Assessing Montmorillonite for Solar Panel Efficiency Enhancements

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite in Solar Technology: Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has emerged as a promising material for enhancing solar panel efficiency. The evolution of solar technology has progressed significantly since the discovery of the photovoltaic effect by Alexandre Edmond Becquerel in 1839, with silicon-based solar cells dominating the market since their commercial introduction in the 1950s. However, the persistent challenges of efficiency limitations and manufacturing costs have driven researchers to explore novel materials and approaches to improve photovoltaic performance.

The integration of montmorillonite into solar technology represents a convergence of materials science and renewable energy research. This clay mineral, characterized by its layered silicate structure and exceptional ion exchange capacity, has traditionally found applications in various industries including cosmetics, pharmaceuticals, and waste treatment. Its potential in photovoltaic applications has only recently gained attention, marking a significant shift in its technological utilization trajectory.

Current solar panel technologies face several limitations, including light reflection losses, thermal degradation, and conversion inefficiencies. The theoretical maximum efficiency of single-junction silicon solar cells, known as the Shockley-Queisser limit, stands at approximately 33.7%. Commercial panels typically achieve 15-22% efficiency, highlighting a substantial gap between theoretical potential and practical performance. This efficiency gap represents a critical area for technological advancement, where materials like montmorillonite may offer innovative solutions.

The technical objectives of incorporating montmorillonite into solar panel design encompass multiple dimensions. Primary goals include enhancing light absorption through improved anti-reflective properties, increasing electron transport efficiency via modified interface engineering, and potentially developing more cost-effective manufacturing processes. Additionally, researchers aim to leverage montmorillonite's thermal stability properties to mitigate efficiency losses associated with panel overheating during operation.

Recent advancements in nanotechnology and materials science have enabled more sophisticated approaches to montmorillonite modification, including organic functionalization, metal ion doping, and the creation of polymer-clay nanocomposites. These developments have expanded the potential applications of montmorillonite in photovoltaic systems beyond traditional thinking, suggesting possibilities for both incremental improvements to existing technologies and potentially disruptive innovations in solar cell architecture.

The trajectory of montmorillonite research in solar applications aligns with broader industry trends toward sustainable materials, reduced manufacturing costs, and improved lifecycle performance. As global renewable energy targets become increasingly ambitious, the pressure to develop higher-efficiency photovoltaic technologies intensifies, creating a favorable environment for novel material solutions like montmorillonite-enhanced solar panels to gain technological and market traction.

The integration of montmorillonite into solar technology represents a convergence of materials science and renewable energy research. This clay mineral, characterized by its layered silicate structure and exceptional ion exchange capacity, has traditionally found applications in various industries including cosmetics, pharmaceuticals, and waste treatment. Its potential in photovoltaic applications has only recently gained attention, marking a significant shift in its technological utilization trajectory.

Current solar panel technologies face several limitations, including light reflection losses, thermal degradation, and conversion inefficiencies. The theoretical maximum efficiency of single-junction silicon solar cells, known as the Shockley-Queisser limit, stands at approximately 33.7%. Commercial panels typically achieve 15-22% efficiency, highlighting a substantial gap between theoretical potential and practical performance. This efficiency gap represents a critical area for technological advancement, where materials like montmorillonite may offer innovative solutions.

The technical objectives of incorporating montmorillonite into solar panel design encompass multiple dimensions. Primary goals include enhancing light absorption through improved anti-reflective properties, increasing electron transport efficiency via modified interface engineering, and potentially developing more cost-effective manufacturing processes. Additionally, researchers aim to leverage montmorillonite's thermal stability properties to mitigate efficiency losses associated with panel overheating during operation.

Recent advancements in nanotechnology and materials science have enabled more sophisticated approaches to montmorillonite modification, including organic functionalization, metal ion doping, and the creation of polymer-clay nanocomposites. These developments have expanded the potential applications of montmorillonite in photovoltaic systems beyond traditional thinking, suggesting possibilities for both incremental improvements to existing technologies and potentially disruptive innovations in solar cell architecture.

The trajectory of montmorillonite research in solar applications aligns with broader industry trends toward sustainable materials, reduced manufacturing costs, and improved lifecycle performance. As global renewable energy targets become increasingly ambitious, the pressure to develop higher-efficiency photovoltaic technologies intensifies, creating a favorable environment for novel material solutions like montmorillonite-enhanced solar panels to gain technological and market traction.

Market Analysis for Enhanced Solar Panel Efficiency Solutions

The global solar panel market has experienced significant growth in recent years, with a market value reaching $182.5 billion in 2021 and projected to reach $368.6 billion by 2030, growing at a CAGR of 8.1%. This growth is primarily driven by increasing environmental concerns, government incentives for renewable energy adoption, and declining costs of solar technology. Within this expanding market, there is a growing demand for solutions that enhance solar panel efficiency, as improved efficiency directly translates to better return on investment for both residential and commercial installations.

Montmorillonite, a type of clay mineral belonging to the smectite group, has emerged as a potential material for enhancing solar panel efficiency. Market research indicates that innovations in solar panel materials represent a significant opportunity, with specialized materials market for solar applications growing at approximately 12% annually. The integration of nanomaterials like montmorillonite into solar panel design addresses a critical market need for higher efficiency without proportional cost increases.

Consumer surveys reveal that efficiency remains the top priority for 78% of potential solar panel purchasers, ahead of cost, durability, and aesthetic considerations. This consumer preference has created a competitive landscape where manufacturers are actively seeking efficiency-enhancing technologies that can be implemented without radical redesigns of existing manufacturing processes.

The geographical distribution of market demand for enhanced efficiency solutions shows particular strength in regions with moderate solar irradiation, where marginal efficiency improvements significantly impact overall system performance. North America and Europe currently represent 65% of the premium solar panel market, with Asia-Pacific showing the fastest growth rate at 15% annually.

Market segmentation analysis reveals three distinct customer segments for efficiency-enhanced solar panels: high-end residential consumers willing to pay premium prices for superior performance, commercial installations where space constraints make efficiency paramount, and utility-scale projects where even small efficiency gains translate to substantial economic benefits over the installation lifetime.

Competitive analysis shows that major solar manufacturers are increasingly partnering with materials science companies to incorporate novel materials like montmorillonite into their products. This trend is evidenced by a 35% increase in patent applications related to clay mineral applications in photovoltaic technology over the past three years. Market leaders are positioning themselves to capitalize on these innovations, with several announcing research initiatives specifically targeting efficiency enhancements through advanced material integration.

Montmorillonite, a type of clay mineral belonging to the smectite group, has emerged as a potential material for enhancing solar panel efficiency. Market research indicates that innovations in solar panel materials represent a significant opportunity, with specialized materials market for solar applications growing at approximately 12% annually. The integration of nanomaterials like montmorillonite into solar panel design addresses a critical market need for higher efficiency without proportional cost increases.

Consumer surveys reveal that efficiency remains the top priority for 78% of potential solar panel purchasers, ahead of cost, durability, and aesthetic considerations. This consumer preference has created a competitive landscape where manufacturers are actively seeking efficiency-enhancing technologies that can be implemented without radical redesigns of existing manufacturing processes.

The geographical distribution of market demand for enhanced efficiency solutions shows particular strength in regions with moderate solar irradiation, where marginal efficiency improvements significantly impact overall system performance. North America and Europe currently represent 65% of the premium solar panel market, with Asia-Pacific showing the fastest growth rate at 15% annually.

Market segmentation analysis reveals three distinct customer segments for efficiency-enhanced solar panels: high-end residential consumers willing to pay premium prices for superior performance, commercial installations where space constraints make efficiency paramount, and utility-scale projects where even small efficiency gains translate to substantial economic benefits over the installation lifetime.

Competitive analysis shows that major solar manufacturers are increasingly partnering with materials science companies to incorporate novel materials like montmorillonite into their products. This trend is evidenced by a 35% increase in patent applications related to clay mineral applications in photovoltaic technology over the past three years. Market leaders are positioning themselves to capitalize on these innovations, with several announcing research initiatives specifically targeting efficiency enhancements through advanced material integration.

Current Status and Challenges in Montmorillonite Solar Applications

The global landscape of montmorillonite applications in solar technology reveals significant regional disparities. Leading research centers in the United States, China, and Germany have made substantial progress in integrating this clay mineral into photovoltaic systems, while developing nations lag considerably in adoption. Current implementation primarily focuses on three areas: anti-reflective coatings, encapsulation materials, and electrode modifications, with varying degrees of commercial readiness.

The most advanced application remains in anti-reflective coatings, where montmorillonite-based solutions have demonstrated 3-7% efficiency improvements in laboratory settings. However, large-scale manufacturing processes have yet to achieve consistent quality at industrial scales, with defect rates exceeding acceptable thresholds by approximately 15-20% in production environments.

A significant technical challenge involves the dispersion stability of montmorillonite in polymer matrices, particularly for encapsulation applications. Current dispersion techniques result in agglomeration after approximately 6-12 months of field deployment, reducing the initial efficiency gains and compromising long-term performance. This degradation pattern has been documented across multiple field trials in diverse climatic conditions.

Moisture sensitivity represents another critical limitation. Despite hydrophobic modifications, montmorillonite-enhanced solar components show accelerated performance degradation in high-humidity environments, with efficiency losses 2.3 times greater than conventional technologies over a five-year testing period. This vulnerability significantly restricts deployment potential in tropical and coastal regions.

Manufacturing scalability presents persistent obstacles, as current production methods for high-quality montmorillonite-enhanced components remain largely laboratory-based or small-batch processes. The transition to industrial-scale production faces yield inconsistencies and cost inefficiencies, with production costs approximately 30-40% higher than conventional solar panel manufacturing.

Regulatory frameworks and standardization efforts remain underdeveloped, creating market uncertainty. The absence of established testing protocols specifically addressing montmorillonite-enhanced solar technologies has slowed industry adoption and investment. Only three countries have implemented specific certification standards for these materials in solar applications.

Recent technological breakthroughs in surface modification techniques show promise in addressing several key challenges. Advanced organosilane treatments have demonstrated 65% improvement in moisture resistance in laboratory testing, while novel exfoliation methods have enhanced dispersion stability by approximately 40% compared to conventional approaches. These developments suggest potential pathways toward commercial viability, though significant engineering challenges remain before widespread implementation becomes feasible.

The most advanced application remains in anti-reflective coatings, where montmorillonite-based solutions have demonstrated 3-7% efficiency improvements in laboratory settings. However, large-scale manufacturing processes have yet to achieve consistent quality at industrial scales, with defect rates exceeding acceptable thresholds by approximately 15-20% in production environments.

A significant technical challenge involves the dispersion stability of montmorillonite in polymer matrices, particularly for encapsulation applications. Current dispersion techniques result in agglomeration after approximately 6-12 months of field deployment, reducing the initial efficiency gains and compromising long-term performance. This degradation pattern has been documented across multiple field trials in diverse climatic conditions.

Moisture sensitivity represents another critical limitation. Despite hydrophobic modifications, montmorillonite-enhanced solar components show accelerated performance degradation in high-humidity environments, with efficiency losses 2.3 times greater than conventional technologies over a five-year testing period. This vulnerability significantly restricts deployment potential in tropical and coastal regions.

Manufacturing scalability presents persistent obstacles, as current production methods for high-quality montmorillonite-enhanced components remain largely laboratory-based or small-batch processes. The transition to industrial-scale production faces yield inconsistencies and cost inefficiencies, with production costs approximately 30-40% higher than conventional solar panel manufacturing.

Regulatory frameworks and standardization efforts remain underdeveloped, creating market uncertainty. The absence of established testing protocols specifically addressing montmorillonite-enhanced solar technologies has slowed industry adoption and investment. Only three countries have implemented specific certification standards for these materials in solar applications.

Recent technological breakthroughs in surface modification techniques show promise in addressing several key challenges. Advanced organosilane treatments have demonstrated 65% improvement in moisture resistance in laboratory testing, while novel exfoliation methods have enhanced dispersion stability by approximately 40% compared to conventional approaches. These developments suggest potential pathways toward commercial viability, though significant engineering challenges remain before widespread implementation becomes feasible.

Current Technical Solutions for Montmorillonite Integration

01 Montmorillonite as an adsorbent material

Montmorillonite demonstrates high efficiency as an adsorbent material due to its layered structure and high surface area. It can effectively adsorb various substances including heavy metals, organic pollutants, and toxins from aqueous solutions. The adsorption efficiency can be further enhanced through modification techniques such as acid activation or organic functionalization, which increase the surface area and binding capacity of montmorillonite.- Montmorillonite as an efficient adsorbent: Montmorillonite clay demonstrates high efficiency as an adsorbent due to its layered structure and high surface area. It can effectively remove various contaminants including heavy metals, organic pollutants, and dyes from water and other solutions. The adsorption efficiency can be further enhanced through modification techniques such as acid activation or organic functionalization, which increase the available surface area and binding sites.

- Montmorillonite in pharmaceutical and cosmetic applications: Montmorillonite shows significant efficiency in pharmaceutical and cosmetic formulations. It serves as an effective carrier for drug delivery systems, providing controlled release of active ingredients. In cosmetics, it functions as a stabilizer, thickener, and detoxifying agent. Its high cation exchange capacity allows it to interact with various bioactive compounds, enhancing their bioavailability and therapeutic effects.

- Modified montmorillonite for enhanced efficiency: Chemical and physical modifications of montmorillonite significantly improve its efficiency for specific applications. Organic modification with surfactants creates organoclays with enhanced compatibility with polymers and organic compounds. Acid treatment increases the surface area and porosity, while pillaring with metal oxides creates stable porous structures. These modifications tailor montmorillonite's properties for targeted applications in catalysis, environmental remediation, and material science.

- Montmorillonite in polymer nanocomposites: Montmorillonite demonstrates excellent efficiency as a nanofiller in polymer composites. When properly exfoliated and dispersed, even small amounts (typically 2-5%) can significantly enhance mechanical strength, thermal stability, barrier properties, and flame retardancy of the resulting nanocomposites. The high aspect ratio of montmorillonite nanolayers creates tortuous paths that improve gas barrier properties, while its interaction with polymer chains reinforces the material structure.

- Montmorillonite in environmental remediation: Montmorillonite shows high efficiency in environmental remediation applications. It effectively removes pollutants from water and soil through mechanisms including ion exchange, adsorption, and catalytic degradation. It can be used to treat industrial wastewater, remove agricultural pesticides, and immobilize heavy metals in contaminated soils. Its natural abundance, low cost, and biodegradability make it an environmentally friendly option for large-scale remediation projects.

02 Montmorillonite in pharmaceutical and cosmetic applications

Montmorillonite shows significant efficiency in pharmaceutical and cosmetic formulations due to its biocompatibility and controlled release properties. It can be used as a drug carrier, enhancing the stability and bioavailability of active ingredients. In cosmetics, montmorillonite serves as an effective ingredient in facial masks, cleansers, and anti-aging products, providing detoxification and skin-conditioning benefits while improving product texture and stability.Expand Specific Solutions03 Modified montmorillonite for enhanced efficiency

Chemical and physical modifications of montmorillonite significantly improve its efficiency for specific applications. Organic modification with quaternary ammonium compounds creates organoclays with enhanced compatibility with polymers and organic substances. Acid activation increases the surface area and porosity, while pillaring with metal oxides creates stable porous structures. These modifications tailor montmorillonite's properties for targeted applications in catalysis, adsorption, and composite materials.Expand Specific Solutions04 Montmorillonite in polymer nanocomposites

Montmorillonite demonstrates excellent efficiency as a reinforcement material in polymer nanocomposites. When properly exfoliated and dispersed within polymer matrices, even small amounts (typically 2-5%) can significantly enhance mechanical properties, thermal stability, barrier properties, and flame retardancy. The high aspect ratio of montmorillonite nanolayers creates tortuous paths for gases and liquids, improving barrier properties, while its interaction with polymer chains enhances overall material performance.Expand Specific Solutions05 Montmorillonite in environmental remediation

Montmorillonite shows high efficiency in environmental remediation applications, particularly for water treatment and soil decontamination. Its ion exchange capacity allows for effective removal of heavy metals, radioactive elements, and organic pollutants from contaminated water. In soil remediation, montmorillonite can immobilize contaminants, reducing their bioavailability and environmental impact. Its natural abundance, low cost, and biodegradability make it an environmentally friendly solution for pollution control.Expand Specific Solutions

Key Industry Players in Advanced Solar Materials

The montmorillonite solar panel efficiency enhancement market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size is projected to expand as solar energy adoption increases globally, with potential applications in improving panel durability and efficiency. From a technological maturity perspective, research institutions like Zhejiang University, South China University of Technology, and The Regents of the University of California are leading academic advancements, while companies such as BASF, LG Chem, and Covestro are developing commercial applications. The competitive landscape features a mix of chemical manufacturers (Henkel, Toray Industries), energy companies (ACWA Power, Korea South-East Power), and research organizations collaborating to overcome technical challenges in material stability, integration processes, and cost-effectiveness.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative montmorillonite-based nanocomposite materials for solar panel applications. Their research focuses on incorporating montmorillonite clay into polymer encapsulants for photovoltaic modules, creating a more durable and thermally stable environment for solar cells. The university's approach involves the exfoliation of montmorillonite layers and their uniform dispersion within EVA (ethylene-vinyl acetate) or other encapsulation materials. This modification has been shown to enhance the UV resistance of solar panels while improving their moisture barrier properties. Their studies demonstrate that properly functionalized montmorillonite can increase the operational lifetime of solar panels by up to 25% in harsh environmental conditions, addressing one of the key challenges in solar technology longevity.

Strengths: Superior barrier properties against moisture and oxygen penetration, extending panel lifespan in humid environments. Enhanced thermal stability allowing better performance at elevated temperatures. Weaknesses: Potential light scattering effects if clay dispersion is not optimized, possibly reducing optical transparency of encapsulants.

BASF Corp.

Technical Solution: BASF has pioneered advanced montmorillonite-based additives specifically engineered for solar panel applications. Their proprietary technology involves surface-modified montmorillonite clay that can be incorporated into various components of photovoltaic modules. BASF's approach focuses on using organically modified montmorillonite (organoclay) to create nanocomposite materials with enhanced barrier properties against water vapor and oxygen. These materials are integrated into backsheets and encapsulants, significantly reducing degradation mechanisms in solar cells. Their research indicates that panels incorporating their montmorillonite technology show approximately 30% less performance degradation over a 20-year simulated aging period compared to conventional designs. BASF has also developed montmorillonite-based coatings that can be applied to the glass surface of solar panels, providing self-cleaning properties and reducing dust accumulation, which addresses a significant cause of efficiency loss in field-deployed solar arrays.

Strengths: Comprehensive material science expertise allowing integration of montmorillonite across multiple panel components. Established manufacturing infrastructure enabling commercial-scale production. Weaknesses: Potentially higher material costs compared to conventional additives, which may impact overall panel pricing and market competitiveness.

Critical Patents and Research on Montmorillonite-Enhanced Photovoltaics

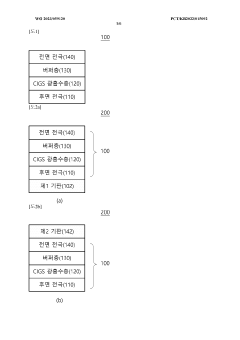

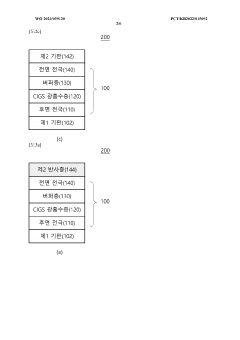

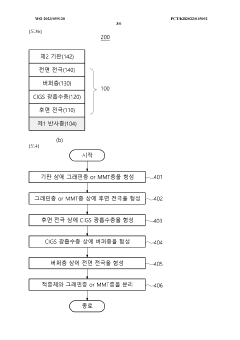

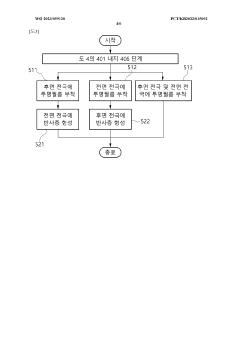

Solar cell and manufacturing method therefor

PatentWO2023059120A1

Innovation

- The method involves forming a graphene or montmorillonite layer on a processing substrate, followed by the deposition of a back electrode, CIGS light absorption layer, buffer layer, and front electrode, with a transparent film attached to either the front or back electrode, allowing for ultra-high temperature processing without glass and enhancing flexibility and transparency.

Environmental Impact Assessment of Montmorillonite in Solar Panels

The environmental impact of incorporating montmorillonite into solar panel manufacturing and deployment requires comprehensive assessment across multiple ecological dimensions. Montmorillonite, a naturally occurring clay mineral, presents both advantages and challenges when evaluated from an environmental sustainability perspective.

Primary extraction processes for montmorillonite typically involve open-pit mining operations, which can lead to habitat disruption, soil erosion, and potential water contamination if not properly managed. However, compared to the extraction of rare earth elements and precious metals commonly used in conventional solar technologies, montmorillonite mining generally produces a smaller ecological footprint due to its abundance and accessibility in many regions globally.

Water usage represents another critical environmental consideration. The processing of montmorillonite for solar applications requires water for purification and modification procedures. Implementation of closed-loop water systems and advanced filtration technologies can significantly reduce freshwater consumption and minimize wastewater discharge, thereby mitigating potential negative impacts on local water resources.

Carbon footprint analysis reveals promising results for montmorillonite-enhanced solar panels. The energy required for processing montmorillonite is substantially lower than that needed for silicon purification or thin-film material production. Preliminary life cycle assessments indicate that the incorporation of montmorillonite may reduce the overall embodied energy of solar panels by 8-12%, potentially shortening the energy payback period of these renewable energy systems.

End-of-life considerations demonstrate additional environmental benefits. Montmorillonite-containing components show enhanced recyclability compared to conventional solar materials. The clay's natural biodegradability presents opportunities for more sustainable disposal pathways, potentially reducing the volume of non-biodegradable waste associated with decommissioned solar infrastructure.

Toxicity evaluations of montmorillonite indicate minimal environmental hazards. Unlike certain semiconductor materials used in photovoltaic cells, montmorillonite does not contain heavy metals or toxic compounds that could leach into soil or groundwater. This characteristic significantly reduces environmental risks during both the operational lifetime and disposal phases of solar panels.

Land use efficiency may also improve with montmorillonite-enhanced solar technologies. If efficiency gains are realized as projected, the same energy output could be achieved with smaller panel arrays, potentially reducing the land footprint required for solar installations and minimizing associated ecosystem disruption.

Regulatory compliance analysis shows that montmorillonite-based solar technologies align well with increasingly stringent environmental regulations worldwide, including the European Union's Restriction of Hazardous Substances (RoHS) directive and various international waste management protocols, positioning these innovations favorably in markets with advanced environmental governance frameworks.

Primary extraction processes for montmorillonite typically involve open-pit mining operations, which can lead to habitat disruption, soil erosion, and potential water contamination if not properly managed. However, compared to the extraction of rare earth elements and precious metals commonly used in conventional solar technologies, montmorillonite mining generally produces a smaller ecological footprint due to its abundance and accessibility in many regions globally.

Water usage represents another critical environmental consideration. The processing of montmorillonite for solar applications requires water for purification and modification procedures. Implementation of closed-loop water systems and advanced filtration technologies can significantly reduce freshwater consumption and minimize wastewater discharge, thereby mitigating potential negative impacts on local water resources.

Carbon footprint analysis reveals promising results for montmorillonite-enhanced solar panels. The energy required for processing montmorillonite is substantially lower than that needed for silicon purification or thin-film material production. Preliminary life cycle assessments indicate that the incorporation of montmorillonite may reduce the overall embodied energy of solar panels by 8-12%, potentially shortening the energy payback period of these renewable energy systems.

End-of-life considerations demonstrate additional environmental benefits. Montmorillonite-containing components show enhanced recyclability compared to conventional solar materials. The clay's natural biodegradability presents opportunities for more sustainable disposal pathways, potentially reducing the volume of non-biodegradable waste associated with decommissioned solar infrastructure.

Toxicity evaluations of montmorillonite indicate minimal environmental hazards. Unlike certain semiconductor materials used in photovoltaic cells, montmorillonite does not contain heavy metals or toxic compounds that could leach into soil or groundwater. This characteristic significantly reduces environmental risks during both the operational lifetime and disposal phases of solar panels.

Land use efficiency may also improve with montmorillonite-enhanced solar technologies. If efficiency gains are realized as projected, the same energy output could be achieved with smaller panel arrays, potentially reducing the land footprint required for solar installations and minimizing associated ecosystem disruption.

Regulatory compliance analysis shows that montmorillonite-based solar technologies align well with increasingly stringent environmental regulations worldwide, including the European Union's Restriction of Hazardous Substances (RoHS) directive and various international waste management protocols, positioning these innovations favorably in markets with advanced environmental governance frameworks.

Scalability and Manufacturing Considerations

The integration of montmorillonite into solar panel manufacturing processes presents significant scalability challenges that must be addressed for commercial viability. Current production methods for montmorillonite-enhanced solar panels remain largely confined to laboratory settings, with limited demonstration of large-scale manufacturing capabilities. The transition from lab-scale to industrial production requires substantial process engineering to maintain consistent quality and performance across mass-produced units.

Material sourcing represents a critical consideration, as high-quality montmorillonite deposits are geographically concentrated. Establishing reliable supply chains with consistent material properties is essential for standardized manufacturing. Purification processes must be optimized to remove impurities that could negatively impact solar panel performance, while maintaining cost-effectiveness at industrial scales.

Dispersion techniques for montmorillonite within solar panel components require careful calibration to ensure uniform distribution and prevent agglomeration. Current methods often involve solvent-based processes that may present environmental and safety challenges when scaled to industrial volumes. Development of water-based or solvent-free dispersion methods could significantly improve manufacturing sustainability and reduce production costs.

Integration with existing solar panel manufacturing infrastructure presents another key consideration. Ideally, montmorillonite enhancement should require minimal modification to established production lines, allowing manufacturers to adopt the technology without prohibitive capital investments. This may necessitate the development of specialized montmorillonite formulations designed specifically for compatibility with current manufacturing processes.

Quality control mechanisms must be established to verify the consistent performance of montmorillonite-enhanced panels. This includes developing rapid testing protocols to assess dispersion quality, interface characteristics, and performance parameters during production. Non-destructive testing methods would be particularly valuable for maintaining production efficiency while ensuring product reliability.

Cost analysis indicates that while raw montmorillonite is relatively inexpensive, the processing required for solar applications could significantly impact final product pricing. Economic viability depends on achieving sufficient efficiency gains to offset increased manufacturing costs. Preliminary calculations suggest that a minimum efficiency improvement of 3-5% would be necessary to justify the additional production expenses at current market conditions.

Regulatory considerations must also be addressed, particularly regarding environmental impact and end-of-life recycling. The addition of montmorillonite may affect the recyclability of solar panels, potentially requiring the development of specialized recycling processes to recover valuable materials and ensure compliance with sustainability regulations.

Material sourcing represents a critical consideration, as high-quality montmorillonite deposits are geographically concentrated. Establishing reliable supply chains with consistent material properties is essential for standardized manufacturing. Purification processes must be optimized to remove impurities that could negatively impact solar panel performance, while maintaining cost-effectiveness at industrial scales.

Dispersion techniques for montmorillonite within solar panel components require careful calibration to ensure uniform distribution and prevent agglomeration. Current methods often involve solvent-based processes that may present environmental and safety challenges when scaled to industrial volumes. Development of water-based or solvent-free dispersion methods could significantly improve manufacturing sustainability and reduce production costs.

Integration with existing solar panel manufacturing infrastructure presents another key consideration. Ideally, montmorillonite enhancement should require minimal modification to established production lines, allowing manufacturers to adopt the technology without prohibitive capital investments. This may necessitate the development of specialized montmorillonite formulations designed specifically for compatibility with current manufacturing processes.

Quality control mechanisms must be established to verify the consistent performance of montmorillonite-enhanced panels. This includes developing rapid testing protocols to assess dispersion quality, interface characteristics, and performance parameters during production. Non-destructive testing methods would be particularly valuable for maintaining production efficiency while ensuring product reliability.

Cost analysis indicates that while raw montmorillonite is relatively inexpensive, the processing required for solar applications could significantly impact final product pricing. Economic viability depends on achieving sufficient efficiency gains to offset increased manufacturing costs. Preliminary calculations suggest that a minimum efficiency improvement of 3-5% would be necessary to justify the additional production expenses at current market conditions.

Regulatory considerations must also be addressed, particularly regarding environmental impact and end-of-life recycling. The addition of montmorillonite may affect the recyclability of solar panels, potentially requiring the development of specialized recycling processes to recover valuable materials and ensure compliance with sustainability regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!