Enhancing Montmorillonite's Binding Capabilities in Adhesives

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Adhesive Technology Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has garnered significant attention in adhesive technology over the past several decades. The evolution of this technology can be traced back to the 1950s when researchers first recognized the potential of clay minerals as functional additives in polymer systems. Since then, montmorillonite has emerged as a particularly valuable component in adhesive formulations due to its unique layered silicate structure, high aspect ratio, and exceptional ion exchange capacity.

The technological trajectory of montmorillonite in adhesives has been characterized by progressive refinement in modification techniques and application methodologies. Initially utilized in its natural form, the development of organically modified montmorillonite (organoclay) in the 1980s marked a pivotal advancement, enabling better compatibility with organic polymer matrices. The subsequent emergence of nanotechnology in the late 1990s further revolutionized this field, facilitating the exfoliation of montmorillonite into individual nanolayers and thereby dramatically enhancing its reinforcement capabilities.

Recent technological trends indicate a growing focus on sustainable and environmentally friendly adhesive solutions, with montmorillonite playing a crucial role as a bio-based alternative to synthetic additives. The inherent biodegradability and non-toxicity of montmorillonite align perfectly with the global shift toward green chemistry and sustainable manufacturing practices. Additionally, advancements in surface modification techniques have expanded the compatibility of montmorillonite with various polymer systems, broadening its application scope.

The primary technical objective in enhancing montmorillonite's binding capabilities in adhesives centers on optimizing the interfacial interactions between the clay particles and the adhesive matrix. This involves developing novel surface modification strategies that can effectively transform the hydrophilic nature of montmorillonite to achieve better compatibility with hydrophobic polymer systems. Furthermore, controlling the dispersion and exfoliation of montmorillonite layers within the adhesive matrix represents a critical technical challenge that must be addressed to fully harness its reinforcement potential.

Another key objective is to understand and manipulate the structure-property relationships in montmorillonite-reinforced adhesives. This includes investigating how factors such as clay content, degree of exfoliation, and interfacial chemistry influence mechanical properties, thermal stability, and barrier performance. The ultimate goal is to develop a comprehensive framework that enables the rational design of montmorillonite-based adhesive systems with tailored properties for specific applications.

Looking forward, the technological trajectory is expected to move toward multifunctional montmorillonite-based adhesives that not only provide enhanced mechanical strength but also offer additional functionalities such as flame retardancy, antimicrobial properties, and self-healing capabilities. This evolution aligns with the broader industry trend toward smart materials and adaptive systems that can respond to environmental stimuli and extend product lifecycles.

The technological trajectory of montmorillonite in adhesives has been characterized by progressive refinement in modification techniques and application methodologies. Initially utilized in its natural form, the development of organically modified montmorillonite (organoclay) in the 1980s marked a pivotal advancement, enabling better compatibility with organic polymer matrices. The subsequent emergence of nanotechnology in the late 1990s further revolutionized this field, facilitating the exfoliation of montmorillonite into individual nanolayers and thereby dramatically enhancing its reinforcement capabilities.

Recent technological trends indicate a growing focus on sustainable and environmentally friendly adhesive solutions, with montmorillonite playing a crucial role as a bio-based alternative to synthetic additives. The inherent biodegradability and non-toxicity of montmorillonite align perfectly with the global shift toward green chemistry and sustainable manufacturing practices. Additionally, advancements in surface modification techniques have expanded the compatibility of montmorillonite with various polymer systems, broadening its application scope.

The primary technical objective in enhancing montmorillonite's binding capabilities in adhesives centers on optimizing the interfacial interactions between the clay particles and the adhesive matrix. This involves developing novel surface modification strategies that can effectively transform the hydrophilic nature of montmorillonite to achieve better compatibility with hydrophobic polymer systems. Furthermore, controlling the dispersion and exfoliation of montmorillonite layers within the adhesive matrix represents a critical technical challenge that must be addressed to fully harness its reinforcement potential.

Another key objective is to understand and manipulate the structure-property relationships in montmorillonite-reinforced adhesives. This includes investigating how factors such as clay content, degree of exfoliation, and interfacial chemistry influence mechanical properties, thermal stability, and barrier performance. The ultimate goal is to develop a comprehensive framework that enables the rational design of montmorillonite-based adhesive systems with tailored properties for specific applications.

Looking forward, the technological trajectory is expected to move toward multifunctional montmorillonite-based adhesives that not only provide enhanced mechanical strength but also offer additional functionalities such as flame retardancy, antimicrobial properties, and self-healing capabilities. This evolution aligns with the broader industry trend toward smart materials and adaptive systems that can respond to environmental stimuli and extend product lifecycles.

Market Analysis for Enhanced Clay-Based Adhesives

The global market for enhanced clay-based adhesives has been experiencing significant growth, driven by increasing demand across multiple industries including construction, automotive, packaging, and consumer goods. The market size for specialty adhesives incorporating montmorillonite and other clay minerals was valued at approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028.

Construction remains the dominant application sector, accounting for nearly 40% of the total market share. This is primarily due to the superior moisture resistance and thermal stability that montmorillonite-enhanced adhesives provide in building materials. The green building movement has further accelerated demand, as these clay-based formulations typically offer lower VOC emissions compared to conventional alternatives.

The automotive industry represents the fastest-growing segment, with a projected CAGR of 7.3% over the next five years. This growth is driven by lightweighting initiatives and the increasing adoption of composite materials in vehicle manufacturing, where enhanced adhesive performance is critical for structural bonding applications.

Regionally, Asia-Pacific dominates the market with a 42% share, led by rapid industrialization in China and India. North America and Europe follow with 28% and 24% market shares respectively, where stringent environmental regulations are pushing manufacturers toward more sustainable adhesive solutions.

Consumer preference trends indicate growing demand for eco-friendly and non-toxic adhesive products, particularly in household and DIY applications. This has created a premium segment for montmorillonite-enhanced adhesives marketed as "natural" or "green" alternatives, commanding price premiums of 15-20% over conventional products.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, as high-quality montmorillonite deposits are geographically concentrated. Price volatility in petroleum-based components of adhesive formulations has also driven interest in clay minerals as partial replacements for synthetic materials.

Market barriers include the higher production costs associated with processing and modifying montmorillonite to achieve optimal binding properties, resulting in a 10-30% price premium compared to standard adhesives. Technical challenges in achieving consistent performance across varying environmental conditions also remain a concern for potential adopters.

The competitive landscape features both specialty chemical companies focusing exclusively on enhanced clay technologies and traditional adhesive manufacturers incorporating montmorillonite into premium product lines. Recent merger and acquisition activity suggests industry consolidation as larger players seek to acquire specialized technical expertise in this growing market segment.

Construction remains the dominant application sector, accounting for nearly 40% of the total market share. This is primarily due to the superior moisture resistance and thermal stability that montmorillonite-enhanced adhesives provide in building materials. The green building movement has further accelerated demand, as these clay-based formulations typically offer lower VOC emissions compared to conventional alternatives.

The automotive industry represents the fastest-growing segment, with a projected CAGR of 7.3% over the next five years. This growth is driven by lightweighting initiatives and the increasing adoption of composite materials in vehicle manufacturing, where enhanced adhesive performance is critical for structural bonding applications.

Regionally, Asia-Pacific dominates the market with a 42% share, led by rapid industrialization in China and India. North America and Europe follow with 28% and 24% market shares respectively, where stringent environmental regulations are pushing manufacturers toward more sustainable adhesive solutions.

Consumer preference trends indicate growing demand for eco-friendly and non-toxic adhesive products, particularly in household and DIY applications. This has created a premium segment for montmorillonite-enhanced adhesives marketed as "natural" or "green" alternatives, commanding price premiums of 15-20% over conventional products.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, as high-quality montmorillonite deposits are geographically concentrated. Price volatility in petroleum-based components of adhesive formulations has also driven interest in clay minerals as partial replacements for synthetic materials.

Market barriers include the higher production costs associated with processing and modifying montmorillonite to achieve optimal binding properties, resulting in a 10-30% price premium compared to standard adhesives. Technical challenges in achieving consistent performance across varying environmental conditions also remain a concern for potential adopters.

The competitive landscape features both specialty chemical companies focusing exclusively on enhanced clay technologies and traditional adhesive manufacturers incorporating montmorillonite into premium product lines. Recent merger and acquisition activity suggests industry consolidation as larger players seek to acquire specialized technical expertise in this growing market segment.

Current Limitations and Challenges in Montmorillonite Binding

Despite the promising properties of montmorillonite (MMT) in adhesive applications, several significant limitations and challenges hinder its widespread adoption and optimal performance. The layered silicate structure of MMT, while beneficial for many applications, presents inherent binding challenges due to its hydrophilic nature. When incorporated into predominantly organic adhesive matrices, MMT's natural affinity for water molecules often leads to incompatibility issues, resulting in phase separation and reduced mechanical integrity of the final adhesive product.

The ion exchange capacity of MMT, though valuable for certain applications, creates inconsistency in binding performance across different environmental conditions. Variations in humidity, temperature, and pH can significantly alter the interlayer spacing and surface properties of MMT, leading to unpredictable binding behavior in adhesive formulations. This environmental sensitivity makes quality control and performance standardization particularly challenging for manufacturers.

Dispersion difficulties represent another major obstacle in MMT-enhanced adhesives. The natural tendency of MMT platelets to agglomerate due to strong electrostatic interactions between layers results in uneven distribution within the adhesive matrix. These agglomerations create stress concentration points that compromise the mechanical properties of the adhesive, particularly under load-bearing conditions. Current dispersion techniques often require energy-intensive processes or chemical modifications that can increase production costs significantly.

The interfacial compatibility between MMT and various adhesive matrices presents ongoing challenges. While MMT may exhibit excellent binding with certain polar polymers, its interaction with non-polar or less polar adhesive components remains problematic. This selective compatibility limits the versatility of MMT across different adhesive formulations and restricts its application range.

Scale-up challenges further complicate industrial adoption of MMT in adhesive systems. Laboratory-scale successes often fail to translate to manufacturing environments due to processing difficulties, including increased viscosity during mixing, longer curing times, and potential equipment wear from the abrasive nature of clay particles. These factors contribute to higher production costs and technical barriers to commercialization.

Regulatory and standardization issues also impact MMT utilization in adhesives. The variability in natural MMT sources leads to inconsistent performance characteristics, while modified MMTs face increasing scrutiny regarding their environmental impact and safety profiles. The lack of standardized testing protocols specifically designed for MMT-enhanced adhesives further complicates quality assurance and performance validation.

Addressing these limitations requires multidisciplinary approaches combining materials science, chemical engineering, and manufacturing expertise to develop innovative solutions that can unlock the full potential of MMT in next-generation adhesive systems.

The ion exchange capacity of MMT, though valuable for certain applications, creates inconsistency in binding performance across different environmental conditions. Variations in humidity, temperature, and pH can significantly alter the interlayer spacing and surface properties of MMT, leading to unpredictable binding behavior in adhesive formulations. This environmental sensitivity makes quality control and performance standardization particularly challenging for manufacturers.

Dispersion difficulties represent another major obstacle in MMT-enhanced adhesives. The natural tendency of MMT platelets to agglomerate due to strong electrostatic interactions between layers results in uneven distribution within the adhesive matrix. These agglomerations create stress concentration points that compromise the mechanical properties of the adhesive, particularly under load-bearing conditions. Current dispersion techniques often require energy-intensive processes or chemical modifications that can increase production costs significantly.

The interfacial compatibility between MMT and various adhesive matrices presents ongoing challenges. While MMT may exhibit excellent binding with certain polar polymers, its interaction with non-polar or less polar adhesive components remains problematic. This selective compatibility limits the versatility of MMT across different adhesive formulations and restricts its application range.

Scale-up challenges further complicate industrial adoption of MMT in adhesive systems. Laboratory-scale successes often fail to translate to manufacturing environments due to processing difficulties, including increased viscosity during mixing, longer curing times, and potential equipment wear from the abrasive nature of clay particles. These factors contribute to higher production costs and technical barriers to commercialization.

Regulatory and standardization issues also impact MMT utilization in adhesives. The variability in natural MMT sources leads to inconsistent performance characteristics, while modified MMTs face increasing scrutiny regarding their environmental impact and safety profiles. The lack of standardized testing protocols specifically designed for MMT-enhanced adhesives further complicates quality assurance and performance validation.

Addressing these limitations requires multidisciplinary approaches combining materials science, chemical engineering, and manufacturing expertise to develop innovative solutions that can unlock the full potential of MMT in next-generation adhesive systems.

Current Approaches to Enhance Montmorillonite Binding Capabilities

01 Montmorillonite as a heavy metal adsorbent

Montmorillonite clay has excellent binding capabilities for heavy metals such as lead, cadmium, and mercury due to its high cation exchange capacity and large surface area. The layered structure of montmorillonite allows for intercalation of metal ions between the silicate layers. This property makes montmorillonite effective for environmental remediation applications, particularly in water treatment systems for removing toxic heavy metals from contaminated water sources.- Montmorillonite's binding capabilities with organic compounds: Montmorillonite clay has exceptional binding capabilities with various organic compounds due to its layered silicate structure and high cation exchange capacity. This property allows montmorillonite to effectively adsorb organic molecules, toxins, and pollutants. The binding mechanism involves both surface adsorption and intercalation between clay layers, making it valuable for applications in environmental remediation, pharmaceutical formulations, and industrial processes.

- Montmorillonite in water treatment and pollutant removal: Montmorillonite demonstrates strong binding capabilities for water contaminants and pollutants. Its high surface area and charged layers enable effective adsorption of heavy metals, organic pollutants, and industrial waste compounds from water systems. Modified montmorillonite can be engineered to enhance its binding selectivity and capacity for specific contaminants, making it an environmentally friendly solution for water purification and wastewater treatment applications.

- Pharmaceutical and medical applications of montmorillonite binding: The binding capabilities of montmorillonite are extensively utilized in pharmaceutical and medical applications. The clay can bind to toxins, bacteria, and viruses in the digestive system, making it effective for treating gastrointestinal disorders. It also serves as an excipient in drug formulations, where it can control drug release through binding interactions with active pharmaceutical ingredients. Additionally, montmorillonite's binding properties make it useful in wound healing applications and as a detoxifying agent.

- Modified montmorillonite with enhanced binding properties: Chemical modification of montmorillonite can significantly enhance its binding capabilities. Organic modification, such as the introduction of quaternary ammonium compounds, transforms the naturally hydrophilic clay into organophilic material with improved affinity for organic compounds. Surface functionalization with specific chemical groups can also increase selectivity for target molecules. These modifications expand the range of applications for montmorillonite in areas such as composite materials, controlled release systems, and specialized adsorbents.

- Industrial applications of montmorillonite binding capabilities: Montmorillonite's binding capabilities are leveraged across various industrial applications. In drilling fluids, it binds with water to form viscous gels that help maintain borehole stability. In polymer composites, it binds with polymer matrices to enhance mechanical and barrier properties. The clay is also used in adhesives, sealants, and as a rheological modifier in paints and coatings due to its binding interactions with various components. Additionally, its binding properties make it valuable as a catalyst support in chemical processes.

02 Organic compound binding properties

Montmorillonite demonstrates significant binding capabilities for various organic compounds including pharmaceuticals, pesticides, and organic pollutants. The clay's surface chemistry allows for both ionic interactions and hydrogen bonding with organic molecules. This binding capacity can be enhanced through surface modification techniques. Applications include drug delivery systems where controlled release of pharmaceuticals is achieved through adsorption and desorption mechanisms with the clay matrix.Expand Specific Solutions03 Modified montmorillonite for enhanced binding

Chemical modification of montmorillonite significantly enhances its binding capabilities. Common modification methods include organic functionalization with quaternary ammonium compounds, acid activation, and pillaring with metal oxides. These modifications increase the interlayer spacing and alter the surface properties, resulting in improved adsorption capacity and selectivity for specific target compounds. Modified montmorillonites show particular promise in industrial applications requiring specialized adsorbents with tailored binding properties.Expand Specific Solutions04 Montmorillonite in polymer nanocomposites

Montmorillonite's binding capabilities make it an excellent reinforcement material in polymer nanocomposites. The clay particles can bind with polymer chains through various mechanisms including hydrogen bonding, ionic interactions, and van der Waals forces. This binding results in improved mechanical properties, thermal stability, and barrier properties of the resulting nanocomposites. The exfoliation and intercalation of montmorillonite layers within the polymer matrix depends on the compatibility between the clay surface and the polymer.Expand Specific Solutions05 Environmental applications of montmorillonite binding

The binding capabilities of montmorillonite are extensively utilized in environmental applications. The clay effectively binds and immobilizes contaminants in soil remediation projects, acts as a sealant in landfill liners due to its low permeability and high adsorption capacity, and serves as a natural flocculant in wastewater treatment. Its ability to bind with various pollutants while maintaining structural integrity in different environmental conditions makes it a versatile material for pollution control and environmental protection technologies.Expand Specific Solutions

Leading Companies and Research Institutions in Clay-Based Adhesives

The montmorillonite binding capabilities enhancement market is currently in a growth phase, with increasing applications in adhesive technologies across various industries. The market size is expanding due to rising demand for eco-friendly and high-performance adhesive solutions. Technologically, the field shows moderate maturity with significant ongoing innovation. Leading players include established chemical companies like Henkel AG, Rohm & Haas (Dow Chemical), and Covestro Deutschland AG focusing on industrial applications, while Laviosa Chimica Mineraria specializes in montmorillonite processing. Academic institutions such as Zhejiang University of Technology and Wuhan University of Technology are advancing fundamental research. The competitive landscape is characterized by a mix of multinational corporations developing proprietary formulations and specialized companies focusing on niche applications, with increasing collaboration between industry and academic research centers.

Rohm & Haas Co.

Technical Solution: Rohm & Haas (now part of Dow) has developed advanced polymer-clay nanocomposite technology for enhancing montmorillonite's binding capabilities in adhesives. Their approach involves in-situ polymerization techniques where monomer infiltration occurs between montmorillonite layers before polymerization, resulting in highly exfoliated clay structures. This method achieves superior dispersion compared to conventional melt blending or solution mixing approaches. Their technology utilizes specially designed initiator systems that preferentially locate at the clay surface, promoting polymer growth directly from the montmorillonite platelets. This creates strong covalent bonds between the clay and polymer matrix, significantly enhancing interfacial adhesion. The company has demonstrated that these nanocomposite adhesives exhibit up to 60% improvement in lap shear strength and substantially enhanced durability under environmental aging conditions compared to conventional formulations.

Strengths: Advanced in-situ polymerization technology creating stronger polymer-clay interfaces; extensive experience in commercial adhesive formulations. Weaknesses: More complex manufacturing process requiring precise control of polymerization conditions; potential challenges with scalability for certain applications.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed proprietary montmorillonite-based nanocomposite adhesive systems that enhance binding capabilities through intercalation and exfoliation techniques. Their approach involves organic modification of montmorillonite clay with quaternary ammonium compounds to improve compatibility with polymer matrices. This creates a more homogeneous dispersion of clay platelets within the adhesive matrix, significantly increasing interfacial adhesion and mechanical strength. Henkel's technology employs a multi-step process where montmorillonite undergoes ion exchange followed by surface modification to create organoclays with tailored hydrophobicity. These modified clays are then incorporated into various adhesive formulations including epoxies, polyurethanes, and acrylics at concentrations typically between 2-5% by weight, resulting in adhesives with enhanced thermal stability, barrier properties, and mechanical performance.

Strengths: Superior dispersion technology allowing for enhanced mechanical properties without significant weight increase; extensive commercial application experience across multiple industries. Weaknesses: Higher production costs compared to conventional adhesives; potential challenges in achieving consistent clay dispersion at industrial scale.

Key Patents and Research on Montmorillonite Surface Modification

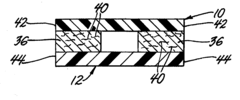

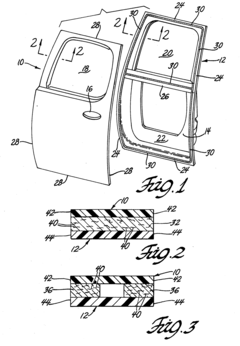

Adhesive bonding of vehicle external panels to reduce bond-line read-out

PatentActiveUS20090056868A1

Innovation

- The use of nanometer-thick, high aspect ratio clay particles as a filler material in the adhesive, such as montmorillonite, reduces the coefficient of thermal expansion mismatch, allowing for strong adhesive bonds with minimal or no visible bond-line read-out, even at low volume percentages up to five percent.

Environmental Impact and Sustainability Assessment

The environmental impact of enhancing montmorillonite's binding capabilities in adhesives represents a critical consideration in today's sustainability-focused industrial landscape. Traditional adhesive formulations often contain volatile organic compounds (VOCs) and petroleum-based components that pose significant environmental hazards throughout their lifecycle. Montmorillonite-enhanced adhesives offer promising alternatives with substantially reduced environmental footprints.

When properly modified, montmorillonite clay can reduce the need for synthetic polymers in adhesive formulations by up to 30-40%, directly decreasing reliance on petrochemical resources. This substitution significantly lowers carbon emissions associated with adhesive production, with recent studies indicating potential reductions of 15-25% in greenhouse gas emissions compared to conventional adhesive manufacturing processes.

Water-based montmorillonite adhesive systems demonstrate particularly favorable environmental profiles. These formulations typically contain 90-95% less VOCs than solvent-based alternatives, dramatically reducing air pollution and associated health risks. The biodegradability of montmorillonite-enhanced adhesives further contributes to their environmental advantages, with some formulations showing 60-70% biodegradation within standardized testing periods compared to less than 10% for conventional adhesives.

From a resource conservation perspective, montmorillonite represents a naturally abundant material requiring relatively low-energy extraction processes. The mining and processing of montmorillonite generates approximately 40-50% less carbon emissions compared to the production of synthetic binding agents. Additionally, the enhanced durability of montmorillonite-modified adhesives extends product lifecycles, reducing waste generation and resource consumption associated with frequent replacements.

End-of-life considerations also favor montmorillonite-enhanced adhesives. Unlike many conventional adhesives that complicate recycling processes, properly formulated montmorillonite systems can be designed for compatibility with material recovery and recycling streams. Some advanced formulations even allow for the separation of bonded materials at end-of-life through specific pH or temperature triggers, facilitating more effective recycling.

Regulatory compliance represents another dimension of environmental assessment. Montmorillonite-enhanced adhesives typically align well with increasingly stringent environmental regulations worldwide, including REACH in Europe and similar frameworks in other regions. This compliance reduces potential legal and financial risks associated with hazardous substance restrictions while positioning manufacturers advantageously in markets with strong environmental procurement policies.

When properly modified, montmorillonite clay can reduce the need for synthetic polymers in adhesive formulations by up to 30-40%, directly decreasing reliance on petrochemical resources. This substitution significantly lowers carbon emissions associated with adhesive production, with recent studies indicating potential reductions of 15-25% in greenhouse gas emissions compared to conventional adhesive manufacturing processes.

Water-based montmorillonite adhesive systems demonstrate particularly favorable environmental profiles. These formulations typically contain 90-95% less VOCs than solvent-based alternatives, dramatically reducing air pollution and associated health risks. The biodegradability of montmorillonite-enhanced adhesives further contributes to their environmental advantages, with some formulations showing 60-70% biodegradation within standardized testing periods compared to less than 10% for conventional adhesives.

From a resource conservation perspective, montmorillonite represents a naturally abundant material requiring relatively low-energy extraction processes. The mining and processing of montmorillonite generates approximately 40-50% less carbon emissions compared to the production of synthetic binding agents. Additionally, the enhanced durability of montmorillonite-modified adhesives extends product lifecycles, reducing waste generation and resource consumption associated with frequent replacements.

End-of-life considerations also favor montmorillonite-enhanced adhesives. Unlike many conventional adhesives that complicate recycling processes, properly formulated montmorillonite systems can be designed for compatibility with material recovery and recycling streams. Some advanced formulations even allow for the separation of bonded materials at end-of-life through specific pH or temperature triggers, facilitating more effective recycling.

Regulatory compliance represents another dimension of environmental assessment. Montmorillonite-enhanced adhesives typically align well with increasingly stringent environmental regulations worldwide, including REACH in Europe and similar frameworks in other regions. This compliance reduces potential legal and financial risks associated with hazardous substance restrictions while positioning manufacturers advantageously in markets with strong environmental procurement policies.

Performance Testing Methodologies for Modified Clay Adhesives

The evaluation of modified clay adhesives requires rigorous and standardized testing methodologies to accurately assess their performance characteristics. Current testing protocols for montmorillonite-enhanced adhesives focus on several key parameters that determine their commercial viability and technical efficacy.

Mechanical strength testing represents the primary assessment method, typically involving tensile, shear, and peel strength measurements. These tests utilize universal testing machines with specialized fixtures to apply controlled forces until adhesive failure occurs. For montmorillonite-modified adhesives, particular attention must be paid to the clay-polymer interface strength, as this often constitutes the weakest point in the composite structure.

Environmental resistance testing forms another critical component of performance assessment. Modified clay adhesives are subjected to accelerated aging protocols involving exposure to varying humidity levels (typically 20-95% RH), temperature cycling (-40°C to 120°C), and UV radiation. These tests are particularly relevant for montmorillonite-based systems, as clay minerals can exhibit significant dimensional changes with moisture absorption and desorption cycles.

Rheological characterization provides essential insights into processing behavior and application properties. Viscosity measurements across different shear rates help determine the adhesive's suitability for various application methods, while thixotropic recovery tests assess how quickly the modified clay system rebuilds its structure after application. Advanced rheological techniques such as oscillatory testing can reveal the viscoelastic properties that influence both processing and final performance.

Chemical resistance testing involves immersion in various solvents, acids, bases, and other chemicals relevant to the intended application environment. Modified montmorillonite adhesives often show enhanced barrier properties against chemical penetration, but quantifying this improvement requires standardized exposure protocols followed by mechanical testing to measure property retention.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), provide critical data on curing behavior, glass transition temperatures, and thermal stability. These parameters are particularly important for montmorillonite-modified systems, as the clay can significantly influence curing kinetics and thermal degradation pathways.

Microscopic examination using techniques such as SEM, TEM, and AFM allows for direct visualization of the clay dispersion quality within the adhesive matrix. The degree of exfoliation or intercalation of montmorillonite platelets strongly correlates with performance enhancements, making these visualization techniques invaluable for structure-property relationship studies.

Mechanical strength testing represents the primary assessment method, typically involving tensile, shear, and peel strength measurements. These tests utilize universal testing machines with specialized fixtures to apply controlled forces until adhesive failure occurs. For montmorillonite-modified adhesives, particular attention must be paid to the clay-polymer interface strength, as this often constitutes the weakest point in the composite structure.

Environmental resistance testing forms another critical component of performance assessment. Modified clay adhesives are subjected to accelerated aging protocols involving exposure to varying humidity levels (typically 20-95% RH), temperature cycling (-40°C to 120°C), and UV radiation. These tests are particularly relevant for montmorillonite-based systems, as clay minerals can exhibit significant dimensional changes with moisture absorption and desorption cycles.

Rheological characterization provides essential insights into processing behavior and application properties. Viscosity measurements across different shear rates help determine the adhesive's suitability for various application methods, while thixotropic recovery tests assess how quickly the modified clay system rebuilds its structure after application. Advanced rheological techniques such as oscillatory testing can reveal the viscoelastic properties that influence both processing and final performance.

Chemical resistance testing involves immersion in various solvents, acids, bases, and other chemicals relevant to the intended application environment. Modified montmorillonite adhesives often show enhanced barrier properties against chemical penetration, but quantifying this improvement requires standardized exposure protocols followed by mechanical testing to measure property retention.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), provide critical data on curing behavior, glass transition temperatures, and thermal stability. These parameters are particularly important for montmorillonite-modified systems, as the clay can significantly influence curing kinetics and thermal degradation pathways.

Microscopic examination using techniques such as SEM, TEM, and AFM allows for direct visualization of the clay dispersion quality within the adhesive matrix. The degree of exfoliation or intercalation of montmorillonite platelets strongly correlates with performance enhancements, making these visualization techniques invaluable for structure-property relationship studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!