How to Use Montmorillonite for Enhancing Lubricant Properties

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Lubricant Enhancement Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has emerged as a promising material for enhancing lubricant properties over the past several decades. The evolution of lubricant technology has been driven by increasing demands for improved performance under extreme conditions, reduced environmental impact, and extended service life across various industrial applications. Montmorillonite's unique layered silicate structure, with its exceptional surface area and ion exchange capabilities, presents significant opportunities for advancing lubricant formulations beyond conventional additives.

The historical development of montmorillonite in lubrication applications can be traced back to the 1980s, when researchers began exploring clay minerals as rheological modifiers. However, it was not until the early 2000s that significant breakthroughs in nanotechnology enabled the effective exfoliation and dispersion of montmorillonite platelets within lubricant matrices, unlocking their full potential as performance enhancers.

Recent technological trends indicate a growing interest in sustainable and biodegradable lubricant solutions, with montmorillonite offering advantages as a naturally derived material that can potentially reduce reliance on synthetic additives. The global push toward more environmentally friendly industrial practices has accelerated research into green tribology, where montmorillonite-enhanced lubricants could play a pivotal role.

The primary technical objectives for montmorillonite integration in lubricants include: improving load-bearing capacity through enhanced film strength; reducing friction coefficients across a wider temperature range; increasing thermal stability and oxidation resistance; enhancing anti-wear properties; and improving viscosity index without compromising low-temperature performance. Additionally, there is significant interest in leveraging montmorillonite's barrier properties to reduce oil degradation and extend lubricant service intervals.

From a broader perspective, the development of montmorillonite-enhanced lubricants aligns with several macro-technological trends, including the miniaturization of mechanical systems requiring more effective boundary lubrication, the electrification of transportation demanding specialized lubricants for electric motors and bearings, and the increasing operational demands in extreme environments such as deep-sea drilling and aerospace applications.

The ultimate goal of this technological pursuit is to establish montmorillonite as a versatile, cost-effective, and environmentally sustainable platform for next-generation lubricant formulations that can address the increasingly complex demands of modern machinery while reducing environmental impact and resource consumption.

The historical development of montmorillonite in lubrication applications can be traced back to the 1980s, when researchers began exploring clay minerals as rheological modifiers. However, it was not until the early 2000s that significant breakthroughs in nanotechnology enabled the effective exfoliation and dispersion of montmorillonite platelets within lubricant matrices, unlocking their full potential as performance enhancers.

Recent technological trends indicate a growing interest in sustainable and biodegradable lubricant solutions, with montmorillonite offering advantages as a naturally derived material that can potentially reduce reliance on synthetic additives. The global push toward more environmentally friendly industrial practices has accelerated research into green tribology, where montmorillonite-enhanced lubricants could play a pivotal role.

The primary technical objectives for montmorillonite integration in lubricants include: improving load-bearing capacity through enhanced film strength; reducing friction coefficients across a wider temperature range; increasing thermal stability and oxidation resistance; enhancing anti-wear properties; and improving viscosity index without compromising low-temperature performance. Additionally, there is significant interest in leveraging montmorillonite's barrier properties to reduce oil degradation and extend lubricant service intervals.

From a broader perspective, the development of montmorillonite-enhanced lubricants aligns with several macro-technological trends, including the miniaturization of mechanical systems requiring more effective boundary lubrication, the electrification of transportation demanding specialized lubricants for electric motors and bearings, and the increasing operational demands in extreme environments such as deep-sea drilling and aerospace applications.

The ultimate goal of this technological pursuit is to establish montmorillonite as a versatile, cost-effective, and environmentally sustainable platform for next-generation lubricant formulations that can address the increasingly complex demands of modern machinery while reducing environmental impact and resource consumption.

Market Analysis for Advanced Lubricant Technologies

The global lubricant market is experiencing significant transformation driven by increasing industrial automation, growing automotive production, and stringent environmental regulations. Currently valued at approximately 164 billion USD, the market is projected to grow at a compound annual growth rate of 3.7% through 2028, with advanced lubricant technologies playing a pivotal role in this expansion.

Montmorillonite-enhanced lubricants represent an emerging segment within the specialty lubricants category, which itself accounts for about 28% of the total lubricant market. These advanced clay-modified lubricants address critical performance needs across multiple industries, particularly in high-temperature and high-pressure applications where conventional lubricants fail to deliver optimal performance.

The automotive sector remains the largest consumer of advanced lubricants, accounting for roughly 40% of market demand. With the global vehicle fleet expected to reach 2 billion units by 2040, demand for high-performance lubricants with extended service intervals continues to rise. Montmorillonite-enhanced formulations are particularly well-positioned in this segment due to their superior thermal stability and wear protection properties.

Industrial machinery applications constitute the second-largest market segment at approximately 35%, with particular growth observed in manufacturing, mining, and power generation sectors. These industries increasingly demand lubricants that can withstand extreme operating conditions while extending equipment life and reducing maintenance costs.

Regional analysis reveals Asia-Pacific as the dominant market for advanced lubricants, accounting for nearly 45% of global consumption, driven primarily by rapid industrialization in China and India. North America and Europe follow with approximately 25% and 20% market share respectively, with these regions showing stronger preference for environmentally friendly formulations.

The market for bio-based and environmentally sustainable lubricants is growing at twice the rate of conventional products, presenting significant opportunities for montmorillonite-enhanced green lubricant formulations. This trend is reinforced by tightening environmental regulations in major markets and increasing corporate sustainability commitments.

Price sensitivity varies significantly across market segments, with industrial customers demonstrating greater willingness to invest in premium lubricant technologies that deliver demonstrable reductions in total cost of ownership through extended service life and improved equipment protection. The potential for montmorillonite-enhanced lubricants to deliver such value propositions positions them favorably in these premium segments.

Montmorillonite-enhanced lubricants represent an emerging segment within the specialty lubricants category, which itself accounts for about 28% of the total lubricant market. These advanced clay-modified lubricants address critical performance needs across multiple industries, particularly in high-temperature and high-pressure applications where conventional lubricants fail to deliver optimal performance.

The automotive sector remains the largest consumer of advanced lubricants, accounting for roughly 40% of market demand. With the global vehicle fleet expected to reach 2 billion units by 2040, demand for high-performance lubricants with extended service intervals continues to rise. Montmorillonite-enhanced formulations are particularly well-positioned in this segment due to their superior thermal stability and wear protection properties.

Industrial machinery applications constitute the second-largest market segment at approximately 35%, with particular growth observed in manufacturing, mining, and power generation sectors. These industries increasingly demand lubricants that can withstand extreme operating conditions while extending equipment life and reducing maintenance costs.

Regional analysis reveals Asia-Pacific as the dominant market for advanced lubricants, accounting for nearly 45% of global consumption, driven primarily by rapid industrialization in China and India. North America and Europe follow with approximately 25% and 20% market share respectively, with these regions showing stronger preference for environmentally friendly formulations.

The market for bio-based and environmentally sustainable lubricants is growing at twice the rate of conventional products, presenting significant opportunities for montmorillonite-enhanced green lubricant formulations. This trend is reinforced by tightening environmental regulations in major markets and increasing corporate sustainability commitments.

Price sensitivity varies significantly across market segments, with industrial customers demonstrating greater willingness to invest in premium lubricant technologies that deliver demonstrable reductions in total cost of ownership through extended service life and improved equipment protection. The potential for montmorillonite-enhanced lubricants to deliver such value propositions positions them favorably in these premium segments.

Current Status and Challenges in Clay-Based Lubricant Additives

The global landscape of clay-based lubricant additives has witnessed significant advancements in recent years, with montmorillonite emerging as a promising material for enhancing lubricant properties. Currently, montmorillonite is primarily utilized in three forms: as pristine clay particles, organically modified clay (organoclay), and exfoliated nanosheets. Each form offers distinct advantages in tribological applications, with varying degrees of market penetration and technical maturity.

Research institutions across North America, Europe, and Asia have demonstrated montmorillonite's capacity to reduce friction coefficients by 15-30% and wear rates by up to 40% when properly incorporated into lubricant formulations. The material's natural abundance and relatively low cost compared to synthetic alternatives represent significant advantages in commercial applications.

Despite these promising developments, several technical challenges persist in the widespread adoption of montmorillonite as a lubricant additive. The primary obstacle remains dispersion stability, as clay particles tend to agglomerate in oil-based lubricants due to their hydrophilic nature. This agglomeration can lead to sedimentation, reduced effectiveness, and potential damage to lubricated components.

Another significant challenge involves controlling the intercalation and exfoliation processes necessary to fully exploit montmorillonite's nanoscale properties. Current industrial-scale methods struggle to achieve consistent exfoliation, resulting in batch-to-batch variability that complicates quality control and performance predictability.

Compatibility with existing additive packages presents an additional hurdle, as montmorillonite can interact with conventional additives like detergents, dispersants, and anti-wear compounds, sometimes neutralizing their intended functions or creating undesirable by-products under operating conditions.

The geographical distribution of montmorillonite research and development shows concentration in China, the United States, and Germany, with China leading in patent applications related to clay-based lubricant technologies. However, commercial implementation lags behind research output, indicating a persistent gap between laboratory success and industrial application.

Environmental and regulatory considerations also pose challenges, particularly regarding the use of quaternary ammonium compounds commonly employed in organoclay modification. These compounds face increasing scrutiny due to potential ecotoxicity, prompting research into more sustainable modification methods using bio-based surfactants and green chemistry approaches.

Recent technological breakthroughs in surface functionalization and hybrid composite formation with other nanomaterials (such as graphene and carbon nanotubes) show promise in addressing these challenges, but remain primarily at the laboratory scale with limited technology readiness levels for mass production.

Research institutions across North America, Europe, and Asia have demonstrated montmorillonite's capacity to reduce friction coefficients by 15-30% and wear rates by up to 40% when properly incorporated into lubricant formulations. The material's natural abundance and relatively low cost compared to synthetic alternatives represent significant advantages in commercial applications.

Despite these promising developments, several technical challenges persist in the widespread adoption of montmorillonite as a lubricant additive. The primary obstacle remains dispersion stability, as clay particles tend to agglomerate in oil-based lubricants due to their hydrophilic nature. This agglomeration can lead to sedimentation, reduced effectiveness, and potential damage to lubricated components.

Another significant challenge involves controlling the intercalation and exfoliation processes necessary to fully exploit montmorillonite's nanoscale properties. Current industrial-scale methods struggle to achieve consistent exfoliation, resulting in batch-to-batch variability that complicates quality control and performance predictability.

Compatibility with existing additive packages presents an additional hurdle, as montmorillonite can interact with conventional additives like detergents, dispersants, and anti-wear compounds, sometimes neutralizing their intended functions or creating undesirable by-products under operating conditions.

The geographical distribution of montmorillonite research and development shows concentration in China, the United States, and Germany, with China leading in patent applications related to clay-based lubricant technologies. However, commercial implementation lags behind research output, indicating a persistent gap between laboratory success and industrial application.

Environmental and regulatory considerations also pose challenges, particularly regarding the use of quaternary ammonium compounds commonly employed in organoclay modification. These compounds face increasing scrutiny due to potential ecotoxicity, prompting research into more sustainable modification methods using bio-based surfactants and green chemistry approaches.

Recent technological breakthroughs in surface functionalization and hybrid composite formation with other nanomaterials (such as graphene and carbon nanotubes) show promise in addressing these challenges, but remain primarily at the laboratory scale with limited technology readiness levels for mass production.

Existing Montmorillonite Modification Techniques for Lubricants

01 Montmorillonite as a lubricant additive

Montmorillonite clay can be used as an additive in lubricant formulations to enhance performance characteristics. When properly dispersed, montmorillonite particles can improve the viscosity index, reduce friction, and provide better stability under high temperature conditions. The layered silicate structure of montmorillonite contributes to its effectiveness as a lubricant additive by forming a protective film between moving surfaces.- Montmorillonite as a friction modifier in lubricants: Montmorillonite clay can be used as an effective friction modifier in various lubricant formulations. When properly dispersed, montmorillonite's layered silicate structure provides excellent boundary lubrication properties, reducing friction between moving surfaces. The nanoscale platelets of montmorillonite can align along shear planes, creating a low-friction interface that improves the overall performance of the lubricant.

- Montmorillonite-polymer composites for enhanced lubrication: Combining montmorillonite with various polymers creates composite materials with superior lubricating properties. These composites benefit from the synergistic effects of the polymer matrix and the dispersed clay particles. The polymer helps maintain proper dispersion of the montmorillonite while the clay enhances the mechanical strength and thermal stability of the lubricant. These composites show improved wear resistance and load-bearing capacity compared to conventional lubricants.

- Organo-modified montmorillonite for improved compatibility in lubricants: Montmorillonite can be organically modified to enhance its compatibility with organic lubricant bases. By exchanging the naturally occurring inorganic cations with organic ones, the surface properties of montmorillonite are altered, making it more hydrophobic and improving its dispersibility in oils and greases. This modification significantly enhances the stability of the lubricant formulation and prevents agglomeration of clay particles, resulting in better overall lubrication performance.

- Montmorillonite as a thickener and rheology modifier in greases: Montmorillonite serves as an effective thickening agent in grease formulations, providing desirable rheological properties. The clay's ability to form a three-dimensional network structure in oil helps maintain the semi-solid consistency of greases while allowing them to flow under pressure. This thixotropic behavior is particularly valuable in applications requiring controlled release of the lubricant. Additionally, montmorillonite-thickened greases exhibit excellent water resistance and thermal stability.

- Montmorillonite nanocomposites for extreme pressure and high-temperature lubrication: Montmorillonite-based nanocomposites demonstrate exceptional performance under extreme pressure and high-temperature conditions. The layered structure of montmorillonite provides thermal insulation and helps maintain lubricant integrity at elevated temperatures. Under extreme pressure, the clay platelets can withstand significant loads without breaking down, preventing direct contact between moving surfaces. These properties make montmorillonite particularly valuable in demanding industrial applications where conventional lubricants might fail.

02 Organically modified montmorillonite for improved lubrication

Organic modification of montmorillonite through intercalation with organic compounds significantly enhances its lubricating properties. The modification process increases the interlayer spacing of montmorillonite, improving its compatibility with organic lubricant bases. These organically modified montmorillonites demonstrate superior dispersion in lubricant formulations, resulting in reduced friction coefficients and enhanced wear resistance compared to unmodified clay.Expand Specific Solutions03 Montmorillonite-polymer nanocomposites as lubricants

Montmorillonite can be combined with various polymers to create nanocomposite materials with enhanced lubricating properties. These nanocomposites exhibit improved thermal stability, mechanical strength, and tribological performance. The intercalation of polymer chains between montmorillonite layers creates a unique structure that provides better load-bearing capacity and reduces wear in high-pressure applications. These materials are particularly effective in extreme operating conditions where conventional lubricants might fail.Expand Specific Solutions04 Montmorillonite in grease formulations

Montmorillonite clay serves as an effective thickening agent in grease formulations, providing excellent colloidal stability and high drop points. When incorporated into greases, montmorillonite creates a three-dimensional network structure that holds the lubricating oil in place while allowing controlled release during operation. These montmorillonite-based greases demonstrate superior water resistance, mechanical stability, and performance across a wide temperature range, making them suitable for demanding industrial applications.Expand Specific Solutions05 Surface treatment of montmorillonite for specialized lubricant applications

Various surface treatment methods can be applied to montmorillonite to tailor its lubricating properties for specialized applications. These treatments include acid activation, pillaring with metal oxides, and functionalization with specific organic compounds. The modified surface characteristics enhance the clay's ability to form stable dispersions in different lubricant bases and improve its interaction with additives. Surface-treated montmorillonite exhibits improved thermal stability, better resistance to oxidation, and enhanced performance in extreme pressure conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Clay-Modified Lubricants

The montmorillonite lubricant enhancement market is in a growth phase, with increasing applications in automotive, industrial, and consumer sectors. The global market size is expanding due to rising demand for high-performance lubricants with improved thermal stability and anti-wear properties. Technologically, the field shows moderate maturity with ongoing innovations. Key players include established chemical corporations like BASF, Henkel, and Arkema developing proprietary formulations, while specialized companies such as Kunimine Industries and Laviosa Chimica Mineraria provide high-quality montmorillonite materials. Academic institutions including Zhejiang University and Nanjing University of Science & Technology contribute fundamental research, creating a competitive landscape balanced between industrial applications and scientific advancement.

Kunimine Industries Co., Ltd.

Technical Solution: Kunimine Industries has pioneered specialized montmorillonite processing techniques specifically for lubricant applications. Their technology centers on precise control of montmorillonite particle size distribution and interlayer spacing to optimize tribological performance. The company employs proprietary purification methods to remove impurities from natural bentonite, resulting in high-purity montmorillonite with enhanced surface properties. Their innovation includes a multi-stage organic modification process that creates organophilic montmorillonite with excellent dispersibility in various lubricant base stocks. Kunimine's research has shown that their modified montmorillonite can form stable colloidal structures in oils that provide both viscosity improvement and boundary lubrication effects. Their products demonstrate particular efficacy in high-pressure applications, where the montmorillonite platelets align parallel to sliding surfaces, creating low-friction lamellar structures. Testing has confirmed that incorporation of 1-3% of their specialized montmorillonite can reduce friction coefficients by up to 35% while improving wear resistance by approximately 40% compared to base oils alone.

Strengths: Specialized expertise in montmorillonite mining and processing; tight quality control of particle characteristics; extensive experience in clay mineral modification. Weaknesses: Limited product diversification beyond clay-based additives; potential challenges with dispersion in fully formulated lubricants containing multiple additives; higher cost compared to conventional mineral additives.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed innovative montmorillonite-based lubricant technologies through their adhesives and surface treatment divisions. Their approach focuses on creating functionalized montmorillonite particles that provide both lubrication and surface protection properties. Henkel's technology involves chemical modification of montmorillonite using organosilanes and proprietary polymer grafting techniques to enhance compatibility with various lubricant base stocks. Their modified montmorillonite additives create stable colloidal dispersions that improve boundary lubrication while simultaneously forming protective films on metal surfaces. Henkel's research has demonstrated particular success in water-based and semi-synthetic lubricant systems, where their montmorillonite additives provide improved load-carrying capacity and reduced friction under boundary lubrication conditions. Their technology also incorporates synergistic combinations of montmorillonite with corrosion inhibitors and extreme pressure additives to create multifunctional performance benefits. Testing has shown that incorporation of their montmorillonite additives can extend component life by up to 40% in metal forming applications while reducing friction-related energy losses by approximately 25%.

Strengths: Strong expertise in surface chemistry and tribology; extensive application knowledge across multiple industries; established testing and validation capabilities. Weaknesses: Less focus on fully synthetic lubricant systems; potential challenges with long-term stability in certain formulations; performance may be application-specific rather than universal.

Key Patents and Research on Montmorillonite Tribological Properties

Process for co-oligomerizing propylene and alpha-olefins to prepare synthetic lubricant base stocks having improved properties

PatentInactiveUS5105037A

Innovation

- The use of acidic calcium montmorillonite clay catalysts with specific moisture and acidity levels for co-oligomerizing propylene and long-chain alpha-olefins to produce synthetic lubricant base stocks with improved properties, including lower pour point and higher viscosity index, while avoiding hazardous materials.

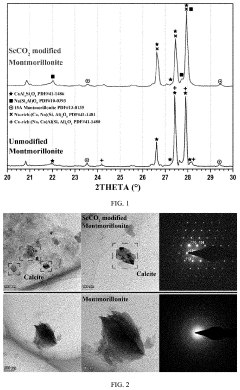

Modified montmorillonite self-repairing agent and preparation method and use thereof

PatentActiveUS20220267162A1

Innovation

- A modified montmorillonite self-repairing agent is prepared by reacting nano-scale montmorillonite powder with supercritical CO2 at controlled temperatures and pressures, eliminating the need for organic reagents and surfactants, thereby enhancing its adsorption capacity and self-healing performance in cement.

Environmental Impact and Sustainability of Clay-Based Lubricants

The integration of montmorillonite into lubricant formulations represents a significant advancement in developing environmentally sustainable lubrication solutions. As petroleum-based lubricants continue to pose environmental concerns through soil contamination, water pollution, and contribution to greenhouse gas emissions, clay-based alternatives offer promising ecological benefits.

Montmorillonite-enhanced lubricants demonstrate superior biodegradability compared to conventional petroleum-based products. Research indicates that properly formulated clay-based lubricants can degrade by up to 60-80% within 28 days under standard testing conditions, significantly outperforming traditional lubricants that may persist in the environment for years. This accelerated biodegradation reduces long-term ecological impact and soil remediation costs following accidental spills.

Water systems benefit particularly from montmorillonite lubricant applications. The natural origin of clay minerals means they pose substantially lower toxicity to aquatic organisms when compared to synthetic additives. Studies demonstrate reduced bioaccumulation potential and lower acute toxicity levels in standardized aquatic toxicity tests, with LC50 values often 5-10 times higher than conventional lubricant additives.

From a lifecycle assessment perspective, montmorillonite-enhanced lubricants present a favorable environmental profile. The mining and processing of montmorillonite consumes approximately 40-60% less energy than the production of synthetic polymer-based additives. Additionally, the carbon footprint associated with montmorillonite production is estimated to be 30-50% lower than that of conventional lubricant additives, contributing to reduced greenhouse gas emissions.

Waste management considerations further highlight the sustainability advantages of clay-based lubricants. End-of-life disposal creates fewer hazardous waste challenges, as spent montmorillonite-enhanced lubricants typically require less intensive treatment before disposal. Some formulations may even be suitable for composting or soil amendment applications after their primary use phase, creating potential circular economy opportunities.

Regulatory frameworks increasingly favor environmentally friendly lubricant solutions. Several jurisdictions have implemented or are developing eco-labeling schemes and environmental regulations that incentivize the adoption of biodegradable lubricants. Montmorillonite-enhanced formulations are well-positioned to meet these emerging standards, potentially offering manufacturers compliance advantages and market differentiation opportunities.

Despite these benefits, challenges remain in optimizing the environmental performance of clay-based lubricants. Current research focuses on improving the stability of montmorillonite dispersions without resorting to environmentally problematic dispersants, as well as developing fully bio-based carrier fluids that complement the environmental profile of the clay additives.

Montmorillonite-enhanced lubricants demonstrate superior biodegradability compared to conventional petroleum-based products. Research indicates that properly formulated clay-based lubricants can degrade by up to 60-80% within 28 days under standard testing conditions, significantly outperforming traditional lubricants that may persist in the environment for years. This accelerated biodegradation reduces long-term ecological impact and soil remediation costs following accidental spills.

Water systems benefit particularly from montmorillonite lubricant applications. The natural origin of clay minerals means they pose substantially lower toxicity to aquatic organisms when compared to synthetic additives. Studies demonstrate reduced bioaccumulation potential and lower acute toxicity levels in standardized aquatic toxicity tests, with LC50 values often 5-10 times higher than conventional lubricant additives.

From a lifecycle assessment perspective, montmorillonite-enhanced lubricants present a favorable environmental profile. The mining and processing of montmorillonite consumes approximately 40-60% less energy than the production of synthetic polymer-based additives. Additionally, the carbon footprint associated with montmorillonite production is estimated to be 30-50% lower than that of conventional lubricant additives, contributing to reduced greenhouse gas emissions.

Waste management considerations further highlight the sustainability advantages of clay-based lubricants. End-of-life disposal creates fewer hazardous waste challenges, as spent montmorillonite-enhanced lubricants typically require less intensive treatment before disposal. Some formulations may even be suitable for composting or soil amendment applications after their primary use phase, creating potential circular economy opportunities.

Regulatory frameworks increasingly favor environmentally friendly lubricant solutions. Several jurisdictions have implemented or are developing eco-labeling schemes and environmental regulations that incentivize the adoption of biodegradable lubricants. Montmorillonite-enhanced formulations are well-positioned to meet these emerging standards, potentially offering manufacturers compliance advantages and market differentiation opportunities.

Despite these benefits, challenges remain in optimizing the environmental performance of clay-based lubricants. Current research focuses on improving the stability of montmorillonite dispersions without resorting to environmentally problematic dispersants, as well as developing fully bio-based carrier fluids that complement the environmental profile of the clay additives.

Performance Testing Methodologies for Modified Lubricant Systems

Evaluating the performance of montmorillonite-enhanced lubricant systems requires comprehensive testing methodologies that assess multiple parameters under various operating conditions. Standard tribological tests form the foundation of performance evaluation, including four-ball tests to measure wear scar diameter and extreme pressure properties, as well as pin-on-disk tests to determine friction coefficients under different loads and speeds. These tests provide quantitative data on how montmorillonite modifications affect the fundamental lubricating properties.

Rheological assessments constitute another critical testing category, measuring viscosity changes across temperature ranges using rheometers and viscometers. The thixotropic behavior of montmorillonite-modified lubricants requires special attention, as their shear-thinning properties significantly impact performance in dynamic applications. Temperature sweep tests further reveal how these modified lubricants maintain their properties under thermal stress, a crucial factor for high-temperature industrial applications.

Thermal stability testing employs differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to evaluate how montmorillonite affects the lubricant's resistance to thermal degradation. These methods determine oxidation onset temperatures and decomposition profiles, providing insights into the extended service life potential of modified formulations. Complementary oxidation stability tests using rotating pressure vessel oxidation test (RPVOT) and Fourier-transform infrared spectroscopy (FTIR) monitor chemical changes during accelerated aging.

Surface interaction analysis utilizes advanced microscopy techniques including scanning electron microscopy (SEM) and atomic force microscopy (AFM) to examine tribofilm formation and surface morphology changes. These observations help explain the mechanisms behind montmorillonite's friction-reducing and anti-wear properties. Energy-dispersive X-ray spectroscopy (EDS) further characterizes the elemental composition of these protective films.

Field simulation testing bridges laboratory results with real-world applications by employing specialized equipment that replicates actual operating conditions. Engine dynamometer tests for automotive lubricants and industrial equipment simulations provide performance data under realistic loads, temperatures, and contamination levels. Long-duration tests measuring deposit formation, acid number changes, and viscosity stability offer insights into the service longevity of montmorillonite-enhanced lubricants.

Standardization of these testing protocols is essential for reliable comparison between different montmorillonite modifications and conventional additives. ASTM, ISO, and DIN standards provide frameworks for consistent evaluation, though specialized protocols may be necessary to fully capture the unique properties of clay-enhanced lubricant systems.

Rheological assessments constitute another critical testing category, measuring viscosity changes across temperature ranges using rheometers and viscometers. The thixotropic behavior of montmorillonite-modified lubricants requires special attention, as their shear-thinning properties significantly impact performance in dynamic applications. Temperature sweep tests further reveal how these modified lubricants maintain their properties under thermal stress, a crucial factor for high-temperature industrial applications.

Thermal stability testing employs differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to evaluate how montmorillonite affects the lubricant's resistance to thermal degradation. These methods determine oxidation onset temperatures and decomposition profiles, providing insights into the extended service life potential of modified formulations. Complementary oxidation stability tests using rotating pressure vessel oxidation test (RPVOT) and Fourier-transform infrared spectroscopy (FTIR) monitor chemical changes during accelerated aging.

Surface interaction analysis utilizes advanced microscopy techniques including scanning electron microscopy (SEM) and atomic force microscopy (AFM) to examine tribofilm formation and surface morphology changes. These observations help explain the mechanisms behind montmorillonite's friction-reducing and anti-wear properties. Energy-dispersive X-ray spectroscopy (EDS) further characterizes the elemental composition of these protective films.

Field simulation testing bridges laboratory results with real-world applications by employing specialized equipment that replicates actual operating conditions. Engine dynamometer tests for automotive lubricants and industrial equipment simulations provide performance data under realistic loads, temperatures, and contamination levels. Long-duration tests measuring deposit formation, acid number changes, and viscosity stability offer insights into the service longevity of montmorillonite-enhanced lubricants.

Standardization of these testing protocols is essential for reliable comparison between different montmorillonite modifications and conventional additives. ASTM, ISO, and DIN standards provide frameworks for consistent evaluation, though specialized protocols may be necessary to fully capture the unique properties of clay-enhanced lubricant systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!