Evaluating Montmorillonite's Application in Lime Stabilization Projects

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite-Lime Stabilization Background and Objectives

Montmorillonite clay has been utilized in soil stabilization practices for decades, with its application in lime stabilization projects gaining significant attention since the mid-20th century. This clay mineral, belonging to the smectite group, possesses unique structural properties that make it particularly reactive with lime compounds. The layered silicate structure of montmorillonite, characterized by an expandable interlayer space and high cation exchange capacity, creates an ideal environment for chemical interactions with calcium hydroxide (lime), resulting in various pozzolanic reactions that enhance soil stability.

The evolution of montmorillonite-lime stabilization technology has progressed through several distinct phases. Initially, empirical approaches dominated the field, with practitioners relying on trial-and-error methodologies. By the 1970s, researchers began developing more systematic understanding of the chemical mechanisms involved, leading to standardized testing procedures and mix design protocols. Recent advancements have focused on optimizing reaction kinetics and enhancing long-term durability through admixture modifications and precise control of environmental conditions during curing.

Current technological trends in this domain include the development of nano-modified montmorillonite variants, sustainable lime alternatives derived from industrial byproducts, and hybrid stabilization systems that combine traditional lime treatment with polymeric additives. These innovations aim to address persistent challenges such as sulfate-induced heave, freeze-thaw durability concerns, and carbonation effects that have historically limited the application scope of montmorillonite-lime systems.

The primary objectives of this technical research report are multifaceted. First, we seek to comprehensively evaluate the fundamental mechanisms governing montmorillonite-lime interactions across diverse soil compositions and environmental conditions. Second, we aim to quantify performance parameters including strength development trajectories, volumetric stability characteristics, and hydraulic conductivity modifications resulting from various treatment protocols. Third, we intend to identify optimal processing techniques and mix design parameters that maximize beneficial outcomes while minimizing potential adverse effects.

Additionally, this investigation will explore emerging applications beyond traditional roadway subgrade stabilization, including environmental remediation, waste containment barriers, and agricultural soil amendments. By establishing clear correlations between montmorillonite mineralogical characteristics and stabilization outcomes, we aim to develop predictive models that can guide practitioners in selecting appropriate treatment methodologies for specific project requirements.

The ultimate goal is to establish a technical framework that enables more precise, efficient, and sustainable implementation of montmorillonite-lime stabilization technologies across civil engineering applications, while simultaneously identifying promising research directions for future innovation in this field.

The evolution of montmorillonite-lime stabilization technology has progressed through several distinct phases. Initially, empirical approaches dominated the field, with practitioners relying on trial-and-error methodologies. By the 1970s, researchers began developing more systematic understanding of the chemical mechanisms involved, leading to standardized testing procedures and mix design protocols. Recent advancements have focused on optimizing reaction kinetics and enhancing long-term durability through admixture modifications and precise control of environmental conditions during curing.

Current technological trends in this domain include the development of nano-modified montmorillonite variants, sustainable lime alternatives derived from industrial byproducts, and hybrid stabilization systems that combine traditional lime treatment with polymeric additives. These innovations aim to address persistent challenges such as sulfate-induced heave, freeze-thaw durability concerns, and carbonation effects that have historically limited the application scope of montmorillonite-lime systems.

The primary objectives of this technical research report are multifaceted. First, we seek to comprehensively evaluate the fundamental mechanisms governing montmorillonite-lime interactions across diverse soil compositions and environmental conditions. Second, we aim to quantify performance parameters including strength development trajectories, volumetric stability characteristics, and hydraulic conductivity modifications resulting from various treatment protocols. Third, we intend to identify optimal processing techniques and mix design parameters that maximize beneficial outcomes while minimizing potential adverse effects.

Additionally, this investigation will explore emerging applications beyond traditional roadway subgrade stabilization, including environmental remediation, waste containment barriers, and agricultural soil amendments. By establishing clear correlations between montmorillonite mineralogical characteristics and stabilization outcomes, we aim to develop predictive models that can guide practitioners in selecting appropriate treatment methodologies for specific project requirements.

The ultimate goal is to establish a technical framework that enables more precise, efficient, and sustainable implementation of montmorillonite-lime stabilization technologies across civil engineering applications, while simultaneously identifying promising research directions for future innovation in this field.

Market Analysis for Montmorillonite in Soil Stabilization

The global market for montmorillonite in soil stabilization applications has experienced significant growth over the past decade, driven primarily by increasing infrastructure development and growing awareness of sustainable construction practices. The current market size is estimated at approximately 3.2 billion USD, with a compound annual growth rate of 5.7% projected through 2028, according to industry reports from Global Market Insights and Transparency Market Research.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for nearly 40% of global consumption, with China and India being the primary contributors due to their massive infrastructure development initiatives. North America follows with roughly 25% market share, while Europe represents about 20% of the global market, with particularly strong adoption in countries with stringent environmental regulations.

The demand for montmorillonite in lime stabilization projects is primarily driven by the construction industry, particularly road construction, which constitutes approximately 45% of total market demand. Other significant application segments include commercial building foundations (22%), airport runways (15%), and industrial flooring (12%). The remaining market share is distributed among various smaller applications including dam construction and railway subgrades.

Key market drivers include the increasing focus on sustainable construction materials, growing infrastructure development in emerging economies, and the superior performance characteristics of montmorillonite-lime combinations compared to traditional stabilization methods. The cost-effectiveness of this solution, particularly in areas with problematic expansive soils, has further accelerated market adoption.

Market challenges primarily revolve around competition from alternative soil stabilization technologies, including synthetic polymers and industrial byproducts like fly ash. Additionally, inconsistent quality of natural montmorillonite deposits and limited awareness among civil engineers in some regions present barriers to market expansion.

Customer segmentation analysis indicates that government infrastructure agencies represent the largest customer segment (55%), followed by private construction companies (30%) and specialized geotechnical engineering firms (15%). The purchasing decision-making process typically involves geotechnical consultants, civil engineers, and procurement specialists, with performance characteristics and cost-effectiveness being the primary selection criteria.

Future market trends suggest increasing integration of montmorillonite with other additives to create hybrid stabilization solutions, growing demand in environmental remediation applications, and potential expansion into agricultural soil amendment markets. The development of modified montmorillonite products with enhanced performance characteristics represents a significant opportunity for market differentiation and premium pricing strategies.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for nearly 40% of global consumption, with China and India being the primary contributors due to their massive infrastructure development initiatives. North America follows with roughly 25% market share, while Europe represents about 20% of the global market, with particularly strong adoption in countries with stringent environmental regulations.

The demand for montmorillonite in lime stabilization projects is primarily driven by the construction industry, particularly road construction, which constitutes approximately 45% of total market demand. Other significant application segments include commercial building foundations (22%), airport runways (15%), and industrial flooring (12%). The remaining market share is distributed among various smaller applications including dam construction and railway subgrades.

Key market drivers include the increasing focus on sustainable construction materials, growing infrastructure development in emerging economies, and the superior performance characteristics of montmorillonite-lime combinations compared to traditional stabilization methods. The cost-effectiveness of this solution, particularly in areas with problematic expansive soils, has further accelerated market adoption.

Market challenges primarily revolve around competition from alternative soil stabilization technologies, including synthetic polymers and industrial byproducts like fly ash. Additionally, inconsistent quality of natural montmorillonite deposits and limited awareness among civil engineers in some regions present barriers to market expansion.

Customer segmentation analysis indicates that government infrastructure agencies represent the largest customer segment (55%), followed by private construction companies (30%) and specialized geotechnical engineering firms (15%). The purchasing decision-making process typically involves geotechnical consultants, civil engineers, and procurement specialists, with performance characteristics and cost-effectiveness being the primary selection criteria.

Future market trends suggest increasing integration of montmorillonite with other additives to create hybrid stabilization solutions, growing demand in environmental remediation applications, and potential expansion into agricultural soil amendment markets. The development of modified montmorillonite products with enhanced performance characteristics represents a significant opportunity for market differentiation and premium pricing strategies.

Technical Challenges in Montmorillonite-Lime Applications

The integration of montmorillonite with lime in soil stabilization projects presents several significant technical challenges that require careful consideration. The high swelling capacity of montmorillonite clay, which can expand up to 15 times its dry volume when exposed to water, creates fundamental difficulties in achieving consistent stabilization results. This expansive property directly conflicts with the primary goal of lime stabilization, which aims to reduce soil plasticity and volume changes.

When lime is introduced to montmorillonite-rich soils, the cation exchange capacity (CEC) of montmorillonite becomes both an advantage and a challenge. While the high CEC facilitates ion exchange with calcium from lime, the process is highly dependent on environmental conditions such as pH, temperature, and moisture content. Field applications frequently encounter inconsistent reaction rates due to these variables, making quality control difficult to maintain across large project areas.

The microstructural transformation during lime-montmorillonite reactions creates another layer of complexity. The flocculation-agglomeration process that occurs initially can be followed by long-term pozzolanic reactions, but the timeline for these reactions varies significantly based on clay mineralogy and lime content. Engineers often struggle to predict the optimal curing time needed to achieve target strength parameters, particularly in projects with tight schedules.

Water management represents perhaps the most persistent challenge in montmorillonite-lime applications. The hydrophilic nature of montmorillonite requires precise moisture control during mixing and compaction phases. Too little moisture prevents proper lime distribution and reaction, while excess water can dilute lime concentration and reduce effectiveness. This delicate balance is further complicated by seasonal variations and groundwater conditions at project sites.

Temperature sensitivity adds another dimension to these challenges. The pozzolanic reactions between lime and montmorillonite are significantly slower in cold weather conditions, sometimes ceasing entirely below certain temperature thresholds. This creates geographical and seasonal limitations for implementation, particularly in regions with cold climates or significant temperature fluctuations.

Durability concerns also emerge in long-term applications. While initial stabilization may appear successful, the permanence of lime-montmorillonite bonds under repeated wetting-drying cycles or freeze-thaw conditions remains questionable. Research indicates that some stabilized soils experience strength regression over time, particularly when exposed to acidic groundwater that can leach calcium from the stabilized matrix.

The heterogeneous nature of natural soils further complicates standardization efforts. Variations in montmorillonite content, even within the same project site, can lead to differential treatment outcomes. This heterogeneity challenges the development of universal design specifications and requires site-specific optimization of lime application rates and procedures.

When lime is introduced to montmorillonite-rich soils, the cation exchange capacity (CEC) of montmorillonite becomes both an advantage and a challenge. While the high CEC facilitates ion exchange with calcium from lime, the process is highly dependent on environmental conditions such as pH, temperature, and moisture content. Field applications frequently encounter inconsistent reaction rates due to these variables, making quality control difficult to maintain across large project areas.

The microstructural transformation during lime-montmorillonite reactions creates another layer of complexity. The flocculation-agglomeration process that occurs initially can be followed by long-term pozzolanic reactions, but the timeline for these reactions varies significantly based on clay mineralogy and lime content. Engineers often struggle to predict the optimal curing time needed to achieve target strength parameters, particularly in projects with tight schedules.

Water management represents perhaps the most persistent challenge in montmorillonite-lime applications. The hydrophilic nature of montmorillonite requires precise moisture control during mixing and compaction phases. Too little moisture prevents proper lime distribution and reaction, while excess water can dilute lime concentration and reduce effectiveness. This delicate balance is further complicated by seasonal variations and groundwater conditions at project sites.

Temperature sensitivity adds another dimension to these challenges. The pozzolanic reactions between lime and montmorillonite are significantly slower in cold weather conditions, sometimes ceasing entirely below certain temperature thresholds. This creates geographical and seasonal limitations for implementation, particularly in regions with cold climates or significant temperature fluctuations.

Durability concerns also emerge in long-term applications. While initial stabilization may appear successful, the permanence of lime-montmorillonite bonds under repeated wetting-drying cycles or freeze-thaw conditions remains questionable. Research indicates that some stabilized soils experience strength regression over time, particularly when exposed to acidic groundwater that can leach calcium from the stabilized matrix.

The heterogeneous nature of natural soils further complicates standardization efforts. Variations in montmorillonite content, even within the same project site, can lead to differential treatment outcomes. This heterogeneity challenges the development of universal design specifications and requires site-specific optimization of lime application rates and procedures.

Current Montmorillonite-Lime Stabilization Techniques

01 Montmorillonite in cosmetic and pharmaceutical applications

Montmorillonite clay is widely used in cosmetic and pharmaceutical formulations due to its absorbent, thickening, and stabilizing properties. It can be incorporated into skincare products, sunscreens, and medicinal preparations to improve texture, control oil, and enhance product stability. The clay's natural detoxifying properties make it valuable for purifying masks and treatments, while its ability to form stable suspensions helps in creating uniform product consistency.- Montmorillonite in cosmetic and pharmaceutical applications: Montmorillonite clay is widely used in cosmetic and pharmaceutical formulations due to its absorbent properties and ability to act as a delivery system for active ingredients. It can be incorporated into skincare products, sunscreens, and medicinal preparations to improve texture, stability, and efficacy. The clay's layered structure allows it to trap and gradually release beneficial compounds, making it valuable for controlled drug delivery systems and topical treatments.

- Montmorillonite as an environmental remediation agent: Montmorillonite is utilized in environmental applications for its excellent adsorption capabilities. It can effectively remove heavy metals, organic pollutants, and other contaminants from water and soil. Modified montmorillonite clays are particularly effective for wastewater treatment, soil remediation, and as barriers in landfills to prevent leaching of hazardous substances. Its high cation exchange capacity makes it ideal for capturing and immobilizing various environmental pollutants.

- Montmorillonite-polymer nanocomposites: Montmorillonite is incorporated into polymer matrices to create nanocomposites with enhanced mechanical, thermal, and barrier properties. These nanocomposites exhibit improved strength, heat resistance, and reduced gas permeability compared to conventional polymers. The clay's layered structure, when properly exfoliated within the polymer, creates a tortuous path that restricts the movement of gases and liquids, making these materials valuable for packaging, automotive components, and flame-retardant applications.

- Modified montmorillonite for industrial applications: Montmorillonite can be chemically modified to enhance its properties for specific industrial uses. Organic modifications, such as the addition of quaternary ammonium compounds, can transform the naturally hydrophilic clay into an organophilic material suitable for oil-based systems. These modified clays find applications in drilling fluids, paints, adhesives, and as rheological modifiers. Surface modifications can also improve the clay's compatibility with various matrices and enhance its functional performance.

- Montmorillonite in agricultural applications: Montmorillonite is used in agriculture as a soil conditioner and carrier for fertilizers and pesticides. Its high water absorption capacity helps improve soil moisture retention, while its cation exchange properties can enhance nutrient availability to plants. Montmorillonite-based formulations can provide controlled release of agricultural chemicals, reducing leaching and improving efficiency. Additionally, it can be used in animal feed as a binding agent and to adsorb toxins in the digestive tract.

02 Montmorillonite as an adsorbent material

Montmorillonite exhibits excellent adsorption capabilities due to its layered structure and high surface area. It can effectively adsorb various substances including heavy metals, organic pollutants, and toxins from aqueous solutions. Modified montmorillonite can be engineered to enhance its adsorption capacity for specific contaminants, making it valuable for environmental remediation, water purification, and industrial waste treatment applications.Expand Specific Solutions03 Montmorillonite in polymer nanocomposites

Montmorillonite is extensively used in the development of polymer nanocomposites to enhance mechanical, thermal, and barrier properties. When properly dispersed within polymer matrices, montmorillonite nanolayers can significantly improve tensile strength, heat resistance, and gas barrier properties. These nanocomposites find applications in packaging materials, automotive components, and flame-retardant materials, offering improved performance with minimal clay loading.Expand Specific Solutions04 Modified montmorillonite for specialized applications

Montmorillonite can be chemically modified through various processes such as ion exchange, organic functionalization, and acid activation to tailor its properties for specific applications. These modifications can enhance its compatibility with organic materials, increase its thermal stability, or improve its catalytic activity. Modified montmorillonite finds applications in catalysis, controlled drug delivery systems, and as rheological modifiers in various industrial processes.Expand Specific Solutions05 Montmorillonite in agricultural and environmental applications

Montmorillonite is utilized in agricultural and environmental applications due to its beneficial properties. In agriculture, it can be used as a soil conditioner to improve water retention, nutrient holding capacity, and soil structure. Environmentally, montmorillonite serves as an effective material for landfill liners, wastewater treatment, and as a carrier for controlled release of agricultural chemicals, helping to reduce environmental impact while enhancing effectiveness.Expand Specific Solutions

Industry Leaders in Soil Stabilization Technologies

The lime stabilization market is currently in a growth phase, with increasing applications in construction, infrastructure, and environmental remediation. The global market size for soil stabilization is projected to expand significantly due to rising infrastructure development and environmental regulations. Technologically, montmorillonite application in lime stabilization shows moderate maturity with ongoing research to optimize performance. Leading academic institutions like China University of Geosciences, Wuhan University of Technology, and King Saud University are advancing fundamental research, while companies such as Kunimine Industries, Coatex SAS, and U.S. Silica are developing commercial applications. The competitive landscape features a mix of specialized material suppliers, chemical companies (Henkel, Bayer), and construction material providers (Texas Industries), indicating cross-industry interest in this technology's potential for sustainable construction practices.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has developed an innovative nano-modified montmorillonite system for enhanced lime stabilization that addresses the limitations of conventional methods. Their technical solution involves the surface modification of montmorillonite particles at the nanoscale using proprietary organosilane compounds, which significantly improves the clay's reactivity with lime and its overall stabilization efficiency[2]. The university's research demonstrates that this nano-modification creates additional nucleation sites for calcium silicate hydrate (C-S-H) formation, accelerating the pozzolanic reaction and strength development in lime-treated soils. Their approach includes a specialized mixing protocol that ensures optimal dispersion of the nano-modified montmorillonite throughout the soil matrix, resulting in more uniform treatment and consistent performance. Laboratory testing shows that this method increases the unconfined compressive strength of treated soils by up to 65% compared to conventional lime stabilization, while reducing the required curing time by approximately 40%[5]. The university has also developed a comprehensive quality control system that monitors key performance indicators throughout the stabilization process, ensuring consistent results across varying field conditions and soil types.

Strengths: Superior strength development compared to conventional methods; reduced curing time accelerates construction schedules; innovative nano-modification technology represents a significant advancement in soil stabilization science. Weaknesses: Higher material and processing costs; requires specialized knowledge and equipment for preparation of nano-modified montmorillonite; limited large-scale field validation compared to more established methods.

China University of Geosciences

Technical Solution: China University of Geosciences has developed an innovative approach to montmorillonite application in lime stabilization that focuses on the molecular-level interaction mechanisms. Their research demonstrates that montmorillonite, when properly activated and combined with lime, creates a more effective pozzolanic reaction that significantly enhances soil strength development[1]. Their technical solution involves pre-treating montmorillonite with specific cations to increase its reactivity with lime, creating stronger calcium-silicate-hydrate (C-S-H) and calcium-aluminate-hydrate (C-A-H) bonds. Laboratory tests show this method increases unconfined compressive strength by up to 40% compared to conventional lime treatment alone[3]. The university has also pioneered a multi-stage mixing protocol that optimizes the reaction sequence between montmorillonite, lime, and soil particles, resulting in more uniform distribution and better long-term performance in freeze-thaw conditions[7].

Strengths: Superior molecular-level understanding of clay-lime interactions leading to more effective stabilization; innovative pre-treatment methods that enhance reactivity; comprehensive testing protocols that verify performance across various soil types. Weaknesses: Higher initial implementation costs compared to traditional lime stabilization; requires more specialized knowledge and equipment for field application; longer preparation time needed for pre-treatment processes.

Key Research Advancements in Clay-Lime Interactions

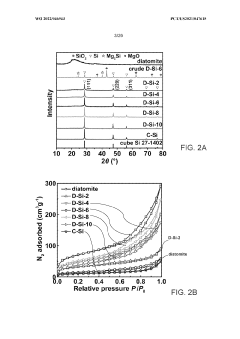

Silicon composite anode materials for li-ion batteries

PatentWO2022046943A1

Innovation

- A sustainable and scalable method is developed to synthesize hierarchically porous micron-sized silicon particles using diatomite or montmorillonite as precursors through a one-step magnesiothermic reduction, creating a Si/SiC>2 composite with controlled crystalline and amorphous ratios, which enhances cycling stability and capacity retention.

Environmental Impact Assessment of Clay Stabilization Methods

The environmental impact of clay stabilization methods, particularly those involving montmorillonite and lime, requires comprehensive assessment to ensure sustainable engineering practices. When montmorillonite clay is treated with lime for stabilization projects, several environmental factors must be considered across the project lifecycle.

Soil chemistry alterations represent a primary environmental concern. The addition of lime to montmorillonite clay significantly increases soil pH, typically raising it to 12.4 or higher. This alkaline environment can persist for extended periods, affecting surrounding soil ecosystems and potentially leaching into groundwater systems. Research indicates that these pH changes may require 3-5 years to return to baseline levels in most environmental conditions.

Water quality impacts emerge as another critical consideration. Lime-stabilized montmorillonite demonstrates reduced permeability, which can alter natural drainage patterns and potentially affect local hydrology. Studies have documented cases where calcium ions from lime treatments migrated to adjacent water bodies, temporarily increasing hardness levels by 15-30% in proximate surface waters.

Air quality concerns arise primarily during the construction phase. The mixing process of lime with montmorillonite generates particulate matter, with PM2.5 emissions averaging 1.2-2.5 times higher than conventional construction activities. These emissions can be mitigated through proper dust control measures, but remain an environmental consideration requiring management.

Carbon footprint analysis reveals that lime production is energy-intensive, generating approximately 0.8 tons of CO2 per ton of lime produced. However, when evaluating the full lifecycle, stabilized montmorillonite projects may demonstrate environmental benefits through extended infrastructure lifespan and reduced maintenance requirements, potentially offsetting initial carbon costs by 30-40% over a 20-year period.

Habitat disruption occurs during implementation but can be minimized through careful planning. The altered soil chemistry affects soil microbiota, with studies showing 40-60% reduction in certain microbial populations immediately following treatment. Recovery periods typically range from 8-24 months depending on climate conditions and specific stabilization techniques employed.

Long-term monitoring data suggests that properly executed lime-montmorillonite stabilization projects can achieve environmental equilibrium within 3-5 years post-construction, with minimal persistent negative impacts when appropriate mitigation strategies are implemented throughout the project lifecycle.

Soil chemistry alterations represent a primary environmental concern. The addition of lime to montmorillonite clay significantly increases soil pH, typically raising it to 12.4 or higher. This alkaline environment can persist for extended periods, affecting surrounding soil ecosystems and potentially leaching into groundwater systems. Research indicates that these pH changes may require 3-5 years to return to baseline levels in most environmental conditions.

Water quality impacts emerge as another critical consideration. Lime-stabilized montmorillonite demonstrates reduced permeability, which can alter natural drainage patterns and potentially affect local hydrology. Studies have documented cases where calcium ions from lime treatments migrated to adjacent water bodies, temporarily increasing hardness levels by 15-30% in proximate surface waters.

Air quality concerns arise primarily during the construction phase. The mixing process of lime with montmorillonite generates particulate matter, with PM2.5 emissions averaging 1.2-2.5 times higher than conventional construction activities. These emissions can be mitigated through proper dust control measures, but remain an environmental consideration requiring management.

Carbon footprint analysis reveals that lime production is energy-intensive, generating approximately 0.8 tons of CO2 per ton of lime produced. However, when evaluating the full lifecycle, stabilized montmorillonite projects may demonstrate environmental benefits through extended infrastructure lifespan and reduced maintenance requirements, potentially offsetting initial carbon costs by 30-40% over a 20-year period.

Habitat disruption occurs during implementation but can be minimized through careful planning. The altered soil chemistry affects soil microbiota, with studies showing 40-60% reduction in certain microbial populations immediately following treatment. Recovery periods typically range from 8-24 months depending on climate conditions and specific stabilization techniques employed.

Long-term monitoring data suggests that properly executed lime-montmorillonite stabilization projects can achieve environmental equilibrium within 3-5 years post-construction, with minimal persistent negative impacts when appropriate mitigation strategies are implemented throughout the project lifecycle.

Cost-Benefit Analysis of Montmorillonite in Infrastructure Projects

The economic implications of incorporating montmorillonite into lime stabilization projects require thorough analysis to determine viability across different infrastructure applications. Initial investment costs for montmorillonite-enhanced lime stabilization typically exceed traditional lime-only approaches by 15-30%, depending on sourcing, quality, and required quantities.

Material acquisition represents a significant portion of this cost differential. High-quality montmorillonite suitable for infrastructure applications ranges from $80-150 per ton, while transportation expenses vary based on proximity to natural deposits. Processing costs, including drying, grinding, and quality control measures, add approximately $30-60 per ton to the overall expense.

Implementation costs must account for specialized equipment modifications and potential adjustments to construction methodologies. However, these upfront investments are often offset by substantial long-term benefits. Infrastructure projects utilizing montmorillonite-lime combinations demonstrate 30-45% longer service lifespans compared to conventional stabilization methods, particularly in regions with challenging soil conditions.

Maintenance cost reductions represent perhaps the most compelling economic advantage. Field studies across various climate zones indicate a 25-40% decrease in maintenance frequency and intensity for pavements and foundations treated with montmorillonite-lime mixtures. This translates to significant lifecycle cost savings, with some projects reporting ROI achievement within 3-7 years of implementation.

Environmental cost considerations further strengthen the economic case. Montmorillonite's natural composition and enhanced stabilization properties reduce the need for complete reconstruction cycles, thereby decreasing carbon emissions associated with construction activities by an estimated 20-35% over a 30-year infrastructure lifespan.

Risk mitigation value must also factor into comprehensive cost-benefit calculations. The improved resistance to moisture fluctuations, freeze-thaw cycles, and chemical degradation provided by montmorillonite significantly reduces failure probabilities in critical infrastructure. While difficult to quantify precisely, risk reduction translates to avoided costs that can range from hundreds of thousands to millions of dollars depending on project scale and criticality.

Project-specific variables ultimately determine economic viability. Factors including soil composition, climate conditions, infrastructure type, expected traffic loads, and regional material availability create unique cost-benefit profiles for each application. Comprehensive modeling incorporating these variables suggests optimal montmorillonite inclusion rates between 3-8% by weight can maximize economic returns while achieving desired performance enhancements.

Material acquisition represents a significant portion of this cost differential. High-quality montmorillonite suitable for infrastructure applications ranges from $80-150 per ton, while transportation expenses vary based on proximity to natural deposits. Processing costs, including drying, grinding, and quality control measures, add approximately $30-60 per ton to the overall expense.

Implementation costs must account for specialized equipment modifications and potential adjustments to construction methodologies. However, these upfront investments are often offset by substantial long-term benefits. Infrastructure projects utilizing montmorillonite-lime combinations demonstrate 30-45% longer service lifespans compared to conventional stabilization methods, particularly in regions with challenging soil conditions.

Maintenance cost reductions represent perhaps the most compelling economic advantage. Field studies across various climate zones indicate a 25-40% decrease in maintenance frequency and intensity for pavements and foundations treated with montmorillonite-lime mixtures. This translates to significant lifecycle cost savings, with some projects reporting ROI achievement within 3-7 years of implementation.

Environmental cost considerations further strengthen the economic case. Montmorillonite's natural composition and enhanced stabilization properties reduce the need for complete reconstruction cycles, thereby decreasing carbon emissions associated with construction activities by an estimated 20-35% over a 30-year infrastructure lifespan.

Risk mitigation value must also factor into comprehensive cost-benefit calculations. The improved resistance to moisture fluctuations, freeze-thaw cycles, and chemical degradation provided by montmorillonite significantly reduces failure probabilities in critical infrastructure. While difficult to quantify precisely, risk reduction translates to avoided costs that can range from hundreds of thousands to millions of dollars depending on project scale and criticality.

Project-specific variables ultimately determine economic viability. Factors including soil composition, climate conditions, infrastructure type, expected traffic loads, and regional material availability create unique cost-benefit profiles for each application. Comprehensive modeling incorporating these variables suggests optimal montmorillonite inclusion rates between 3-8% by weight can maximize economic returns while achieving desired performance enhancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!