifications.

Technical complexity constitutes a third major barrier, as developing and maintaining sophisticated digital twin systems requires specialized expertise in simulation modeling, data science, and domain-specific knowledge. The shortage of qualified professionals with cross-disciplinary skills has created implementation bottlenecks across industries. Additionally, the computational requirements for high-fidelity digital twins, particularly those involving complex physics simulations or machine learning components, can be prohibitively expensive for many potential adopters.

Scalability challenges further complicate the digital twin landscape, as organizations struggle to expand pilot implementations to enterprise-wide deployments. The transition from isolated use cases to integrated digital twin ecosystems demands substantial architectural considerations and organizational change management. Moreover, quantifying the return on investment for digital twin initiatives remains difficult due to the indirect nature of many benefits and the long-term horizon for realizing operational improvements.

Despite substantial progress, the digital twin technology landscape faces several critical barriers to widespread adoption. Interoperability remains a significant challenge, as digital twin implementations often require seamless integration with diverse legacy systems, IoT devices, and enterprise applications. The absence of standardized protocols and data formats impedes cross-platform compatibility and limits the potential for ecosystem expansion. This fragmentation necessitates costly custom integration efforts that can undermine the economic viability of digital twin initiatives, particularly for small and medium enterprises.

Data management presents another formidable barrier, with digital twin systems generating and processing enormous volumes of heterogeneous data. Organizations struggle with issues related to data quality, consistency, and governance, which directly impact the accuracy and reliability of digital twin models. The real-time synchronization between physical assets and their digital counterparts demands robust data pipelines and processing capabilities that many organizations lack. Furthermore, concerns regarding data security and intellectual property protection have emerged as digital twins often contain sensitive operational information and proprietary design specifications.

Technical complexity constitutes a third major barrier, as developing and maintaining sophisticated digital twin systems requires specialized expertise in simulation modeling, data science, and domain-specific knowledge. The shortage of qualified professionals with cross-disciplinary skills has created implementation bottlenecks across industries. Additionally, the computational requirements for high-fidelity digital twins, particularly those involving complex physics simulations or machine learning components, can be prohibitively expensive for many potential adopters.

Scalability challenges further complicate the digital twin landscape, as organizations struggle to expand pilot implementations to enterprise-wide deployments. The transition from isolated use cases to integrated digital twin ecosystems demands substantial architectural considerations and organizational change management. Moreover, quantifying the return on investment for digital twin initiatives remains difficult due to the indirect nature of many benefits and the long-term horizon for realizing operational improvements.

Leading Digital Twin Implementation Frameworks

01 Digital Twin for Industrial Systems and Manufacturing

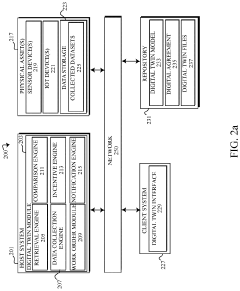

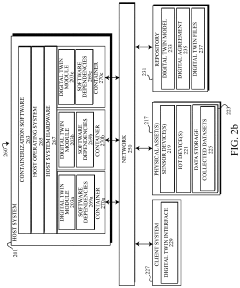

Digital twins are virtual replicas of physical industrial systems and manufacturing processes that enable real-time monitoring, simulation, and optimization. These digital representations collect data from sensors and IoT devices to create accurate models that can predict performance, identify potential failures, and optimize operations. By implementing digital twins in manufacturing environments, companies can improve efficiency, reduce downtime, and enhance product quality through continuous analysis and adjustment of production parameters.- Digital Twin for Industrial Systems and Manufacturing: Digital twins are virtual replicas of physical industrial systems and manufacturing processes that enable real-time monitoring, simulation, and optimization. These digital models collect data from sensors and IoT devices to create accurate representations of equipment, production lines, and factories. By analyzing this data, manufacturers can predict maintenance needs, optimize production efficiency, and reduce downtime. The technology allows for testing changes in a virtual environment before implementing them in the physical world, significantly reducing risks and costs associated with process modifications.

- Digital Twin in Healthcare and Medical Applications: Digital twin technology is being applied in healthcare to create virtual models of patients, organs, or medical devices. These models use patient-specific data to simulate physiological responses, predict treatment outcomes, and personalize medical care. Digital twins enable healthcare providers to test different treatment approaches virtually before applying them to actual patients, improving safety and efficacy. The technology also supports remote patient monitoring, predictive diagnostics, and the development of precision medicine approaches by integrating real-time health data with computational models.

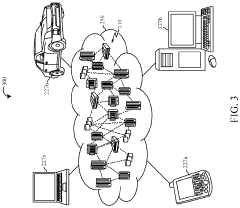

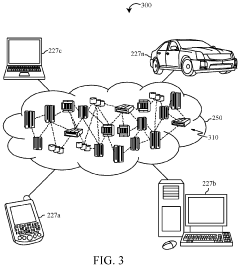

- Digital Twin for Smart Cities and Infrastructure: Digital twins are being implemented to model and manage urban environments and infrastructure systems. These virtual replicas integrate data from various sources including IoT sensors, cameras, and public records to create comprehensive models of cities, buildings, transportation networks, and utilities. The technology enables city planners and managers to visualize complex urban systems, simulate scenarios, optimize resource allocation, and improve emergency response. Digital twins help in predicting the impact of changes to infrastructure, managing energy consumption, and enhancing the overall sustainability and resilience of urban environments.

- Digital Twin Integration with AI and Machine Learning: The integration of artificial intelligence and machine learning with digital twin technology enhances the capabilities of virtual models to analyze data, identify patterns, and make predictions. AI algorithms process the vast amounts of data collected by digital twins to generate insights, optimize operations, and enable autonomous decision-making. Machine learning models continuously improve the accuracy of digital twins by learning from historical data and real-time feedback. This combination of technologies enables advanced simulations, predictive analytics, and adaptive systems that can respond to changing conditions without human intervention.

- Digital Twin Security and Data Management: As digital twins collect and process vast amounts of sensitive data, robust security measures and efficient data management systems are essential. This includes encryption protocols, access controls, and authentication mechanisms to protect against unauthorized access and cyber threats. Digital twin platforms must also address data privacy concerns, especially when handling personal or proprietary information. Effective data management strategies involve data governance frameworks, storage solutions, and integration capabilities that enable seamless data flow between physical assets, sensors, and the digital twin environment while maintaining data integrity and compliance with regulations.

02 Digital Twin Technology in Healthcare and Medical Applications

Digital twin technology is being applied in healthcare to create virtual models of patients, medical devices, and healthcare systems. These digital representations enable personalized medicine by simulating patient responses to treatments, predicting disease progression, and optimizing medical interventions. Healthcare digital twins integrate patient data, medical imaging, and physiological parameters to create comprehensive models that support clinical decision-making, improve patient outcomes, and enhance medical training through realistic simulations of procedures and treatments.Expand Specific Solutions03 Digital Twin for Smart Cities and Infrastructure Management

Digital twins are being deployed to model and manage urban environments and critical infrastructure. These virtual replicas integrate data from various sources including IoT sensors, surveillance systems, and utility networks to create comprehensive models of cities and infrastructure assets. By implementing digital twins for urban planning and infrastructure management, authorities can optimize resource allocation, improve emergency response, predict maintenance needs, and enhance sustainability through scenario testing and real-time monitoring of environmental conditions and resource consumption.Expand Specific Solutions04 Digital Twin Integration with AI and Machine Learning

The integration of artificial intelligence and machine learning with digital twin technology enhances predictive capabilities and autonomous decision-making. These advanced digital twins can learn from historical data, identify patterns, and make intelligent predictions about future states or behaviors of physical assets. By combining AI algorithms with digital twin frameworks, systems can perform complex simulations, optimize operations autonomously, detect anomalies before they cause failures, and continuously improve performance through adaptive learning mechanisms that refine the virtual model based on real-world feedback.Expand Specific Solutions05 Digital Twin Security and Data Management Frameworks

Security and data management are critical aspects of digital twin implementation, requiring robust frameworks to protect sensitive information while ensuring data integrity and availability. These frameworks include encryption protocols, access control mechanisms, and secure communication channels for data exchange between physical assets and their digital counterparts. Effective digital twin security solutions address challenges related to data privacy, intellectual property protection, and vulnerability management while enabling efficient data storage, processing, and analysis across distributed systems and cloud environments.Expand Specific Solutions

Key Industry Players and Competitive Dynamics

The digital twin market in global industrial digitalization is experiencing rapid growth, currently in its early maturity phase with increasing adoption across sectors. The market is projected to expand significantly, reaching approximately $35-45 billion by 2026, driven by Industry 4.0 initiatives and IoT integration. Technology maturity varies across players, with established leaders like IBM, Siemens, and Rockwell Automation offering comprehensive solutions with advanced AI capabilities. Companies such as Huawei, TCS, and BASF are rapidly advancing their offerings, while specialized players like Simacro and Fedem Technology provide niche expertise. Academic institutions including National University of Singapore and Beihang University are contributing significant research advancements, accelerating the technology's evolution from conceptual to practical industrial applications.

International Business Machines Corp.

Technical Solution: IBM's digital twin solution leverages its Watson IoT platform to create comprehensive virtual replicas of physical assets, processes, and systems. The company's approach integrates AI, machine learning, and advanced analytics to enable real-time monitoring, predictive maintenance, and optimization of industrial operations. IBM's digital twin technology creates a continuous feedback loop between physical and digital environments, allowing for simulation of various scenarios before implementation in the real world. Their solution incorporates data from multiple sources including IoT sensors, historical records, and environmental factors to create highly accurate models. IBM has implemented this technology across various industries including manufacturing, energy, and infrastructure, resulting in reported operational efficiency improvements of up to 25% and maintenance cost reductions of approximately 30% for clients[1][3]. The platform's open architecture allows for integration with existing enterprise systems and third-party applications, creating a scalable ecosystem for industrial digitalization.

Strengths: Strong integration with AI and analytics capabilities; robust cloud infrastructure; extensive industry expertise across sectors; comprehensive service offerings including consulting. Weaknesses: Higher implementation costs compared to some competitors; complex deployment requirements; potential vendor lock-in concerns; requires significant data infrastructure.

Siemens AG

Technical Solution: Siemens has developed a comprehensive digital twin platform called Xcelerator that spans the entire product lifecycle from design and engineering to manufacturing and service. Their solution creates virtual replicas at three levels: product, production, and performance. The product digital twin enables virtual product development and testing, reducing physical prototyping by up to 70%[2]. The production digital twin simulates manufacturing processes and plant operations before physical implementation, optimizing workflows and reducing commissioning time by approximately 30%. The performance digital twin continuously collects operational data from physical assets to enable predictive maintenance and optimization. Siemens' technology incorporates physics-based simulation, real-time IoT data, and AI analytics to create highly accurate models. Their MindSphere IoT platform serves as the foundation for connecting physical assets to their digital counterparts, processing over 30 million data points daily for some industrial clients[4]. Siemens has implemented this technology across automotive, aerospace, energy, and manufacturing sectors with documented productivity improvements of 15-20%.

Strengths: Comprehensive end-to-end digital twin capabilities across product lifecycle; strong domain expertise in industrial automation; extensive industrial software portfolio; seamless integration with manufacturing systems. Weaknesses: Solutions can be complex to implement for smaller organizations; significant investment required for full ecosystem adoption; learning curve for users transitioning from traditional systems.

Critical Patents and Technical Innovations in Digital Twin

Digital twin workflow simulation

PatentActiveUS20210374032A1

Innovation

- A computer-implemented method for simulating digital twin performance that allows users to selectively bypass certain input parameters and components, using customizable configurations to focus on specific parts, substitute alternative components, and provide overriding values for intermediate simulation results, enabling more targeted analysis and optimization.

Digital twin maturation tracking

PatentActiveUS20210096975A1

Innovation

- A computer-implemented method and system that compares the original digital twin of a physical asset to its mature state, determining the relevance of proposed changes and applying updates as needed, while also providing incentives for owners who have already performed relevant changes, using a digital twin module that tracks changes and simulates asset performance.

Cross-Industry Digital Twin Application Cases

Digital twin technology has demonstrated remarkable versatility across multiple industries, transforming operational paradigms and creating new value streams. In manufacturing, companies like Siemens have implemented digital twins to optimize production lines, resulting in 25% efficiency improvements and 15% reduction in maintenance costs. Their digital twin platform enables real-time monitoring of equipment performance, predictive maintenance scheduling, and virtual testing of production modifications before physical implementation.

In the energy sector, General Electric utilizes digital twins for wind farm optimization. By creating virtual replicas of wind turbines, operators can analyze performance under various weather conditions, optimize blade angles, and predict maintenance needs. This application has increased energy output by up to 20% while reducing downtime by 30% in several deployments across Europe and North America.

Healthcare has embraced digital twin technology for personalized medicine approaches. Philips Healthcare has developed patient-specific digital twins that simulate physiological responses to treatments. These models allow physicians to test different therapeutic strategies virtually before administering them to patients, particularly valuable in complex cardiac cases where treatment outcomes can be difficult to predict.

Urban planning and smart city initiatives represent another significant application area. Singapore's Virtual Singapore project created a comprehensive digital twin of the entire city-state, enabling simulation of traffic patterns, energy consumption, and emergency response scenarios. This platform supports urban planning decisions, infrastructure development, and sustainability initiatives by providing data-driven insights into city operations.

In logistics and supply chain management, companies like DHL have implemented digital twins to optimize warehouse operations and delivery routes. These virtual replicas simulate different inventory arrangements, staffing levels, and fulfillment strategies to identify optimal configurations. Implementation data shows up to 15% improvement in warehouse throughput and 12% reduction in delivery times.

The aerospace industry leverages digital twins for aircraft design, manufacturing, and maintenance. Boeing's digital twin implementation for the 777X program enabled engineers to identify and resolve design issues virtually, reducing physical prototyping costs by approximately 40% and accelerating time-to-market. During operations, these digital twins continue providing value through predictive maintenance capabilities.

Water management utilities have adopted digital twins to optimize distribution networks and treatment facilities. Thames Water in the UK implemented a comprehensive digital twin of their infrastructure, enabling real-time monitoring of water quality, pressure management, and leak detection across their network, resulting in 20% reduction in water losses and improved response times to infrastructure failures.

In the energy sector, General Electric utilizes digital twins for wind farm optimization. By creating virtual replicas of wind turbines, operators can analyze performance under various weather conditions, optimize blade angles, and predict maintenance needs. This application has increased energy output by up to 20% while reducing downtime by 30% in several deployments across Europe and North America.

Healthcare has embraced digital twin technology for personalized medicine approaches. Philips Healthcare has developed patient-specific digital twins that simulate physiological responses to treatments. These models allow physicians to test different therapeutic strategies virtually before administering them to patients, particularly valuable in complex cardiac cases where treatment outcomes can be difficult to predict.

Urban planning and smart city initiatives represent another significant application area. Singapore's Virtual Singapore project created a comprehensive digital twin of the entire city-state, enabling simulation of traffic patterns, energy consumption, and emergency response scenarios. This platform supports urban planning decisions, infrastructure development, and sustainability initiatives by providing data-driven insights into city operations.

In logistics and supply chain management, companies like DHL have implemented digital twins to optimize warehouse operations and delivery routes. These virtual replicas simulate different inventory arrangements, staffing levels, and fulfillment strategies to identify optimal configurations. Implementation data shows up to 15% improvement in warehouse throughput and 12% reduction in delivery times.

The aerospace industry leverages digital twins for aircraft design, manufacturing, and maintenance. Boeing's digital twin implementation for the 777X program enabled engineers to identify and resolve design issues virtually, reducing physical prototyping costs by approximately 40% and accelerating time-to-market. During operations, these digital twins continue providing value through predictive maintenance capabilities.

Water management utilities have adopted digital twins to optimize distribution networks and treatment facilities. Thames Water in the UK implemented a comprehensive digital twin of their infrastructure, enabling real-time monitoring of water quality, pressure management, and leak detection across their network, resulting in 20% reduction in water losses and improved response times to infrastructure failures.

Data Security and Governance Considerations

As digital twins become increasingly integrated into industrial digitalization strategies, data security and governance have emerged as critical considerations that can either accelerate or impede adoption. The implementation of digital twin technology necessitates the collection, processing, and analysis of vast amounts of sensitive operational data, creating significant security vulnerabilities that must be addressed through comprehensive protection frameworks. Organizations deploying digital twins must establish robust encryption protocols, access control mechanisms, and secure data transmission channels to safeguard against unauthorized access and potential breaches.

Data sovereignty concerns present another layer of complexity, particularly for multinational corporations operating digital twins across various jurisdictions. Regulatory frameworks such as GDPR in Europe, CCPA in California, and emerging data protection laws in Asia impose strict requirements on data localization, cross-border transfers, and processing activities. These regulations often mandate that certain types of industrial data remain within national boundaries, compelling organizations to implement geographically distributed digital twin architectures that comply with regional data sovereignty requirements.

The governance of digital twin data requires establishing clear policies regarding data ownership, retention periods, and usage rights. This becomes particularly challenging when digital twins incorporate data from multiple stakeholders across supply chains, creating complex questions about intellectual property rights and competitive intelligence protection. Forward-thinking organizations are developing data sharing agreements and contractual frameworks that explicitly define ownership boundaries and usage limitations for digital twin implementations.

Privacy considerations extend beyond regulatory compliance to encompass ethical dimensions of data utilization. Even in industrial contexts, digital twins may capture information that could be linked to individual workers, raising concerns about workplace surveillance and employee privacy. Implementing privacy-by-design principles in digital twin architectures helps mitigate these risks by minimizing unnecessary data collection and incorporating anonymization techniques where appropriate.

The long-term governance of digital twin implementations necessitates establishing data lifecycle management protocols that address how information is created, stored, archived, and eventually deleted. This includes developing clear policies for data retention that balance operational needs against security risks and compliance requirements. Organizations must also implement audit mechanisms that provide transparency into how digital twin data is being accessed and utilized throughout its lifecycle.

Data sovereignty concerns present another layer of complexity, particularly for multinational corporations operating digital twins across various jurisdictions. Regulatory frameworks such as GDPR in Europe, CCPA in California, and emerging data protection laws in Asia impose strict requirements on data localization, cross-border transfers, and processing activities. These regulations often mandate that certain types of industrial data remain within national boundaries, compelling organizations to implement geographically distributed digital twin architectures that comply with regional data sovereignty requirements.

The governance of digital twin data requires establishing clear policies regarding data ownership, retention periods, and usage rights. This becomes particularly challenging when digital twins incorporate data from multiple stakeholders across supply chains, creating complex questions about intellectual property rights and competitive intelligence protection. Forward-thinking organizations are developing data sharing agreements and contractual frameworks that explicitly define ownership boundaries and usage limitations for digital twin implementations.

Privacy considerations extend beyond regulatory compliance to encompass ethical dimensions of data utilization. Even in industrial contexts, digital twins may capture information that could be linked to individual workers, raising concerns about workplace surveillance and employee privacy. Implementing privacy-by-design principles in digital twin architectures helps mitigate these risks by minimizing unnecessary data collection and incorporating anonymization techniques where appropriate.

The long-term governance of digital twin implementations necessitates establishing data lifecycle management protocols that address how information is created, stored, archived, and eventually deleted. This includes developing clear policies for data retention that balance operational needs against security risks and compliance requirements. Organizations must also implement audit mechanisms that provide transparency into how digital twin data is being accessed and utilized throughout its lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!