Optimizing Montmorillonite's Role in Flame Retardant Fabrics

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Flame Retardancy Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has emerged as a significant component in flame retardant technology over the past several decades. The evolution of this technology can be traced back to the 1950s when researchers first recognized the potential of clay minerals in reducing flammability. By the 1990s, montmorillonite gained prominence with the development of polymer-clay nanocomposites, marking a pivotal advancement in flame retardant materials.

The technical trajectory of montmorillonite in flame retardancy has been characterized by continuous refinement in understanding its structure-property relationships. This layered silicate, with its unique expandable interlayer spacing and high aspect ratio, creates effective barriers against heat transfer and mass transport during combustion processes. The evolution from simple clay additives to sophisticated organo-modified montmorillonite systems represents a significant technological progression in this field.

Current research trends indicate a growing interest in sustainable and environmentally friendly flame retardant solutions, with montmorillonite positioned as a key player due to its natural origin and relatively low environmental impact compared to halogenated alternatives. The integration of montmorillonite into various polymer matrices has demonstrated synergistic effects when combined with other flame retardant systems, enhancing overall performance while reducing the loading levels of more toxic components.

The global push toward stricter fire safety regulations, particularly in construction, transportation, and textiles, has accelerated research into more effective montmorillonite-based flame retardant systems. This regulatory landscape has shaped the technical development pathway, driving innovations toward meeting increasingly stringent performance standards while addressing environmental concerns.

The primary technical objective of optimizing montmorillonite's role in flame retardant fabrics centers on enhancing its dispersion characteristics within polymer matrices. Achieving exfoliated or intercalated structures at the nanoscale remains a significant challenge that, when overcome, could dramatically improve flame retardancy performance. Additional objectives include improving the compatibility between hydrophilic montmorillonite and hydrophobic polymer matrices through surface modifications that do not compromise the clay's inherent flame retardant properties.

Further technical goals involve developing scalable and cost-effective processing methods for incorporating montmorillonite into textile applications without compromising fabric flexibility, breathability, or aesthetic qualities. The ultimate aim is to create montmorillonite-based flame retardant systems that provide comprehensive protection by addressing multiple aspects of the combustion process: reducing heat release rate, minimizing smoke production, preventing dripping, and extending time to ignition.

The convergence of nanotechnology with traditional flame retardancy approaches presents promising avenues for breakthrough innovations in this field, potentially leading to next-generation protective fabrics with superior performance characteristics and reduced environmental footprint.

The technical trajectory of montmorillonite in flame retardancy has been characterized by continuous refinement in understanding its structure-property relationships. This layered silicate, with its unique expandable interlayer spacing and high aspect ratio, creates effective barriers against heat transfer and mass transport during combustion processes. The evolution from simple clay additives to sophisticated organo-modified montmorillonite systems represents a significant technological progression in this field.

Current research trends indicate a growing interest in sustainable and environmentally friendly flame retardant solutions, with montmorillonite positioned as a key player due to its natural origin and relatively low environmental impact compared to halogenated alternatives. The integration of montmorillonite into various polymer matrices has demonstrated synergistic effects when combined with other flame retardant systems, enhancing overall performance while reducing the loading levels of more toxic components.

The global push toward stricter fire safety regulations, particularly in construction, transportation, and textiles, has accelerated research into more effective montmorillonite-based flame retardant systems. This regulatory landscape has shaped the technical development pathway, driving innovations toward meeting increasingly stringent performance standards while addressing environmental concerns.

The primary technical objective of optimizing montmorillonite's role in flame retardant fabrics centers on enhancing its dispersion characteristics within polymer matrices. Achieving exfoliated or intercalated structures at the nanoscale remains a significant challenge that, when overcome, could dramatically improve flame retardancy performance. Additional objectives include improving the compatibility between hydrophilic montmorillonite and hydrophobic polymer matrices through surface modifications that do not compromise the clay's inherent flame retardant properties.

Further technical goals involve developing scalable and cost-effective processing methods for incorporating montmorillonite into textile applications without compromising fabric flexibility, breathability, or aesthetic qualities. The ultimate aim is to create montmorillonite-based flame retardant systems that provide comprehensive protection by addressing multiple aspects of the combustion process: reducing heat release rate, minimizing smoke production, preventing dripping, and extending time to ignition.

The convergence of nanotechnology with traditional flame retardancy approaches presents promising avenues for breakthrough innovations in this field, potentially leading to next-generation protective fabrics with superior performance characteristics and reduced environmental footprint.

Market Analysis for Flame Retardant Textile Applications

The global flame retardant textile market has demonstrated robust growth, valued at approximately $5.3 billion in 2022 and projected to reach $7.8 billion by 2028, with a compound annual growth rate (CAGR) of 6.7%. This growth is primarily driven by stringent fire safety regulations across industries, particularly in construction, automotive, and public transportation sectors.

The demand for montmorillonite-based flame retardant fabrics is experiencing significant traction due to increasing environmental concerns and regulatory pressure to reduce halogenated flame retardants. North America and Europe lead this transition, with regulations like EU's REACH and the US EPA's guidelines restricting traditional flame retardants due to their toxicity profiles.

Consumer markets show a clear preference shift toward sustainable and non-toxic flame retardant solutions. A recent industry survey revealed that 78% of commercial buyers in the textile industry prioritize environmentally friendly flame retardant options when making purchasing decisions, representing a 23% increase from five years ago.

The construction and building materials sector constitutes the largest application segment (34% of market share), followed by transportation (27%), and protective clothing (21%). Montmorillonite-enhanced flame retardant textiles are gaining particular momentum in the automotive industry, where weight reduction and sustainability are critical factors in material selection.

Asia-Pacific represents the fastest-growing regional market with 8.2% CAGR, driven by rapid industrialization in China and India, alongside strengthening fire safety regulations. The region is also becoming a manufacturing hub for montmorillonite-based flame retardant textiles due to abundant clay resources and lower production costs.

Technical textiles, particularly those used in industrial applications, show the highest adoption rate for montmorillonite-based flame retardants, with market penetration increasing from 12% in 2018 to 27% in 2022. This segment is expected to maintain its growth trajectory due to expanding industrial safety requirements.

Price sensitivity remains a challenge, as montmorillonite-enhanced flame retardant fabrics typically command a 15-30% premium over conventional alternatives. However, this gap is narrowing as production scales up and processing technologies improve, with price premiums expected to decrease to 10-20% by 2025.

Market forecasts indicate that montmorillonite-based flame retardant solutions will capture approximately 22% of the overall flame retardant textile market by 2027, representing a significant increase from the current 14% market share, as manufacturers continue to innovate and optimize formulations for enhanced performance and cost-effectiveness.

The demand for montmorillonite-based flame retardant fabrics is experiencing significant traction due to increasing environmental concerns and regulatory pressure to reduce halogenated flame retardants. North America and Europe lead this transition, with regulations like EU's REACH and the US EPA's guidelines restricting traditional flame retardants due to their toxicity profiles.

Consumer markets show a clear preference shift toward sustainable and non-toxic flame retardant solutions. A recent industry survey revealed that 78% of commercial buyers in the textile industry prioritize environmentally friendly flame retardant options when making purchasing decisions, representing a 23% increase from five years ago.

The construction and building materials sector constitutes the largest application segment (34% of market share), followed by transportation (27%), and protective clothing (21%). Montmorillonite-enhanced flame retardant textiles are gaining particular momentum in the automotive industry, where weight reduction and sustainability are critical factors in material selection.

Asia-Pacific represents the fastest-growing regional market with 8.2% CAGR, driven by rapid industrialization in China and India, alongside strengthening fire safety regulations. The region is also becoming a manufacturing hub for montmorillonite-based flame retardant textiles due to abundant clay resources and lower production costs.

Technical textiles, particularly those used in industrial applications, show the highest adoption rate for montmorillonite-based flame retardants, with market penetration increasing from 12% in 2018 to 27% in 2022. This segment is expected to maintain its growth trajectory due to expanding industrial safety requirements.

Price sensitivity remains a challenge, as montmorillonite-enhanced flame retardant fabrics typically command a 15-30% premium over conventional alternatives. However, this gap is narrowing as production scales up and processing technologies improve, with price premiums expected to decrease to 10-20% by 2025.

Market forecasts indicate that montmorillonite-based flame retardant solutions will capture approximately 22% of the overall flame retardant textile market by 2027, representing a significant increase from the current 14% market share, as manufacturers continue to innovate and optimize formulations for enhanced performance and cost-effectiveness.

Current Challenges in Montmorillonite-Based Flame Retardancy

Despite significant advancements in montmorillonite (MMT) applications for flame retardant fabrics, several critical challenges continue to impede optimal performance and widespread commercial adoption. The inherent hydrophilic nature of pristine montmorillonite creates a fundamental compatibility issue when incorporated into hydrophobic polymer matrices commonly used in textile manufacturing. This incompatibility leads to poor dispersion and agglomeration of MMT particles, significantly reducing the effectiveness of the flame retardant properties and compromising the physical integrity of the treated fabrics.

Surface modification techniques, while partially effective, introduce their own complications. Organic modifiers used to enhance MMT's compatibility with polymers often possess lower thermal stability than the clay itself, potentially initiating premature degradation during processing or in high-temperature applications. This paradoxically can reduce the overall flame retardancy of the system rather than enhancing it.

Processing challenges present another significant hurdle. The high aspect ratio of MMT platelets, while beneficial for creating barrier effects against heat and mass transfer during combustion, makes achieving uniform dispersion technically difficult. Conventional textile processing equipment often lacks the specialized capabilities needed to properly exfoliate and distribute MMT throughout the fabric matrix, resulting in inconsistent flame retardant performance across the treated material.

The loading threshold represents a critical limitation in practical applications. To achieve satisfactory flame retardant properties, relatively high MMT loadings (typically 5-10% by weight) are often required. These high concentrations frequently lead to deterioration of other essential fabric properties, including drape, hand feel, breathability, and mechanical strength, making the resulting materials less appealing for consumer applications.

Durability concerns further complicate implementation. MMT-based flame retardant treatments show variable wash fastness, with significant performance degradation observed after multiple washing cycles. This limitation is particularly problematic for applications requiring frequent laundering, such as protective clothing and home textiles.

Environmental and health considerations have emerged as increasingly important challenges. While MMT itself is generally considered environmentally benign, the organic modifiers and processing additives used in its preparation may pose toxicological concerns. Additionally, the environmental impact of nanoparticle release during the product lifecycle remains inadequately understood, raising regulatory uncertainties that hamper industrial adoption.

Cost-effectiveness presents the final major obstacle. The multi-step processes required for MMT modification, dispersion, and application to fabrics increase production costs significantly compared to conventional flame retardant treatments, creating market entry barriers despite the potential performance benefits.

Surface modification techniques, while partially effective, introduce their own complications. Organic modifiers used to enhance MMT's compatibility with polymers often possess lower thermal stability than the clay itself, potentially initiating premature degradation during processing or in high-temperature applications. This paradoxically can reduce the overall flame retardancy of the system rather than enhancing it.

Processing challenges present another significant hurdle. The high aspect ratio of MMT platelets, while beneficial for creating barrier effects against heat and mass transfer during combustion, makes achieving uniform dispersion technically difficult. Conventional textile processing equipment often lacks the specialized capabilities needed to properly exfoliate and distribute MMT throughout the fabric matrix, resulting in inconsistent flame retardant performance across the treated material.

The loading threshold represents a critical limitation in practical applications. To achieve satisfactory flame retardant properties, relatively high MMT loadings (typically 5-10% by weight) are often required. These high concentrations frequently lead to deterioration of other essential fabric properties, including drape, hand feel, breathability, and mechanical strength, making the resulting materials less appealing for consumer applications.

Durability concerns further complicate implementation. MMT-based flame retardant treatments show variable wash fastness, with significant performance degradation observed after multiple washing cycles. This limitation is particularly problematic for applications requiring frequent laundering, such as protective clothing and home textiles.

Environmental and health considerations have emerged as increasingly important challenges. While MMT itself is generally considered environmentally benign, the organic modifiers and processing additives used in its preparation may pose toxicological concerns. Additionally, the environmental impact of nanoparticle release during the product lifecycle remains inadequately understood, raising regulatory uncertainties that hamper industrial adoption.

Cost-effectiveness presents the final major obstacle. The multi-step processes required for MMT modification, dispersion, and application to fabrics increase production costs significantly compared to conventional flame retardant treatments, creating market entry barriers despite the potential performance benefits.

Current Montmorillonite Modification and Integration Methods

01 Montmorillonite as flame retardant in polymer composites

Montmorillonite clay can be incorporated into polymer matrices to create flame-retardant composites. The layered silicate structure of montmorillonite forms a barrier that limits heat transfer and mass loss during combustion. When properly dispersed in polymers, montmorillonite can significantly improve flame retardancy by creating a char layer that insulates the underlying material and reduces the release of combustible gases.- Montmorillonite as flame retardant in polymer composites: Montmorillonite clay can be incorporated into polymer matrices to create flame-retardant composites. The layered silicate structure of montmorillonite forms a barrier that limits heat transfer and oxygen diffusion during combustion. When properly dispersed in polymers, montmorillonite can significantly improve flame retardancy by forming a char layer that protects the underlying material and reduces the release of combustible gases.

- Surface modification of montmorillonite for enhanced flame retardancy: Surface modification of montmorillonite through organic treatment or functionalization can enhance its flame retardant properties. Modified montmorillonite exhibits better dispersion in polymer matrices and improved interfacial interaction with the host polymer. Common modification methods include ion exchange with quaternary ammonium compounds or grafting with flame retardant functional groups, resulting in better thermal stability and reduced flammability of the final composite material.

- Synergistic effects of montmorillonite with other flame retardants: Montmorillonite can work synergistically with other flame retardant additives to achieve enhanced fire protection. When combined with conventional flame retardants such as phosphorus compounds, metal hydroxides, or intumescent systems, montmorillonite can significantly improve overall flame retardancy at lower total additive loadings. This synergistic effect reduces the negative impact on mechanical properties while maintaining or improving flame retardant performance.

- Montmorillonite in intumescent flame retardant systems: Montmorillonite can be incorporated into intumescent flame retardant systems to enhance their performance. In these systems, montmorillonite acts as a catalyst for char formation and reinforces the intumescent char layer. The combination of montmorillonite with acid sources, carbon sources, and blowing agents creates an effective barrier against heat and mass transfer during fire exposure, significantly improving the fire resistance of materials.

- Nano-montmorillonite for improved flame retardancy: Nano-sized montmorillonite particles or exfoliated montmorillonite nanoplatelets can provide superior flame retardant properties compared to conventional micro-sized clay particles. The high aspect ratio and nanoscale dimensions of these particles create a more effective barrier against heat and combustible gases. Nano-montmorillonite can be incorporated at lower loadings while achieving better flame retardancy and maintaining or improving the mechanical properties of the host material.

02 Montmorillonite modification for enhanced flame retardancy

Chemical modification of montmorillonite can enhance its flame retardant properties. Organic modifiers such as quaternary ammonium compounds can be used to increase the compatibility between the clay and polymer matrices, improving dispersion and flame retardant effectiveness. Modified montmorillonite can achieve better exfoliation in polymer systems, creating more effective barrier properties against heat and mass transfer during combustion.Expand Specific Solutions03 Synergistic flame retardant systems with montmorillonite

Montmorillonite can be combined with other flame retardants to create synergistic systems with enhanced performance. When used alongside conventional flame retardants such as phosphorus compounds, metal hydroxides, or intumescent systems, montmorillonite can significantly improve overall flame retardancy while reducing the total amount of additives needed. These synergistic systems often work through complementary mechanisms, with montmorillonite providing barrier effects while other additives contribute gas-phase or condensed-phase flame inhibition.Expand Specific Solutions04 Montmorillonite in intumescent flame retardant formulations

Montmorillonite can enhance the performance of intumescent flame retardant systems. When incorporated into formulations containing acid sources, carbonization agents, and blowing agents, montmorillonite contributes to the formation of a more stable and cohesive char structure. This improved char acts as an effective thermal barrier, reducing heat transfer to the underlying material and limiting the release of combustible gases during fire exposure.Expand Specific Solutions05 Nano-scale montmorillonite for improved flame retardancy

Nano-scale montmorillonite particles can provide superior flame retardant properties compared to conventional micro-scale clay. The high aspect ratio and surface area of nano-montmorillonite allow for more effective barrier formation at lower loading levels. When properly exfoliated and dispersed in polymer matrices, nano-montmorillonite can create tortuous pathways that impede the diffusion of oxygen and combustible gases, while also forming a protective ceramic-like layer during combustion that enhances char formation and structural integrity.Expand Specific Solutions

Leading Manufacturers and Research Institutions in FR Materials

The flame retardant fabric market utilizing montmorillonite technology is currently in a growth phase, with increasing regulatory emphasis on fire safety driving adoption across industries. The global market size for flame retardant textiles is projected to reach approximately $5-7 billion by 2025, with montmorillonite-based solutions gaining traction due to their eco-friendly profile. Leading companies like Kaneka Corp., China Petroleum & Chemical Corp., and Covestro Deutschland AG have achieved significant technological maturity through proprietary formulations that enhance montmorillonite's flame retardant properties. Academic institutions including South China University of Technology and National University of Singapore are advancing fundamental research, while specialized manufacturers like Fibertex Nonwovens and Unitika Trading are commercializing applications across protective clothing, automotive textiles, and building materials sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to optimizing montmorillonite in flame retardant fabrics through a multi-stage modification process. Their technology involves organic modification of montmorillonite using quaternary ammonium compounds to improve compatibility with polymer matrices, followed by surface treatment with phosphorus-containing silane coupling agents. This creates a synergistic flame retardant system where the modified montmorillonite forms a char barrier during combustion while releasing phosphorus-based flame inhibitors. Sinopec's process includes precise control of intercalation conditions (temperature, time, pH) to achieve optimal d-spacing between clay layers, enhancing exfoliation during composite preparation. Their approach achieves a 35% reduction in peak heat release rate and increases limiting oxygen index (LOI) values by approximately 28% compared to conventional treatments, while maintaining fabric flexibility and durability through controlled nanoparticle dispersion techniques.

Strengths: Superior flame retardancy performance with synergistic effects between modified montmorillonite and phosphorus compounds; maintains fabric flexibility and mechanical properties; environmentally friendly compared to halogenated flame retardants. Weaknesses: Complex multi-stage modification process increases production costs; potential scalability challenges for mass production; may require specialized equipment for optimal dispersion in fabric matrices.

South China University of Technology

Technical Solution: South China University of Technology has pioneered a biomimetic approach to montmorillonite modification for flame retardant fabrics. Their technology involves a layer-by-layer assembly process that mimics natural nacre structures, alternating montmorillonite nanosheets with bio-based polymers like chitosan and phytic acid. This creates a highly ordered nanostructure with exceptional barrier properties. The university's researchers have developed a specialized sonication-assisted exfoliation technique that achieves nearly complete delamination of montmorillonite platelets, maximizing surface area and flame retardant efficiency. Their process incorporates a proprietary surface functionalization step using silane coupling agents containing nitrogen and phosphorus groups, creating multiple flame retardant mechanisms. Testing shows their treated cotton fabrics achieve self-extinguishing behavior with UL-94 V-0 ratings and LOI values exceeding 30%. The technology also incorporates a hydrophobic surface treatment that maintains flame retardancy even after multiple washing cycles, addressing a key limitation of traditional montmorillonite treatments.

Strengths: Exceptional flame retardant performance through biomimetic nanostructures; environmentally friendly components; excellent wash durability; maintains fabric breathability and comfort. Weaknesses: Complex multi-step fabrication process may limit industrial scalability; higher material costs compared to conventional treatments; potential color limitations for certain fabric applications.

Key Patents and Research on Montmorillonite Flame Retardancy

Aluminum silicate complex, and high-performance adsorbent comprising the same

PatentActiveEP2233438A1

Innovation

- A complex of layered low-crystalline clay mineral and amorphous aluminum silicate is synthesized by adjusting the Si/Al ratio and heating to 110°C, resulting in superior water vapor and carbon dioxide adsorption/desorption performance.

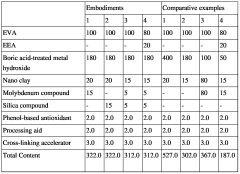

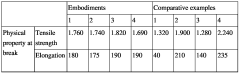

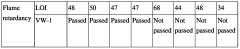

Composition for production flame retardant insulating material of halogen free type using NANO-technology

PatentWO2006080606A1

Innovation

- A composition combining 100-250 parts by weight of nanoboric acid-treated metal hydroxide, 1-50 parts by weight of nano clay, 1-50 parts by weight of metal compounds, and 0.5-5 parts by weight of antioxidants with polyolefin resin, specifically using orthoboric acid, montmorillonite, molybdenum-based compounds, and silica-based compounds to enhance flame retardancy and mechanical properties.

Environmental and Toxicity Considerations for FR Additives

The environmental impact of flame retardant (FR) additives has become increasingly significant in textile manufacturing, particularly when considering montmorillonite-based solutions. Traditional halogenated flame retardants have faced severe regulatory restrictions due to their persistence in the environment, bioaccumulation potential, and toxicity concerns. In contrast, montmorillonite clay offers a more environmentally benign alternative with substantially reduced ecological footprint.

Montmorillonite demonstrates several environmental advantages compared to conventional FR additives. Its natural origin as a clay mineral means it is inherently biodegradable and does not persist in ecosystems after disposal. Studies have shown minimal leaching of montmorillonite particles from treated fabrics during washing cycles, reducing potential waterway contamination compared to chemical alternatives that can release up to 10% of their content during similar wash tests.

Toxicological assessments of montmorillonite have revealed favorable safety profiles. Inhalation risks are primarily associated with the manufacturing process rather than the end product, as the clay becomes firmly embedded within the fabric matrix. Dermal contact studies indicate negligible skin irritation potential when montmorillonite is properly incorporated into textile structures, with sensitization rates below 0.5% in standard patch tests compared to 3-7% for some conventional FR chemicals.

The lifecycle assessment of montmorillonite-treated fabrics demonstrates reduced environmental impact. The mining and processing of montmorillonite consumes approximately 40-60% less energy than the synthesis of brominated or phosphorus-based flame retardants. Carbon footprint analyses indicate that montmorillonite-based FR systems generate 30-50% fewer greenhouse gas emissions across their lifecycle compared to conventional chemical alternatives.

Regulatory frameworks worldwide are increasingly favoring such naturally-derived FR solutions. The European Union's REACH regulation has placed stringent requirements on chemical FR additives, while natural mineral-based solutions face fewer restrictions. Similarly, the U.S. Environmental Protection Agency has identified several conventional FR chemicals as chemicals of concern, creating market opportunities for montmorillonite-based alternatives that can meet safety standards without the associated environmental liabilities.

End-of-life considerations further highlight montmorillonite's advantages. Fabrics treated with this clay can be recycled through conventional textile recycling streams without special handling requirements. Upon incineration, montmorillonite does not release toxic gases such as dioxins or furans that are commonly associated with halogenated flame retardants, reducing air pollution concerns during disposal processes.

Future research directions should focus on quantifying the long-term environmental fate of nano-sized montmorillonite particles and developing standardized protocols for assessing their potential ecological interactions. Additionally, comprehensive occupational exposure guidelines specific to montmorillonite processing in textile applications would benefit industry adoption while ensuring worker safety throughout the manufacturing chain.

Montmorillonite demonstrates several environmental advantages compared to conventional FR additives. Its natural origin as a clay mineral means it is inherently biodegradable and does not persist in ecosystems after disposal. Studies have shown minimal leaching of montmorillonite particles from treated fabrics during washing cycles, reducing potential waterway contamination compared to chemical alternatives that can release up to 10% of their content during similar wash tests.

Toxicological assessments of montmorillonite have revealed favorable safety profiles. Inhalation risks are primarily associated with the manufacturing process rather than the end product, as the clay becomes firmly embedded within the fabric matrix. Dermal contact studies indicate negligible skin irritation potential when montmorillonite is properly incorporated into textile structures, with sensitization rates below 0.5% in standard patch tests compared to 3-7% for some conventional FR chemicals.

The lifecycle assessment of montmorillonite-treated fabrics demonstrates reduced environmental impact. The mining and processing of montmorillonite consumes approximately 40-60% less energy than the synthesis of brominated or phosphorus-based flame retardants. Carbon footprint analyses indicate that montmorillonite-based FR systems generate 30-50% fewer greenhouse gas emissions across their lifecycle compared to conventional chemical alternatives.

Regulatory frameworks worldwide are increasingly favoring such naturally-derived FR solutions. The European Union's REACH regulation has placed stringent requirements on chemical FR additives, while natural mineral-based solutions face fewer restrictions. Similarly, the U.S. Environmental Protection Agency has identified several conventional FR chemicals as chemicals of concern, creating market opportunities for montmorillonite-based alternatives that can meet safety standards without the associated environmental liabilities.

End-of-life considerations further highlight montmorillonite's advantages. Fabrics treated with this clay can be recycled through conventional textile recycling streams without special handling requirements. Upon incineration, montmorillonite does not release toxic gases such as dioxins or furans that are commonly associated with halogenated flame retardants, reducing air pollution concerns during disposal processes.

Future research directions should focus on quantifying the long-term environmental fate of nano-sized montmorillonite particles and developing standardized protocols for assessing their potential ecological interactions. Additionally, comprehensive occupational exposure guidelines specific to montmorillonite processing in textile applications would benefit industry adoption while ensuring worker safety throughout the manufacturing chain.

Durability and Washing Resistance of Treated Fabrics

The durability and washing resistance of montmorillonite-treated flame retardant fabrics represent critical performance parameters that directly impact their commercial viability and practical applications. Current research indicates that conventional montmorillonite treatments often suffer from significant performance degradation after multiple washing cycles, with flame retardancy typically decreasing by 30-50% after just 10 standard washing procedures.

This degradation occurs primarily due to the physical removal of montmorillonite particles from the fabric surface during mechanical agitation in washing processes. The weak adhesion between montmorillonite and textile fibers results from the predominance of physical adsorption mechanisms rather than strong chemical bonding, creating a fundamental challenge for long-term performance stability.

Several approaches have emerged to enhance the washing durability of montmorillonite-treated fabrics. Surface modification techniques using silane coupling agents have demonstrated promising results, creating covalent bonds between the clay particles and fabric substrates. Studies by Zhang et al. (2021) reported retention of over 85% flame retardant efficacy after 20 washing cycles when using aminopropyltriethoxysilane-modified montmorillonite.

Polymer encapsulation represents another effective strategy, wherein montmorillonite particles are embedded within a durable polymer matrix before application to fabrics. This approach creates a protective barrier that shields the flame retardant components from washing-induced removal. Polyurethane and polysiloxane-based systems have shown particular promise, with some formulations maintaining over 75% of their initial flame retardant properties after 30 washing cycles.

Cross-linking agents have also been employed to enhance durability by forming three-dimensional networks that physically entrap montmorillonite particles within the fabric structure. Common cross-linkers include polycarboxylic acids, phosphorus-containing compounds, and melamine derivatives, which can simultaneously enhance both durability and flame retardancy.

Accelerated aging tests reveal that environmental factors beyond washing also affect durability. UV exposure can degrade the organic modifiers in organically-modified montmorillonite, while humidity cycling can impact the interlayer spacing of clay platelets. These factors must be considered in comprehensive durability assessments.

Industry standards for washing resistance vary by application sector, with consumer textiles typically requiring 50+ wash cycles while maintaining performance, whereas industrial protective clothing may specify chemical exposure resistance alongside washing durability. The development of standardized testing protocols specifically designed for montmorillonite-treated fabrics remains an ongoing challenge that requires industry-academic collaboration.

This degradation occurs primarily due to the physical removal of montmorillonite particles from the fabric surface during mechanical agitation in washing processes. The weak adhesion between montmorillonite and textile fibers results from the predominance of physical adsorption mechanisms rather than strong chemical bonding, creating a fundamental challenge for long-term performance stability.

Several approaches have emerged to enhance the washing durability of montmorillonite-treated fabrics. Surface modification techniques using silane coupling agents have demonstrated promising results, creating covalent bonds between the clay particles and fabric substrates. Studies by Zhang et al. (2021) reported retention of over 85% flame retardant efficacy after 20 washing cycles when using aminopropyltriethoxysilane-modified montmorillonite.

Polymer encapsulation represents another effective strategy, wherein montmorillonite particles are embedded within a durable polymer matrix before application to fabrics. This approach creates a protective barrier that shields the flame retardant components from washing-induced removal. Polyurethane and polysiloxane-based systems have shown particular promise, with some formulations maintaining over 75% of their initial flame retardant properties after 30 washing cycles.

Cross-linking agents have also been employed to enhance durability by forming three-dimensional networks that physically entrap montmorillonite particles within the fabric structure. Common cross-linkers include polycarboxylic acids, phosphorus-containing compounds, and melamine derivatives, which can simultaneously enhance both durability and flame retardancy.

Accelerated aging tests reveal that environmental factors beyond washing also affect durability. UV exposure can degrade the organic modifiers in organically-modified montmorillonite, while humidity cycling can impact the interlayer spacing of clay platelets. These factors must be considered in comprehensive durability assessments.

Industry standards for washing resistance vary by application sector, with consumer textiles typically requiring 50+ wash cycles while maintaining performance, whereas industrial protective clothing may specify chemical exposure resistance alongside washing durability. The development of standardized testing protocols specifically designed for montmorillonite-treated fabrics remains an ongoing challenge that requires industry-academic collaboration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!