How to Improve Montmorillonite's Compatibility with Polymers

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite-Polymer Compatibility Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has garnered significant attention in materials science over the past several decades. Its unique layered silicate structure, high aspect ratio, and exceptional ion exchange capacity make it an attractive candidate for polymer reinforcement. The evolution of montmorillonite-polymer composites can be traced back to the 1950s when researchers first began exploring the potential of clay minerals as fillers in polymer matrices. However, it wasn't until the 1990s that Toyota researchers achieved a breakthrough by developing nylon-clay nanocomposites with dramatically improved mechanical and thermal properties.

The fundamental challenge in creating effective montmorillonite-polymer composites lies in the inherent incompatibility between the hydrophilic clay surfaces and typically hydrophobic polymer matrices. This incompatibility results in poor dispersion and weak interfacial interactions, limiting the potential performance enhancements. The technical evolution in this field has primarily focused on developing effective modification strategies to transform the naturally hydrophilic clay into organophilic materials that can achieve better compatibility with polymers.

Recent technological trends indicate a shift toward more sophisticated and environmentally friendly modification approaches. Traditional organic modifiers like quaternary ammonium compounds are being supplemented or replaced by bio-based modifiers, reactive compatibilizers, and multi-functional modification strategies. Additionally, there is growing interest in leveraging montmorillonite's unique properties for advanced applications beyond simple mechanical reinforcement, including barrier properties, flame retardancy, and controlled release systems.

The primary technical objective in this field is to develop systematic approaches for tailoring montmorillonite's surface chemistry to achieve optimal compatibility with specific polymer matrices. This includes understanding the fundamental mechanisms governing clay-polymer interactions at the molecular level, developing predictive models for compatibility, and establishing structure-property relationships that can guide the design of next-generation composites.

Secondary objectives include enhancing the processing characteristics of montmorillonite-polymer composites, improving the sustainability profile of modification techniques, and expanding the application range of these materials into emerging fields such as flexible electronics, biomedical devices, and energy storage systems. The ultimate goal is to transform montmorillonite from a simple filler to a multifunctional component that can impart a spectrum of enhanced properties to polymer systems while maintaining processability and cost-effectiveness.

The fundamental challenge in creating effective montmorillonite-polymer composites lies in the inherent incompatibility between the hydrophilic clay surfaces and typically hydrophobic polymer matrices. This incompatibility results in poor dispersion and weak interfacial interactions, limiting the potential performance enhancements. The technical evolution in this field has primarily focused on developing effective modification strategies to transform the naturally hydrophilic clay into organophilic materials that can achieve better compatibility with polymers.

Recent technological trends indicate a shift toward more sophisticated and environmentally friendly modification approaches. Traditional organic modifiers like quaternary ammonium compounds are being supplemented or replaced by bio-based modifiers, reactive compatibilizers, and multi-functional modification strategies. Additionally, there is growing interest in leveraging montmorillonite's unique properties for advanced applications beyond simple mechanical reinforcement, including barrier properties, flame retardancy, and controlled release systems.

The primary technical objective in this field is to develop systematic approaches for tailoring montmorillonite's surface chemistry to achieve optimal compatibility with specific polymer matrices. This includes understanding the fundamental mechanisms governing clay-polymer interactions at the molecular level, developing predictive models for compatibility, and establishing structure-property relationships that can guide the design of next-generation composites.

Secondary objectives include enhancing the processing characteristics of montmorillonite-polymer composites, improving the sustainability profile of modification techniques, and expanding the application range of these materials into emerging fields such as flexible electronics, biomedical devices, and energy storage systems. The ultimate goal is to transform montmorillonite from a simple filler to a multifunctional component that can impart a spectrum of enhanced properties to polymer systems while maintaining processability and cost-effectiveness.

Market Analysis for Montmorillonite-Polymer Nanocomposites

The global market for montmorillonite-polymer nanocomposites has experienced significant growth over the past decade, driven by increasing demand for high-performance materials across multiple industries. The current market size is estimated at approximately 3.5 billion USD, with a compound annual growth rate (CAGR) of 7.2% projected through 2028. This growth trajectory is supported by expanding applications in automotive, packaging, construction, and electronics sectors.

Packaging represents the largest application segment, accounting for roughly 32% of the total market share. The demand for lightweight, durable, and barrier-enhanced packaging materials continues to drive adoption of montmorillonite-polymer nanocomposites, particularly in food packaging where extended shelf life is a critical requirement. The automotive sector follows closely at 27% market share, where weight reduction and mechanical strength improvements remain key drivers.

Regional analysis reveals Asia-Pacific as the dominant market, representing 41% of global consumption, with China and India leading manufacturing and consumption. North America and Europe collectively account for 48% of the market, with stronger focus on high-value applications in aerospace and medical devices. The Middle East and Latin America regions show promising growth potential, albeit from smaller base values.

Key market drivers include increasingly stringent environmental regulations promoting lightweight materials for fuel efficiency, growing consumer preference for sustainable packaging solutions, and continuous industrial demand for materials with enhanced mechanical and thermal properties. The push toward circular economy principles has also accelerated interest in biodegradable polymer nanocomposites, creating a specialized high-growth subsegment.

Market challenges primarily revolve around processing difficulties, cost considerations, and inconsistent quality of montmorillonite sources. The price premium for nanocomposites remains a barrier for mass adoption in cost-sensitive applications, though this gap is narrowing as production technologies mature and economies of scale improve.

Customer segmentation reveals three distinct market tiers: high-performance specialized applications commanding premium pricing (aerospace, medical), mid-tier industrial applications with balanced performance-cost requirements (automotive, industrial equipment), and mass-market applications where cost sensitivity is highest (consumer goods, general packaging).

Future market expansion is expected in emerging applications such as 3D printing materials, smart packaging with embedded sensors, and advanced filtration systems. The growing focus on sustainability is likely to accelerate development of bio-based polymer matrices compatible with montmorillonite, potentially opening new market segments worth an estimated 500 million USD by 2030.

Packaging represents the largest application segment, accounting for roughly 32% of the total market share. The demand for lightweight, durable, and barrier-enhanced packaging materials continues to drive adoption of montmorillonite-polymer nanocomposites, particularly in food packaging where extended shelf life is a critical requirement. The automotive sector follows closely at 27% market share, where weight reduction and mechanical strength improvements remain key drivers.

Regional analysis reveals Asia-Pacific as the dominant market, representing 41% of global consumption, with China and India leading manufacturing and consumption. North America and Europe collectively account for 48% of the market, with stronger focus on high-value applications in aerospace and medical devices. The Middle East and Latin America regions show promising growth potential, albeit from smaller base values.

Key market drivers include increasingly stringent environmental regulations promoting lightweight materials for fuel efficiency, growing consumer preference for sustainable packaging solutions, and continuous industrial demand for materials with enhanced mechanical and thermal properties. The push toward circular economy principles has also accelerated interest in biodegradable polymer nanocomposites, creating a specialized high-growth subsegment.

Market challenges primarily revolve around processing difficulties, cost considerations, and inconsistent quality of montmorillonite sources. The price premium for nanocomposites remains a barrier for mass adoption in cost-sensitive applications, though this gap is narrowing as production technologies mature and economies of scale improve.

Customer segmentation reveals three distinct market tiers: high-performance specialized applications commanding premium pricing (aerospace, medical), mid-tier industrial applications with balanced performance-cost requirements (automotive, industrial equipment), and mass-market applications where cost sensitivity is highest (consumer goods, general packaging).

Future market expansion is expected in emerging applications such as 3D printing materials, smart packaging with embedded sensors, and advanced filtration systems. The growing focus on sustainability is likely to accelerate development of bio-based polymer matrices compatible with montmorillonite, potentially opening new market segments worth an estimated 500 million USD by 2030.

Technical Barriers in Montmorillonite-Polymer Integration

Despite the promising applications of montmorillonite (MMT) in polymer composites, several significant technical barriers impede the effective integration of these materials. The primary challenge stems from the inherent hydrophilic nature of montmorillonite, which contrasts sharply with the hydrophobic character of most polymers. This fundamental incompatibility creates weak interfacial interactions between the clay and polymer matrix, resulting in poor dispersion and diminished mechanical properties in the final composite.

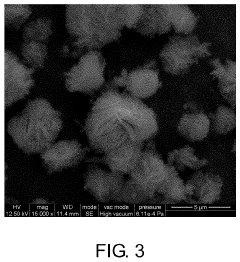

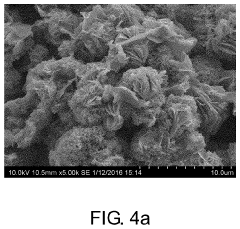

The layered silicate structure of montmorillonite presents another substantial obstacle. These clay platelets naturally stack together through strong electrostatic forces and van der Waals interactions, forming tactoids or agglomerates. Breaking down these structures to achieve exfoliation—where individual clay layers are completely separated and dispersed throughout the polymer matrix—remains technically challenging. Partial exfoliation or intercalation is more commonly achieved, but this limits the full potential of property enhancement.

Processing difficulties further complicate montmorillonite-polymer integration. The high viscosity that develops when clay is added to polymer melts creates processing challenges during extrusion or injection molding. This increased viscosity can lead to equipment wear, longer processing times, and potential thermal degradation of the polymer matrix due to the higher shear forces and temperatures required.

Thermal stability mismatches between montmorillonite and polymers represent another significant barrier. While montmorillonite exhibits excellent thermal stability, the organic modifiers commonly used to improve its compatibility with polymers often degrade at processing temperatures typical for many engineering polymers. This degradation can compromise the composite's properties and release undesirable byproducts.

The variability in montmorillonite composition and quality from different sources introduces inconsistency in composite performance. Natural montmorillonite contains various impurities and exhibits batch-to-batch variations in cation exchange capacity, layer charge density, and particle size distribution, making standardization difficult.

Scale-up challenges persist when transitioning from laboratory-scale to industrial production. Techniques that work effectively at small scales, such as solution blending, often become economically or technically unfeasible at commercial scales. Alternative methods like melt intercalation may not achieve the same level of dispersion quality.

Long-term stability issues also plague montmorillonite-polymer composites. Environmental factors such as moisture, UV radiation, and temperature fluctuations can degrade the interface between the clay and polymer over time, potentially leading to property deterioration during the service life of the composite material.

The layered silicate structure of montmorillonite presents another substantial obstacle. These clay platelets naturally stack together through strong electrostatic forces and van der Waals interactions, forming tactoids or agglomerates. Breaking down these structures to achieve exfoliation—where individual clay layers are completely separated and dispersed throughout the polymer matrix—remains technically challenging. Partial exfoliation or intercalation is more commonly achieved, but this limits the full potential of property enhancement.

Processing difficulties further complicate montmorillonite-polymer integration. The high viscosity that develops when clay is added to polymer melts creates processing challenges during extrusion or injection molding. This increased viscosity can lead to equipment wear, longer processing times, and potential thermal degradation of the polymer matrix due to the higher shear forces and temperatures required.

Thermal stability mismatches between montmorillonite and polymers represent another significant barrier. While montmorillonite exhibits excellent thermal stability, the organic modifiers commonly used to improve its compatibility with polymers often degrade at processing temperatures typical for many engineering polymers. This degradation can compromise the composite's properties and release undesirable byproducts.

The variability in montmorillonite composition and quality from different sources introduces inconsistency in composite performance. Natural montmorillonite contains various impurities and exhibits batch-to-batch variations in cation exchange capacity, layer charge density, and particle size distribution, making standardization difficult.

Scale-up challenges persist when transitioning from laboratory-scale to industrial production. Techniques that work effectively at small scales, such as solution blending, often become economically or technically unfeasible at commercial scales. Alternative methods like melt intercalation may not achieve the same level of dispersion quality.

Long-term stability issues also plague montmorillonite-polymer composites. Environmental factors such as moisture, UV radiation, and temperature fluctuations can degrade the interface between the clay and polymer over time, potentially leading to property deterioration during the service life of the composite material.

Current Surface Modification Approaches for Montmorillonite

01 Montmorillonite compatibility with polymers

Montmorillonite clay can be effectively incorporated into various polymer matrices to create nanocomposites with enhanced properties. The compatibility between montmorillonite and polymers can be improved through surface modification of the clay particles, such as organic treatment or functionalization. These modifications help to reduce the hydrophilicity of montmorillonite and increase its affinity for polymer matrices, resulting in better dispersion and stronger interfacial interactions.- Compatibility with polymers and resins: Montmorillonite clay can be effectively incorporated into various polymer and resin systems to create nanocomposites with enhanced properties. The compatibility between montmorillonite and polymers can be improved through surface modification of the clay particles, such as organic treatment or functionalization. These modifications help to reduce the hydrophilicity of montmorillonite and improve its dispersion in hydrophobic polymer matrices, resulting in better mechanical properties, thermal stability, and barrier performance of the final composite materials.

- Compatibility with pharmaceutical and cosmetic formulations: Montmorillonite demonstrates good compatibility with various pharmaceutical and cosmetic ingredients, making it suitable for use in drug delivery systems, topical formulations, and personal care products. The clay can act as a stabilizer, thickener, or active ingredient carrier in these formulations. Its ability to adsorb toxins, control release of active ingredients, and provide rheological properties makes it valuable in pharmaceutical and cosmetic applications, though compatibility with specific active ingredients must be evaluated on a case-by-case basis.

- Compatibility with water treatment systems: Montmorillonite shows excellent compatibility with water treatment processes and can be used as an effective adsorbent for removing contaminants from water. The clay's high cation exchange capacity and large surface area allow it to adsorb heavy metals, organic pollutants, and other impurities. Modified montmorillonite can be incorporated into filtration systems, membranes, or used as a flocculant in water purification processes, demonstrating good compatibility with existing water treatment infrastructure and chemicals.

- Compatibility with agricultural applications: Montmorillonite exhibits compatibility with various agricultural inputs and can be used in soil amendment, pesticide formulations, and controlled-release fertilizers. The clay can improve soil structure, water retention, and nutrient availability. When used in pesticide formulations, montmorillonite can act as a carrier for active ingredients, providing controlled release and reducing environmental impact. Its natural origin and biodegradability make it compatible with sustainable agricultural practices and organic farming systems.

- Compatibility enhancement through surface modification: The compatibility of montmorillonite with various matrices can be significantly improved through surface modification techniques. These include organic modification with quaternary ammonium compounds, silane coupling agents, or polymer grafting. Such modifications alter the surface properties of montmorillonite from hydrophilic to hydrophobic or organophilic, enhancing its compatibility with organic phases. Modified montmorillonite shows improved dispersion in polymers, better rheological properties in formulations, and enhanced adsorption capabilities for specific applications.

02 Montmorillonite in pharmaceutical and cosmetic formulations

Montmorillonite demonstrates good compatibility with various pharmaceutical and cosmetic ingredients, making it suitable for use in drug delivery systems and personal care products. Its high adsorption capacity allows it to interact with active ingredients while maintaining stability in formulations. The clay can be used as a carrier for drugs or active cosmetic ingredients, providing controlled release properties and improving the overall efficacy of the formulation.Expand Specific Solutions03 Montmorillonite compatibility with water treatment systems

Montmorillonite shows excellent compatibility with water treatment systems due to its ion exchange properties and high surface area. It can effectively remove contaminants such as heavy metals, organic pollutants, and microorganisms from water. The clay can be modified to enhance its adsorption capacity and selectivity for specific contaminants, making it a versatile material for various water purification applications.Expand Specific Solutions04 Montmorillonite compatibility with agricultural products

Montmorillonite demonstrates good compatibility with agricultural products and can be used as a carrier for pesticides, fertilizers, and other agrochemicals. The clay's layered structure allows for the intercalation of active ingredients, providing controlled release properties and protecting them from degradation. This compatibility enhances the efficacy of agricultural products while reducing their environmental impact.Expand Specific Solutions05 Montmorillonite in barrier and sealing applications

Montmorillonite shows excellent compatibility with various materials used in barrier and sealing applications. Its swelling properties in the presence of water make it effective for creating impermeable barriers. The clay can be incorporated into geosynthetic clay liners, concrete, and other construction materials to enhance their sealing properties. Modified montmorillonite can also improve the barrier properties of packaging materials against gases, moisture, and other permeants.Expand Specific Solutions

Leading Companies in Clay-Polymer Nanocomposite Industry

The montmorillonite-polymer compatibility market is in a growth phase, with increasing demand driven by polymer nanocomposite applications across automotive, packaging, and construction industries. Market size is expanding as industries seek enhanced material properties and sustainability solutions. Technologically, the field shows moderate maturity with ongoing innovation. Leading companies like BASF SE, ExxonMobil Chemical, and LG Chem are developing advanced surface modification techniques, while academic institutions such as South China University of Technology and University of Akron contribute fundamental research. Specialized players like Laviosa Chimica Mineraria focus on clay mineral functionalization, while polymer manufacturers including Arkema France and Kingfa Sci. & Tech. are developing compatible polymer matrices for improved dispersion and interfacial adhesion.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical has developed sophisticated technologies for enhancing montmorillonite-polymer compatibility, particularly focused on polyolefin nanocomposites. Their approach centers on a multi-stage modification process that transforms the naturally hydrophilic clay into organophilic materials highly compatible with non-polar polymers. ExxonMobil's primary innovation involves the use of specially designed surfactant packages containing quaternary ammonium compounds with optimized alkyl chain lengths and distributions. These surfactants effectively increase the clay's interlayer spacing while providing sufficient hydrophobicity for polymer intercalation. Their technology also incorporates functionalized polyolefin compatibilizers, particularly maleic anhydride grafted polyethylene and polypropylene, which serve as interfacial agents between the modified clay and polymer matrix. ExxonMobil has further refined their approach by developing in-situ polymerization techniques where metallocene catalysts are immobilized on modified montmorillonite surfaces, enabling exceptional clay exfoliation during polymerization. This results in nanocomposites with superior mechanical properties and enhanced barrier characteristics. Additionally, their process includes specialized thermal treatment steps that improve the thermal stability of organically modified montmorillonite, addressing a common limitation in high-temperature processing applications.

Strengths: ExxonMobil's technology provides exceptional compatibility with polyolefins, which traditionally have poor interaction with clay fillers. Their in-situ polymerization approach achieves superior clay exfoliation and distribution throughout the polymer matrix. The modified clays show improved thermal stability during high-temperature processing. Weaknesses: The multi-stage modification process can be complex and costly for large-scale implementation. Some specialized compatibilizers and catalysts may add significant cost to the final product.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced technologies for improving montmorillonite-polymer compatibility through a multi-faceted approach. Their primary innovation involves a proprietary organic modification process using specially designed intercalating agents with varying polarity and chain length to match specific polymer matrices. Sinopec's research has focused on developing montmorillonite modifications tailored for polyolefins, which are traditionally difficult to compatibilize with clay due to their non-polar nature. Their technology employs a combination of quaternary ammonium compounds with oligomeric compatibilizers that create a gradient interface between the clay and polymer. Additionally, Sinopec has pioneered solvent-free modification methods that reduce environmental impact while maintaining high efficiency. Their process includes controlled ion-exchange reactions followed by specialized drying and milling procedures that preserve the modified clay's structure and prevent reagglomeration. Sinopec has also developed in-situ polymerization techniques where modified montmorillonite serves as a catalyst support, enabling exceptional clay dispersion in the resulting nanocomposites.

Strengths: Sinopec's technology offers excellent compatibility with a wide range of polymers, particularly polyolefins that traditionally have poor interaction with clay fillers. Their solvent-free approach provides environmental benefits and cost savings in industrial applications. Weaknesses: The process requires sophisticated equipment for precise control of modification parameters. Some specialized intercalating agents used in their technology may have limited availability and higher costs compared to conventional modifiers.

Key Patents in Montmorillonite Compatibility Enhancement

Polyisobutylene-based polyurethanes containing organically modified montmorillonite

PatentWO2014018509A1

Innovation

- The use of organic quaternary ammonium salts with less acidic -NR3+ groups, such as trimethyl-1-propyl amine ammonium iodide, for electrostatic attachment to OmMMT, allowing the -NH2 group to react with isocyanates and act as a chain extender, ensuring the clay's exfoliation and integral incorporation into the polyurethane molecule.

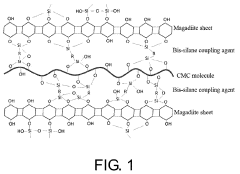

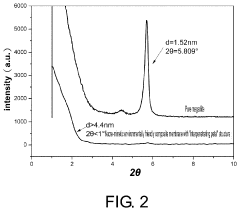

Nacre-mimetic environmentally friendly composite membrane with "interpenetrating petal" structure and preparation method therefor

PatentInactiveUS20190345264A1

Innovation

- A nacre-mimetic composite membrane with an 'interpenetrating petal' structure is developed using magadiite as the hard phase, carboxymethyl cellulose (CMC) as the soft phase, and a bis-silane coupling agent to enhance interfacial bonding and stress distribution, forming a stable and balanced internal stress state.

Environmental Impact of Modified Montmorillonite Materials

The modification of montmorillonite for polymer compatibility raises significant environmental considerations that must be addressed in any comprehensive technical assessment. The environmental impact of modified montmorillonite materials spans their entire lifecycle, from raw material extraction to end-of-life disposal or recycling.

During the production phase, traditional modification methods often employ quaternary ammonium compounds and other organic modifiers that can be environmentally problematic. These compounds may release volatile organic compounds (VOCs) during processing, contributing to air pollution and potential health hazards for workers. Additionally, the chemical modification processes frequently involve organic solvents that require proper handling and disposal to prevent environmental contamination.

Water usage and wastewater management represent another critical environmental concern. The purification and modification of montmorillonite typically requires substantial water resources, and the resulting wastewater may contain residual chemicals that require treatment before discharge. Companies implementing greener modification techniques have reported 30-40% reductions in water consumption compared to conventional methods.

The environmental benefits of successfully modified montmorillonite-polymer composites must also be considered. These materials often enable the production of lighter-weight components with enhanced properties, potentially reducing fuel consumption in transportation applications. Studies indicate that vehicles incorporating montmorillonite-polymer composites can achieve 5-8% improvements in fuel efficiency due to weight reduction.

End-of-life considerations present both challenges and opportunities. While unmodified montmorillonite is naturally biodegradable, chemical modifications may alter this property, potentially extending environmental persistence. Research indicates that certain organic modifiers can significantly slow biodegradation rates, with some modified clays showing less than 10% degradation after standard composting periods where unmodified clays would substantially decompose.

Recent innovations focus on developing environmentally benign modification approaches, including the use of bio-based modifiers derived from renewable resources. These green alternatives, such as modified starches and cellulose derivatives, have demonstrated promising compatibility results while reducing environmental footprint. Life cycle assessments show that bio-based modification routes can reduce carbon footprint by 40-60% compared to conventional organo-modification techniques.

Regulatory frameworks increasingly influence modification strategies, with restrictions on certain chemical modifiers driving research toward more sustainable alternatives. The development of environmentally responsible modification technologies represents not only a technical challenge but also a market opportunity as industries increasingly prioritize sustainable material solutions.

During the production phase, traditional modification methods often employ quaternary ammonium compounds and other organic modifiers that can be environmentally problematic. These compounds may release volatile organic compounds (VOCs) during processing, contributing to air pollution and potential health hazards for workers. Additionally, the chemical modification processes frequently involve organic solvents that require proper handling and disposal to prevent environmental contamination.

Water usage and wastewater management represent another critical environmental concern. The purification and modification of montmorillonite typically requires substantial water resources, and the resulting wastewater may contain residual chemicals that require treatment before discharge. Companies implementing greener modification techniques have reported 30-40% reductions in water consumption compared to conventional methods.

The environmental benefits of successfully modified montmorillonite-polymer composites must also be considered. These materials often enable the production of lighter-weight components with enhanced properties, potentially reducing fuel consumption in transportation applications. Studies indicate that vehicles incorporating montmorillonite-polymer composites can achieve 5-8% improvements in fuel efficiency due to weight reduction.

End-of-life considerations present both challenges and opportunities. While unmodified montmorillonite is naturally biodegradable, chemical modifications may alter this property, potentially extending environmental persistence. Research indicates that certain organic modifiers can significantly slow biodegradation rates, with some modified clays showing less than 10% degradation after standard composting periods where unmodified clays would substantially decompose.

Recent innovations focus on developing environmentally benign modification approaches, including the use of bio-based modifiers derived from renewable resources. These green alternatives, such as modified starches and cellulose derivatives, have demonstrated promising compatibility results while reducing environmental footprint. Life cycle assessments show that bio-based modification routes can reduce carbon footprint by 40-60% compared to conventional organo-modification techniques.

Regulatory frameworks increasingly influence modification strategies, with restrictions on certain chemical modifiers driving research toward more sustainable alternatives. The development of environmentally responsible modification technologies represents not only a technical challenge but also a market opportunity as industries increasingly prioritize sustainable material solutions.

Scale-up Challenges for Industrial Applications

The transition from laboratory-scale experiments to industrial production represents a significant hurdle in the commercialization of montmorillonite-polymer composites. While small-scale experiments can demonstrate proof of concept, industrial applications require consistent quality, cost-effectiveness, and reproducibility across large production volumes.

One of the primary scale-up challenges is maintaining uniform dispersion of montmorillonite in polymer matrices during mass production. Laboratory methods often involve careful, time-intensive processes that ensure optimal clay exfoliation and distribution. However, these methods may not be feasible in industrial settings where processing times are significantly shorter and equipment configurations differ substantially from laboratory setups.

Processing equipment compatibility presents another major obstacle. Industrial extruders, injection molding machines, and other polymer processing equipment operate under different shear conditions and residence times compared to laboratory equipment. These differences can significantly impact the intercalation and exfoliation behavior of montmorillonite in polymer matrices, potentially reducing the effectiveness of compatibility treatments that worked well at smaller scales.

Quality control and consistency become increasingly difficult as production volumes increase. Variations in raw material properties, particularly in natural montmorillonite sources, can lead to inconsistent performance in the final composite products. Establishing robust quality control protocols that can detect and compensate for these variations is essential for successful industrial implementation.

Cost considerations also intensify during scale-up. Surface modification agents and compatibility enhancers that are economically viable in laboratory settings may become prohibitively expensive when applied to industrial quantities. Finding cost-effective alternatives or optimizing the efficiency of existing treatments becomes crucial for commercial viability.

Environmental and safety concerns emerge more prominently at industrial scales. Some organic modifiers used to enhance montmorillonite-polymer compatibility may pose health or environmental risks when handled in large quantities. Regulatory compliance and worker safety protocols must be developed specifically for industrial-scale operations.

Energy consumption during processing represents another scale-up challenge. The high viscosity of polymer-clay composites often requires more energy for mixing and extrusion compared to unmodified polymers. Optimizing processing parameters to reduce energy requirements while maintaining product quality becomes essential for sustainable industrial production.

One of the primary scale-up challenges is maintaining uniform dispersion of montmorillonite in polymer matrices during mass production. Laboratory methods often involve careful, time-intensive processes that ensure optimal clay exfoliation and distribution. However, these methods may not be feasible in industrial settings where processing times are significantly shorter and equipment configurations differ substantially from laboratory setups.

Processing equipment compatibility presents another major obstacle. Industrial extruders, injection molding machines, and other polymer processing equipment operate under different shear conditions and residence times compared to laboratory equipment. These differences can significantly impact the intercalation and exfoliation behavior of montmorillonite in polymer matrices, potentially reducing the effectiveness of compatibility treatments that worked well at smaller scales.

Quality control and consistency become increasingly difficult as production volumes increase. Variations in raw material properties, particularly in natural montmorillonite sources, can lead to inconsistent performance in the final composite products. Establishing robust quality control protocols that can detect and compensate for these variations is essential for successful industrial implementation.

Cost considerations also intensify during scale-up. Surface modification agents and compatibility enhancers that are economically viable in laboratory settings may become prohibitively expensive when applied to industrial quantities. Finding cost-effective alternatives or optimizing the efficiency of existing treatments becomes crucial for commercial viability.

Environmental and safety concerns emerge more prominently at industrial scales. Some organic modifiers used to enhance montmorillonite-polymer compatibility may pose health or environmental risks when handled in large quantities. Regulatory compliance and worker safety protocols must be developed specifically for industrial-scale operations.

Energy consumption during processing represents another scale-up challenge. The high viscosity of polymer-clay composites often requires more energy for mixing and extrusion compared to unmodified polymers. Optimizing processing parameters to reduce energy requirements while maintaining product quality becomes essential for sustainable industrial production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!