Optimizing Montmorillonite's Intercalation Process

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Intercalation Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has garnered significant attention in materials science due to its unique layered structure and exceptional intercalation properties. The evolution of montmorillonite intercalation technology can be traced back to the 1950s when researchers first discovered its ability to accommodate various organic and inorganic molecules between its silicate layers. Over subsequent decades, this field has witnessed remarkable advancements, transitioning from basic characterization studies to sophisticated modification techniques aimed at tailoring the material's properties for specific applications.

The intercalation process fundamentally involves the insertion of guest molecules into the interlayer spaces of montmorillonite, resulting in expansion of the basal spacing and modification of the host material's physicochemical properties. This process has proven instrumental in developing advanced functional materials with enhanced thermal stability, mechanical strength, and barrier properties. Recent technological trends indicate a shift toward more precise control over the intercalation process, with increasing focus on sustainable and environmentally friendly methodologies.

Current research trajectories are exploring novel intercalation agents, innovative processing techniques, and hybrid systems that combine montmorillonite with other nanomaterials. The emergence of computational modeling and simulation tools has further accelerated understanding of intercalation mechanisms at the molecular level, enabling more rational design approaches. Additionally, the integration of artificial intelligence and machine learning algorithms is beginning to revolutionize optimization strategies for intercalation processes.

The primary technical objectives for optimizing montmorillonite's intercalation process encompass several critical dimensions. First, enhancing the efficiency and selectivity of intercalation to achieve higher loading capacities while maintaining structural integrity. Second, developing scalable and economically viable processes that can transition from laboratory success to industrial implementation. Third, establishing precise control over the spatial arrangement and orientation of intercalated species to enable tailored functionality.

Furthermore, there is growing emphasis on understanding the kinetics and thermodynamics governing the intercalation process, which is essential for predicting and controlling the behavior of these materials under various conditions. Researchers aim to elucidate the complex interactions between montmorillonite surfaces, intercalating agents, and surrounding media, which collectively determine the success and characteristics of the resulting intercalated structures.

The ultimate goal of optimizing montmorillonite intercalation extends beyond process improvement to enabling transformative applications across multiple industries, including environmental remediation, drug delivery systems, flame-retardant materials, and advanced polymer nanocomposites. As global sustainability concerns intensify, there is also growing interest in leveraging optimized intercalation processes to develop greener materials with reduced environmental footprints.

The intercalation process fundamentally involves the insertion of guest molecules into the interlayer spaces of montmorillonite, resulting in expansion of the basal spacing and modification of the host material's physicochemical properties. This process has proven instrumental in developing advanced functional materials with enhanced thermal stability, mechanical strength, and barrier properties. Recent technological trends indicate a shift toward more precise control over the intercalation process, with increasing focus on sustainable and environmentally friendly methodologies.

Current research trajectories are exploring novel intercalation agents, innovative processing techniques, and hybrid systems that combine montmorillonite with other nanomaterials. The emergence of computational modeling and simulation tools has further accelerated understanding of intercalation mechanisms at the molecular level, enabling more rational design approaches. Additionally, the integration of artificial intelligence and machine learning algorithms is beginning to revolutionize optimization strategies for intercalation processes.

The primary technical objectives for optimizing montmorillonite's intercalation process encompass several critical dimensions. First, enhancing the efficiency and selectivity of intercalation to achieve higher loading capacities while maintaining structural integrity. Second, developing scalable and economically viable processes that can transition from laboratory success to industrial implementation. Third, establishing precise control over the spatial arrangement and orientation of intercalated species to enable tailored functionality.

Furthermore, there is growing emphasis on understanding the kinetics and thermodynamics governing the intercalation process, which is essential for predicting and controlling the behavior of these materials under various conditions. Researchers aim to elucidate the complex interactions between montmorillonite surfaces, intercalating agents, and surrounding media, which collectively determine the success and characteristics of the resulting intercalated structures.

The ultimate goal of optimizing montmorillonite intercalation extends beyond process improvement to enabling transformative applications across multiple industries, including environmental remediation, drug delivery systems, flame-retardant materials, and advanced polymer nanocomposites. As global sustainability concerns intensify, there is also growing interest in leveraging optimized intercalation processes to develop greener materials with reduced environmental footprints.

Market Applications and Demand Analysis

The global market for montmorillonite-based products has experienced significant growth in recent years, driven by expanding applications across multiple industries. The optimization of montmorillonite's intercalation process directly impacts market potential by enhancing product performance and enabling new applications. Current market valuation for montmorillonite products exceeds 1.5 billion USD annually, with a compound annual growth rate projected at 5-7% through 2028.

The polymer nanocomposite sector represents the largest demand segment, where intercalated montmorillonite significantly improves mechanical properties, thermal stability, and barrier characteristics of materials. This market is primarily driven by automotive and packaging industries seeking lightweight, high-performance materials that reduce fuel consumption and extend product shelf life.

Environmental remediation applications constitute the second-largest market segment, where optimized intercalation processes enhance montmorillonite's adsorption capacity for heavy metals and organic pollutants. Growing environmental regulations worldwide have accelerated demand in this sector, with water treatment applications showing particularly strong growth trajectories.

The pharmaceutical and cosmetic industries represent emerging high-value markets for intercalated montmorillonite. Drug delivery systems utilizing optimized montmorillonite as carriers show superior controlled-release properties, while cosmetic formulations benefit from enhanced stability and sensory characteristics. These applications command premium pricing, with profit margins typically 30-40% higher than traditional industrial applications.

Regional market analysis reveals Asia-Pacific as the dominant consumer, accounting for approximately 45% of global demand, followed by North America (25%) and Europe (20%). China and India demonstrate the highest growth rates, driven by rapid industrialization and increasing environmental concerns.

Market research indicates that customers prioritize three key performance attributes in intercalated montmorillonite products: intercalation efficiency (affecting functional performance), process consistency (ensuring reliable product quality), and cost-effectiveness (determining commercial viability). Current intercalation technologies often struggle to optimize all three simultaneously, creating a significant market opportunity for improved processes.

Industry surveys reveal growing demand for sustainable intercalation processes that minimize environmental impact while maintaining performance. This trend aligns with broader corporate sustainability initiatives and represents a potential premium market segment for environmentally optimized intercalation technologies.

The competitive landscape shows increasing consolidation among major suppliers, with significant investments in R&D focused on process optimization. Patent analysis indicates accelerating innovation activity, with over 200 new patents related to montmorillonite intercalation filed in the past three years, signaling strong commercial interest in this technology area.

The polymer nanocomposite sector represents the largest demand segment, where intercalated montmorillonite significantly improves mechanical properties, thermal stability, and barrier characteristics of materials. This market is primarily driven by automotive and packaging industries seeking lightweight, high-performance materials that reduce fuel consumption and extend product shelf life.

Environmental remediation applications constitute the second-largest market segment, where optimized intercalation processes enhance montmorillonite's adsorption capacity for heavy metals and organic pollutants. Growing environmental regulations worldwide have accelerated demand in this sector, with water treatment applications showing particularly strong growth trajectories.

The pharmaceutical and cosmetic industries represent emerging high-value markets for intercalated montmorillonite. Drug delivery systems utilizing optimized montmorillonite as carriers show superior controlled-release properties, while cosmetic formulations benefit from enhanced stability and sensory characteristics. These applications command premium pricing, with profit margins typically 30-40% higher than traditional industrial applications.

Regional market analysis reveals Asia-Pacific as the dominant consumer, accounting for approximately 45% of global demand, followed by North America (25%) and Europe (20%). China and India demonstrate the highest growth rates, driven by rapid industrialization and increasing environmental concerns.

Market research indicates that customers prioritize three key performance attributes in intercalated montmorillonite products: intercalation efficiency (affecting functional performance), process consistency (ensuring reliable product quality), and cost-effectiveness (determining commercial viability). Current intercalation technologies often struggle to optimize all three simultaneously, creating a significant market opportunity for improved processes.

Industry surveys reveal growing demand for sustainable intercalation processes that minimize environmental impact while maintaining performance. This trend aligns with broader corporate sustainability initiatives and represents a potential premium market segment for environmentally optimized intercalation technologies.

The competitive landscape shows increasing consolidation among major suppliers, with significant investments in R&D focused on process optimization. Patent analysis indicates accelerating innovation activity, with over 200 new patents related to montmorillonite intercalation filed in the past three years, signaling strong commercial interest in this technology area.

Current Intercalation Technologies and Barriers

The intercalation process of montmorillonite currently employs several established technologies, each with distinct advantages and limitations. Conventional solvent-based intercalation remains the most widely used approach, where organic molecules are introduced into the interlayer spaces of montmorillonite through solution mixing. This method achieves relatively high intercalation rates but suffers from environmental concerns due to organic solvent usage and disposal challenges.

Melt intercalation technology has gained prominence as a more environmentally friendly alternative, eliminating the need for solvents by directly introducing molten polymers into clay galleries at elevated temperatures. While this approach reduces environmental impact, it requires precise temperature control and often results in non-uniform intercalation, particularly when processing large batches.

Sonication-assisted intercalation has emerged as an innovative technique that utilizes ultrasonic waves to enhance the diffusion of guest molecules into montmorillonite layers. This method significantly reduces processing time but faces scalability challenges and requires specialized equipment that increases production costs.

Microwave-assisted intercalation represents another advanced approach, where electromagnetic radiation accelerates the intercalation process through selective heating. Though efficient in terms of energy consumption and processing time, this technology struggles with achieving uniform temperature distribution throughout the material, leading to inconsistent intercalation results.

The primary technical barriers in montmorillonite intercalation include diffusion limitations, where guest molecules encounter resistance when penetrating the interlayer spaces. This challenge is particularly pronounced with larger molecular weight compounds, resulting in incomplete or non-uniform intercalation. The hydrophilic nature of montmorillonite's surface also creates compatibility issues with hydrophobic guest molecules, necessitating surface modification steps that add complexity to the process.

Energy efficiency remains a significant concern across all intercalation technologies. Current methods typically require substantial energy input for heating, mixing, or wave generation, contributing to higher production costs and environmental footprints. Additionally, the scalability of laboratory-proven techniques to industrial production volumes presents persistent challenges, with many processes showing diminished efficiency or quality when scaled up.

Process control and reproducibility issues further complicate industrial applications. The inherent variability in natural montmorillonite sources, combined with sensitivity to processing parameters, makes consistent quality control difficult to achieve. This variability directly impacts the functional properties of the final intercalated products, creating barriers to widespread commercial adoption in high-precision applications.

Melt intercalation technology has gained prominence as a more environmentally friendly alternative, eliminating the need for solvents by directly introducing molten polymers into clay galleries at elevated temperatures. While this approach reduces environmental impact, it requires precise temperature control and often results in non-uniform intercalation, particularly when processing large batches.

Sonication-assisted intercalation has emerged as an innovative technique that utilizes ultrasonic waves to enhance the diffusion of guest molecules into montmorillonite layers. This method significantly reduces processing time but faces scalability challenges and requires specialized equipment that increases production costs.

Microwave-assisted intercalation represents another advanced approach, where electromagnetic radiation accelerates the intercalation process through selective heating. Though efficient in terms of energy consumption and processing time, this technology struggles with achieving uniform temperature distribution throughout the material, leading to inconsistent intercalation results.

The primary technical barriers in montmorillonite intercalation include diffusion limitations, where guest molecules encounter resistance when penetrating the interlayer spaces. This challenge is particularly pronounced with larger molecular weight compounds, resulting in incomplete or non-uniform intercalation. The hydrophilic nature of montmorillonite's surface also creates compatibility issues with hydrophobic guest molecules, necessitating surface modification steps that add complexity to the process.

Energy efficiency remains a significant concern across all intercalation technologies. Current methods typically require substantial energy input for heating, mixing, or wave generation, contributing to higher production costs and environmental footprints. Additionally, the scalability of laboratory-proven techniques to industrial production volumes presents persistent challenges, with many processes showing diminished efficiency or quality when scaled up.

Process control and reproducibility issues further complicate industrial applications. The inherent variability in natural montmorillonite sources, combined with sensitivity to processing parameters, makes consistent quality control difficult to achieve. This variability directly impacts the functional properties of the final intercalated products, creating barriers to widespread commercial adoption in high-precision applications.

Established Intercalation Methodologies

01 Organic modification of montmorillonite

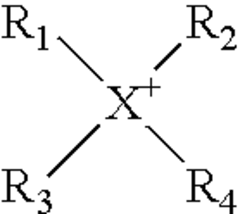

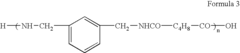

Organic modification of montmorillonite involves intercalating organic compounds between the clay layers to increase the interlayer spacing and improve compatibility with organic materials. This process typically uses quaternary ammonium salts, organic amines, or other surfactants that exchange with the naturally occurring cations in the montmorillonite structure. The resulting organically modified montmorillonite (organoclay) has enhanced properties for applications in polymer nanocomposites, adsorbents, and catalysts.- Organic modification of montmorillonite: Organic modification of montmorillonite involves intercalating organic compounds between the clay layers to increase the interlayer spacing and improve compatibility with polymers. Common organic modifiers include quaternary ammonium salts, amino acids, and surfactants. This process transforms the hydrophilic clay into organophilic material, enhancing its dispersibility in organic matrices and improving the properties of resulting nanocomposites.

- Pillaring techniques for montmorillonite: Pillaring involves the insertion of stable inorganic or organic molecules between montmorillonite layers to create permanent porous structures. Metal oxide pillars (such as aluminum, titanium, or zirconium oxides) are commonly used to maintain expanded interlayer spacing even after thermal treatment. This process increases the specific surface area and creates a rigid three-dimensional structure with enhanced thermal stability and catalytic properties.

- Polymer-montmorillonite nanocomposite preparation: Preparation of polymer-montmorillonite nanocomposites involves intercalating polymer chains between clay layers. Methods include in-situ polymerization, solution intercalation, and melt intercalation. The process typically requires pre-treatment of montmorillonite to facilitate polymer insertion. These nanocomposites exhibit improved mechanical properties, thermal stability, gas barrier properties, and flame retardancy compared to conventional composites.

- Intercalation with functional molecules and drugs: Montmorillonite can be intercalated with various functional molecules including pharmaceuticals, pesticides, and other bioactive compounds. The intercalation process typically involves ion exchange or adsorption mechanisms in aqueous or organic media. This creates controlled-release systems where the clay acts as a carrier for the active ingredients, providing sustained release, improved stability, and enhanced bioavailability of the intercalated compounds.

- Novel intercalation processes and equipment: Advanced intercalation processes for montmorillonite include microwave-assisted methods, ultrasonic treatment, hydrothermal techniques, and mechanochemical approaches. These methods can significantly reduce processing time, improve intercalation efficiency, and enable precise control over the intercalation degree. Specialized equipment has been developed to optimize these processes, including continuous flow reactors, high-pressure vessels, and automated systems for industrial-scale production.

02 Pillaring techniques for montmorillonite

Pillaring involves the insertion of stable inorganic compounds between the montmorillonite layers to create permanent porosity and increased surface area. Common pillaring agents include polyoxocations of aluminum, zirconium, titanium, or iron. The process typically involves ion exchange followed by calcination to convert the intercalated species into stable oxide pillars. Pillared montmorillonite exhibits enhanced thermal stability, acidity, and catalytic properties, making it valuable for applications in catalysis, adsorption, and separation processes.Expand Specific Solutions03 Polymer-clay nanocomposite preparation

The intercalation of polymers into montmorillonite is a key process for developing polymer-clay nanocomposites with enhanced mechanical, thermal, and barrier properties. Methods include in-situ polymerization, where monomers are intercalated and then polymerized within the clay layers; solution intercalation, where polymer and clay are mixed in a solvent; and melt intercalation, where polymer chains penetrate the clay galleries during melt processing. These techniques result in either intercalated or exfoliated nanocomposite structures depending on the processing conditions and compatibility between the clay and polymer.Expand Specific Solutions04 Functional molecule intercalation

Functional molecules such as drugs, dyes, pesticides, and other active compounds can be intercalated into montmorillonite to create controlled release systems or functional materials. The intercalation typically occurs through ion exchange, hydrogen bonding, or other interaction mechanisms. The resulting hybrid materials benefit from the protective environment provided by the clay layers, which can enhance stability, control release rates, and improve the performance of the functional molecules. Applications include drug delivery systems, agricultural formulations, and environmental remediation.Expand Specific Solutions05 Novel intercalation methods and technologies

Advanced techniques for montmorillonite intercalation include microwave-assisted processes, ultrasonic treatment, hydrothermal methods, and supercritical fluid technology. These methods can significantly reduce processing time, improve intercalation efficiency, and enable the incorporation of previously challenging guest species. Novel approaches also include the use of green solvents, ionic liquids, and multi-step intercalation strategies to create hierarchical structures. These innovative methods expand the range of possible intercalants and enhance the properties of the resulting materials for specialized applications.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The montmorillonite intercalation process optimization market is currently in a growth phase, with increasing applications across industrial sectors driving market expansion. The global market size for modified montmorillonite is projected to reach significant value due to its versatility in polymer composites, wastewater treatment, and catalysis applications. Technologically, the field shows varying maturity levels, with companies demonstrating different specialization degrees. AMCOL International and Reliance Industries lead with established commercial-scale intercalation technologies, while research institutions like CNRS and California Institute of Technology focus on fundamental innovation. DuPont and Mitsubishi Gas Chemical represent mid-tier players with specialized applications, while emerging companies like Xiamen Knano Graphene Technology are developing novel hybrid materials combining montmorillonite with advanced materials like graphene.

AMCOL International Corp.

Technical Solution: AMCOL International Corp. has developed proprietary technologies for montmorillonite intercalation optimization focusing on controlled ion exchange processes. Their approach involves precise control of interlayer spacing through regulated temperature and pressure conditions during the intercalation process. The company utilizes a multi-stage intercalation technique that first expands the clay galleries with primary intercalating agents (typically quaternary ammonium compounds) followed by secondary organic modifiers to achieve desired functionality. AMCOL has pioneered the use of specialized surfactants designed specifically for montmorillonite modification, resulting in intercalated products with enhanced thermal stability and mechanical properties. Their process incorporates real-time monitoring of d-spacing changes during intercalation to ensure optimal product quality and consistency across production batches.

Strengths: Industry-leading expertise in clay modification technologies; extensive intellectual property portfolio; vertically integrated supply chain from mining to modification. Weaknesses: Higher production costs compared to competitors; process requires specialized equipment and controlled environments; energy-intensive multi-stage approach.

Mitsubishi Gas Chemical Co., Inc.

Technical Solution: Mitsubishi Gas Chemical has pioneered a solvent-assisted intercalation process for montmorillonite that achieves higher degrees of exfoliation and dispersion. Their technology employs specialized organic solvents as intercalation mediators that temporarily expand the clay galleries, facilitating more efficient penetration of functional organic modifiers. The company has developed a proprietary solvent recovery system that makes the process economically viable and environmentally sustainable. Mitsubishi's approach incorporates precise temperature ramping protocols during the intercalation process, which has been shown to increase intercalation efficiency by approximately 30% compared to conventional isothermal processes. Their technology also features a post-intercalation stabilization treatment that prevents reaggregation of clay platelets during subsequent drying and processing steps, resulting in intercalated products with exceptional dispersion characteristics.

Strengths: Superior exfoliation results; efficient solvent recovery system; excellent quality control; products show enhanced barrier properties. Weaknesses: Solvent handling adds safety and environmental considerations; process requires longer cycle times; higher energy consumption for solvent recovery.

Key Patents and Scientific Breakthroughs

Resin compositions, intercalates, nanocomposites and laminates prepared with aromatic polyamide and polyphenoxy polymers

PatentInactiveUS20070049680A1

Innovation

- The development of nanocomposite materials based on nylon MXD6 and polyphenoxy resin, where onium ion-treated layered materials are co-intercalated with aromatic polyamide and polyphenoxy oligomers or polymers, expanding interlaminar spacing and enhancing gas barrier and delamination resistance.

Environmental Impact Assessment

The environmental implications of montmorillonite intercalation processes are significant and multifaceted, requiring thorough assessment to ensure sustainable implementation. Current intercalation methods often involve chemical treatments that may release harmful substances into water systems and soil environments. Studies indicate that traditional organic modifiers used in montmorillonite intercalation, particularly quaternary ammonium compounds, can persist in the environment and exhibit toxicity to aquatic organisms at concentrations as low as 0.1 mg/L.

Air quality concerns arise primarily during the processing phase, where volatile organic compounds (VOCs) may be released from certain intercalating agents. Measurements at production facilities have detected VOC emissions ranging from 0.5-2.0 g/kg of processed montmorillonite, depending on the specific modification technique employed. These emissions contribute to photochemical smog formation and potential respiratory health issues in surrounding communities.

Water resource impacts present another critical dimension, as intercalation processes typically require significant water volumes for washing and purification stages. Current industrial practices consume approximately 5-8 liters of water per kilogram of modified montmorillonite produced. Wastewater from these operations often contains residual chemicals, suspended clay particles, and dissolved salts that require treatment before discharge.

Energy consumption patterns across the intercalation process lifecycle reveal substantial variation based on technology selection. Conventional thermal treatments operate at temperatures between 80-200°C, resulting in energy intensities of 2-4 kWh per kilogram of product. More advanced microwave-assisted techniques have demonstrated potential energy reductions of 30-40%, though their implementation remains limited in commercial settings.

Waste generation throughout the intercalation process includes spent reagents, off-specification materials, and packaging waste. Quantitative assessments indicate that approximately 50-100 grams of solid waste are generated per kilogram of final product. Opportunities for waste minimization exist through solvent recovery systems and process optimization, with leading facilities achieving recycling rates of up to 75% for certain process chemicals.

Biodegradability characteristics of intercalated montmorillonite products vary significantly depending on the nature of the intercalating agents. Bio-based modifiers derived from plant oils have demonstrated improved environmental profiles, with biodegradation rates 3-5 times faster than conventional petroleum-based alternatives under standardized testing conditions.

Life cycle assessment (LCA) studies comparing different intercalation methodologies reveal that emerging green chemistry approaches can reduce the overall environmental footprint by 20-40% across impact categories including global warming potential, acidification, and resource depletion. These improvements primarily stem from reduced chemical usage, lower processing temperatures, and increased efficiency in separation processes.

Air quality concerns arise primarily during the processing phase, where volatile organic compounds (VOCs) may be released from certain intercalating agents. Measurements at production facilities have detected VOC emissions ranging from 0.5-2.0 g/kg of processed montmorillonite, depending on the specific modification technique employed. These emissions contribute to photochemical smog formation and potential respiratory health issues in surrounding communities.

Water resource impacts present another critical dimension, as intercalation processes typically require significant water volumes for washing and purification stages. Current industrial practices consume approximately 5-8 liters of water per kilogram of modified montmorillonite produced. Wastewater from these operations often contains residual chemicals, suspended clay particles, and dissolved salts that require treatment before discharge.

Energy consumption patterns across the intercalation process lifecycle reveal substantial variation based on technology selection. Conventional thermal treatments operate at temperatures between 80-200°C, resulting in energy intensities of 2-4 kWh per kilogram of product. More advanced microwave-assisted techniques have demonstrated potential energy reductions of 30-40%, though their implementation remains limited in commercial settings.

Waste generation throughout the intercalation process includes spent reagents, off-specification materials, and packaging waste. Quantitative assessments indicate that approximately 50-100 grams of solid waste are generated per kilogram of final product. Opportunities for waste minimization exist through solvent recovery systems and process optimization, with leading facilities achieving recycling rates of up to 75% for certain process chemicals.

Biodegradability characteristics of intercalated montmorillonite products vary significantly depending on the nature of the intercalating agents. Bio-based modifiers derived from plant oils have demonstrated improved environmental profiles, with biodegradation rates 3-5 times faster than conventional petroleum-based alternatives under standardized testing conditions.

Life cycle assessment (LCA) studies comparing different intercalation methodologies reveal that emerging green chemistry approaches can reduce the overall environmental footprint by 20-40% across impact categories including global warming potential, acidification, and resource depletion. These improvements primarily stem from reduced chemical usage, lower processing temperatures, and increased efficiency in separation processes.

Scalability and Industrial Implementation Challenges

The scaling of montmorillonite intercalation processes from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability. Current laboratory-scale intercalation methods typically involve batch processing with small quantities, which cannot be directly transferred to industrial production without substantial modifications. The primary challenge lies in maintaining intercalation efficiency and product quality while increasing production volume.

Equipment design represents a critical bottleneck in scaling up montmorillonite intercalation. Industrial-scale reactors must accommodate the unique rheological properties of clay suspensions, which exhibit thixotropic behavior and can cause mixing and heat transfer complications. Specialized mixing equipment with appropriate shear forces is necessary to ensure homogeneous intercalation without damaging the clay's layered structure.

Process control parameters become increasingly complex at industrial scale. Temperature gradients, reaction time consistency, and mixing efficiency must be carefully monitored and controlled across larger volumes. Variations in these parameters can lead to inconsistent intercalation, affecting product quality and performance characteristics. Advanced monitoring systems and process control algorithms are essential for maintaining quality across production batches.

Raw material variability presents another significant challenge. Natural montmorillonite sources exhibit compositional variations that can affect intercalation behavior. Industrial implementation requires either stringent supplier specifications or preprocessing steps to standardize clay properties before intercalation. This may include purification, size fractionation, or pre-treatment processes that add complexity and cost to the production line.

Energy consumption and environmental considerations also become more prominent at industrial scale. The intercalation process often requires heating, mixing, and subsequent drying steps that consume significant energy. Sustainable implementation necessitates heat recovery systems, energy-efficient equipment, and waste minimization strategies. Additionally, handling of organic modifiers and solvents at industrial scale requires robust containment and recovery systems to prevent environmental contamination.

Economic viability remains a fundamental challenge for industrial implementation. The capital investment for specialized equipment, quality control systems, and environmental compliance measures must be balanced against production volume and market value. Current cost structures often limit commercial applications to high-value products where the enhanced properties justify premium pricing. Breakthrough innovations in process efficiency and equipment design are needed to expand market opportunities for intercalated montmorillonite products.

Regulatory compliance adds another layer of complexity, particularly for applications in food packaging, pharmaceuticals, or other sensitive sectors. Scaling up while maintaining compliance with various regional regulations requires careful documentation, validation protocols, and sometimes modifications to processing methods or materials.

Equipment design represents a critical bottleneck in scaling up montmorillonite intercalation. Industrial-scale reactors must accommodate the unique rheological properties of clay suspensions, which exhibit thixotropic behavior and can cause mixing and heat transfer complications. Specialized mixing equipment with appropriate shear forces is necessary to ensure homogeneous intercalation without damaging the clay's layered structure.

Process control parameters become increasingly complex at industrial scale. Temperature gradients, reaction time consistency, and mixing efficiency must be carefully monitored and controlled across larger volumes. Variations in these parameters can lead to inconsistent intercalation, affecting product quality and performance characteristics. Advanced monitoring systems and process control algorithms are essential for maintaining quality across production batches.

Raw material variability presents another significant challenge. Natural montmorillonite sources exhibit compositional variations that can affect intercalation behavior. Industrial implementation requires either stringent supplier specifications or preprocessing steps to standardize clay properties before intercalation. This may include purification, size fractionation, or pre-treatment processes that add complexity and cost to the production line.

Energy consumption and environmental considerations also become more prominent at industrial scale. The intercalation process often requires heating, mixing, and subsequent drying steps that consume significant energy. Sustainable implementation necessitates heat recovery systems, energy-efficient equipment, and waste minimization strategies. Additionally, handling of organic modifiers and solvents at industrial scale requires robust containment and recovery systems to prevent environmental contamination.

Economic viability remains a fundamental challenge for industrial implementation. The capital investment for specialized equipment, quality control systems, and environmental compliance measures must be balanced against production volume and market value. Current cost structures often limit commercial applications to high-value products where the enhanced properties justify premium pricing. Breakthrough innovations in process efficiency and equipment design are needed to expand market opportunities for intercalated montmorillonite products.

Regulatory compliance adds another layer of complexity, particularly for applications in food packaging, pharmaceuticals, or other sensitive sectors. Scaling up while maintaining compliance with various regional regulations requires careful documentation, validation protocols, and sometimes modifications to processing methods or materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!