Innovations in Half Wave Rectifier Materials and Components

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Evolution and Objectives

Half wave rectifiers have played a crucial role in the development of electronic circuits since their inception in the early 20th century. The evolution of these components has been driven by the need for more efficient and reliable power conversion in various applications. Initially, vacuum tube diodes were used as rectifying elements, but their large size, high power consumption, and limited lifespan posed significant challenges.

The advent of semiconductor technology in the 1940s marked a turning point in half wave rectifier development. The introduction of solid-state diodes, particularly silicon diodes, revolutionized the field by offering smaller size, improved efficiency, and longer operational life. This transition from vacuum tubes to semiconductors enabled the miniaturization of electronic devices and paved the way for modern power electronics.

Throughout the latter half of the 20th century, continuous improvements in semiconductor materials and manufacturing processes led to the development of more advanced diode types. Schottky diodes, with their lower forward voltage drop and faster switching speeds, became popular for high-frequency applications. Power diodes with higher current and voltage ratings expanded the use of half wave rectifiers in industrial and power distribution systems.

The objectives of half wave rectifier innovation have evolved alongside technological advancements. Early goals focused on basic functionality and reliability. As applications became more diverse and demanding, objectives shifted towards improving efficiency, reducing power losses, and enhancing thermal management. In recent years, the focus has expanded to include miniaturization, integration with other circuit components, and compatibility with emerging power electronics technologies.

Current innovation objectives in half wave rectifier materials and components are multifaceted. One primary goal is to develop materials with higher breakdown voltages and lower on-state resistances, enabling more efficient power conversion across a wider range of voltages and currents. Another objective is to improve the thermal characteristics of rectifier components, allowing for better heat dissipation and increased power density in compact designs.

Researchers are also exploring novel semiconductor materials beyond silicon, such as silicon carbide (SiC) and gallium nitride (GaN), to push the boundaries of rectifier performance. These wide-bandgap semiconductors offer the potential for higher operating temperatures, faster switching speeds, and reduced losses, making them particularly attractive for high-frequency and high-power applications.

Additionally, there is a growing emphasis on developing smart rectifier components with integrated sensing and control capabilities. These advanced devices aim to optimize power conversion efficiency in real-time, adapt to varying load conditions, and provide enhanced protection against overcurrent and overvoltage events. The integration of such intelligent features aligns with the broader trend towards more sophisticated and autonomous power management systems.

The advent of semiconductor technology in the 1940s marked a turning point in half wave rectifier development. The introduction of solid-state diodes, particularly silicon diodes, revolutionized the field by offering smaller size, improved efficiency, and longer operational life. This transition from vacuum tubes to semiconductors enabled the miniaturization of electronic devices and paved the way for modern power electronics.

Throughout the latter half of the 20th century, continuous improvements in semiconductor materials and manufacturing processes led to the development of more advanced diode types. Schottky diodes, with their lower forward voltage drop and faster switching speeds, became popular for high-frequency applications. Power diodes with higher current and voltage ratings expanded the use of half wave rectifiers in industrial and power distribution systems.

The objectives of half wave rectifier innovation have evolved alongside technological advancements. Early goals focused on basic functionality and reliability. As applications became more diverse and demanding, objectives shifted towards improving efficiency, reducing power losses, and enhancing thermal management. In recent years, the focus has expanded to include miniaturization, integration with other circuit components, and compatibility with emerging power electronics technologies.

Current innovation objectives in half wave rectifier materials and components are multifaceted. One primary goal is to develop materials with higher breakdown voltages and lower on-state resistances, enabling more efficient power conversion across a wider range of voltages and currents. Another objective is to improve the thermal characteristics of rectifier components, allowing for better heat dissipation and increased power density in compact designs.

Researchers are also exploring novel semiconductor materials beyond silicon, such as silicon carbide (SiC) and gallium nitride (GaN), to push the boundaries of rectifier performance. These wide-bandgap semiconductors offer the potential for higher operating temperatures, faster switching speeds, and reduced losses, making them particularly attractive for high-frequency and high-power applications.

Additionally, there is a growing emphasis on developing smart rectifier components with integrated sensing and control capabilities. These advanced devices aim to optimize power conversion efficiency in real-time, adapt to varying load conditions, and provide enhanced protection against overcurrent and overvoltage events. The integration of such intelligent features aligns with the broader trend towards more sophisticated and autonomous power management systems.

Market Analysis for Advanced Rectifiers

The market for advanced rectifiers, particularly those utilizing innovative materials and components for half-wave rectification, is experiencing significant growth and transformation. This surge is driven by the increasing demand for more efficient and compact power conversion solutions across various industries. The global rectifier market, which encompasses half-wave rectifiers, is projected to reach substantial market value in the coming years, with a compound annual growth rate (CAGR) outpacing many other electronic component sectors.

Key factors fueling this market growth include the rapid expansion of renewable energy systems, electric vehicles, and consumer electronics. In the renewable energy sector, advanced rectifiers play a crucial role in improving the efficiency of power conversion from solar panels and wind turbines. The automotive industry's shift towards electrification has also created a strong demand for high-performance rectifiers capable of handling higher voltages and currents while maintaining compact form factors.

Consumer electronics, including smartphones, laptops, and IoT devices, continue to drive demand for miniaturized, highly efficient rectifiers. The trend towards faster charging technologies and wireless power transfer systems further amplifies the need for advanced rectification solutions. In industrial applications, the push for more energy-efficient motor drives and power supplies is creating new opportunities for innovative half-wave rectifier technologies.

Geographically, Asia-Pacific leads the market for advanced rectifiers, with China, Japan, and South Korea being major contributors. This dominance is attributed to the region's strong presence in electronics manufacturing and its rapid adoption of renewable energy technologies. North America and Europe follow closely, driven by their automotive and industrial sectors' technological advancements.

The market is characterized by intense competition among key players, including established semiconductor manufacturers and emerging startups focusing on novel materials and designs. Silicon carbide (SiC) and gallium nitride (GaN) based rectifiers are gaining traction due to their superior performance in high-power applications, challenging traditional silicon-based solutions.

Looking ahead, the market for advanced rectifiers is expected to continue its upward trajectory. Emerging applications in 5G infrastructure, data centers, and smart grid systems are likely to create new demand streams. Additionally, the ongoing research into novel materials and nanostructures for rectification promises to unlock new levels of efficiency and miniaturization, potentially reshaping the market landscape in the coming years.

Key factors fueling this market growth include the rapid expansion of renewable energy systems, electric vehicles, and consumer electronics. In the renewable energy sector, advanced rectifiers play a crucial role in improving the efficiency of power conversion from solar panels and wind turbines. The automotive industry's shift towards electrification has also created a strong demand for high-performance rectifiers capable of handling higher voltages and currents while maintaining compact form factors.

Consumer electronics, including smartphones, laptops, and IoT devices, continue to drive demand for miniaturized, highly efficient rectifiers. The trend towards faster charging technologies and wireless power transfer systems further amplifies the need for advanced rectification solutions. In industrial applications, the push for more energy-efficient motor drives and power supplies is creating new opportunities for innovative half-wave rectifier technologies.

Geographically, Asia-Pacific leads the market for advanced rectifiers, with China, Japan, and South Korea being major contributors. This dominance is attributed to the region's strong presence in electronics manufacturing and its rapid adoption of renewable energy technologies. North America and Europe follow closely, driven by their automotive and industrial sectors' technological advancements.

The market is characterized by intense competition among key players, including established semiconductor manufacturers and emerging startups focusing on novel materials and designs. Silicon carbide (SiC) and gallium nitride (GaN) based rectifiers are gaining traction due to their superior performance in high-power applications, challenging traditional silicon-based solutions.

Looking ahead, the market for advanced rectifiers is expected to continue its upward trajectory. Emerging applications in 5G infrastructure, data centers, and smart grid systems are likely to create new demand streams. Additionally, the ongoing research into novel materials and nanostructures for rectification promises to unlock new levels of efficiency and miniaturization, potentially reshaping the market landscape in the coming years.

Current Challenges in Rectifier Technology

Half wave rectifiers, despite their long-standing presence in electronic circuits, continue to face several challenges that hinder their performance and efficiency. One of the primary issues is the significant power loss during the rectification process. This loss occurs due to the forward voltage drop across the diode, which can be substantial in traditional silicon-based components. As a result, the overall efficiency of the rectifier circuit is compromised, leading to increased heat generation and reduced power output.

Another critical challenge lies in the reverse recovery time of rectifier diodes. When the diode transitions from forward to reverse bias, there is a brief period where it continues to conduct in the reverse direction before fully turning off. This phenomenon, known as reverse recovery, introduces additional power losses and can generate electromagnetic interference (EMI) in the circuit. The reverse recovery time becomes particularly problematic in high-frequency applications, limiting the operational speed of rectifier circuits.

The temperature sensitivity of rectifier components poses yet another significant challenge. As the temperature of the device increases, its electrical characteristics can change, affecting the overall performance and reliability of the rectifier circuit. This temperature dependence can lead to inconsistent output and potential failure in extreme operating conditions, making thermal management a crucial consideration in rectifier design.

Voltage spikes and transients present a persistent challenge in rectifier technology. These sudden increases in voltage can damage the rectifier components and the connected load. While various protection mechanisms exist, such as snubber circuits and transient voltage suppressors, integrating these solutions effectively without compromising the rectifier's performance remains a complex task.

Miniaturization of rectifier circuits, particularly for portable and wearable electronics, introduces additional challenges. As device sizes shrink, power density increases, exacerbating thermal management issues. Moreover, smaller components are often more susceptible to voltage stress and electromagnetic interference, requiring innovative design approaches to maintain reliability and performance.

The increasing demand for high-power applications, such as in electric vehicles and renewable energy systems, has pushed the limits of current rectifier technology. Scaling up rectifier circuits to handle higher voltages and currents while maintaining efficiency and reliability presents significant engineering challenges. This includes managing increased heat dissipation, ensuring uniform current distribution, and preventing voltage breakdown in high-power scenarios.

Lastly, the environmental impact of rectifier materials and manufacturing processes has become a growing concern. Many traditional rectifier components contain hazardous materials or require energy-intensive production methods. Developing eco-friendly alternatives that maintain or improve upon the performance of existing technologies remains a significant challenge in the field of rectifier innovation.

Another critical challenge lies in the reverse recovery time of rectifier diodes. When the diode transitions from forward to reverse bias, there is a brief period where it continues to conduct in the reverse direction before fully turning off. This phenomenon, known as reverse recovery, introduces additional power losses and can generate electromagnetic interference (EMI) in the circuit. The reverse recovery time becomes particularly problematic in high-frequency applications, limiting the operational speed of rectifier circuits.

The temperature sensitivity of rectifier components poses yet another significant challenge. As the temperature of the device increases, its electrical characteristics can change, affecting the overall performance and reliability of the rectifier circuit. This temperature dependence can lead to inconsistent output and potential failure in extreme operating conditions, making thermal management a crucial consideration in rectifier design.

Voltage spikes and transients present a persistent challenge in rectifier technology. These sudden increases in voltage can damage the rectifier components and the connected load. While various protection mechanisms exist, such as snubber circuits and transient voltage suppressors, integrating these solutions effectively without compromising the rectifier's performance remains a complex task.

Miniaturization of rectifier circuits, particularly for portable and wearable electronics, introduces additional challenges. As device sizes shrink, power density increases, exacerbating thermal management issues. Moreover, smaller components are often more susceptible to voltage stress and electromagnetic interference, requiring innovative design approaches to maintain reliability and performance.

The increasing demand for high-power applications, such as in electric vehicles and renewable energy systems, has pushed the limits of current rectifier technology. Scaling up rectifier circuits to handle higher voltages and currents while maintaining efficiency and reliability presents significant engineering challenges. This includes managing increased heat dissipation, ensuring uniform current distribution, and preventing voltage breakdown in high-power scenarios.

Lastly, the environmental impact of rectifier materials and manufacturing processes has become a growing concern. Many traditional rectifier components contain hazardous materials or require energy-intensive production methods. Developing eco-friendly alternatives that maintain or improve upon the performance of existing technologies remains a significant challenge in the field of rectifier innovation.

State-of-the-Art Half Wave Rectifier Designs

01 Diode materials for half-wave rectifiers

Half-wave rectifiers commonly use semiconductor diodes as the main rectifying component. These diodes are typically made from materials such as silicon or germanium. The choice of diode material affects the rectifier's performance, including its forward voltage drop, reverse breakdown voltage, and switching speed.- Diode materials for half-wave rectifiers: Half-wave rectifiers commonly use semiconductor diodes as the main rectifying component. These diodes are typically made from materials such as silicon or germanium. The choice of diode material affects the rectifier's performance, including its forward voltage drop, reverse breakdown voltage, and switching speed.

- Transformer components in half-wave rectifiers: Transformers are often used in half-wave rectifier circuits to step up or step down the input voltage. The transformer's primary and secondary windings, core material, and turns ratio are crucial factors in determining the rectifier's output characteristics. Proper selection of transformer components can improve efficiency and reduce electromagnetic interference.

- Capacitor selection for smoothing output: Capacitors play a vital role in smoothing the pulsating DC output of half-wave rectifiers. The choice of capacitor type, capacitance value, and voltage rating affects the ripple reduction and overall performance of the rectifier circuit. Electrolytic capacitors are commonly used for their high capacitance values and ability to handle higher voltages.

- Heat dissipation components: Half-wave rectifiers can generate significant heat during operation, especially in high-power applications. Heat sinks, thermal compounds, and cooling fans are essential components for managing temperature and ensuring reliable operation. Proper thermal management extends the lifespan of the rectifier components and improves overall efficiency.

- Protection and filtering components: Various protection and filtering components are used in half-wave rectifier circuits to improve performance and reliability. These may include fuses for overcurrent protection, varistors for overvoltage protection, and inductors for additional filtering. EMI/RFI suppression components such as ferrite beads or common-mode chokes can also be incorporated to reduce electromagnetic interference.

02 Transformer components in half-wave rectifiers

Transformers are often used in half-wave rectifier circuits to step up or step down the input voltage. The transformer's primary and secondary windings, core material, and turns ratio are crucial factors in determining the rectifier's output characteristics. Proper transformer design can help reduce harmonics and improve overall efficiency.Expand Specific Solutions03 Capacitor selection for smoothing

Capacitors play a vital role in smoothing the pulsating DC output of a half-wave rectifier. The choice of capacitor type, capacitance value, and voltage rating affects the ripple reduction and overall performance of the rectifier circuit. Electrolytic capacitors are commonly used for their high capacitance values and compact size.Expand Specific Solutions04 Protection components for half-wave rectifiers

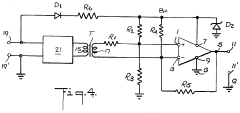

Various protection components are used in half-wave rectifier circuits to ensure safe and reliable operation. These may include fuses, surge suppressors, and voltage regulators. These components protect against overcurrent, overvoltage, and other potentially damaging conditions, enhancing the longevity and reliability of the rectifier circuit.Expand Specific Solutions05 Integrated circuit solutions for half-wave rectification

Modern half-wave rectifier designs often incorporate integrated circuit (IC) solutions that combine multiple components into a single package. These ICs may include the rectifying diode, voltage regulator, and protection circuitry, offering improved performance, reduced size, and simplified circuit design compared to discrete component implementations.Expand Specific Solutions

Key Players in Rectifier Industry

The field of half wave rectifier materials and components is currently in a mature stage of development, with ongoing innovations driving incremental improvements. The market size is substantial, given the widespread use of rectifiers in power electronics and electrical systems. Technologically, the field is well-established but continues to evolve, with companies like Sumitomo Chemical, Sony, and Fujitsu leading in advanced materials and component design. Universities such as MIT and Technical University of Denmark contribute to fundamental research, while companies like Huawei and Toshiba focus on practical applications and integration into larger systems. The competitive landscape is diverse, with both specialized component manufacturers and large electronics conglomerates vying for market share and technological edge.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed innovative materials for half-wave rectifiers, focusing on improving efficiency and reducing power loss. Their approach involves the use of advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), to create high-performance rectifier components. These materials offer superior electrical properties compared to traditional silicon-based devices, including higher breakdown voltage, lower on-resistance, and faster switching speeds [1][3]. Sumitomo's rectifier materials are designed to operate at higher frequencies and temperatures, making them suitable for a wide range of applications, from consumer electronics to industrial power systems [5].

Strengths: Superior electrical properties, higher efficiency, and broader application range. Weaknesses: Potentially higher production costs and limited availability of advanced materials.

Sony Group Corp.

Technical Solution: Sony has made significant strides in half-wave rectifier technology, particularly in the realm of miniaturization and integration. Their approach focuses on developing compact, high-efficiency rectifier circuits for use in portable electronics and IoT devices. Sony's innovation lies in the integration of rectifier components with other circuit elements on a single chip, reducing overall device size and power consumption. They have also explored the use of organic semiconductors for flexible electronics applications, which could revolutionize the design of wearable devices and flexible displays [2][4]. Additionally, Sony has invested in research on quantum dot-based rectifiers, which promise even higher efficiency and faster switching speeds in the future [6].

Strengths: Miniaturization expertise, integration capabilities, and potential for flexible electronics. Weaknesses: Limited focus on high-power applications and potential scalability issues with newer technologies.

Innovative Materials for Rectifier Diodes

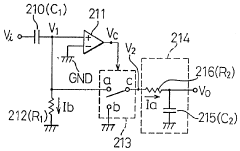

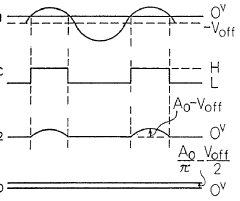

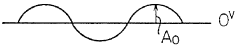

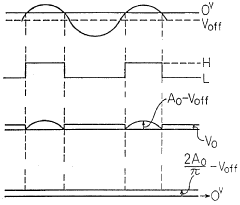

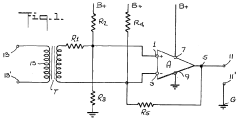

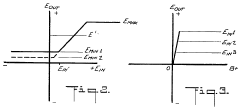

Half-wave rectifier circuit

PatentInactiveUS5579214A

Innovation

- The proposed half-wave rectifier circuit design includes a capacitor to remove DC components, a comparator with an operational amplifier and capacitor to accumulate offset voltage, and a switch circuit with high input impedance during the OFF state to eliminate the influence of offset voltage, ensuring accurate output voltage generation.

Half-wave rectifier circuit

PatentInactiveUS3936720A

Innovation

- A high-gain differential amplifier-based half-wave rectifier circuit operating from a single power supply, eliminating the need for voltage regulation and reducing temperature dependence, with resistor ratios optimized to minimize errors and achieve minimal output voltage drop.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the development and implementation of half wave rectifier technologies. As power electronics continue to play an increasingly important role in various applications, from consumer electronics to industrial systems, the need for more efficient rectification processes becomes paramount. Half wave rectifiers, while simple in design, have traditionally been associated with lower efficiency compared to full wave rectifiers. However, recent innovations in materials and components have led to significant improvements in their energy efficiency.

One of the primary factors affecting the energy efficiency of half wave rectifiers is the forward voltage drop across the rectifying diode. Traditional silicon diodes typically exhibit a forward voltage drop of 0.6-0.7 volts, which contributes to power losses during the rectification process. The introduction of Schottky diodes has been a game-changer in this regard. With their lower forward voltage drop of around 0.2-0.3 volts, Schottky diodes significantly reduce conduction losses, thereby improving overall efficiency.

Another area of focus for enhancing energy efficiency in half wave rectifiers is the reduction of reverse recovery losses. Silicon carbide (SiC) and gallium nitride (GaN) based diodes have emerged as promising alternatives to traditional silicon diodes. These wide bandgap semiconductors offer faster switching speeds and lower reverse recovery charges, which translate to reduced switching losses and improved efficiency, especially at higher frequencies.

The development of advanced rectifier topologies has also contributed to improved energy efficiency. For instance, synchronous rectification techniques, which replace diodes with actively controlled MOSFETs, can significantly reduce conduction losses. While traditionally associated with full wave rectifiers, these techniques are now being adapted for use in half wave rectifier configurations, offering substantial efficiency gains.

Thermal management plays a crucial role in maintaining the energy efficiency of half wave rectifiers. Innovations in packaging and heat dissipation technologies have led to improved thermal performance, allowing rectifiers to operate at higher power densities without compromising efficiency. Advanced thermal interface materials and novel cooling solutions, such as integrated heat spreaders and micro-channel cooling, have enabled more efficient heat removal from rectifier components.

The integration of smart control systems and power management ICs has further enhanced the energy efficiency of half wave rectifier circuits. These intelligent systems can dynamically adjust rectifier parameters based on load conditions, optimizing performance and minimizing losses across a wide range of operating scenarios. Additionally, the implementation of soft-switching techniques and resonant topologies has helped reduce switching losses, particularly in high-frequency applications.

As the demand for more energy-efficient power conversion solutions continues to grow, research into novel materials and circuit designs for half wave rectifiers remains active. Emerging technologies such as graphene-based diodes and quantum dot rectifiers show promise for future high-efficiency rectification solutions. These advancements, coupled with ongoing improvements in existing technologies, are expected to drive further enhancements in the energy efficiency of half wave rectifier systems in the coming years.

One of the primary factors affecting the energy efficiency of half wave rectifiers is the forward voltage drop across the rectifying diode. Traditional silicon diodes typically exhibit a forward voltage drop of 0.6-0.7 volts, which contributes to power losses during the rectification process. The introduction of Schottky diodes has been a game-changer in this regard. With their lower forward voltage drop of around 0.2-0.3 volts, Schottky diodes significantly reduce conduction losses, thereby improving overall efficiency.

Another area of focus for enhancing energy efficiency in half wave rectifiers is the reduction of reverse recovery losses. Silicon carbide (SiC) and gallium nitride (GaN) based diodes have emerged as promising alternatives to traditional silicon diodes. These wide bandgap semiconductors offer faster switching speeds and lower reverse recovery charges, which translate to reduced switching losses and improved efficiency, especially at higher frequencies.

The development of advanced rectifier topologies has also contributed to improved energy efficiency. For instance, synchronous rectification techniques, which replace diodes with actively controlled MOSFETs, can significantly reduce conduction losses. While traditionally associated with full wave rectifiers, these techniques are now being adapted for use in half wave rectifier configurations, offering substantial efficiency gains.

Thermal management plays a crucial role in maintaining the energy efficiency of half wave rectifiers. Innovations in packaging and heat dissipation technologies have led to improved thermal performance, allowing rectifiers to operate at higher power densities without compromising efficiency. Advanced thermal interface materials and novel cooling solutions, such as integrated heat spreaders and micro-channel cooling, have enabled more efficient heat removal from rectifier components.

The integration of smart control systems and power management ICs has further enhanced the energy efficiency of half wave rectifier circuits. These intelligent systems can dynamically adjust rectifier parameters based on load conditions, optimizing performance and minimizing losses across a wide range of operating scenarios. Additionally, the implementation of soft-switching techniques and resonant topologies has helped reduce switching losses, particularly in high-frequency applications.

As the demand for more energy-efficient power conversion solutions continues to grow, research into novel materials and circuit designs for half wave rectifiers remains active. Emerging technologies such as graphene-based diodes and quantum dot rectifiers show promise for future high-efficiency rectification solutions. These advancements, coupled with ongoing improvements in existing technologies, are expected to drive further enhancements in the energy efficiency of half wave rectifier systems in the coming years.

Thermal Management Strategies

Thermal management is a critical aspect of half wave rectifier design, particularly as innovations in materials and components push the boundaries of performance and efficiency. As rectifiers handle significant power loads, they generate substantial heat that must be effectively dissipated to maintain optimal operation and prevent component failure. Several strategies have emerged to address this challenge, each offering unique advantages depending on the specific application requirements.

Passive cooling techniques remain a cornerstone of thermal management in half wave rectifiers. Advanced heat sink designs, incorporating optimized fin structures and high thermal conductivity materials such as aluminum alloys or copper, provide enhanced heat dissipation without additional power consumption. Recent innovations in heat sink geometry, including micro-channel and pin-fin designs, have shown promising results in improving thermal performance while minimizing size and weight.

Active cooling solutions have also seen significant advancements, particularly in high-power applications where passive methods alone may be insufficient. Forced-air cooling systems, utilizing compact, high-efficiency fans or blowers, offer improved heat transfer rates and can be dynamically controlled to match varying thermal loads. For more demanding scenarios, liquid cooling systems have been adapted for use in rectifier applications, providing superior heat dissipation capabilities at the cost of increased complexity and maintenance requirements.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer between components and cooling systems. Novel TIMs, such as phase-change materials and graphene-based compounds, offer improved thermal conductivity and long-term stability compared to traditional thermal greases or pads. These advanced materials help to minimize thermal resistance at critical interfaces, enhancing overall cooling efficiency.

Integrated thermal management solutions are gaining traction, incorporating cooling mechanisms directly into the rectifier package or substrate. Examples include embedded heat pipes, thermoelectric coolers, and microfluidic cooling channels. These integrated approaches allow for more compact designs and can provide targeted cooling to specific high-heat areas within the rectifier assembly.

Smart thermal management systems, leveraging temperature sensors and microcontroller-based control algorithms, are emerging as a promising strategy for optimizing cooling performance while minimizing energy consumption. These systems can dynamically adjust cooling parameters based on real-time temperature data, load conditions, and environmental factors, ensuring efficient operation across a wide range of operating scenarios.

As half wave rectifier technologies continue to evolve, thermal management strategies must keep pace to support increased power densities and reliability requirements. The integration of advanced materials, innovative cooling techniques, and intelligent control systems will be crucial in addressing the thermal challenges posed by next-generation rectifier designs.

Passive cooling techniques remain a cornerstone of thermal management in half wave rectifiers. Advanced heat sink designs, incorporating optimized fin structures and high thermal conductivity materials such as aluminum alloys or copper, provide enhanced heat dissipation without additional power consumption. Recent innovations in heat sink geometry, including micro-channel and pin-fin designs, have shown promising results in improving thermal performance while minimizing size and weight.

Active cooling solutions have also seen significant advancements, particularly in high-power applications where passive methods alone may be insufficient. Forced-air cooling systems, utilizing compact, high-efficiency fans or blowers, offer improved heat transfer rates and can be dynamically controlled to match varying thermal loads. For more demanding scenarios, liquid cooling systems have been adapted for use in rectifier applications, providing superior heat dissipation capabilities at the cost of increased complexity and maintenance requirements.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer between components and cooling systems. Novel TIMs, such as phase-change materials and graphene-based compounds, offer improved thermal conductivity and long-term stability compared to traditional thermal greases or pads. These advanced materials help to minimize thermal resistance at critical interfaces, enhancing overall cooling efficiency.

Integrated thermal management solutions are gaining traction, incorporating cooling mechanisms directly into the rectifier package or substrate. Examples include embedded heat pipes, thermoelectric coolers, and microfluidic cooling channels. These integrated approaches allow for more compact designs and can provide targeted cooling to specific high-heat areas within the rectifier assembly.

Smart thermal management systems, leveraging temperature sensors and microcontroller-based control algorithms, are emerging as a promising strategy for optimizing cooling performance while minimizing energy consumption. These systems can dynamically adjust cooling parameters based on real-time temperature data, load conditions, and environmental factors, ensuring efficient operation across a wide range of operating scenarios.

As half wave rectifier technologies continue to evolve, thermal management strategies must keep pace to support increased power densities and reliability requirements. The integration of advanced materials, innovative cooling techniques, and intelligent control systems will be crucial in addressing the thermal challenges posed by next-generation rectifier designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!