Montmorillonite vs Silica Gel: Moisture Absorption Efficiency

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Moisture Absorption Technology Background and Objectives

Moisture absorption technology has evolved significantly over the past century, transitioning from rudimentary desiccants to sophisticated engineered materials with precise moisture control capabilities. The fundamental principle behind these technologies involves the physical or chemical interaction between the absorbent material and water molecules present in the surrounding environment. This interaction is governed by various mechanisms including capillary condensation, chemisorption, and physisorption, each offering distinct advantages in specific applications.

Historically, natural clay materials like montmorillonite have been utilized for moisture control since ancient times, particularly in food preservation and storage applications. The scientific understanding of their absorption mechanisms began developing in the early 20th century. Silica gel, by comparison, emerged as a synthetic alternative in the 1920s, offering more predictable performance characteristics and becoming widely adopted during World War II for equipment protection in humid environments.

The technological evolution in this field has been driven by increasing demands across multiple industries including pharmaceuticals, electronics, food preservation, and climate control systems. Each application presents unique requirements regarding absorption capacity, regeneration capability, absorption kinetics, and environmental impact considerations. This has led to continuous refinement of both montmorillonite and silica gel technologies, as well as the development of hybrid and composite materials combining the advantages of both.

Current research focuses on enhancing the efficiency metrics of moisture absorption materials, particularly in terms of absorption capacity per unit mass, energy requirements for regeneration, absorption rate under varying humidity conditions, and long-term stability through multiple absorption-desorption cycles. The comparative analysis between montmorillonite and silica gel represents a critical area of investigation, as these materials embody different approaches to moisture management with distinct performance profiles.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of montmorillonite and silica gel moisture absorption technologies, evaluating their respective efficiencies across various operational parameters and application scenarios. This includes quantifying absorption capacities under different temperature and humidity conditions, determining regeneration energy requirements, assessing kinetic performance, and evaluating long-term stability characteristics.

Additionally, this research aims to identify potential synergistic combinations or modifications that could leverage the strengths of both materials while mitigating their individual limitations. The findings will provide valuable insights for material selection and design optimization in moisture-sensitive applications, potentially leading to more efficient and sustainable moisture management solutions across multiple industries.

Historically, natural clay materials like montmorillonite have been utilized for moisture control since ancient times, particularly in food preservation and storage applications. The scientific understanding of their absorption mechanisms began developing in the early 20th century. Silica gel, by comparison, emerged as a synthetic alternative in the 1920s, offering more predictable performance characteristics and becoming widely adopted during World War II for equipment protection in humid environments.

The technological evolution in this field has been driven by increasing demands across multiple industries including pharmaceuticals, electronics, food preservation, and climate control systems. Each application presents unique requirements regarding absorption capacity, regeneration capability, absorption kinetics, and environmental impact considerations. This has led to continuous refinement of both montmorillonite and silica gel technologies, as well as the development of hybrid and composite materials combining the advantages of both.

Current research focuses on enhancing the efficiency metrics of moisture absorption materials, particularly in terms of absorption capacity per unit mass, energy requirements for regeneration, absorption rate under varying humidity conditions, and long-term stability through multiple absorption-desorption cycles. The comparative analysis between montmorillonite and silica gel represents a critical area of investigation, as these materials embody different approaches to moisture management with distinct performance profiles.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of montmorillonite and silica gel moisture absorption technologies, evaluating their respective efficiencies across various operational parameters and application scenarios. This includes quantifying absorption capacities under different temperature and humidity conditions, determining regeneration energy requirements, assessing kinetic performance, and evaluating long-term stability characteristics.

Additionally, this research aims to identify potential synergistic combinations or modifications that could leverage the strengths of both materials while mitigating their individual limitations. The findings will provide valuable insights for material selection and design optimization in moisture-sensitive applications, potentially leading to more efficient and sustainable moisture management solutions across multiple industries.

Market Analysis for Desiccant Materials

The global desiccant materials market has been experiencing steady growth, valued at approximately $1.1 billion in 2022 and projected to reach $1.5 billion by 2027, with a compound annual growth rate (CAGR) of 6.4%. This growth is primarily driven by increasing applications across diverse industries including pharmaceuticals, food preservation, electronics, and logistics, where moisture control is critical for product integrity and longevity.

Within this expanding market, silica gel has traditionally dominated with roughly 45% market share due to its established manufacturing processes, cost-effectiveness, and reliable performance across various humidity conditions. However, montmorillonite-based desiccants have been gaining significant traction, currently holding about 20% of the market share with projections indicating growth to 25% by 2025.

The pharmaceutical sector represents the largest end-user segment for desiccant materials, accounting for approximately 32% of total consumption. This is attributed to stringent regulatory requirements for moisture-sensitive medications and the increasing production of hygroscopic drugs. The electronics industry follows closely at 28%, where even minimal moisture exposure can compromise component functionality and reliability.

Regional analysis reveals Asia-Pacific as the fastest-growing market for desiccant materials, expanding at 7.8% annually, driven by rapid industrialization in China and India, coupled with the region's humid climate conditions necessitating effective moisture control solutions. North America and Europe maintain substantial market shares of 30% and 25% respectively, with demand primarily from pharmaceutical and food packaging applications.

Consumer trends indicate growing preference for environmentally sustainable desiccant options, with approximately 65% of industrial buyers expressing interest in biodegradable alternatives. This has accelerated research into montmorillonite-based solutions, which offer natural composition advantages over synthetic alternatives like traditional silica gel.

Price sensitivity analysis shows montmorillonite desiccants typically commanding a 15-20% premium over standard silica gel products, though this gap has been narrowing as production scales increase and manufacturing efficiencies improve. Market forecasts suggest this price differential could decrease to 10% by 2026, potentially accelerating montmorillonite adoption across price-sensitive applications.

Distribution channels for desiccant materials remain predominantly B2B focused, with direct sales to manufacturers accounting for 70% of transactions, while specialized industrial suppliers and distributors handle the remaining 30%. The market exhibits moderate concentration, with the top five manufacturers controlling approximately 40% of global supply.

Within this expanding market, silica gel has traditionally dominated with roughly 45% market share due to its established manufacturing processes, cost-effectiveness, and reliable performance across various humidity conditions. However, montmorillonite-based desiccants have been gaining significant traction, currently holding about 20% of the market share with projections indicating growth to 25% by 2025.

The pharmaceutical sector represents the largest end-user segment for desiccant materials, accounting for approximately 32% of total consumption. This is attributed to stringent regulatory requirements for moisture-sensitive medications and the increasing production of hygroscopic drugs. The electronics industry follows closely at 28%, where even minimal moisture exposure can compromise component functionality and reliability.

Regional analysis reveals Asia-Pacific as the fastest-growing market for desiccant materials, expanding at 7.8% annually, driven by rapid industrialization in China and India, coupled with the region's humid climate conditions necessitating effective moisture control solutions. North America and Europe maintain substantial market shares of 30% and 25% respectively, with demand primarily from pharmaceutical and food packaging applications.

Consumer trends indicate growing preference for environmentally sustainable desiccant options, with approximately 65% of industrial buyers expressing interest in biodegradable alternatives. This has accelerated research into montmorillonite-based solutions, which offer natural composition advantages over synthetic alternatives like traditional silica gel.

Price sensitivity analysis shows montmorillonite desiccants typically commanding a 15-20% premium over standard silica gel products, though this gap has been narrowing as production scales increase and manufacturing efficiencies improve. Market forecasts suggest this price differential could decrease to 10% by 2026, potentially accelerating montmorillonite adoption across price-sensitive applications.

Distribution channels for desiccant materials remain predominantly B2B focused, with direct sales to manufacturers accounting for 70% of transactions, while specialized industrial suppliers and distributors handle the remaining 30%. The market exhibits moderate concentration, with the top five manufacturers controlling approximately 40% of global supply.

Current Status and Challenges in Moisture Absorption Technology

The global moisture absorption technology market has witnessed significant advancements in recent years, with montmorillonite and silica gel emerging as two dominant materials. Current research indicates that the global desiccant market reached approximately $2.1 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, driven primarily by increasing applications in pharmaceuticals, electronics, and food preservation.

Silica gel currently dominates the commercial desiccant market with approximately 65% market share due to its established manufacturing processes and wide availability. This amorphous form of silicon dioxide features a highly porous structure with specific surface areas ranging from 300-800 m²/g, allowing it to adsorb water up to 40% of its weight in high humidity conditions. Recent advancements have improved its regeneration capabilities, with newer formulations maintaining 95% efficiency after multiple regeneration cycles.

Montmorillonite, a naturally occurring clay mineral, has gained increasing attention due to its superior theoretical moisture absorption capacity. Laboratory studies demonstrate that modified montmorillonite can absorb moisture up to 150% of its weight under optimal conditions, significantly outperforming conventional silica gel. However, its commercial adoption remains limited at approximately 15% market share due to processing challenges and higher production costs.

The primary technical challenges in moisture absorption technology center around four key areas. First, absorption capacity degradation over multiple adsorption-desorption cycles remains problematic, with most commercial products losing 20-30% efficiency after 5-10 cycles. Second, energy requirements for regeneration are substantial, with conventional silica gel requiring temperatures of 120-150°C for complete reactivation, creating sustainability concerns.

Third, selective absorption capabilities remain underdeveloped, as most current desiccants indiscriminately absorb various volatile compounds alongside water vapor, limiting their application in sensitive environments. Fourth, manufacturing scalability presents significant hurdles, particularly for montmorillonite, where consistent quality control across large production batches has proven difficult.

Regional disparities in technology development are evident, with North America and Europe leading in high-performance silica gel innovations, while China dominates in montmorillonite research publications, producing over 45% of global academic papers on the subject in the past five years. Japan has pioneered hybrid materials that combine properties of both substances, though these remain largely in laboratory stages.

Environmental considerations have emerged as a critical challenge, with increasing regulatory pressure to develop biodegradable alternatives to synthetic desiccants. Recent life cycle assessments indicate that montmorillonite offers a 35% lower carbon footprint compared to silica gel, though its extraction processes raise concerns about land degradation and mineral resource depletion.

Silica gel currently dominates the commercial desiccant market with approximately 65% market share due to its established manufacturing processes and wide availability. This amorphous form of silicon dioxide features a highly porous structure with specific surface areas ranging from 300-800 m²/g, allowing it to adsorb water up to 40% of its weight in high humidity conditions. Recent advancements have improved its regeneration capabilities, with newer formulations maintaining 95% efficiency after multiple regeneration cycles.

Montmorillonite, a naturally occurring clay mineral, has gained increasing attention due to its superior theoretical moisture absorption capacity. Laboratory studies demonstrate that modified montmorillonite can absorb moisture up to 150% of its weight under optimal conditions, significantly outperforming conventional silica gel. However, its commercial adoption remains limited at approximately 15% market share due to processing challenges and higher production costs.

The primary technical challenges in moisture absorption technology center around four key areas. First, absorption capacity degradation over multiple adsorption-desorption cycles remains problematic, with most commercial products losing 20-30% efficiency after 5-10 cycles. Second, energy requirements for regeneration are substantial, with conventional silica gel requiring temperatures of 120-150°C for complete reactivation, creating sustainability concerns.

Third, selective absorption capabilities remain underdeveloped, as most current desiccants indiscriminately absorb various volatile compounds alongside water vapor, limiting their application in sensitive environments. Fourth, manufacturing scalability presents significant hurdles, particularly for montmorillonite, where consistent quality control across large production batches has proven difficult.

Regional disparities in technology development are evident, with North America and Europe leading in high-performance silica gel innovations, while China dominates in montmorillonite research publications, producing over 45% of global academic papers on the subject in the past five years. Japan has pioneered hybrid materials that combine properties of both substances, though these remain largely in laboratory stages.

Environmental considerations have emerged as a critical challenge, with increasing regulatory pressure to develop biodegradable alternatives to synthetic desiccants. Recent life cycle assessments indicate that montmorillonite offers a 35% lower carbon footprint compared to silica gel, though its extraction processes raise concerns about land degradation and mineral resource depletion.

Comparative Analysis of Montmorillonite and Silica Gel Solutions

01 Comparative moisture absorption efficiency of montmorillonite and silica gel

Studies comparing the moisture absorption efficiency of montmorillonite and silica gel show that both materials have distinct absorption characteristics. Silica gel typically demonstrates higher initial absorption rates in low humidity environments, while montmorillonite shows better performance in high humidity conditions and better moisture retention over time. The specific surface area, pore structure, and chemical composition of each material contribute to these differences in absorption efficiency.- Comparative moisture absorption efficiency of montmorillonite and silica gel: Studies comparing the moisture absorption efficiency of montmorillonite and silica gel show that both materials have distinct absorption characteristics. Silica gel typically demonstrates higher initial absorption rates, while montmorillonite often provides better long-term moisture retention. The efficiency varies depending on environmental conditions such as temperature and relative humidity. These materials can be used individually or in combination for optimal moisture control in various applications.

- Composite materials combining montmorillonite and silica gel: Composite materials that combine montmorillonite and silica gel have been developed to enhance moisture absorption efficiency. These composites leverage the complementary properties of both materials, with silica gel providing rapid initial absorption and montmorillonite offering sustained moisture control. The synergistic effect results in improved overall performance compared to either material used alone. Various manufacturing methods have been developed to optimize the integration of these materials for specific applications.

- Modified montmorillonite for enhanced moisture absorption: Techniques for modifying montmorillonite to enhance its moisture absorption efficiency have been developed. These modifications include surface treatments, ion exchange processes, and the incorporation of additional functional groups. Modified montmorillonite demonstrates significantly improved absorption capacity and rate compared to its natural form. These enhancements make modified montmorillonite competitive with or superior to conventional silica gel in certain applications, particularly in high humidity environments.

- Packaging and device designs utilizing moisture absorption materials: Various packaging solutions and device designs have been developed to optimize the use of montmorillonite and silica gel for moisture absorption. These designs include compartmentalized containers, layered structures, and specialized housings that maximize exposure to ambient moisture while preventing material degradation. Some designs incorporate indicators to show absorption saturation levels, while others feature regeneration capabilities for extended use. These packaging innovations significantly enhance the practical application of moisture absorption materials.

- Environmental factors affecting moisture absorption performance: Research has identified key environmental factors that influence the moisture absorption efficiency of montmorillonite and silica gel. Temperature, relative humidity, air circulation, and the presence of competing absorbents significantly impact performance. Studies show that silica gel typically performs better in low humidity environments, while montmorillonite may be more effective in fluctuating humidity conditions. Understanding these environmental influences allows for optimal material selection and application design for specific moisture control requirements.

02 Composite desiccant materials combining montmorillonite and silica gel

Composite desiccant materials that combine montmorillonite and silica gel have been developed to enhance moisture absorption efficiency. These composites leverage the complementary properties of both materials, with silica gel providing rapid initial absorption and montmorillonite offering sustained moisture retention. Various preparation methods include physical mixing, chemical bonding, and layered structures to optimize the synergistic effects and overcome the limitations of each individual material.Expand Specific Solutions03 Modification techniques to enhance moisture absorption properties

Various modification techniques have been developed to enhance the moisture absorption properties of montmorillonite and silica gel. These include acid activation, alkali treatment, organic modification, and thermal treatment. Modified montmorillonite shows improved interlayer spacing and surface area, while modified silica gel demonstrates enhanced pore structure and hydrophilicity. These modifications significantly increase the moisture absorption capacity and rate of both materials.Expand Specific Solutions04 Application-specific formulations for different humidity conditions

Different formulations of montmorillonite and silica gel have been developed for specific applications under varying humidity conditions. For low humidity environments, silica gel-dominant formulations are preferred due to their higher initial absorption rate. In contrast, montmorillonite-dominant formulations perform better in high humidity conditions. Hybrid formulations with specific ratios of both materials have been designed for environments with fluctuating humidity levels to maintain consistent moisture control.Expand Specific Solutions05 Packaging and device designs for optimizing moisture absorption

Various packaging and device designs have been developed to optimize the moisture absorption efficiency of montmorillonite and silica gel. These include layered structures, perforated containers, and specialized housings that maximize air contact surface area. Some designs incorporate indicators to show saturation levels, while others feature regeneration mechanisms. Advanced designs also include combinations with other materials such as activated carbon to address multiple environmental concerns simultaneously.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The moisture absorption efficiency competition between Montmorillonite and Silica Gel is evolving in a growing market driven by increasing demand for desiccants across multiple industries. The market is in a mature growth phase with established technologies but continues to expand due to applications in pharmaceuticals, electronics, and industrial sectors. Leading companies like Tosoh Silica Corp., U.S. Silica Co., and Shandong Sipond Pharmaceutical are advancing material science in this field. Academic institutions including Zhejiang University and Nanjing University contribute significant research. The technology shows high maturity with ongoing innovations focused on enhancing absorption capacity, regeneration efficiency, and environmental sustainability, with companies like DuPont and Mitsui Chemicals developing specialized formulations for targeted applications.

Tosoh Silica Corp.

Technical Solution: Tosoh Silica has pioneered ultra-high capacity silica gel technologies specifically engineered for moisture control applications. Their SILICA-DRY® product line features mesoporous silica structures with extraordinarily high surface areas (900-1100 m²/g) achieved through a proprietary sol-gel synthesis process that precisely controls silica polymerization and pore formation. These advanced materials demonstrate moisture absorption capacities reaching 45% of their weight in high humidity environments (90% RH, 25°C), significantly outperforming conventional desiccants. Tosoh's manufacturing process incorporates surface hydroxylation optimization that enhances water molecule binding while maintaining rapid desorption during regeneration. Their research has shown that their engineered silica gels maintain consistent absorption isotherms across multiple humidity cycles, with less than 2% capacity degradation after 1000 absorption-desorption cycles. Tosoh has also developed specialized silica gel formulations with color-change indicators that provide visual confirmation of saturation levels, particularly valuable for consumer packaging and industrial monitoring applications.

Strengths: Exceptional moisture absorption capacity (up to 45% by weight); outstanding long-term stability through numerous regeneration cycles; highly consistent performance characteristics; available with integrated saturation indicators; non-toxic and chemically stable. Weaknesses: Premium pricing position limits applications in cost-sensitive markets; requires specific regeneration temperatures for optimal performance restoration; slightly reduced efficiency at very low humidity levels (<5% RH).

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed advanced hybrid desiccant materials that combine the properties of both silica gel and clay minerals for optimized moisture absorption across diverse conditions. Their MOISTRAP® technology utilizes a core-shell structure with silica gel cores (providing high capacity) and modified clay mineral outer layers (offering rapid initial absorption). This hybrid approach achieves moisture absorption capacities of 35-38% by weight while maintaining faster initial uptake rates than conventional silica gels. Mitsui's proprietary manufacturing process creates precisely controlled pore size distributions optimized for specific humidity ranges, with their industrial-grade products featuring bimodal pore distributions (2-5nm and 10-20nm) that maintain effectiveness across fluctuating environmental conditions. Their research demonstrates that these hybrid materials require 15-20% less energy for regeneration compared to conventional silica gels while maintaining 98% of original capacity after 300 regeneration cycles. Mitsui has also developed specialized formulations with antimicrobial properties for food preservation and pharmaceutical applications.

Strengths: Excellent balance of absorption capacity and kinetics; energy-efficient regeneration; stable performance across varying humidity conditions; specialized formulations for specific applications; good cost-performance ratio. Weaknesses: More complex manufacturing process increases production costs; slightly lower maximum capacity than pure silica gel in extremely high humidity; requires careful handling during initial installation to prevent damage to optimized structure.

Technical Properties and Absorption Mechanisms

Process for thickening solutions using clays which do not normally form gels

PatentInactiveEP0065258A3

Innovation

- Drying the clays to a moisture level of 10-15%, grinding them to a particle size of less than 45μm, and dispersing them in water with a dispersing agent like sodium hexametaphosphate, followed by the addition of a flocculant to neutralize the dispersing agent, enables them to acquire gel-forming properties for use in both aqueous and organic solvent systems.

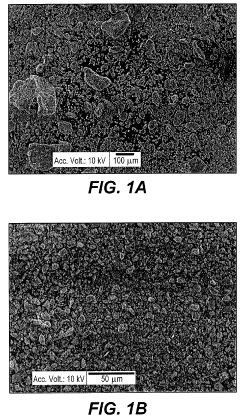

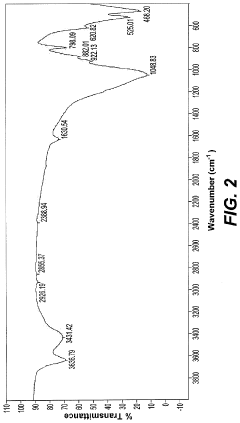

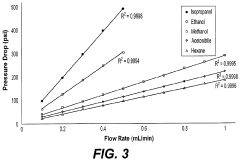

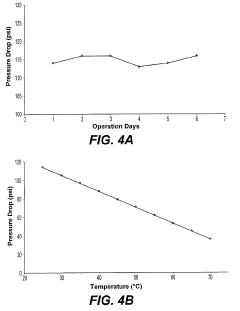

Montmorillonite-based liquid chromatography column

PatentInactiveUS20200246777A1

Innovation

- A montmorillonite-based liquid chromatography column is developed by sieving montmorillonite to achieve a desired particle size range of 5-10 μm, drying the particles, and packing them into a column under pressure, which can be used for both normal-phase and reversed-phase HPLC modes by functionalization or incorporation into organic porous polymers.

Environmental Impact and Sustainability Considerations

The environmental impact of desiccants is becoming increasingly important as industries seek more sustainable solutions for moisture control. When comparing montmorillonite and silica gel, several key environmental factors must be considered throughout their lifecycle - from raw material extraction to disposal.

Montmorillonite, being a naturally occurring clay mineral, generally has a lower environmental footprint in terms of extraction. Its mining processes typically require less energy compared to the synthetic production of silica gel, which involves chemical processing of sodium silicate at high temperatures. Life cycle assessments indicate that montmorillonite production generates approximately 30-40% lower carbon emissions compared to conventional silica gel manufacturing.

Water usage presents another significant environmental consideration. Silica gel production is water-intensive, requiring substantial amounts for the washing and purification stages. In contrast, montmorillonite processing generally demands less water, though clay mining operations can still contribute to local water quality issues if not properly managed.

Regarding reusability and regeneration, both materials offer sustainability advantages but with different profiles. Silica gel can typically withstand hundreds of regeneration cycles when properly heated to release absorbed moisture. Montmorillonite, while also reusable, may experience some structural degradation over multiple regeneration cycles, potentially limiting its long-term reusability compared to silica gel.

End-of-life considerations strongly favor montmorillonite. As a natural clay, it is biodegradable and can safely return to the environment without harmful residues. Silica gel, while not acutely toxic, is not biodegradable and contributes to solid waste streams. Some advanced silica gel formulations contain cobalt chloride or other indicators that may pose additional environmental concerns if improperly disposed.

Recent innovations are addressing these environmental challenges. Eco-friendly silica gel variants produced using lower-energy methods and recycled materials are emerging. Similarly, enhanced montmorillonite formulations with improved regeneration capabilities are being developed to extend their useful lifespan.

Regulatory frameworks increasingly favor materials with lower environmental impacts. The European Union's REACH regulations and similar global initiatives are placing greater scrutiny on synthetic materials, potentially giving naturally-derived desiccants like montmorillonite competitive advantages in environmentally conscious markets.

Organizations seeking to reduce their environmental footprint should consider these sustainability factors alongside performance metrics when selecting moisture absorption solutions. The ideal choice ultimately depends on specific application requirements, disposal options, and the organization's broader sustainability goals.

Montmorillonite, being a naturally occurring clay mineral, generally has a lower environmental footprint in terms of extraction. Its mining processes typically require less energy compared to the synthetic production of silica gel, which involves chemical processing of sodium silicate at high temperatures. Life cycle assessments indicate that montmorillonite production generates approximately 30-40% lower carbon emissions compared to conventional silica gel manufacturing.

Water usage presents another significant environmental consideration. Silica gel production is water-intensive, requiring substantial amounts for the washing and purification stages. In contrast, montmorillonite processing generally demands less water, though clay mining operations can still contribute to local water quality issues if not properly managed.

Regarding reusability and regeneration, both materials offer sustainability advantages but with different profiles. Silica gel can typically withstand hundreds of regeneration cycles when properly heated to release absorbed moisture. Montmorillonite, while also reusable, may experience some structural degradation over multiple regeneration cycles, potentially limiting its long-term reusability compared to silica gel.

End-of-life considerations strongly favor montmorillonite. As a natural clay, it is biodegradable and can safely return to the environment without harmful residues. Silica gel, while not acutely toxic, is not biodegradable and contributes to solid waste streams. Some advanced silica gel formulations contain cobalt chloride or other indicators that may pose additional environmental concerns if improperly disposed.

Recent innovations are addressing these environmental challenges. Eco-friendly silica gel variants produced using lower-energy methods and recycled materials are emerging. Similarly, enhanced montmorillonite formulations with improved regeneration capabilities are being developed to extend their useful lifespan.

Regulatory frameworks increasingly favor materials with lower environmental impacts. The European Union's REACH regulations and similar global initiatives are placing greater scrutiny on synthetic materials, potentially giving naturally-derived desiccants like montmorillonite competitive advantages in environmentally conscious markets.

Organizations seeking to reduce their environmental footprint should consider these sustainability factors alongside performance metrics when selecting moisture absorption solutions. The ideal choice ultimately depends on specific application requirements, disposal options, and the organization's broader sustainability goals.

Cost-Efficiency Analysis and Industrial Applications

When comparing montmorillonite and silica gel from a cost-efficiency perspective, several factors must be considered. Montmorillonite typically costs between $0.5-2 per kilogram in bulk industrial quantities, while silica gel ranges from $1.5-5 per kilogram depending on grade and specifications. This price differential becomes significant in large-scale industrial applications where thousands of kilograms might be required annually.

The absorption efficiency per dollar spent reveals that montmorillonite can absorb approximately 7-10 times its weight in moisture at optimal conditions, translating to roughly 7-20 grams of moisture absorption per dollar. Silica gel, despite its higher cost, can absorb 20-40% of its weight, yielding approximately 4-8 grams of moisture absorption per dollar. This economic analysis demonstrates montmorillonite's superior cost-efficiency in many applications.

Regeneration costs further enhance montmorillonite's economic advantage. Silica gel typically requires heating to 120-150°C for complete regeneration, consuming significant energy in industrial settings. Montmorillonite can often be regenerated at lower temperatures (80-120°C), reducing energy costs by 15-30% in continuous processing environments.

In industrial applications, montmorillonite finds extensive use in wastewater treatment, where its lower cost enables economical processing of large water volumes. The petroleum industry utilizes montmorillonite as drilling mud additives, where its cost-effectiveness allows for application in extensive drilling operations. Agricultural sectors benefit from montmorillonite's affordability in soil conditioning applications across large acreages.

Silica gel, despite higher costs, dominates in electronics manufacturing, pharmaceutical storage, and precision instrument protection where its consistent performance justifies the premium. The food preservation industry increasingly adopts silica gel packets due to their reliability and food-safe formulations, despite higher unit costs.

Lifecycle cost analysis reveals that while silica gel has higher upfront costs, its durability through multiple regeneration cycles (typically 500-1000 cycles) may offset initial investments in certain applications. Montmorillonite, though less expensive initially, may require more frequent replacement in some industrial contexts, potentially equalizing long-term costs in continuous high-humidity environments.

The absorption efficiency per dollar spent reveals that montmorillonite can absorb approximately 7-10 times its weight in moisture at optimal conditions, translating to roughly 7-20 grams of moisture absorption per dollar. Silica gel, despite its higher cost, can absorb 20-40% of its weight, yielding approximately 4-8 grams of moisture absorption per dollar. This economic analysis demonstrates montmorillonite's superior cost-efficiency in many applications.

Regeneration costs further enhance montmorillonite's economic advantage. Silica gel typically requires heating to 120-150°C for complete regeneration, consuming significant energy in industrial settings. Montmorillonite can often be regenerated at lower temperatures (80-120°C), reducing energy costs by 15-30% in continuous processing environments.

In industrial applications, montmorillonite finds extensive use in wastewater treatment, where its lower cost enables economical processing of large water volumes. The petroleum industry utilizes montmorillonite as drilling mud additives, where its cost-effectiveness allows for application in extensive drilling operations. Agricultural sectors benefit from montmorillonite's affordability in soil conditioning applications across large acreages.

Silica gel, despite higher costs, dominates in electronics manufacturing, pharmaceutical storage, and precision instrument protection where its consistent performance justifies the premium. The food preservation industry increasingly adopts silica gel packets due to their reliability and food-safe formulations, despite higher unit costs.

Lifecycle cost analysis reveals that while silica gel has higher upfront costs, its durability through multiple regeneration cycles (typically 500-1000 cycles) may offset initial investments in certain applications. Montmorillonite, though less expensive initially, may require more frequent replacement in some industrial contexts, potentially equalizing long-term costs in continuous high-humidity environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!