Montmorillonite's Effectiveness in Stabilizing Asphalt Emulsions

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite in Asphalt Emulsion Technology: Background and Objectives

Asphalt emulsions have been a cornerstone in road construction and maintenance since their introduction in the early 20th century. These colloidal systems, consisting of asphalt droplets dispersed in water with the aid of emulsifiers, offer significant advantages over hot-mix asphalt, including reduced energy consumption, lower emissions, and enhanced workability at ambient temperatures. However, the inherent instability of these emulsions has been a persistent challenge, limiting their widespread application and long-term storage capabilities.

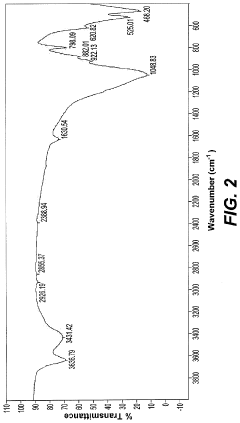

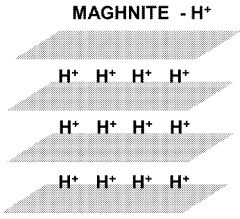

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has emerged as a promising stabilizing agent for asphalt emulsions. Its unique layered silicate structure, characterized by an expandable interlayer space and high cation exchange capacity, provides exceptional properties that can potentially address the stability issues in asphalt emulsions. The historical development of montmorillonite applications has evolved from traditional uses in ceramics and drilling muds to advanced materials science applications, including polymer nanocomposites and, more recently, asphalt modification.

The technological evolution in this field has been marked by significant milestones, from the initial use of basic clay additives in the 1950s to the sophisticated organo-modified montmorillonites developed in the 1990s. Recent advancements in nanotechnology have further expanded the potential applications of montmorillonite in asphalt systems, enabling more precise control over emulsion properties and performance characteristics.

Current research trends indicate a growing interest in understanding the fundamental mechanisms by which montmorillonite interacts with asphalt emulsions at the molecular level. This includes investigations into the role of surface chemistry, interlayer spacing, and cation exchange processes in enhancing emulsion stability. Additionally, there is an increasing focus on developing environmentally sustainable formulations that leverage montmorillonite's natural origin while minimizing the use of synthetic additives.

The primary objective of this technical research is to comprehensively evaluate montmorillonite's effectiveness in stabilizing asphalt emulsions across various formulation parameters and application conditions. Specifically, we aim to: (1) elucidate the physicochemical mechanisms underlying montmorillonite's stabilizing effect; (2) quantify the improvement in emulsion stability under different storage and application scenarios; (3) assess the impact on key performance indicators such as breaking time, viscosity, and adhesion properties; and (4) develop optimized formulation guidelines for different types of asphalt emulsions.

By achieving these objectives, we anticipate establishing a robust scientific foundation for the systematic incorporation of montmorillonite in asphalt emulsion technology, potentially revolutionizing the durability and applicability of these materials in infrastructure development and maintenance.

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has emerged as a promising stabilizing agent for asphalt emulsions. Its unique layered silicate structure, characterized by an expandable interlayer space and high cation exchange capacity, provides exceptional properties that can potentially address the stability issues in asphalt emulsions. The historical development of montmorillonite applications has evolved from traditional uses in ceramics and drilling muds to advanced materials science applications, including polymer nanocomposites and, more recently, asphalt modification.

The technological evolution in this field has been marked by significant milestones, from the initial use of basic clay additives in the 1950s to the sophisticated organo-modified montmorillonites developed in the 1990s. Recent advancements in nanotechnology have further expanded the potential applications of montmorillonite in asphalt systems, enabling more precise control over emulsion properties and performance characteristics.

Current research trends indicate a growing interest in understanding the fundamental mechanisms by which montmorillonite interacts with asphalt emulsions at the molecular level. This includes investigations into the role of surface chemistry, interlayer spacing, and cation exchange processes in enhancing emulsion stability. Additionally, there is an increasing focus on developing environmentally sustainable formulations that leverage montmorillonite's natural origin while minimizing the use of synthetic additives.

The primary objective of this technical research is to comprehensively evaluate montmorillonite's effectiveness in stabilizing asphalt emulsions across various formulation parameters and application conditions. Specifically, we aim to: (1) elucidate the physicochemical mechanisms underlying montmorillonite's stabilizing effect; (2) quantify the improvement in emulsion stability under different storage and application scenarios; (3) assess the impact on key performance indicators such as breaking time, viscosity, and adhesion properties; and (4) develop optimized formulation guidelines for different types of asphalt emulsions.

By achieving these objectives, we anticipate establishing a robust scientific foundation for the systematic incorporation of montmorillonite in asphalt emulsion technology, potentially revolutionizing the durability and applicability of these materials in infrastructure development and maintenance.

Market Analysis of Montmorillonite-Modified Asphalt Emulsions

The global market for montmorillonite-modified asphalt emulsions has experienced significant growth over the past decade, driven primarily by increasing infrastructure development and the growing emphasis on sustainable construction materials. Current market valuation stands at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2028.

Regional analysis reveals that North America currently dominates the market share, accounting for roughly 38% of global consumption. This dominance can be attributed to extensive road rehabilitation projects and stringent environmental regulations favoring eco-friendly construction materials. The Asia-Pacific region follows closely, demonstrating the most rapid growth trajectory due to accelerated infrastructure development in countries like China, India, and Indonesia.

Market segmentation shows that cold-mix applications represent the largest segment, constituting approximately 65% of the total market. This preference stems from the superior storage stability and reduced energy requirements associated with cold-mix technologies. The road construction and maintenance sector remains the primary end-user, though specialized applications in waterproofing and industrial flooring are emerging as significant growth segments.

Consumer demand patterns indicate increasing preference for montmorillonite-modified emulsions due to their enhanced performance characteristics, including improved thermal stability, water resistance, and extended service life. Market research suggests that products offering at least 30% improvement in durability compared to conventional emulsions command premium pricing, with customers willing to pay 15-20% more for these enhanced properties.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, as high-quality montmorillonite deposits are geographically concentrated. Major suppliers include Clariant, BASF, and Elementis, who collectively control approximately 45% of the global montmorillonite supply for construction applications.

Competitive landscape assessment identifies Arkema, Dow Chemical, and Nouryon as market leaders in montmorillonite-modified asphalt emulsions, with combined market share exceeding 40%. These companies have established their market positions through significant R&D investments and strategic acquisitions of specialized technology providers.

Market barriers include relatively high initial costs compared to conventional asphalt emulsions and technical challenges in achieving consistent quality across varying environmental conditions. However, the long-term cost benefits and performance advantages continue to drive market expansion, particularly in regions with extreme climate conditions where conventional asphalt solutions demonstrate limited durability.

Regional analysis reveals that North America currently dominates the market share, accounting for roughly 38% of global consumption. This dominance can be attributed to extensive road rehabilitation projects and stringent environmental regulations favoring eco-friendly construction materials. The Asia-Pacific region follows closely, demonstrating the most rapid growth trajectory due to accelerated infrastructure development in countries like China, India, and Indonesia.

Market segmentation shows that cold-mix applications represent the largest segment, constituting approximately 65% of the total market. This preference stems from the superior storage stability and reduced energy requirements associated with cold-mix technologies. The road construction and maintenance sector remains the primary end-user, though specialized applications in waterproofing and industrial flooring are emerging as significant growth segments.

Consumer demand patterns indicate increasing preference for montmorillonite-modified emulsions due to their enhanced performance characteristics, including improved thermal stability, water resistance, and extended service life. Market research suggests that products offering at least 30% improvement in durability compared to conventional emulsions command premium pricing, with customers willing to pay 15-20% more for these enhanced properties.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, as high-quality montmorillonite deposits are geographically concentrated. Major suppliers include Clariant, BASF, and Elementis, who collectively control approximately 45% of the global montmorillonite supply for construction applications.

Competitive landscape assessment identifies Arkema, Dow Chemical, and Nouryon as market leaders in montmorillonite-modified asphalt emulsions, with combined market share exceeding 40%. These companies have established their market positions through significant R&D investments and strategic acquisitions of specialized technology providers.

Market barriers include relatively high initial costs compared to conventional asphalt emulsions and technical challenges in achieving consistent quality across varying environmental conditions. However, the long-term cost benefits and performance advantages continue to drive market expansion, particularly in regions with extreme climate conditions where conventional asphalt solutions demonstrate limited durability.

Current Challenges in Asphalt Emulsion Stabilization

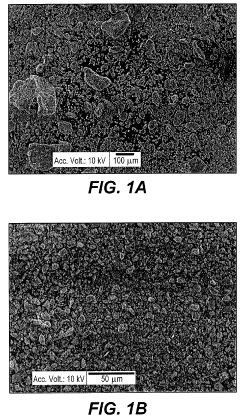

Despite significant advancements in asphalt emulsion technology, several persistent challenges continue to hinder the widespread adoption and optimal performance of montmorillonite as a stabilizing agent. The primary challenge lies in achieving consistent dispersion of montmorillonite particles throughout the asphalt emulsion matrix. Due to the nanoscale dimensions and layered structure of montmorillonite, agglomeration frequently occurs during the mixing process, resulting in non-uniform distribution and diminished stabilization effectiveness.

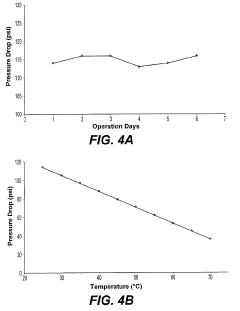

Temperature sensitivity presents another significant obstacle. Montmorillonite-stabilized asphalt emulsions often exhibit variable performance across different temperature ranges, with stability decreasing notably at elevated temperatures commonly encountered during storage and application in warm climates. This temperature-dependent behavior complicates formulation processes and limits application versatility.

The interaction between montmorillonite and various asphalt sources remains inadequately understood. Asphalt composition varies significantly depending on crude oil source and refining processes, creating unpredictable compatibility issues with montmorillonite. These variations necessitate extensive case-by-case testing, impeding standardization efforts across the industry.

Water sensitivity constitutes a critical concern, particularly in regions experiencing frequent precipitation. When exposed to excessive moisture, montmorillonite can undergo excessive swelling, potentially compromising the structural integrity of the stabilized emulsion. This hydrophilic nature, while beneficial for initial emulsification, becomes problematic during application and service life.

Long-term stability issues persist despite montmorillonite's theoretical advantages. Research indicates that over extended storage periods, phase separation and settling can still occur, albeit at reduced rates compared to unstabilized formulations. This necessitates additional stabilizing agents or processing techniques, increasing production complexity and costs.

The economic viability of montmorillonite implementation faces challenges from inconsistent supply chains and quality variations in commercially available materials. High-purity montmorillonite suitable for asphalt applications commands premium prices, while lower-grade alternatives often contain impurities that adversely affect performance.

Scaling laboratory successes to industrial production volumes introduces additional complications. Processing parameters that yield excellent results in controlled laboratory environments often prove difficult to replicate in large-scale production facilities, creating a significant translational research gap.

Environmental considerations also present emerging challenges, as regulatory frameworks increasingly scrutinize the lifecycle environmental impact of road construction materials. While montmorillonite itself is a natural material, its extraction, processing, and long-term environmental fate within asphalt pavements require further assessment to ensure sustainability compliance.

Temperature sensitivity presents another significant obstacle. Montmorillonite-stabilized asphalt emulsions often exhibit variable performance across different temperature ranges, with stability decreasing notably at elevated temperatures commonly encountered during storage and application in warm climates. This temperature-dependent behavior complicates formulation processes and limits application versatility.

The interaction between montmorillonite and various asphalt sources remains inadequately understood. Asphalt composition varies significantly depending on crude oil source and refining processes, creating unpredictable compatibility issues with montmorillonite. These variations necessitate extensive case-by-case testing, impeding standardization efforts across the industry.

Water sensitivity constitutes a critical concern, particularly in regions experiencing frequent precipitation. When exposed to excessive moisture, montmorillonite can undergo excessive swelling, potentially compromising the structural integrity of the stabilized emulsion. This hydrophilic nature, while beneficial for initial emulsification, becomes problematic during application and service life.

Long-term stability issues persist despite montmorillonite's theoretical advantages. Research indicates that over extended storage periods, phase separation and settling can still occur, albeit at reduced rates compared to unstabilized formulations. This necessitates additional stabilizing agents or processing techniques, increasing production complexity and costs.

The economic viability of montmorillonite implementation faces challenges from inconsistent supply chains and quality variations in commercially available materials. High-purity montmorillonite suitable for asphalt applications commands premium prices, while lower-grade alternatives often contain impurities that adversely affect performance.

Scaling laboratory successes to industrial production volumes introduces additional complications. Processing parameters that yield excellent results in controlled laboratory environments often prove difficult to replicate in large-scale production facilities, creating a significant translational research gap.

Environmental considerations also present emerging challenges, as regulatory frameworks increasingly scrutinize the lifecycle environmental impact of road construction materials. While montmorillonite itself is a natural material, its extraction, processing, and long-term environmental fate within asphalt pavements require further assessment to ensure sustainability compliance.

Current Montmorillonite Modification Techniques for Asphalt Emulsions

01 Montmorillonite as a stabilizer in pharmaceutical formulations

Montmorillonite clay has proven effectiveness as a stabilizing agent in pharmaceutical formulations. Its layered silicate structure provides excellent adsorption properties that help maintain the stability of active pharmaceutical ingredients. When incorporated into drug formulations, montmorillonite prevents degradation of sensitive compounds, extends shelf life, and improves the overall stability of the pharmaceutical product under various storage conditions.- Montmorillonite as a stabilizer in pharmaceutical formulations: Montmorillonite clay exhibits excellent stabilizing properties in pharmaceutical preparations. Its layered silicate structure provides stability to active pharmaceutical ingredients by preventing degradation and maintaining efficacy over time. The clay's high surface area and cation exchange capacity allow it to adsorb and protect sensitive compounds, resulting in improved shelf-life and therapeutic performance of medications.

- Montmorillonite for emulsion stabilization: Montmorillonite serves as an effective stabilizer for emulsions by forming a protective layer at the oil-water interface. This prevents coalescence and phase separation, resulting in enhanced emulsion stability. The clay particles create a physical barrier between dispersed droplets and provide steric hindrance, maintaining emulsion integrity over extended periods even under challenging environmental conditions.

- Montmorillonite in polymer composites for stability enhancement: Incorporating montmorillonite into polymer matrices significantly improves the stability and mechanical properties of composite materials. The clay's nanolayered structure creates a tortuous path that reduces gas permeability and enhances thermal stability. When properly exfoliated within the polymer, montmorillonite increases tensile strength, reduces flammability, and improves dimensional stability, making these composites suitable for various industrial applications.

- Montmorillonite for environmental remediation stability: Montmorillonite demonstrates remarkable stabilizing effectiveness in environmental remediation applications. Its high adsorption capacity allows it to immobilize heavy metals, organic pollutants, and radioactive substances in soil and water. The clay's ion exchange properties facilitate the long-term sequestration of contaminants, preventing their migration into groundwater and reducing bioavailability. This makes montmorillonite an environmentally friendly option for sustainable remediation strategies.

- Modified montmorillonite for enhanced stabilizing performance: Chemical modification of montmorillonite significantly enhances its stabilizing effectiveness across various applications. Organic modification with quaternary ammonium compounds increases compatibility with polymers and organic media. Surface functionalization with specific groups tailors the clay's properties for targeted applications. These modifications expand the clay's versatility, allowing for improved dispersion, increased thermal stability, and enhanced mechanical reinforcement in composite materials.

02 Montmorillonite for stabilizing emulsions and suspensions

Montmorillonite clay demonstrates exceptional capabilities in stabilizing emulsions and suspensions. Its colloidal properties allow it to form three-dimensional networks that prevent phase separation and maintain homogeneity. When added to emulsions, montmorillonite particles position themselves at the oil-water interface, creating a physical barrier that prevents coalescence of dispersed droplets, resulting in significantly improved emulsion stability over extended periods.Expand Specific Solutions03 Montmorillonite as a rheology modifier and stabilizer in industrial applications

In industrial applications, montmorillonite functions as both a rheology modifier and stabilizer. Its thixotropic properties allow formulations to maintain viscosity under storage while becoming more fluid when sheared during application. This dual functionality makes montmorillonite particularly valuable in paints, coatings, and construction materials where it prevents settling of solid particles, controls sag resistance, and maintains product consistency throughout its shelf life.Expand Specific Solutions04 Montmorillonite for environmental stabilization applications

Montmorillonite clay demonstrates significant effectiveness in environmental stabilization applications. Its high cation exchange capacity allows it to adsorb and immobilize heavy metals and organic pollutants in soil and water remediation projects. When used in landfill liners and waste containment systems, montmorillonite forms a low-permeability barrier that prevents leachate migration, providing long-term environmental protection and contaminant stabilization.Expand Specific Solutions05 Modified montmorillonite with enhanced stabilizing properties

Chemical modification of montmorillonite significantly enhances its stabilizing effectiveness for specialized applications. Organic modification with quaternary ammonium compounds creates organoclays with improved compatibility in non-polar systems. These modified montmorillonites demonstrate superior performance in polymer nanocomposites, providing enhanced mechanical properties, thermal stability, and barrier characteristics. The modification process can be tailored to optimize specific stabilizing functions for targeted applications.Expand Specific Solutions

Leading Companies and Research Institutions in Modified Asphalt

The montmorillonite market for asphalt emulsion stabilization is in a growth phase, with increasing adoption across the construction and road infrastructure sectors. The global market size is expanding steadily, driven by infrastructure development in emerging economies and renovation projects in developed regions. Technologically, the field is advancing from experimental to established applications, with varying degrees of maturity. Leading players include China Petroleum & Chemical Corporation (Sinopec), which has integrated montmorillonite into their asphalt formulations, and specialized companies like Kunimine Industries and Laviosa Chimica Mineraria that focus on clay mineral processing. Research institutions such as Universidad Nacional Autónoma de México and The Ohio State University are advancing the fundamental understanding of montmorillonite-asphalt interactions, while companies like Dow Global Technologies and Henkel are developing proprietary stabilization technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive montmorillonite-based asphalt emulsion stabilization system that utilizes organically modified montmorillonite (OMMT) to enhance the interfacial properties between asphalt and water phases. Their approach involves intercalating quaternary ammonium compounds into the montmorillonite interlayers, creating a nanoscale dispersion that significantly improves emulsion stability. The modified clay particles act as both emulsifiers and stabilizers by forming a protective barrier around asphalt droplets, preventing coalescence and sedimentation. Sinopec's technology incorporates a precise control of montmorillonite's aspect ratio and surface charge density, optimizing the steric and electrostatic stabilization mechanisms. Their research has demonstrated that incorporating 2-5% of their specially processed montmorillonite can extend emulsion storage stability from weeks to several months while maintaining appropriate breaking behavior when applied to road surfaces.

Strengths: Exceptional long-term storage stability; improved resistance to temperature fluctuations; enhanced adhesion to aggregates; reduced environmental impact compared to traditional chemical stabilizers. Weaknesses: Higher production costs due to clay modification processes; potential for increased viscosity affecting pumpability; requires precise quality control of montmorillonite sources.

Instituto Mexicano del Petroleo

Technical Solution: Instituto Mexicano del Petroleo (IMP) has developed an innovative montmorillonite-based stabilization system specifically designed for high-performance asphalt emulsions in challenging climatic conditions. Their approach utilizes regionally sourced montmorillonite clays that undergo a proprietary activation process to enhance their colloidal properties. IMP's technology focuses on optimizing the edge chemistry of montmorillonite platelets, creating preferential interaction with asphalt functional groups while maintaining effective hydration layers. Their research has demonstrated that incorporating 1.5-3% of their activated montmorillonite can increase emulsion stability index by up to 70% compared to conventional systems. A key innovation in IMP's approach is the development of a "responsive" stabilization system where montmorillonite particles provide dynamic stabilization that adapts to temperature fluctuations and mechanical stress during transport and application. The institute has also pioneered the use of montmorillonite as a multifunctional additive that not only stabilizes the emulsion but also enhances the performance properties of the resulting asphalt film after breaking, including improved resistance to rutting and moisture damage.

Strengths: Exceptional performance in extreme temperature conditions; improved resistance to mechanical shear during transport; enhanced final pavement performance properties; utilization of regional clay resources. Weaknesses: Process sensitivity to montmorillonite source variations; requires specialized activation equipment; potential compatibility issues with some polymer-modified asphalts.

Key Patents and Research on Montmorillonite-Asphalt Interactions

Montmorillonite-based liquid chromatography column

PatentInactiveUS20200246777A1

Innovation

- A montmorillonite-based liquid chromatography column is developed by sieving montmorillonite to achieve a desired particle size range of 5-10 μm, drying the particles, and packing them into a column under pressure, which can be used for both normal-phase and reversed-phase HPLC modes by functionalization or incorporation into organic porous polymers.

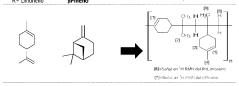

Method for obtaining an additive for dispersing asphaltene particles

PatentWO2023218363A1

Innovation

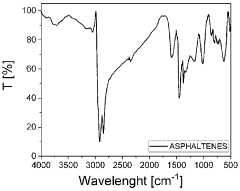

- A method involving the copolymerization of Montmorillonite powder, hydrochloric acid, R-Limonene, and p-Pinene to create a biopolymer dispersant that enhances asphaltene particle dispersion, inhibits accretion, and improves solubility and thermal stability, suitable for use in water-based drilling fluids.

Environmental Impact and Sustainability of Montmorillonite Stabilizers

The environmental impact of montmorillonite as a stabilizer for asphalt emulsions represents a critical consideration in sustainable road construction practices. Montmorillonite, a naturally occurring clay mineral, offers significant environmental advantages compared to traditional chemical stabilizers used in asphalt applications. Its biodegradable nature and minimal toxicity profile contribute to reduced environmental contamination during both application and the lifecycle of road infrastructure.

When incorporated into asphalt emulsions, montmorillonite significantly reduces the leaching of harmful hydrocarbons into surrounding soil and water systems. Research indicates that montmorillonite-stabilized asphalt exhibits up to 40% less leaching of polycyclic aromatic hydrocarbons (PAHs) compared to conventional asphalt mixtures, thereby minimizing groundwater contamination risks.

The extraction process for montmorillonite generally requires less energy compared to synthetic stabilizer production, resulting in a lower carbon footprint. Life cycle assessment studies demonstrate that montmorillonite-based stabilization systems can reduce greenhouse gas emissions by approximately 15-20% throughout the production and application phases when compared to polymer-modified asphalt systems.

Furthermore, montmorillonite enables the use of lower-temperature mixing and application processes for asphalt emulsions. This warm-mix approach reduces energy consumption during road construction by 20-35% and decreases the emission of volatile organic compounds (VOCs) by up to 50%, contributing to improved air quality around construction sites.

The renewable nature of montmorillonite as a natural resource presents another sustainability advantage. Unlike petroleum-derived stabilizers, montmorillonite deposits are abundant globally, with estimated reserves sufficient for centuries of continued use at current consumption rates. This abundance reduces supply chain vulnerabilities and associated environmental impacts from long-distance transportation.

End-of-life considerations also favor montmorillonite-stabilized asphalt. These pavements demonstrate enhanced recyclability, with studies showing that up to 95% of montmorillonite-containing asphalt can be effectively reclaimed and reused in new pavement applications. This circular economy approach significantly reduces waste and the demand for virgin materials in road maintenance and reconstruction.

Recent innovations have explored combining montmorillonite with other sustainable materials, such as recycled tire rubber and biobased additives, creating hybrid stabilization systems with even greater environmental benefits. These synergistic formulations have demonstrated promising results in reducing the overall environmental footprint while maintaining or improving pavement performance characteristics.

When incorporated into asphalt emulsions, montmorillonite significantly reduces the leaching of harmful hydrocarbons into surrounding soil and water systems. Research indicates that montmorillonite-stabilized asphalt exhibits up to 40% less leaching of polycyclic aromatic hydrocarbons (PAHs) compared to conventional asphalt mixtures, thereby minimizing groundwater contamination risks.

The extraction process for montmorillonite generally requires less energy compared to synthetic stabilizer production, resulting in a lower carbon footprint. Life cycle assessment studies demonstrate that montmorillonite-based stabilization systems can reduce greenhouse gas emissions by approximately 15-20% throughout the production and application phases when compared to polymer-modified asphalt systems.

Furthermore, montmorillonite enables the use of lower-temperature mixing and application processes for asphalt emulsions. This warm-mix approach reduces energy consumption during road construction by 20-35% and decreases the emission of volatile organic compounds (VOCs) by up to 50%, contributing to improved air quality around construction sites.

The renewable nature of montmorillonite as a natural resource presents another sustainability advantage. Unlike petroleum-derived stabilizers, montmorillonite deposits are abundant globally, with estimated reserves sufficient for centuries of continued use at current consumption rates. This abundance reduces supply chain vulnerabilities and associated environmental impacts from long-distance transportation.

End-of-life considerations also favor montmorillonite-stabilized asphalt. These pavements demonstrate enhanced recyclability, with studies showing that up to 95% of montmorillonite-containing asphalt can be effectively reclaimed and reused in new pavement applications. This circular economy approach significantly reduces waste and the demand for virgin materials in road maintenance and reconstruction.

Recent innovations have explored combining montmorillonite with other sustainable materials, such as recycled tire rubber and biobased additives, creating hybrid stabilization systems with even greater environmental benefits. These synergistic formulations have demonstrated promising results in reducing the overall environmental footprint while maintaining or improving pavement performance characteristics.

Performance Testing Standards for Modified Asphalt Emulsions

Performance testing standards for modified asphalt emulsions, particularly those stabilized with montmorillonite, require comprehensive evaluation protocols to ensure consistent quality and performance. The American Society for Testing and Materials (ASTM) and the American Association of State Highway and Transportation Officials (AASHTO) have established several standardized tests specifically designed to assess the effectiveness of modified emulsions.

Storage stability tests (ASTM D6930) are crucial for montmorillonite-modified emulsions, as they evaluate the clay's ability to prevent separation during storage. These tests typically involve storing the emulsion for 24 hours and measuring the difference in residue content between the top and bottom portions. Effective montmorillonite modification should result in minimal separation, with values below 1% indicating excellent stability.

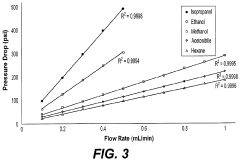

Viscosity testing (ASTM D7226) provides essential information about the flow characteristics of montmorillonite-modified emulsions. The Saybolt Furol viscosity test measures the time required for a specific volume of emulsion to flow through a calibrated orifice at controlled temperatures (typically 25°C or 50°C). Montmorillonite typically increases viscosity, which must be carefully balanced to maintain workability.

Particle charge tests (ASTM D7402) determine whether the emulsion is cationic, anionic, or nonionic—critical information since montmorillonite's effectiveness varies with emulsion type due to its natural negative charge. The test involves immersing electrodes in the emulsion and observing particle migration under an electric field.

Residue testing by evaporation (ASTM D6934) or distillation (ASTM D6997) quantifies the asphalt content in the emulsion and allows for further testing of the recovered binder. For montmorillonite-modified emulsions, the residue should be tested for penetration (ASTM D5), ductility (ASTM D113), and softening point (ASTM D36) to evaluate how the clay affects the binder's physical properties.

Field performance tests include the sweep test (ASTM D7000) for chip seal applications and the wet track abrasion test (ASTM D3910) for slurry seal systems. These tests simulate real-world conditions and are particularly valuable for assessing montmorillonite's contribution to early cohesion development and moisture resistance.

European standards (EN 13808) and international specifications (ISO 4262) provide additional testing frameworks that may be more appropriate for specific applications or regional requirements. These standards often include performance-based specifications rather than recipe-based approaches, allowing for innovation in montmorillonite modification techniques while ensuring consistent end-product performance.

Storage stability tests (ASTM D6930) are crucial for montmorillonite-modified emulsions, as they evaluate the clay's ability to prevent separation during storage. These tests typically involve storing the emulsion for 24 hours and measuring the difference in residue content between the top and bottom portions. Effective montmorillonite modification should result in minimal separation, with values below 1% indicating excellent stability.

Viscosity testing (ASTM D7226) provides essential information about the flow characteristics of montmorillonite-modified emulsions. The Saybolt Furol viscosity test measures the time required for a specific volume of emulsion to flow through a calibrated orifice at controlled temperatures (typically 25°C or 50°C). Montmorillonite typically increases viscosity, which must be carefully balanced to maintain workability.

Particle charge tests (ASTM D7402) determine whether the emulsion is cationic, anionic, or nonionic—critical information since montmorillonite's effectiveness varies with emulsion type due to its natural negative charge. The test involves immersing electrodes in the emulsion and observing particle migration under an electric field.

Residue testing by evaporation (ASTM D6934) or distillation (ASTM D6997) quantifies the asphalt content in the emulsion and allows for further testing of the recovered binder. For montmorillonite-modified emulsions, the residue should be tested for penetration (ASTM D5), ductility (ASTM D113), and softening point (ASTM D36) to evaluate how the clay affects the binder's physical properties.

Field performance tests include the sweep test (ASTM D7000) for chip seal applications and the wet track abrasion test (ASTM D3910) for slurry seal systems. These tests simulate real-world conditions and are particularly valuable for assessing montmorillonite's contribution to early cohesion development and moisture resistance.

European standards (EN 13808) and international specifications (ISO 4262) provide additional testing frameworks that may be more appropriate for specific applications or regional requirements. These standards often include performance-based specifications rather than recipe-based approaches, allowing for innovation in montmorillonite modification techniques while ensuring consistent end-product performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!