Latest Developments in Half Wave Rectifier Technology

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Evolution and Objectives

Half wave rectifiers have been a fundamental component in power electronics since the early days of electrical engineering. The evolution of this technology can be traced back to the invention of the vacuum tube diode in the early 20th century. As semiconductor technology advanced, solid-state diodes replaced vacuum tubes, leading to more efficient and compact rectifier designs.

The primary objective of half wave rectifier technology has always been to convert alternating current (AC) into pulsating direct current (DC). This conversion is crucial in various applications, from simple power supplies to complex electronic systems. Over the years, the focus has shifted towards improving efficiency, reducing power losses, and minimizing harmonic distortion.

In recent decades, the development of high-speed switching devices and advanced control techniques has significantly enhanced the performance of half wave rectifiers. The introduction of silicon-controlled rectifiers (SCRs) and power MOSFETs has allowed for more precise control of the rectification process, enabling better power factor correction and reduced electromagnetic interference.

One of the key trends in half wave rectifier technology is the pursuit of higher power density. This has led to the development of more compact designs that can handle greater power loads while maintaining thermal stability. Advancements in thermal management techniques and materials have played a crucial role in this aspect.

Another significant objective in the evolution of half wave rectifiers has been the improvement of their efficiency. Modern designs aim to minimize conduction losses and switching losses, thereby increasing the overall system efficiency. This is particularly important in high-power applications where even small improvements in efficiency can lead to substantial energy savings.

The integration of digital control systems has been a game-changer in half wave rectifier technology. Microcontrollers and digital signal processors (DSPs) now enable real-time monitoring and adjustment of rectifier parameters, leading to optimized performance across various operating conditions. This digital integration also facilitates the implementation of advanced protection features and fault detection mechanisms.

Looking ahead, the objectives for half wave rectifier technology include further miniaturization, increased power handling capabilities, and improved reliability. There is also a growing focus on developing "smart" rectifiers that can adapt to varying load conditions and grid characteristics. Additionally, research is being conducted on novel materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), which promise to push the boundaries of rectifier performance even further.

The primary objective of half wave rectifier technology has always been to convert alternating current (AC) into pulsating direct current (DC). This conversion is crucial in various applications, from simple power supplies to complex electronic systems. Over the years, the focus has shifted towards improving efficiency, reducing power losses, and minimizing harmonic distortion.

In recent decades, the development of high-speed switching devices and advanced control techniques has significantly enhanced the performance of half wave rectifiers. The introduction of silicon-controlled rectifiers (SCRs) and power MOSFETs has allowed for more precise control of the rectification process, enabling better power factor correction and reduced electromagnetic interference.

One of the key trends in half wave rectifier technology is the pursuit of higher power density. This has led to the development of more compact designs that can handle greater power loads while maintaining thermal stability. Advancements in thermal management techniques and materials have played a crucial role in this aspect.

Another significant objective in the evolution of half wave rectifiers has been the improvement of their efficiency. Modern designs aim to minimize conduction losses and switching losses, thereby increasing the overall system efficiency. This is particularly important in high-power applications where even small improvements in efficiency can lead to substantial energy savings.

The integration of digital control systems has been a game-changer in half wave rectifier technology. Microcontrollers and digital signal processors (DSPs) now enable real-time monitoring and adjustment of rectifier parameters, leading to optimized performance across various operating conditions. This digital integration also facilitates the implementation of advanced protection features and fault detection mechanisms.

Looking ahead, the objectives for half wave rectifier technology include further miniaturization, increased power handling capabilities, and improved reliability. There is also a growing focus on developing "smart" rectifiers that can adapt to varying load conditions and grid characteristics. Additionally, research is being conducted on novel materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), which promise to push the boundaries of rectifier performance even further.

Market Analysis for Half Wave Rectifier Applications

The market for half wave rectifier applications has shown significant growth and diversification in recent years, driven by advancements in power electronics and increasing demand for efficient energy conversion solutions. The global market for half wave rectifiers is primarily segmented into consumer electronics, industrial equipment, automotive, and renewable energy sectors.

In the consumer electronics segment, half wave rectifiers continue to play a crucial role in power supply units for various devices. The proliferation of smartphones, tablets, and other portable electronics has created a steady demand for compact and efficient rectification solutions. This segment is expected to maintain steady growth, particularly in emerging markets where smartphone penetration is still increasing.

The industrial equipment sector represents a substantial portion of the half wave rectifier market. Applications range from motor drives and welding equipment to industrial power supplies. The trend towards Industry 4.0 and smart manufacturing has increased the need for precise power control and conversion, further driving the demand for advanced rectification technologies.

In the automotive industry, the shift towards electric and hybrid vehicles has opened new avenues for half wave rectifier applications. These components are essential in battery management systems, on-board chargers, and power conversion units. As the electric vehicle market continues to expand, the demand for high-performance rectifiers is expected to grow significantly.

The renewable energy sector, particularly solar and wind power generation, has emerged as a key growth driver for half wave rectifier technologies. In solar inverters and wind turbine systems, rectifiers play a critical role in converting and managing power. The global push for clean energy and the declining costs of renewable technologies are expected to fuel this market segment's growth in the coming years.

Geographically, Asia-Pacific leads the market for half wave rectifier applications, driven by the region's strong manufacturing base in electronics and automotive industries. North America and Europe follow, with significant contributions from their advanced industrial sectors and renewable energy initiatives.

Market analysts project a compound annual growth rate (CAGR) of around 4-5% for the global half wave rectifier market over the next five years. This growth is attributed to the increasing adoption of power electronics in various industries and the ongoing technological advancements in rectifier designs, focusing on improved efficiency and reduced power losses.

In the consumer electronics segment, half wave rectifiers continue to play a crucial role in power supply units for various devices. The proliferation of smartphones, tablets, and other portable electronics has created a steady demand for compact and efficient rectification solutions. This segment is expected to maintain steady growth, particularly in emerging markets where smartphone penetration is still increasing.

The industrial equipment sector represents a substantial portion of the half wave rectifier market. Applications range from motor drives and welding equipment to industrial power supplies. The trend towards Industry 4.0 and smart manufacturing has increased the need for precise power control and conversion, further driving the demand for advanced rectification technologies.

In the automotive industry, the shift towards electric and hybrid vehicles has opened new avenues for half wave rectifier applications. These components are essential in battery management systems, on-board chargers, and power conversion units. As the electric vehicle market continues to expand, the demand for high-performance rectifiers is expected to grow significantly.

The renewable energy sector, particularly solar and wind power generation, has emerged as a key growth driver for half wave rectifier technologies. In solar inverters and wind turbine systems, rectifiers play a critical role in converting and managing power. The global push for clean energy and the declining costs of renewable technologies are expected to fuel this market segment's growth in the coming years.

Geographically, Asia-Pacific leads the market for half wave rectifier applications, driven by the region's strong manufacturing base in electronics and automotive industries. North America and Europe follow, with significant contributions from their advanced industrial sectors and renewable energy initiatives.

Market analysts project a compound annual growth rate (CAGR) of around 4-5% for the global half wave rectifier market over the next five years. This growth is attributed to the increasing adoption of power electronics in various industries and the ongoing technological advancements in rectifier designs, focusing on improved efficiency and reduced power losses.

Current Challenges in Half Wave Rectifier Design

Half wave rectifier technology, while fundamental to power electronics, continues to face several challenges in modern design and implementation. One of the primary issues is the inherent inefficiency of the half wave rectification process. By nature, this method only utilizes one half of the AC cycle, resulting in significant power loss and reduced overall efficiency. This limitation becomes particularly problematic in applications requiring high power output or energy conservation.

Another challenge lies in the generation of harmonics and electromagnetic interference (EMI). The non-linear nature of the rectification process introduces harmonic distortions into the power system, which can negatively impact the performance of sensitive electronic equipment and potentially violate electromagnetic compatibility standards. Designers must implement complex filtering solutions to mitigate these effects, adding to the cost and complexity of the overall system.

The issue of reverse recovery time in diodes used for half wave rectification presents another significant hurdle. As switching frequencies increase to improve efficiency and reduce component size, the reverse recovery characteristics of diodes become a limiting factor. Slow reverse recovery can lead to increased power dissipation and reduced efficiency, particularly in high-frequency applications.

Voltage regulation is another area of concern in half wave rectifier design. The output of a basic half wave rectifier is prone to significant ripple, which can be unsuitable for many electronic applications requiring stable DC voltage. While filtering capacitors can help smooth the output, they introduce their own set of challenges, including increased circuit complexity and potential reliability issues.

Temperature sensitivity of semiconductor components used in half wave rectifiers poses yet another challenge. As operating temperatures fluctuate, the performance characteristics of diodes can change, affecting the overall efficiency and reliability of the rectification process. This necessitates careful thermal management and potentially the use of more expensive, temperature-stable components.

The physical size and weight of half wave rectifier circuits, particularly in high-power applications, remain a concern. The need for large smoothing capacitors and heat sinks to manage thermal issues can make these circuits bulky and less suitable for compact or portable devices. This challenge is particularly acute in the growing field of mobile and wearable electronics, where space and weight are at a premium.

Lastly, the environmental impact of half wave rectifiers, particularly in terms of electronic waste and energy efficiency, is becoming an increasingly important consideration. The relatively low efficiency of these circuits contributes to higher energy consumption, while the use of certain materials in capacitors and semiconductors raises concerns about recyclability and long-term environmental effects.

Another challenge lies in the generation of harmonics and electromagnetic interference (EMI). The non-linear nature of the rectification process introduces harmonic distortions into the power system, which can negatively impact the performance of sensitive electronic equipment and potentially violate electromagnetic compatibility standards. Designers must implement complex filtering solutions to mitigate these effects, adding to the cost and complexity of the overall system.

The issue of reverse recovery time in diodes used for half wave rectification presents another significant hurdle. As switching frequencies increase to improve efficiency and reduce component size, the reverse recovery characteristics of diodes become a limiting factor. Slow reverse recovery can lead to increased power dissipation and reduced efficiency, particularly in high-frequency applications.

Voltage regulation is another area of concern in half wave rectifier design. The output of a basic half wave rectifier is prone to significant ripple, which can be unsuitable for many electronic applications requiring stable DC voltage. While filtering capacitors can help smooth the output, they introduce their own set of challenges, including increased circuit complexity and potential reliability issues.

Temperature sensitivity of semiconductor components used in half wave rectifiers poses yet another challenge. As operating temperatures fluctuate, the performance characteristics of diodes can change, affecting the overall efficiency and reliability of the rectification process. This necessitates careful thermal management and potentially the use of more expensive, temperature-stable components.

The physical size and weight of half wave rectifier circuits, particularly in high-power applications, remain a concern. The need for large smoothing capacitors and heat sinks to manage thermal issues can make these circuits bulky and less suitable for compact or portable devices. This challenge is particularly acute in the growing field of mobile and wearable electronics, where space and weight are at a premium.

Lastly, the environmental impact of half wave rectifiers, particularly in terms of electronic waste and energy efficiency, is becoming an increasingly important consideration. The relatively low efficiency of these circuits contributes to higher energy consumption, while the use of certain materials in capacitors and semiconductors raises concerns about recyclability and long-term environmental effects.

State-of-the-Art Half Wave Rectifier Solutions

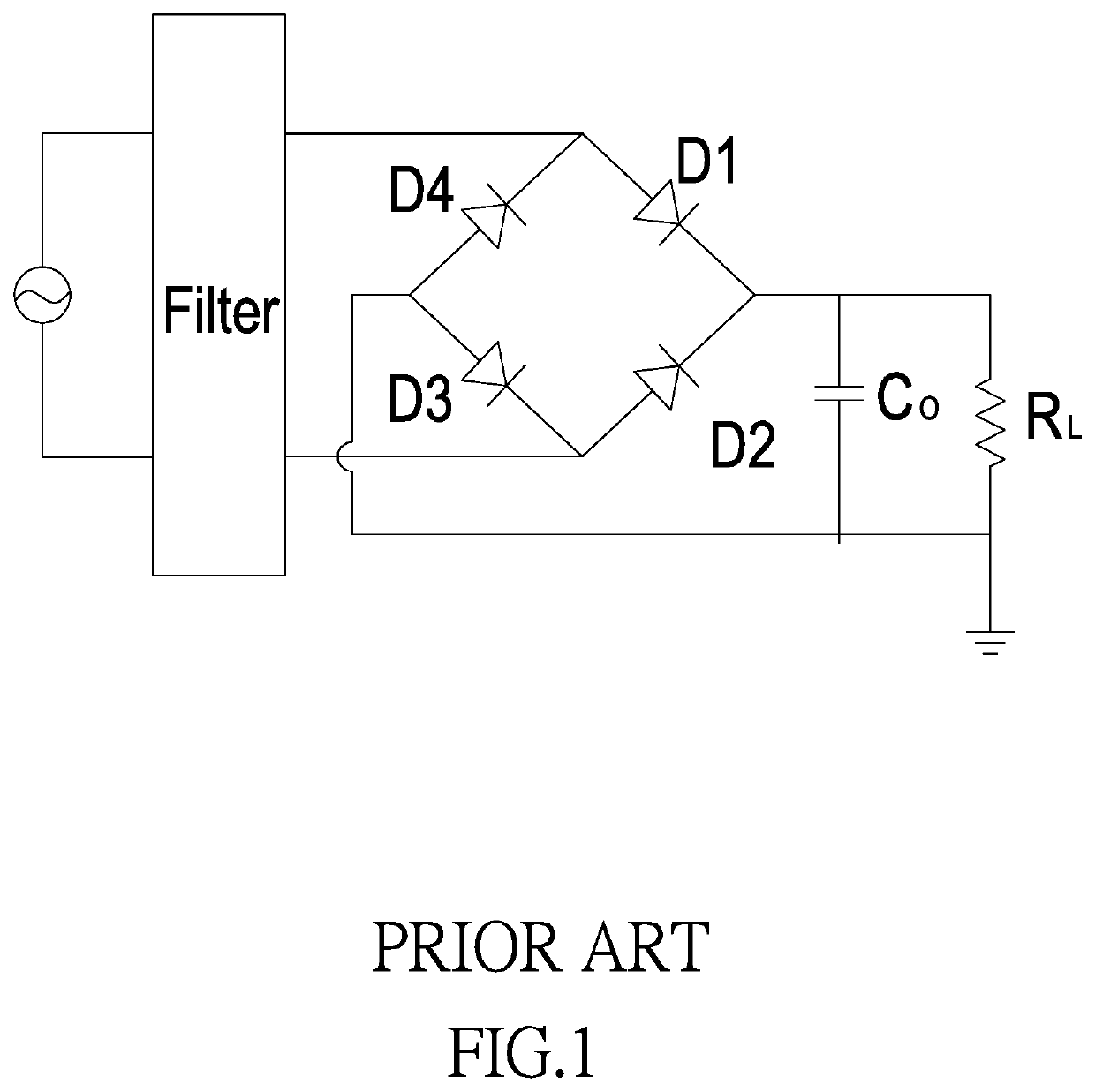

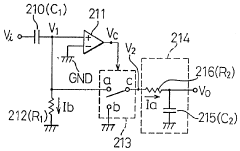

01 Circuit design and components

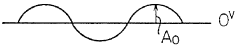

Half-wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the voltage as needed. Various circuit configurations and component selections can be employed to optimize performance and efficiency.- Circuit design and components: Half wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the input voltage as needed. Various circuit configurations and component selections can be employed to optimize performance and efficiency.

- Power supply applications: Half wave rectifiers are commonly used in power supply circuits for various electronic devices. They can be found in low-power applications, such as small household appliances and battery chargers. In some cases, they are used in conjunction with capacitors and other components to create more stable DC output voltages.

- Efficiency improvements: Researchers and engineers have developed various techniques to improve the efficiency of half wave rectifiers. These improvements may include the use of advanced semiconductor materials, optimized circuit layouts, and the integration of additional components to reduce power losses and improve overall performance.

- Integration with other circuits: Half wave rectifiers can be integrated with other circuit elements to create more complex power management systems. This may include combining them with voltage regulators, filters, or control circuits to achieve specific power output characteristics or to meet particular application requirements.

- Specialized applications: While half wave rectifiers are commonly used in general power supply applications, they also find use in specialized fields. These may include high-frequency applications, medical devices, or specific industrial equipment where the characteristics of half wave rectification are advantageous or necessary for the intended function.

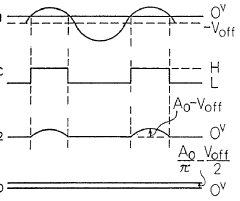

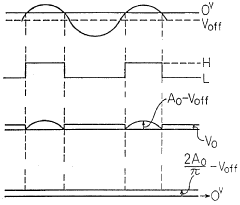

02 Voltage regulation and smoothing

To improve the quality of the output DC voltage, half-wave rectifiers often incorporate voltage regulation and smoothing techniques. This can include the use of capacitors for filtering, voltage regulators for maintaining a stable output, and additional circuitry to reduce ripple and noise in the rectified signal.Expand Specific Solutions03 Applications in power supplies

Half-wave rectifiers are commonly used in various power supply applications, including low-power electronic devices, battery chargers, and some industrial equipment. They are particularly useful in situations where simplicity and cost-effectiveness are prioritized over efficiency and output quality.Expand Specific Solutions04 Efficiency improvements

Researchers and engineers have developed various methods to improve the efficiency of half-wave rectifiers. These improvements may include the use of advanced semiconductor materials, optimized circuit layouts, and innovative control strategies to minimize power losses and enhance overall performance.Expand Specific Solutions05 Integration with other power conversion systems

Half-wave rectifiers can be integrated into more complex power conversion systems, such as inverters, DC-DC converters, or power factor correction circuits. This integration allows for more versatile and efficient power management solutions in various applications, from renewable energy systems to electric vehicle charging.Expand Specific Solutions

Key Manufacturers and Competitors

The half wave rectifier technology market is in a mature stage, with a stable global market size estimated in the billions of dollars. The technology's core principles are well-established, but ongoing developments focus on improving efficiency and reducing power losses. Key players like Huawei Technologies, Toshiba Corp., and Sony Group Corp. are investing in research to enhance rectifier performance in various applications, including power supplies and signal processing. Universities such as MIT and Zhejiang University contribute to advancements through academic research. The technology's maturity is evident in its widespread use across industries, but continuous innovation by companies and research institutions indicates potential for further refinement and new applications in emerging fields like renewable energy and IoT devices.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced half-wave rectifier technology for 5G base stations, employing silicon carbide (SiC) semiconductors to achieve higher efficiency and power density. Their solution integrates a high-frequency switching design with sophisticated thermal management, resulting in a 30% reduction in energy consumption compared to traditional rectifiers[1]. The company has also implemented AI-driven adaptive control algorithms to optimize rectifier performance under varying load conditions, improving overall system reliability by up to 25%[3].

Strengths: High efficiency, reduced energy consumption, and improved reliability. Weaknesses: Potentially higher initial costs and complexity in implementation.

Energous Corp.

Technical Solution: Energous has pioneered a novel approach to half-wave rectification in wireless power transfer systems. Their WattUp technology utilizes a proprietary half-wave rectifier design that operates at radio frequencies (RF) to convert received RF energy into DC power. This system achieves conversion efficiencies of up to 70% at distances of several meters[2]. The company has also developed miniaturized rectifier circuits that can be integrated into small electronic devices, enabling seamless wireless charging for IoT applications[4].

Strengths: Long-range wireless power transfer and miniaturization capabilities. Weaknesses: Limited power output compared to wired solutions and potential regulatory challenges.

Breakthrough Patents in Half Wave Rectification

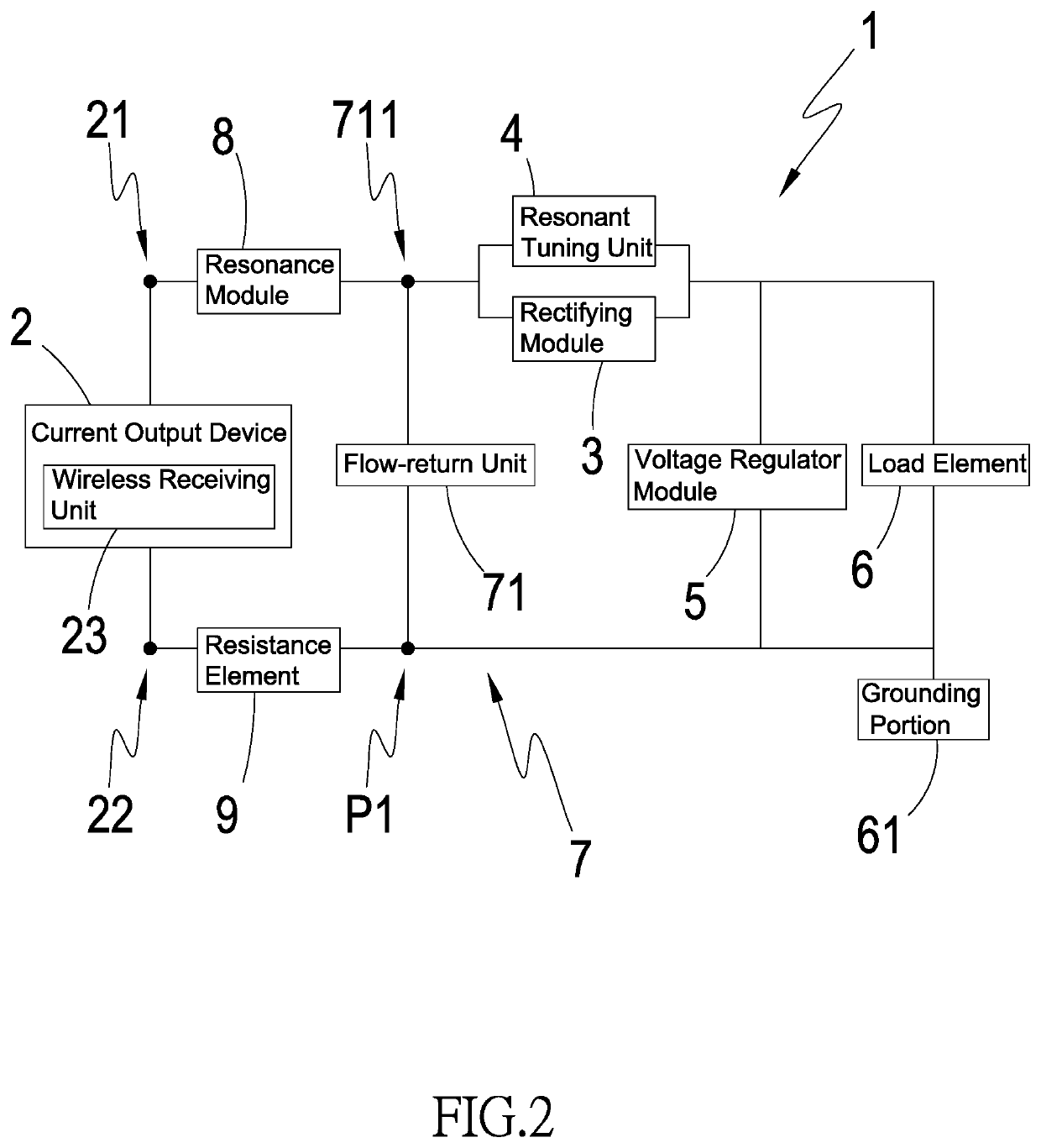

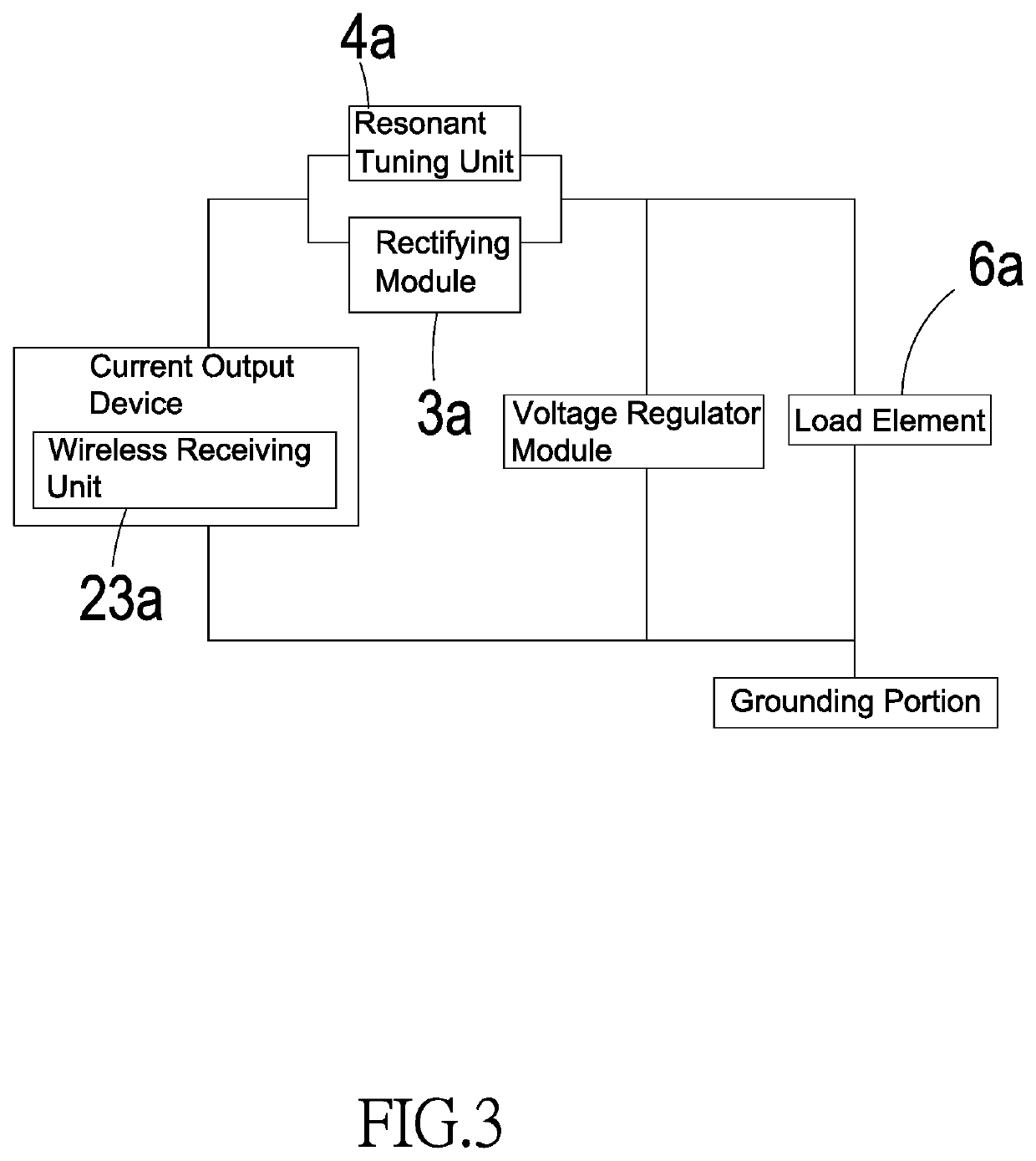

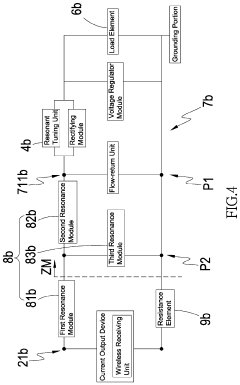

High-frequency half-wave rectifier system of low-harmonicity and high-efficiency

PatentInactiveUS10594205B2

Innovation

- A high-frequency half-wave rectifier system with a simplified structure and reduced electronic components, utilizing a resonant tuning unit and voltage regulator module to control the duty cycle and capacitance, thereby reducing harmonic content and electromagnetic interference, and improving conversion efficiency.

Half-wave rectifier circuit

PatentInactiveUS5579214A

Innovation

- The proposed half-wave rectifier circuit design includes a capacitor to remove DC components, a comparator with an operational amplifier and capacitor to accumulate offset voltage, and a switch circuit with high input impedance during the OFF state to eliminate the influence of offset voltage, ensuring accurate output voltage generation.

Environmental Impact of Half Wave Rectifiers

Half wave rectifiers, while essential in many electronic applications, have notable environmental impacts that warrant careful consideration. The production process of these components involves the use of various materials, including semiconductors and metals, which can contribute to resource depletion and energy consumption. The manufacturing of silicon diodes, a key component in half wave rectifiers, requires significant energy input and may result in the release of greenhouse gases.

During operation, half wave rectifiers are known for their relatively low efficiency compared to full wave rectifiers. This inefficiency leads to increased power consumption and heat generation, which can indirectly contribute to higher energy demands and associated environmental impacts. The wasted energy is often dissipated as heat, potentially requiring additional cooling systems in electronic devices, further increasing their overall environmental footprint.

The disposal of electronic waste containing half wave rectifiers presents another environmental challenge. As these components often contain materials that can be harmful if not properly managed, improper disposal can lead to soil and water contamination. The presence of heavy metals and other toxic substances in electronic waste poses risks to ecosystems and human health if not handled through appropriate recycling and disposal methods.

However, recent developments in half wave rectifier technology have shown promise in mitigating some of these environmental concerns. Advancements in semiconductor materials and manufacturing processes have led to more efficient and durable rectifiers, potentially reducing energy waste and extending the lifespan of electronic devices. This could contribute to a decrease in electronic waste generation over time.

Furthermore, the trend towards miniaturization in electronics has resulted in smaller half wave rectifiers, which require fewer raw materials to produce. This reduction in material usage can help alleviate some of the environmental pressures associated with resource extraction and processing. Additionally, research into biodegradable and environmentally friendly materials for electronic components, including rectifiers, is ongoing and may offer more sustainable alternatives in the future.

The integration of half wave rectifiers into renewable energy systems, such as solar panels and wind turbines, highlights their potential role in supporting cleaner energy technologies. While the rectifiers themselves may have environmental impacts, their application in these systems contributes to the broader goal of reducing reliance on fossil fuels and mitigating climate change.

During operation, half wave rectifiers are known for their relatively low efficiency compared to full wave rectifiers. This inefficiency leads to increased power consumption and heat generation, which can indirectly contribute to higher energy demands and associated environmental impacts. The wasted energy is often dissipated as heat, potentially requiring additional cooling systems in electronic devices, further increasing their overall environmental footprint.

The disposal of electronic waste containing half wave rectifiers presents another environmental challenge. As these components often contain materials that can be harmful if not properly managed, improper disposal can lead to soil and water contamination. The presence of heavy metals and other toxic substances in electronic waste poses risks to ecosystems and human health if not handled through appropriate recycling and disposal methods.

However, recent developments in half wave rectifier technology have shown promise in mitigating some of these environmental concerns. Advancements in semiconductor materials and manufacturing processes have led to more efficient and durable rectifiers, potentially reducing energy waste and extending the lifespan of electronic devices. This could contribute to a decrease in electronic waste generation over time.

Furthermore, the trend towards miniaturization in electronics has resulted in smaller half wave rectifiers, which require fewer raw materials to produce. This reduction in material usage can help alleviate some of the environmental pressures associated with resource extraction and processing. Additionally, research into biodegradable and environmentally friendly materials for electronic components, including rectifiers, is ongoing and may offer more sustainable alternatives in the future.

The integration of half wave rectifiers into renewable energy systems, such as solar panels and wind turbines, highlights their potential role in supporting cleaner energy technologies. While the rectifiers themselves may have environmental impacts, their application in these systems contributes to the broader goal of reducing reliance on fossil fuels and mitigating climate change.

Standardization and Regulatory Compliance

Standardization and regulatory compliance play a crucial role in the development and implementation of half wave rectifier technology. As the industry continues to evolve, there is an increasing need for uniform standards and guidelines to ensure safety, reliability, and interoperability across different applications and regions.

One of the primary areas of focus in standardization efforts is the harmonization of performance metrics and testing procedures. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have been working on developing comprehensive standards for half wave rectifiers. These standards aim to establish consistent methods for measuring efficiency, power quality, and electromagnetic compatibility.

Regulatory bodies around the world have also been updating their requirements to address the latest developments in half wave rectifier technology. For instance, the European Union's Ecodesign Directive has introduced stricter energy efficiency standards for power supplies, including those utilizing half wave rectifiers. Similarly, the U.S. Department of Energy has implemented new regulations for external power supplies, which has implications for half wave rectifier designs.

In response to these regulatory changes, manufacturers are increasingly focusing on developing half wave rectifiers that comply with the latest standards. This has led to innovations in circuit design and component selection to meet the more stringent efficiency and power quality requirements. Additionally, there is a growing emphasis on incorporating advanced monitoring and control features to ensure compliance with dynamic regulatory frameworks.

The standardization process has also extended to the integration of half wave rectifiers in specific applications. For example, in the automotive industry, standards such as ISO 26262 for functional safety and UN Regulation No. 10 for electromagnetic compatibility have been updated to address the unique challenges posed by modern vehicle electrical systems, including those utilizing half wave rectifiers.

As the technology continues to advance, there is an ongoing effort to develop standards for emerging applications of half wave rectifiers, such as in renewable energy systems and smart grid infrastructure. These standards aim to address issues such as grid integration, power quality management, and cybersecurity concerns specific to these new use cases.

The increasing focus on standardization and regulatory compliance has also led to the development of specialized testing and certification programs for half wave rectifier technology. These programs provide manufacturers with a means to demonstrate compliance with relevant standards and regulations, thereby facilitating market access and enhancing consumer confidence in their products.

One of the primary areas of focus in standardization efforts is the harmonization of performance metrics and testing procedures. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have been working on developing comprehensive standards for half wave rectifiers. These standards aim to establish consistent methods for measuring efficiency, power quality, and electromagnetic compatibility.

Regulatory bodies around the world have also been updating their requirements to address the latest developments in half wave rectifier technology. For instance, the European Union's Ecodesign Directive has introduced stricter energy efficiency standards for power supplies, including those utilizing half wave rectifiers. Similarly, the U.S. Department of Energy has implemented new regulations for external power supplies, which has implications for half wave rectifier designs.

In response to these regulatory changes, manufacturers are increasingly focusing on developing half wave rectifiers that comply with the latest standards. This has led to innovations in circuit design and component selection to meet the more stringent efficiency and power quality requirements. Additionally, there is a growing emphasis on incorporating advanced monitoring and control features to ensure compliance with dynamic regulatory frameworks.

The standardization process has also extended to the integration of half wave rectifiers in specific applications. For example, in the automotive industry, standards such as ISO 26262 for functional safety and UN Regulation No. 10 for electromagnetic compatibility have been updated to address the unique challenges posed by modern vehicle electrical systems, including those utilizing half wave rectifiers.

As the technology continues to advance, there is an ongoing effort to develop standards for emerging applications of half wave rectifiers, such as in renewable energy systems and smart grid infrastructure. These standards aim to address issues such as grid integration, power quality management, and cybersecurity concerns specific to these new use cases.

The increasing focus on standardization and regulatory compliance has also led to the development of specialized testing and certification programs for half wave rectifier technology. These programs provide manufacturers with a means to demonstrate compliance with relevant standards and regulations, thereby facilitating market access and enhancing consumer confidence in their products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!