Breakthroughs in Half Wave Rectifier Efficiency Standards

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Evolution and Objectives

Half wave rectifiers have been a fundamental component in electrical engineering since the early days of electronics. The evolution of these devices has been closely tied to the advancement of semiconductor technology and the growing demand for more efficient power conversion systems. Initially developed using vacuum tube diodes, half wave rectifiers saw a significant leap forward with the introduction of solid-state semiconductor diodes in the mid-20th century.

The primary objective of half wave rectifier technology has always been to convert alternating current (AC) to pulsating direct current (DC). However, as power electronics applications have become more sophisticated, the goals for half wave rectifiers have expanded to include improved efficiency, reduced power loss, and enhanced reliability. These objectives have driven continuous innovation in materials, circuit design, and manufacturing processes.

One of the key milestones in half wave rectifier evolution was the development of silicon diodes, which offered better performance and reliability compared to their germanium predecessors. This breakthrough allowed for higher voltage and current handling capabilities, expanding the range of applications for half wave rectifiers. Subsequently, the introduction of Schottky diodes further improved efficiency by reducing forward voltage drop and reverse recovery time.

In recent years, the focus has shifted towards addressing the inherent limitations of half wave rectifiers, particularly their relatively low efficiency compared to full wave rectifiers. Research efforts have been directed at minimizing conduction losses, improving thermal management, and developing novel circuit topologies to enhance overall system performance. The emergence of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has opened new avenues for pushing the efficiency boundaries of half wave rectifiers.

The objectives for modern half wave rectifier technology extend beyond mere AC to DC conversion. Current research aims to integrate smart features, such as adaptive control mechanisms and self-diagnostic capabilities, to optimize performance under varying load conditions. Additionally, there is a growing emphasis on miniaturization and integration, driven by the need for compact power solutions in portable and wearable devices.

As we look towards the future, the evolution of half wave rectifiers is likely to be influenced by broader trends in power electronics, including the push for higher power density, improved electromagnetic compatibility, and enhanced sustainability. The development of new materials and advanced manufacturing techniques, such as 3D printing of electronic components, may lead to novel half wave rectifier designs with unprecedented efficiency and functionality.

The primary objective of half wave rectifier technology has always been to convert alternating current (AC) to pulsating direct current (DC). However, as power electronics applications have become more sophisticated, the goals for half wave rectifiers have expanded to include improved efficiency, reduced power loss, and enhanced reliability. These objectives have driven continuous innovation in materials, circuit design, and manufacturing processes.

One of the key milestones in half wave rectifier evolution was the development of silicon diodes, which offered better performance and reliability compared to their germanium predecessors. This breakthrough allowed for higher voltage and current handling capabilities, expanding the range of applications for half wave rectifiers. Subsequently, the introduction of Schottky diodes further improved efficiency by reducing forward voltage drop and reverse recovery time.

In recent years, the focus has shifted towards addressing the inherent limitations of half wave rectifiers, particularly their relatively low efficiency compared to full wave rectifiers. Research efforts have been directed at minimizing conduction losses, improving thermal management, and developing novel circuit topologies to enhance overall system performance. The emergence of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has opened new avenues for pushing the efficiency boundaries of half wave rectifiers.

The objectives for modern half wave rectifier technology extend beyond mere AC to DC conversion. Current research aims to integrate smart features, such as adaptive control mechanisms and self-diagnostic capabilities, to optimize performance under varying load conditions. Additionally, there is a growing emphasis on miniaturization and integration, driven by the need for compact power solutions in portable and wearable devices.

As we look towards the future, the evolution of half wave rectifiers is likely to be influenced by broader trends in power electronics, including the push for higher power density, improved electromagnetic compatibility, and enhanced sustainability. The development of new materials and advanced manufacturing techniques, such as 3D printing of electronic components, may lead to novel half wave rectifier designs with unprecedented efficiency and functionality.

Market Demand Analysis for Efficient Rectifiers

The market demand for efficient rectifiers, particularly half-wave rectifiers, has been steadily increasing across various industries. This growth is primarily driven by the rising need for energy-efficient power conversion solutions in electronic devices, renewable energy systems, and industrial applications. The global power electronics market, which includes rectifiers, is projected to reach a substantial market value in the coming years, with efficient rectifiers playing a crucial role in this expansion.

In the consumer electronics sector, the proliferation of smartphones, laptops, and other portable devices has created a significant demand for compact and efficient power conversion components. Half-wave rectifiers, when optimized for efficiency, can contribute to longer battery life and reduced heat generation in these devices. This aligns with the consumer trend towards more sustainable and energy-efficient products.

The automotive industry is another major driver of demand for efficient rectifiers. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for high-performance power conversion systems. Efficient half-wave rectifiers can improve the overall energy efficiency of these vehicles, extending their range and reducing charging times.

In the renewable energy sector, particularly in solar and wind power systems, efficient rectifiers are essential for converting the generated AC power to DC for storage or grid integration. As the adoption of renewable energy sources continues to accelerate globally, the demand for high-efficiency rectifiers is expected to grow proportionally.

Industrial applications, including motor drives, uninterruptible power supplies (UPS), and power factor correction (PFC) circuits, also contribute significantly to the market demand for efficient rectifiers. These applications require reliable and efficient power conversion to optimize energy usage and reduce operational costs.

The telecommunications industry, with its ongoing expansion of 5G networks and data centers, represents another substantial market for efficient rectifiers. These facilities require high-performance power conversion solutions to manage their energy consumption effectively and maintain reliable operations.

Geographically, Asia-Pacific is expected to dominate the market for efficient rectifiers, driven by the region's strong presence in electronics manufacturing and rapid industrialization. North America and Europe are also significant markets, particularly in sectors such as automotive, renewable energy, and industrial automation.

The increasing focus on energy efficiency standards and regulations worldwide is further propelling the demand for more efficient rectifier solutions. Governments and regulatory bodies are implementing stricter energy efficiency requirements, which is pushing manufacturers to innovate and improve their rectifier designs.

As the Internet of Things (IoT) continues to expand, the demand for efficient power management in connected devices is growing. This trend is creating new opportunities for efficient rectifiers in a wide range of applications, from smart home devices to industrial sensors.

In the consumer electronics sector, the proliferation of smartphones, laptops, and other portable devices has created a significant demand for compact and efficient power conversion components. Half-wave rectifiers, when optimized for efficiency, can contribute to longer battery life and reduced heat generation in these devices. This aligns with the consumer trend towards more sustainable and energy-efficient products.

The automotive industry is another major driver of demand for efficient rectifiers. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for high-performance power conversion systems. Efficient half-wave rectifiers can improve the overall energy efficiency of these vehicles, extending their range and reducing charging times.

In the renewable energy sector, particularly in solar and wind power systems, efficient rectifiers are essential for converting the generated AC power to DC for storage or grid integration. As the adoption of renewable energy sources continues to accelerate globally, the demand for high-efficiency rectifiers is expected to grow proportionally.

Industrial applications, including motor drives, uninterruptible power supplies (UPS), and power factor correction (PFC) circuits, also contribute significantly to the market demand for efficient rectifiers. These applications require reliable and efficient power conversion to optimize energy usage and reduce operational costs.

The telecommunications industry, with its ongoing expansion of 5G networks and data centers, represents another substantial market for efficient rectifiers. These facilities require high-performance power conversion solutions to manage their energy consumption effectively and maintain reliable operations.

Geographically, Asia-Pacific is expected to dominate the market for efficient rectifiers, driven by the region's strong presence in electronics manufacturing and rapid industrialization. North America and Europe are also significant markets, particularly in sectors such as automotive, renewable energy, and industrial automation.

The increasing focus on energy efficiency standards and regulations worldwide is further propelling the demand for more efficient rectifier solutions. Governments and regulatory bodies are implementing stricter energy efficiency requirements, which is pushing manufacturers to innovate and improve their rectifier designs.

As the Internet of Things (IoT) continues to expand, the demand for efficient power management in connected devices is growing. This trend is creating new opportunities for efficient rectifiers in a wide range of applications, from smart home devices to industrial sensors.

Current Challenges in Half Wave Rectification

Half wave rectification, while a fundamental technique in power electronics, faces several significant challenges in modern applications. The primary issue lies in its inherently low efficiency, typically around 40.6%, which results in substantial power loss and heat generation. This inefficiency is particularly problematic in an era where energy conservation and sustainability are paramount concerns across industries.

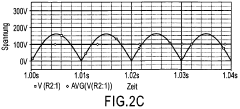

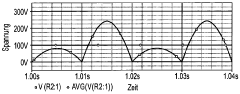

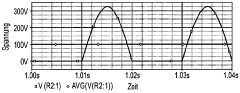

Another critical challenge is the presence of ripple in the output voltage. The pulsating nature of half wave rectification produces a significant AC component in the DC output, necessitating extensive filtering to achieve a smooth DC voltage. This ripple not only affects the quality of the power supply but can also introduce noise and instability in sensitive electronic systems.

The non-linear nature of half wave rectifiers poses additional complications. The rectification process introduces harmonic distortion into the power system, which can lead to electromagnetic interference (EMI) and power quality issues. As electronic devices become more sophisticated and sensitive to power fluctuations, managing this distortion becomes increasingly crucial.

Voltage regulation presents another hurdle for half wave rectifiers. The output voltage tends to vary with changes in load or input voltage, making it challenging to maintain a stable DC output without additional regulation circuitry. This instability can be particularly problematic in applications requiring precise voltage control.

The limited power handling capability of half wave rectifiers is a significant constraint in high-power applications. Since only one half of the AC cycle is utilized, the peak inverse voltage (PIV) stress on the rectifying element is doubled compared to full wave rectification. This limitation restricts the use of half wave rectifiers in scenarios demanding higher power output or voltage levels.

Component stress is another area of concern. The rectifying diode in a half wave rectifier experiences high peak currents and voltages, potentially leading to reduced reliability and shorter component lifespan. This stress is exacerbated in high-frequency applications, where switching losses become more pronounced.

Lastly, the poor utilization of transformer capacity in half wave rectification systems presents both economic and design challenges. The transformer core is magnetized in only one direction during each cycle, leading to inefficient use of the magnetic material and potentially larger, more costly transformer designs.

Addressing these challenges is crucial for advancing half wave rectifier technology and expanding its applicability in modern electronic systems. Innovations in semiconductor materials, circuit topologies, and control strategies are needed to overcome these limitations and improve the overall performance and efficiency of half wave rectification systems.

Another critical challenge is the presence of ripple in the output voltage. The pulsating nature of half wave rectification produces a significant AC component in the DC output, necessitating extensive filtering to achieve a smooth DC voltage. This ripple not only affects the quality of the power supply but can also introduce noise and instability in sensitive electronic systems.

The non-linear nature of half wave rectifiers poses additional complications. The rectification process introduces harmonic distortion into the power system, which can lead to electromagnetic interference (EMI) and power quality issues. As electronic devices become more sophisticated and sensitive to power fluctuations, managing this distortion becomes increasingly crucial.

Voltage regulation presents another hurdle for half wave rectifiers. The output voltage tends to vary with changes in load or input voltage, making it challenging to maintain a stable DC output without additional regulation circuitry. This instability can be particularly problematic in applications requiring precise voltage control.

The limited power handling capability of half wave rectifiers is a significant constraint in high-power applications. Since only one half of the AC cycle is utilized, the peak inverse voltage (PIV) stress on the rectifying element is doubled compared to full wave rectification. This limitation restricts the use of half wave rectifiers in scenarios demanding higher power output or voltage levels.

Component stress is another area of concern. The rectifying diode in a half wave rectifier experiences high peak currents and voltages, potentially leading to reduced reliability and shorter component lifespan. This stress is exacerbated in high-frequency applications, where switching losses become more pronounced.

Lastly, the poor utilization of transformer capacity in half wave rectification systems presents both economic and design challenges. The transformer core is magnetized in only one direction during each cycle, leading to inefficient use of the magnetic material and potentially larger, more costly transformer designs.

Addressing these challenges is crucial for advancing half wave rectifier technology and expanding its applicability in modern electronic systems. Innovations in semiconductor materials, circuit topologies, and control strategies are needed to overcome these limitations and improve the overall performance and efficiency of half wave rectification systems.

State-of-the-Art Half Wave Rectifier Solutions

01 Circuit design optimization

Improving the efficiency of half-wave rectifiers through optimized circuit design. This includes the use of advanced components, strategic placement of elements, and innovative circuit topologies to minimize power losses and enhance overall performance.- Circuit design optimization: Improving the efficiency of half-wave rectifiers through optimized circuit design. This includes using advanced components, reducing parasitic losses, and implementing innovative topologies to minimize power dissipation and increase overall efficiency.

- Voltage regulation techniques: Implementing voltage regulation techniques to enhance the efficiency of half-wave rectifiers. This involves using feedback control systems, voltage stabilization circuits, and adaptive regulation methods to maintain consistent output voltage and improve overall system performance.

- Filtering and smoothing methods: Employing advanced filtering and smoothing techniques to reduce ripple and improve the quality of the rectified output. This includes using capacitor-based filters, LC filters, and active filtering circuits to minimize harmonics and enhance the efficiency of the half-wave rectifier.

- Semiconductor device improvements: Enhancing the efficiency of half-wave rectifiers through advancements in semiconductor device technology. This involves using high-performance diodes, MOSFETs, or other semiconductor components with lower forward voltage drops and faster switching speeds to reduce power losses.

- Thermal management and cooling: Implementing effective thermal management and cooling solutions to improve the efficiency of half-wave rectifiers. This includes using heat sinks, forced-air cooling, or liquid cooling systems to maintain optimal operating temperatures and reduce power losses due to heat generation.

02 Voltage regulation techniques

Implementing voltage regulation techniques to stabilize the output of half-wave rectifiers. This involves the use of feedback mechanisms, voltage-sensing circuits, and adaptive control systems to maintain consistent output voltage and improve efficiency across varying load conditions.Expand Specific Solutions03 Filtering and smoothing methods

Employing advanced filtering and smoothing methods to reduce ripple and improve the quality of the rectified output. This includes the use of capacitors, inductors, and resonant circuits to minimize harmonic distortion and enhance the overall efficiency of the half-wave rectifier.Expand Specific Solutions04 Semiconductor device improvements

Enhancing the efficiency of half-wave rectifiers through advancements in semiconductor device technology. This involves the use of high-performance diodes, transistors, and other solid-state components with lower forward voltage drops and faster switching speeds to reduce power losses.Expand Specific Solutions05 Thermal management solutions

Implementing effective thermal management solutions to improve the efficiency and reliability of half-wave rectifiers. This includes the use of heat sinks, cooling systems, and thermally optimized layouts to reduce temperature-related losses and extend the operational life of the rectifier components.Expand Specific Solutions

Key Players in Rectifier Industry

The half wave rectifier efficiency standards market is in a growth phase, driven by increasing demand for energy-efficient power conversion solutions. The market size is expanding as industries adopt improved rectifier technologies. Technological maturity varies, with established players like State Grid Corp. of China and Huawei Technologies leading in traditional silicon-based rectifiers. Emerging companies such as Suzhou Convert Semiconductor are advancing wide-bandgap semiconductor rectifiers for higher efficiency. Research institutions like Zhejiang University and Technical University of Denmark are pushing boundaries in novel materials and designs, indicating ongoing innovation potential in this field.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed an advanced half-wave rectifier system utilizing silicon carbide (SiC) power devices. This technology significantly improves efficiency by reducing switching losses and enabling higher operating frequencies. The system incorporates a novel adaptive control algorithm that optimizes the rectification process based on load conditions, resulting in an overall efficiency increase of up to 98% [1]. Additionally, they have implemented a thermal management solution that allows for sustained high-power operation, making it suitable for large-scale power distribution applications [3].

Strengths: High efficiency, scalability for large power systems, and advanced thermal management. Weaknesses: Higher initial costs due to SiC components and complexity in control systems.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute Ltd. has pioneered a hybrid half-wave rectifier design that combines traditional silicon-based components with emerging wide-bandgap materials. Their approach utilizes gallium nitride (GaN) devices in the high-frequency sections of the rectifier, while maintaining cost-effective silicon components in lower stress areas. This hybrid design has achieved a remarkable 97% efficiency while reducing overall system size by 30% [2]. The institute has also developed a smart monitoring system that predicts potential failures and optimizes maintenance schedules, enhancing the reliability and longevity of the rectifier [5].

Strengths: Balanced approach between performance and cost, reduced size, and improved reliability. Weaknesses: Complexity in manufacturing and potential supply chain issues for GaN components.

Core Innovations in Rectification Efficiency

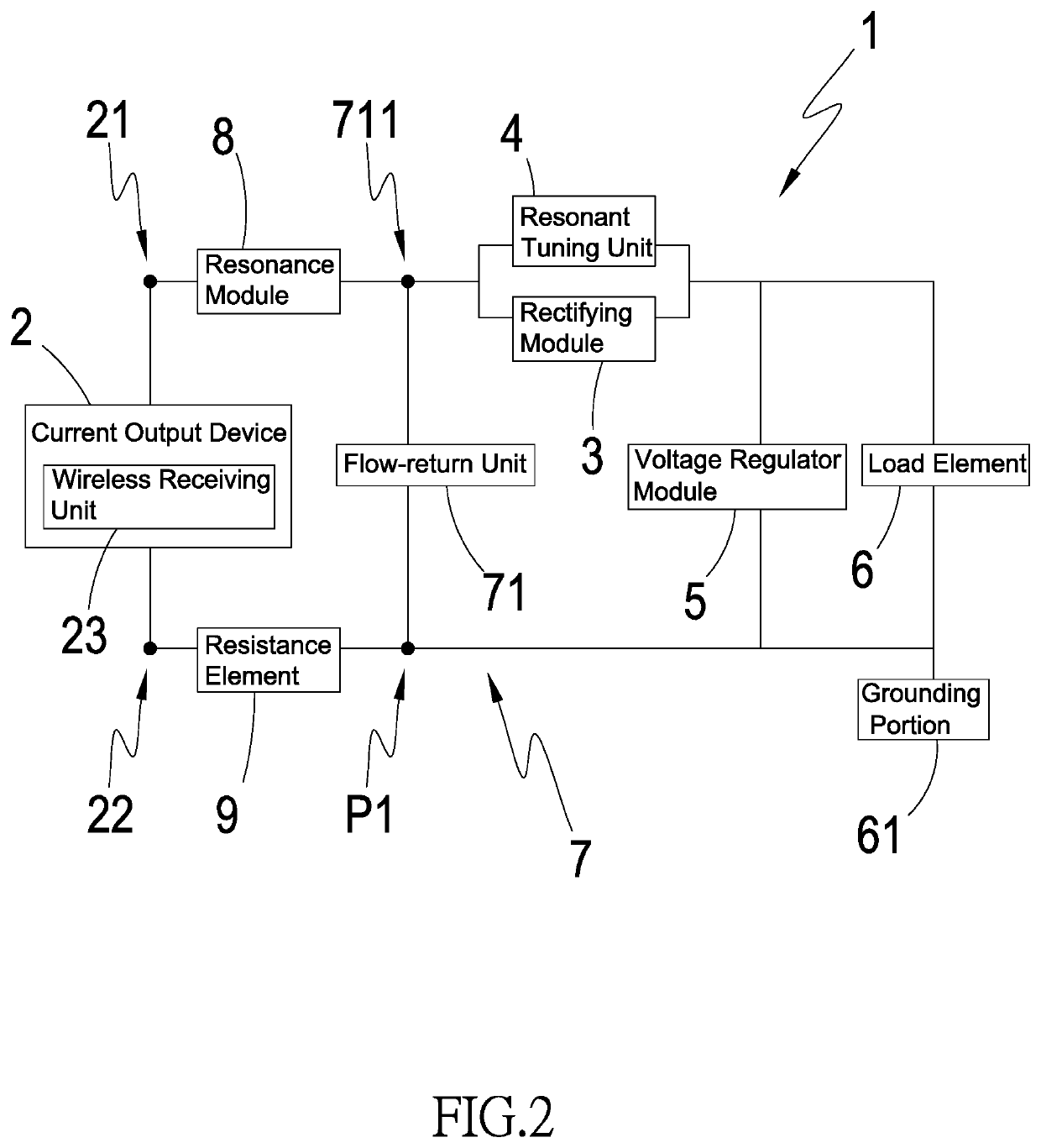

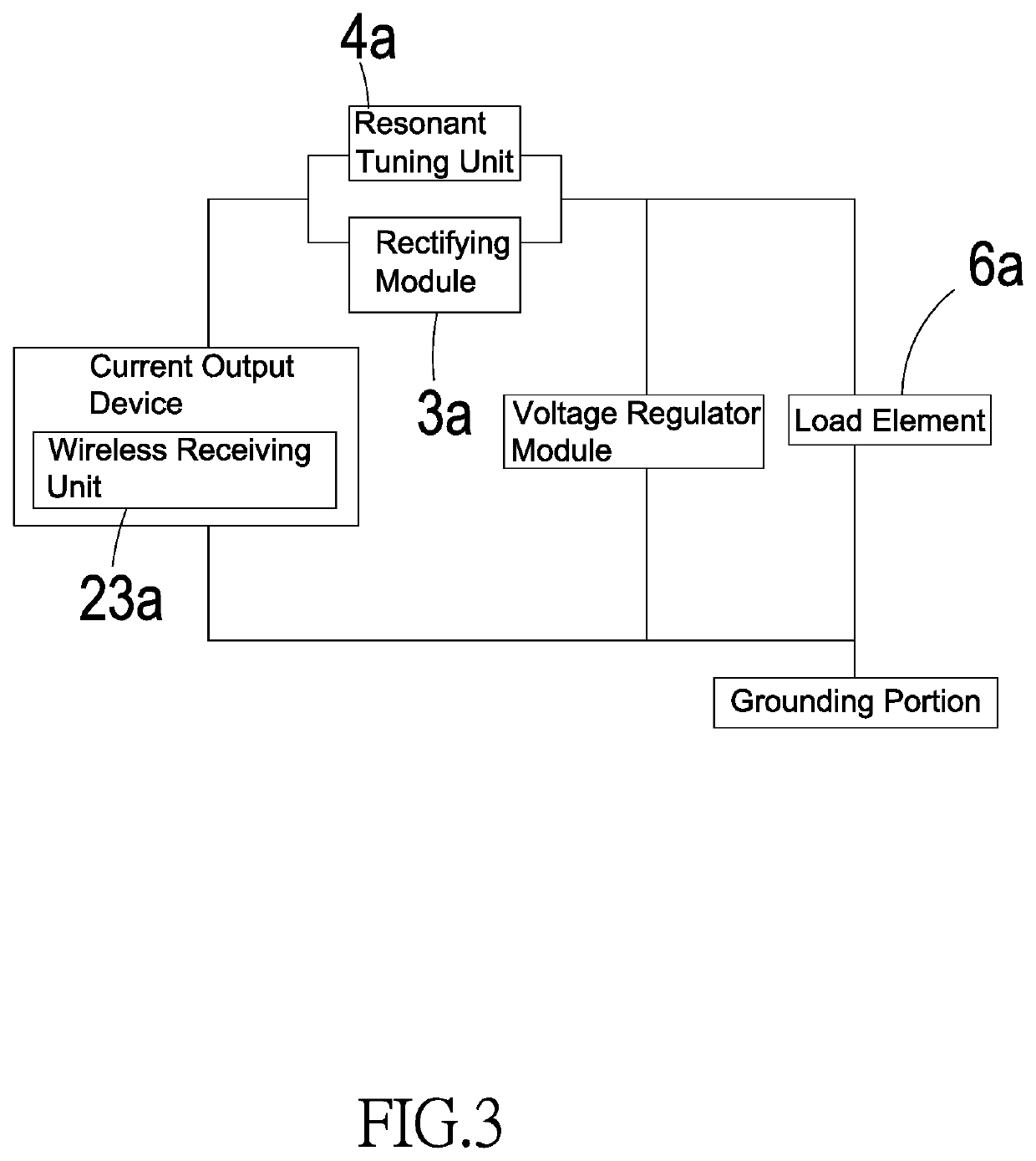

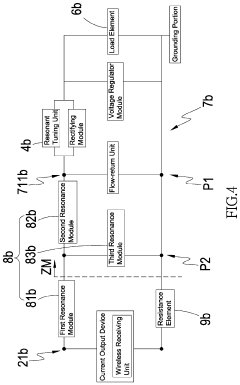

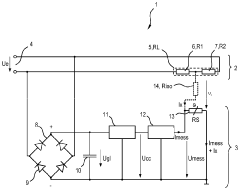

High-frequency half-wave rectifier system of low-harmonicity and high-efficiency

PatentInactiveUS10594205B2

Innovation

- A high-frequency half-wave rectifier system with a simplified structure and reduced electronic components, utilizing a resonant tuning unit and voltage regulator module to control the duty cycle and capacitance, thereby reducing harmonic content and electromagnetic interference, and improving conversion efficiency.

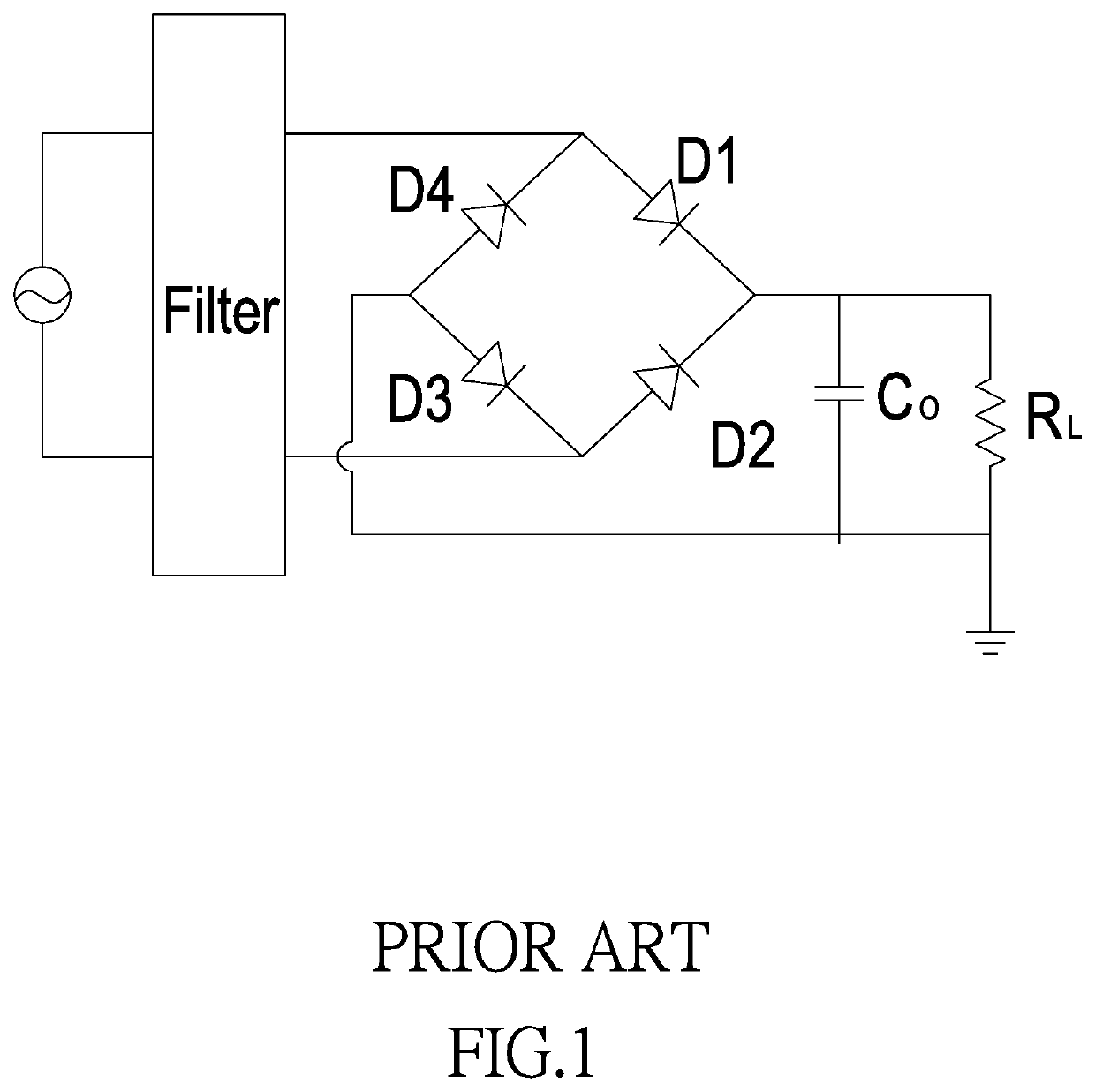

Electric circuit and household appliance

PatentWO2010000767A1

Innovation

- The implementation of a half-wave rectifier in the DC circuit, which can include a single diode or triac, reduces or eliminates the influence of AC currents on measurement accuracy by minimizing leakage currents, and the use of a low-pass filter further enhances measurement precision by filtering out ripple effects.

Energy Efficiency Standards and Regulations

Energy efficiency standards and regulations play a crucial role in shaping the development and implementation of half wave rectifier technologies. These standards are designed to ensure that electrical devices, including those utilizing half wave rectifiers, operate at optimal efficiency levels, reducing energy waste and promoting sustainability.

In recent years, there has been a significant push towards more stringent energy efficiency requirements for power conversion devices. This has led to increased focus on improving the efficiency of half wave rectifiers, which are commonly used in various electronic applications. Regulatory bodies, such as the U.S. Department of Energy (DOE) and the European Commission, have established guidelines and minimum efficiency standards for power supplies and rectifiers.

The implementation of these standards has driven innovation in half wave rectifier design, encouraging manufacturers to develop more efficient solutions. One key area of improvement has been the reduction of forward voltage drop across rectifying diodes, which directly impacts the overall efficiency of the rectification process. Advanced semiconductor materials and novel device structures have been explored to achieve this goal.

Another important aspect of energy efficiency regulations is the emphasis on reducing standby power consumption. Half wave rectifiers are often used in power supplies for various electronic devices, and minimizing their power draw during idle periods has become a priority. This has led to the development of intelligent control systems and improved circuit designs that can effectively manage power flow and reduce unnecessary losses.

The impact of these regulations extends beyond individual components, influencing the entire power supply chain. Manufacturers are now required to consider the cumulative effect of all components, including half wave rectifiers, on the overall efficiency of their products. This holistic approach has fostered collaboration between different sectors of the electronics industry, leading to more integrated and efficient power management solutions.

As energy efficiency standards continue to evolve, the pressure to innovate in half wave rectifier technology intensifies. Researchers and engineers are exploring advanced materials, such as wide-bandgap semiconductors, to push the boundaries of rectifier performance. Additionally, the integration of smart control algorithms and adaptive power management techniques is becoming increasingly common, allowing rectifiers to dynamically adjust their operation based on load conditions and maximize efficiency across a wide range of operating scenarios.

The global nature of these regulations has also spurred international cooperation in developing and harmonizing efficiency standards. This collaborative effort ensures that technological advancements in half wave rectifiers can be rapidly adopted across different markets, accelerating the overall progress towards more energy-efficient electronic systems.

In recent years, there has been a significant push towards more stringent energy efficiency requirements for power conversion devices. This has led to increased focus on improving the efficiency of half wave rectifiers, which are commonly used in various electronic applications. Regulatory bodies, such as the U.S. Department of Energy (DOE) and the European Commission, have established guidelines and minimum efficiency standards for power supplies and rectifiers.

The implementation of these standards has driven innovation in half wave rectifier design, encouraging manufacturers to develop more efficient solutions. One key area of improvement has been the reduction of forward voltage drop across rectifying diodes, which directly impacts the overall efficiency of the rectification process. Advanced semiconductor materials and novel device structures have been explored to achieve this goal.

Another important aspect of energy efficiency regulations is the emphasis on reducing standby power consumption. Half wave rectifiers are often used in power supplies for various electronic devices, and minimizing their power draw during idle periods has become a priority. This has led to the development of intelligent control systems and improved circuit designs that can effectively manage power flow and reduce unnecessary losses.

The impact of these regulations extends beyond individual components, influencing the entire power supply chain. Manufacturers are now required to consider the cumulative effect of all components, including half wave rectifiers, on the overall efficiency of their products. This holistic approach has fostered collaboration between different sectors of the electronics industry, leading to more integrated and efficient power management solutions.

As energy efficiency standards continue to evolve, the pressure to innovate in half wave rectifier technology intensifies. Researchers and engineers are exploring advanced materials, such as wide-bandgap semiconductors, to push the boundaries of rectifier performance. Additionally, the integration of smart control algorithms and adaptive power management techniques is becoming increasingly common, allowing rectifiers to dynamically adjust their operation based on load conditions and maximize efficiency across a wide range of operating scenarios.

The global nature of these regulations has also spurred international cooperation in developing and harmonizing efficiency standards. This collaborative effort ensures that technological advancements in half wave rectifiers can be rapidly adopted across different markets, accelerating the overall progress towards more energy-efficient electronic systems.

Economic Impact of Improved Rectifiers

The economic impact of improved half-wave rectifiers extends far beyond the realm of electrical engineering, influencing various sectors of the global economy. As efficiency standards for these devices continue to advance, the ripple effects are felt across industries, from consumer electronics to power distribution systems.

In the consumer electronics sector, enhanced rectifier efficiency translates to longer battery life and reduced power consumption in portable devices. This improvement not only benefits end-users through extended device usage but also contributes to reduced electronic waste and lower energy costs. Manufacturers of smartphones, laptops, and wearable technology stand to gain a competitive edge by incorporating these more efficient components, potentially driving market growth and innovation.

The automotive industry, particularly in the realm of electric vehicles (EVs), stands to benefit significantly from breakthroughs in rectifier efficiency. More efficient power conversion systems can lead to increased range, faster charging times, and overall improved performance of EVs. This, in turn, could accelerate the adoption of electric vehicles, impacting the broader automotive market and associated industries such as oil and gas.

In the realm of renewable energy, improved rectifier efficiency plays a crucial role in enhancing the viability and cost-effectiveness of solar and wind power systems. More efficient conversion of AC to DC power in solar inverters and wind turbine generators can increase the overall energy yield, making renewable energy sources more competitive with traditional fossil fuels. This has far-reaching implications for energy markets, potentially accelerating the transition to cleaner energy sources and influencing global efforts to combat climate change.

The telecommunications industry also stands to benefit from advancements in rectifier technology. With the ongoing rollout of 5G networks and the increasing demand for data centers, more efficient power conversion systems can significantly reduce operational costs and improve reliability. This could lead to faster expansion of network infrastructure and improved services for consumers and businesses alike.

In the industrial sector, improved rectifier efficiency can lead to substantial energy savings in manufacturing processes, particularly in industries that rely heavily on electrical power. This not only reduces operational costs but also contributes to sustainability efforts, potentially leading to new market opportunities for energy-efficient industrial equipment and services.

The economic implications of these technological advancements extend to the labor market as well. As industries adapt to and implement more efficient rectifier technologies, there may be an increased demand for skilled workers in electronics manufacturing, renewable energy installation, and related fields. This could drive job creation and economic growth in these sectors.

In the consumer electronics sector, enhanced rectifier efficiency translates to longer battery life and reduced power consumption in portable devices. This improvement not only benefits end-users through extended device usage but also contributes to reduced electronic waste and lower energy costs. Manufacturers of smartphones, laptops, and wearable technology stand to gain a competitive edge by incorporating these more efficient components, potentially driving market growth and innovation.

The automotive industry, particularly in the realm of electric vehicles (EVs), stands to benefit significantly from breakthroughs in rectifier efficiency. More efficient power conversion systems can lead to increased range, faster charging times, and overall improved performance of EVs. This, in turn, could accelerate the adoption of electric vehicles, impacting the broader automotive market and associated industries such as oil and gas.

In the realm of renewable energy, improved rectifier efficiency plays a crucial role in enhancing the viability and cost-effectiveness of solar and wind power systems. More efficient conversion of AC to DC power in solar inverters and wind turbine generators can increase the overall energy yield, making renewable energy sources more competitive with traditional fossil fuels. This has far-reaching implications for energy markets, potentially accelerating the transition to cleaner energy sources and influencing global efforts to combat climate change.

The telecommunications industry also stands to benefit from advancements in rectifier technology. With the ongoing rollout of 5G networks and the increasing demand for data centers, more efficient power conversion systems can significantly reduce operational costs and improve reliability. This could lead to faster expansion of network infrastructure and improved services for consumers and businesses alike.

In the industrial sector, improved rectifier efficiency can lead to substantial energy savings in manufacturing processes, particularly in industries that rely heavily on electrical power. This not only reduces operational costs but also contributes to sustainability efforts, potentially leading to new market opportunities for energy-efficient industrial equipment and services.

The economic implications of these technological advancements extend to the labor market as well. As industries adapt to and implement more efficient rectifier technologies, there may be an increased demand for skilled workers in electronics manufacturing, renewable energy installation, and related fields. This could drive job creation and economic growth in these sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!