How to Design a Half Wave Rectifier for Maximum Output?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half-wave rectification has been a fundamental technique in power electronics since the early days of electrical engineering. This process, which converts alternating current (AC) to pulsating direct current (DC), has played a crucial role in the development of various electronic devices and power supply systems. The evolution of half-wave rectifiers has been driven by the increasing demand for more efficient and reliable power conversion methods in a wide range of applications, from simple household appliances to complex industrial equipment.

The primary objective of designing a half-wave rectifier for maximum output is to optimize the conversion of AC to DC while minimizing power losses and improving overall efficiency. This goal aligns with the broader trends in power electronics, which emphasize energy conservation, miniaturization, and enhanced performance. Achieving maximum output in a half-wave rectifier involves addressing several key factors, including component selection, circuit configuration, and load characteristics.

As technology has progressed, the design of half-wave rectifiers has become more sophisticated, incorporating advanced materials and innovative circuit topologies. Modern half-wave rectifiers often utilize high-performance diodes, such as Schottky diodes, which offer lower forward voltage drops and faster switching speeds compared to traditional silicon diodes. These improvements contribute to reduced power losses and increased efficiency in the rectification process.

The pursuit of maximum output in half-wave rectifier design also involves considering the specific requirements of the target application. For instance, in low-power consumer electronics, the focus may be on minimizing component size and cost while maintaining acceptable performance. In contrast, high-power industrial applications may prioritize robustness, reliability, and heat dissipation capabilities.

Recent technological advancements have opened up new possibilities for enhancing half-wave rectifier performance. The integration of digital control systems and smart power management techniques has enabled more precise regulation of the rectification process, adapting to varying load conditions and input voltages. Additionally, the emergence of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has introduced new opportunities for improving rectifier efficiency and power density.

Looking ahead, the development of half-wave rectifiers is expected to continue evolving in response to emerging trends in power electronics. These include the growing adoption of renewable energy sources, the proliferation of electric vehicles, and the increasing demand for high-efficiency power conversion in data centers and telecommunications infrastructure. As such, the design of half-wave rectifiers for maximum output remains a relevant and dynamic field of study, with ongoing research focused on pushing the boundaries of efficiency, reliability, and performance in power conversion systems.

The primary objective of designing a half-wave rectifier for maximum output is to optimize the conversion of AC to DC while minimizing power losses and improving overall efficiency. This goal aligns with the broader trends in power electronics, which emphasize energy conservation, miniaturization, and enhanced performance. Achieving maximum output in a half-wave rectifier involves addressing several key factors, including component selection, circuit configuration, and load characteristics.

As technology has progressed, the design of half-wave rectifiers has become more sophisticated, incorporating advanced materials and innovative circuit topologies. Modern half-wave rectifiers often utilize high-performance diodes, such as Schottky diodes, which offer lower forward voltage drops and faster switching speeds compared to traditional silicon diodes. These improvements contribute to reduced power losses and increased efficiency in the rectification process.

The pursuit of maximum output in half-wave rectifier design also involves considering the specific requirements of the target application. For instance, in low-power consumer electronics, the focus may be on minimizing component size and cost while maintaining acceptable performance. In contrast, high-power industrial applications may prioritize robustness, reliability, and heat dissipation capabilities.

Recent technological advancements have opened up new possibilities for enhancing half-wave rectifier performance. The integration of digital control systems and smart power management techniques has enabled more precise regulation of the rectification process, adapting to varying load conditions and input voltages. Additionally, the emergence of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has introduced new opportunities for improving rectifier efficiency and power density.

Looking ahead, the development of half-wave rectifiers is expected to continue evolving in response to emerging trends in power electronics. These include the growing adoption of renewable energy sources, the proliferation of electric vehicles, and the increasing demand for high-efficiency power conversion in data centers and telecommunications infrastructure. As such, the design of half-wave rectifiers for maximum output remains a relevant and dynamic field of study, with ongoing research focused on pushing the boundaries of efficiency, reliability, and performance in power conversion systems.

Market Demand Analysis for Efficient Power Supplies

The market demand for efficient power supplies, particularly those incorporating half-wave rectifiers for maximum output, has been steadily increasing across various industries. This growth is primarily driven by the rising need for energy-efficient solutions in consumer electronics, industrial equipment, and renewable energy systems.

In the consumer electronics sector, the proliferation of smartphones, tablets, and laptops has created a substantial demand for compact and efficient power supplies. These devices require reliable power conversion with minimal energy loss, making half-wave rectifiers an essential component in their charging systems. The global smartphone market alone is expected to reach 1.5 billion units by 2026, indicating a significant potential for power supply manufacturers.

The industrial sector presents another substantial market opportunity for efficient power supplies. Manufacturing facilities, data centers, and automation systems require robust and energy-efficient power conversion solutions to reduce operational costs and meet stringent environmental regulations. The industrial power supply market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026, reaching a value of $54 billion by the end of the forecast period.

Renewable energy systems, particularly solar and wind power installations, represent a rapidly expanding market for efficient power supplies. As the world transitions towards cleaner energy sources, the demand for high-performance rectifiers in inverters and charge controllers is increasing. The global solar inverter market is expected to grow at a CAGR of 15.45% from 2021 to 2026, further driving the need for advanced rectifier designs.

The automotive industry is another key driver of market demand for efficient power supplies. With the growing adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for high-performance power conversion systems. The global EV market is projected to reach 34 million units by 2030, creating a substantial opportunity for power supply manufacturers specializing in automotive applications.

Emerging technologies such as 5G networks and Internet of Things (IoT) devices are also contributing to the demand for efficient power supplies. These technologies require reliable and compact power conversion solutions to support their widespread deployment and operation. The global 5G infrastructure market is expected to grow at a CAGR of 49.8% from 2021 to 2028, indicating a significant potential for power supply manufacturers in this sector.

As energy efficiency becomes increasingly important across all industries, the demand for power supplies with optimized half-wave rectifiers is expected to continue growing. Manufacturers that can deliver innovative solutions with improved efficiency, reduced size, and enhanced reliability will be well-positioned to capitalize on this expanding market opportunity.

In the consumer electronics sector, the proliferation of smartphones, tablets, and laptops has created a substantial demand for compact and efficient power supplies. These devices require reliable power conversion with minimal energy loss, making half-wave rectifiers an essential component in their charging systems. The global smartphone market alone is expected to reach 1.5 billion units by 2026, indicating a significant potential for power supply manufacturers.

The industrial sector presents another substantial market opportunity for efficient power supplies. Manufacturing facilities, data centers, and automation systems require robust and energy-efficient power conversion solutions to reduce operational costs and meet stringent environmental regulations. The industrial power supply market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026, reaching a value of $54 billion by the end of the forecast period.

Renewable energy systems, particularly solar and wind power installations, represent a rapidly expanding market for efficient power supplies. As the world transitions towards cleaner energy sources, the demand for high-performance rectifiers in inverters and charge controllers is increasing. The global solar inverter market is expected to grow at a CAGR of 15.45% from 2021 to 2026, further driving the need for advanced rectifier designs.

The automotive industry is another key driver of market demand for efficient power supplies. With the growing adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for high-performance power conversion systems. The global EV market is projected to reach 34 million units by 2030, creating a substantial opportunity for power supply manufacturers specializing in automotive applications.

Emerging technologies such as 5G networks and Internet of Things (IoT) devices are also contributing to the demand for efficient power supplies. These technologies require reliable and compact power conversion solutions to support their widespread deployment and operation. The global 5G infrastructure market is expected to grow at a CAGR of 49.8% from 2021 to 2028, indicating a significant potential for power supply manufacturers in this sector.

As energy efficiency becomes increasingly important across all industries, the demand for power supplies with optimized half-wave rectifiers is expected to continue growing. Manufacturers that can deliver innovative solutions with improved efficiency, reduced size, and enhanced reliability will be well-positioned to capitalize on this expanding market opportunity.

Current Challenges in Half Wave Rectifier Design

Half wave rectifiers face several significant challenges in achieving maximum output, primarily due to their inherent design limitations and the evolving demands of modern electronic applications. One of the foremost issues is the low efficiency of these rectifiers, as they only utilize one half of the AC input cycle. This results in a considerable amount of wasted energy and reduced power output compared to full-wave rectifiers.

Another critical challenge is the high ripple content in the output voltage. The pulsating nature of the half-wave rectified output requires substantial filtering to produce a smooth DC voltage, which can be problematic in applications requiring high-quality power supplies. This ripple not only affects the overall efficiency but also introduces noise and potential instability in sensitive electronic circuits.

The peak inverse voltage (PIV) stress on the rectifying diode presents an additional design hurdle. During the negative half-cycle, the diode must withstand the full peak voltage of the AC source, necessitating the use of higher-rated components and potentially increasing costs and complexity.

Furthermore, the non-linear behavior of diodes introduces harmonic distortion into the rectified output. This distortion can propagate through the power supply system, potentially affecting the performance of connected devices and creating electromagnetic interference (EMI) issues.

Temperature sensitivity is another significant challenge in half-wave rectifier design. The performance of semiconductor diodes varies with temperature, affecting the rectifier's efficiency and reliability across different operating conditions. This necessitates careful component selection and thermal management strategies to ensure consistent performance.

The limited current handling capacity of half-wave rectifiers poses difficulties in high-power applications. The rectifying diode must handle the full load current during its conduction period, which can lead to increased stress and potential failure in demanding scenarios.

Addressing these challenges requires innovative approaches in circuit design and component selection. Engineers are exploring advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), to improve diode performance. Additionally, the integration of active power factor correction (PFC) circuits and sophisticated control algorithms is being investigated to enhance efficiency and reduce harmonic distortion.

Emerging research is also focusing on hybrid rectifier topologies that combine the simplicity of half-wave rectifiers with additional components to mitigate their limitations. These designs aim to improve efficiency, reduce ripple, and enhance overall performance while maintaining the cost-effectiveness and simplicity that make half-wave rectifiers attractive in certain applications.

Another critical challenge is the high ripple content in the output voltage. The pulsating nature of the half-wave rectified output requires substantial filtering to produce a smooth DC voltage, which can be problematic in applications requiring high-quality power supplies. This ripple not only affects the overall efficiency but also introduces noise and potential instability in sensitive electronic circuits.

The peak inverse voltage (PIV) stress on the rectifying diode presents an additional design hurdle. During the negative half-cycle, the diode must withstand the full peak voltage of the AC source, necessitating the use of higher-rated components and potentially increasing costs and complexity.

Furthermore, the non-linear behavior of diodes introduces harmonic distortion into the rectified output. This distortion can propagate through the power supply system, potentially affecting the performance of connected devices and creating electromagnetic interference (EMI) issues.

Temperature sensitivity is another significant challenge in half-wave rectifier design. The performance of semiconductor diodes varies with temperature, affecting the rectifier's efficiency and reliability across different operating conditions. This necessitates careful component selection and thermal management strategies to ensure consistent performance.

The limited current handling capacity of half-wave rectifiers poses difficulties in high-power applications. The rectifying diode must handle the full load current during its conduction period, which can lead to increased stress and potential failure in demanding scenarios.

Addressing these challenges requires innovative approaches in circuit design and component selection. Engineers are exploring advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), to improve diode performance. Additionally, the integration of active power factor correction (PFC) circuits and sophisticated control algorithms is being investigated to enhance efficiency and reduce harmonic distortion.

Emerging research is also focusing on hybrid rectifier topologies that combine the simplicity of half-wave rectifiers with additional components to mitigate their limitations. These designs aim to improve efficiency, reduce ripple, and enhance overall performance while maintaining the cost-effectiveness and simplicity that make half-wave rectifiers attractive in certain applications.

Existing Half Wave Rectifier Design Solutions

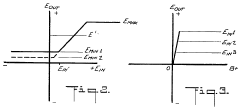

01 Output voltage characteristics

Half-wave rectifiers produce a pulsating DC output voltage with only positive or negative half-cycles of the input AC waveform. This results in a lower average output voltage compared to full-wave rectifiers and higher ripple content. The output waveform consists of discrete pulses separated by zero-voltage periods.- Output voltage characteristics: The output of a half-wave rectifier is characterized by a pulsating DC voltage with only positive half-cycles of the input AC waveform. This results in a lower average output voltage compared to full-wave rectification. The output contains significant ripple, which may require additional filtering for smoother DC output.

- Efficiency and power considerations: Half-wave rectifiers have lower efficiency compared to full-wave rectifiers due to utilizing only half of the input waveform. This results in higher power loss and lower power output. They are typically used in low-power applications or where simplicity is preferred over efficiency.

- Filtering and smoothing techniques: To improve the quality of the output, various filtering and smoothing techniques can be applied to the half-wave rectifier output. Common methods include using capacitors for smoothing, LC filters for ripple reduction, and active filtering circuits to achieve a more stable DC output voltage.

- Applications in power supplies: Half-wave rectifiers are used in various power supply applications, particularly in low-power devices. They can be found in simple AC adapters, battery chargers, and some electronic circuits where cost and simplicity are prioritized over performance. In some cases, they are used as part of more complex power supply designs.

- Improvements and modifications: Various improvements and modifications have been developed to enhance the performance of half-wave rectifiers. These include the use of Schottky diodes for lower voltage drop, synchronous rectification for improved efficiency, and integration with other circuit elements to create more advanced power conversion solutions.

02 Filtering and smoothing techniques

To improve the quality of the half-wave rectifier output, various filtering and smoothing techniques are employed. These may include capacitor filters, inductor-capacitor (LC) filters, or more complex filter networks. Such techniques help reduce ripple and provide a more stable DC output voltage for various applications.Expand Specific Solutions03 Efficiency and power factor considerations

Half-wave rectifiers generally have lower efficiency and power factor compared to full-wave rectifiers. This is due to the utilization of only one half-cycle of the input waveform. Various circuit modifications and control strategies can be implemented to improve efficiency and power factor, such as active power factor correction techniques.Expand Specific Solutions04 Applications in power supplies and charging circuits

Half-wave rectifiers find applications in various power supply and charging circuits, particularly in low-power applications. They are used in simple AC-DC converters, battery chargers, and some consumer electronics. In these applications, the rectifier output may be further processed or regulated to meet specific voltage and current requirements.Expand Specific Solutions05 Protection and control mechanisms

To ensure safe and reliable operation of half-wave rectifier circuits, various protection and control mechanisms are implemented. These may include overvoltage protection, current limiting, thermal protection, and feedback control systems. Such mechanisms help prevent damage to the rectifier components and connected loads, while also improving overall performance and stability.Expand Specific Solutions

Key Players in Power Electronics Industry

The half-wave rectifier design landscape is characterized by a mature technology in a stable market phase. While the core concept is well-established, ongoing innovations focus on improving efficiency and output quality. Companies like Mitsubishi Electric, Sanken Electric, and Fuji Electric are key players, leveraging their expertise in power electronics to refine rectifier designs. The market size is moderate but steady, driven by applications in power supplies and signal processing. Technological advancements are incremental, with firms like Mixed-Signal Devices and Semiconductor Energy Laboratory pushing boundaries in integrated circuit solutions for enhanced rectification performance.

Sanken Electric Co., Ltd.

Technical Solution: Sanken Electric has developed a robust half-wave rectifier solution designed for maximum output in industrial and automotive applications. Their approach focuses on reliability and efficiency, utilizing proprietary high-voltage diodes with optimized recovery characteristics. The rectifier design incorporates a unique passive snubber network that effectively suppresses voltage spikes without significant power loss[9]. Sanken's implementation also features an innovative thermal spreading technique that evenly distributes heat across the device, enhancing overall reliability and allowing for higher power handling. Additionally, they have integrated a compact EMI filter design that ensures compliance with stringent electromagnetic compatibility standards without compromising the rectifier's efficiency[10].

Strengths: High reliability, excellent EMI performance, and robust thermal design. Weaknesses: Potentially overdesigned for low-power consumer applications, and may have a higher cost due to specialized components.

Fuji Electric Co., Ltd.

Technical Solution: Fuji Electric has engineered a highly efficient half-wave rectifier design focused on maximizing output while minimizing losses. Their approach utilizes advanced power semiconductor devices, such as super-junction MOSFETs, which offer lower on-resistance and faster switching speeds compared to conventional devices[7]. The rectifier circuit incorporates a sophisticated gate drive system that optimizes switching timing to reduce losses during the transition periods. Fuji's design also includes an innovative passive cooling solution that enhances heat dissipation without the need for active cooling in many applications. Furthermore, they have implemented a digital control system that allows for real-time adjustment of rectification parameters based on input and load conditions, ensuring optimal performance across a wide range of operating scenarios[8].

Strengths: High efficiency, excellent thermal performance without active cooling, and adaptable digital control. Weaknesses: Potential for higher initial costs due to advanced components, and possible complexity for simple applications.

Core Innovations in Rectifier Circuit Design

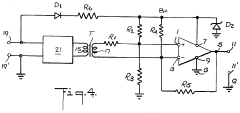

Semiconductor device and method for manufacturing semiconductor device

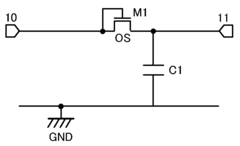

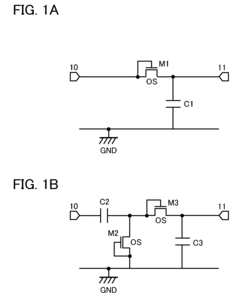

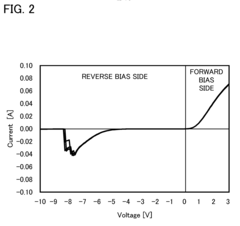

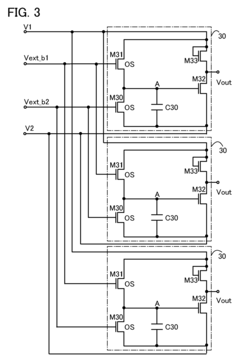

PatentInactiveUS20110216566A1

Innovation

- A rectifier circuit utilizing transistors with oxide semiconductor channel formation regions, specifically indium gallium zinc oxide (IGZO), which have significantly lower off-state currents, thereby reducing the risk of breakdown and improving reliability and efficiency by using a full-wave voltage doubler configuration and optimizing heat treatment processes to form high-quality oxide semiconductors.

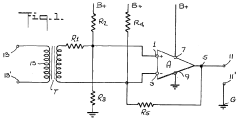

Half-wave rectifier circuit

PatentInactiveUS3936720A

Innovation

- A high-gain differential amplifier-based half-wave rectifier circuit operating from a single power supply, eliminating the need for voltage regulation and reducing temperature dependence, with resistor ratios optimized to minimize errors and achieve minimal output voltage drop.

Component Selection and Performance Impact

The selection of components for a half-wave rectifier plays a crucial role in maximizing its output performance. The primary components of a half-wave rectifier include a diode, a transformer, and a load resistor. Each of these elements significantly impacts the rectifier's efficiency and output quality.

The diode is the heart of the rectifier circuit, responsible for converting AC to pulsating DC. Choosing a diode with low forward voltage drop and fast recovery time is essential for minimizing power loss and improving efficiency. Silicon diodes are commonly used due to their balance of cost and performance. However, for high-frequency applications, Schottky diodes may be preferred due to their lower forward voltage drop and faster switching capabilities.

The transformer serves to step down or step up the input voltage as required and provides isolation between the input and output circuits. The selection of an appropriate transformer depends on the desired output voltage and current requirements. A transformer with low core losses and good regulation characteristics will contribute to higher efficiency and better output stability.

The load resistor determines the current drawn from the rectifier and affects the ripple in the output voltage. A higher load resistance results in lower current and potentially higher output voltage, but may lead to increased ripple. Conversely, a lower load resistance draws more current, potentially reducing the output voltage but with less ripple.

To maximize output, careful consideration must be given to the voltage ratings and current handling capabilities of all components. The diode's peak inverse voltage (PIV) rating should be at least twice the peak input voltage to ensure reliable operation. Similarly, the transformer's voltage and current ratings should match or exceed the circuit requirements to prevent saturation and overheating.

The impact of component selection on performance is significant. High-quality components with tight tolerances can lead to improved efficiency, reduced power loss, and better overall performance. For instance, using a diode with lower forward voltage drop can increase the output voltage and reduce power dissipation. Similarly, a transformer with lower core losses will improve overall efficiency.

Temperature considerations are also crucial. Components should be selected to operate within their specified temperature ranges under expected load conditions. Proper heat sinking may be necessary for high-power applications to maintain component reliability and performance.

In conclusion, the careful selection of components, considering their individual characteristics and their interactions within the circuit, is paramount in designing a half-wave rectifier for maximum output. Balancing factors such as efficiency, cost, and reliability will lead to an optimized design that meets the specific requirements of the application.

The diode is the heart of the rectifier circuit, responsible for converting AC to pulsating DC. Choosing a diode with low forward voltage drop and fast recovery time is essential for minimizing power loss and improving efficiency. Silicon diodes are commonly used due to their balance of cost and performance. However, for high-frequency applications, Schottky diodes may be preferred due to their lower forward voltage drop and faster switching capabilities.

The transformer serves to step down or step up the input voltage as required and provides isolation between the input and output circuits. The selection of an appropriate transformer depends on the desired output voltage and current requirements. A transformer with low core losses and good regulation characteristics will contribute to higher efficiency and better output stability.

The load resistor determines the current drawn from the rectifier and affects the ripple in the output voltage. A higher load resistance results in lower current and potentially higher output voltage, but may lead to increased ripple. Conversely, a lower load resistance draws more current, potentially reducing the output voltage but with less ripple.

To maximize output, careful consideration must be given to the voltage ratings and current handling capabilities of all components. The diode's peak inverse voltage (PIV) rating should be at least twice the peak input voltage to ensure reliable operation. Similarly, the transformer's voltage and current ratings should match or exceed the circuit requirements to prevent saturation and overheating.

The impact of component selection on performance is significant. High-quality components with tight tolerances can lead to improved efficiency, reduced power loss, and better overall performance. For instance, using a diode with lower forward voltage drop can increase the output voltage and reduce power dissipation. Similarly, a transformer with lower core losses will improve overall efficiency.

Temperature considerations are also crucial. Components should be selected to operate within their specified temperature ranges under expected load conditions. Proper heat sinking may be necessary for high-power applications to maintain component reliability and performance.

In conclusion, the careful selection of components, considering their individual characteristics and their interactions within the circuit, is paramount in designing a half-wave rectifier for maximum output. Balancing factors such as efficiency, cost, and reliability will lead to an optimized design that meets the specific requirements of the application.

Thermal Management Considerations

Thermal management is a critical aspect of designing a half-wave rectifier for maximum output. As the rectifier operates, it generates heat due to power dissipation in the diode and other components. Effective thermal management is essential to maintain the rectifier's performance, reliability, and longevity.

The primary source of heat in a half-wave rectifier is the diode. During the conduction phase, the diode experiences forward voltage drop, resulting in power dissipation. This power is converted into heat, which must be efficiently removed to prevent thermal runaway and component failure. The amount of heat generated is directly proportional to the current flowing through the diode and its forward voltage drop.

To address thermal concerns, proper heat sinking is crucial. Heat sinks are designed to increase the surface area available for heat dissipation, allowing for more efficient cooling. The selection of an appropriate heat sink depends on factors such as the power dissipation of the diode, ambient temperature, and available space. Thermal interface materials, such as thermal paste or pads, are often used to improve heat transfer between the diode and the heat sink.

In addition to heat sinking, forced air cooling may be necessary for high-power applications. This can be achieved through the use of fans or blowers to increase air circulation and enhance convective heat transfer. The placement and orientation of cooling components should be carefully considered to optimize airflow and minimize thermal resistance.

Temperature monitoring is another important aspect of thermal management. Implementing temperature sensors near critical components allows for real-time monitoring of operating temperatures. This information can be used to trigger protective measures, such as reducing input power or activating additional cooling mechanisms, if temperatures exceed safe operating limits.

The layout of the rectifier circuit also plays a role in thermal management. Proper component placement and PCB design can help distribute heat more evenly and reduce hot spots. Using thicker copper traces and larger copper areas can improve heat dissipation through the PCB itself.

For high-power applications, more advanced cooling techniques may be required. These can include liquid cooling systems or thermoelectric coolers, which offer superior heat removal capabilities compared to traditional air cooling methods.

Thermal simulation tools can be valuable in the design process, allowing engineers to predict temperature distributions and identify potential thermal issues before physical prototyping. These tools can help optimize component placement, heat sink design, and overall thermal management strategies.

By carefully considering thermal management aspects in the design of a half-wave rectifier, engineers can ensure optimal performance, improved reliability, and extended component life. This approach contributes to achieving maximum output while maintaining safe operating temperatures and preventing thermal-related failures.

The primary source of heat in a half-wave rectifier is the diode. During the conduction phase, the diode experiences forward voltage drop, resulting in power dissipation. This power is converted into heat, which must be efficiently removed to prevent thermal runaway and component failure. The amount of heat generated is directly proportional to the current flowing through the diode and its forward voltage drop.

To address thermal concerns, proper heat sinking is crucial. Heat sinks are designed to increase the surface area available for heat dissipation, allowing for more efficient cooling. The selection of an appropriate heat sink depends on factors such as the power dissipation of the diode, ambient temperature, and available space. Thermal interface materials, such as thermal paste or pads, are often used to improve heat transfer between the diode and the heat sink.

In addition to heat sinking, forced air cooling may be necessary for high-power applications. This can be achieved through the use of fans or blowers to increase air circulation and enhance convective heat transfer. The placement and orientation of cooling components should be carefully considered to optimize airflow and minimize thermal resistance.

Temperature monitoring is another important aspect of thermal management. Implementing temperature sensors near critical components allows for real-time monitoring of operating temperatures. This information can be used to trigger protective measures, such as reducing input power or activating additional cooling mechanisms, if temperatures exceed safe operating limits.

The layout of the rectifier circuit also plays a role in thermal management. Proper component placement and PCB design can help distribute heat more evenly and reduce hot spots. Using thicker copper traces and larger copper areas can improve heat dissipation through the PCB itself.

For high-power applications, more advanced cooling techniques may be required. These can include liquid cooling systems or thermoelectric coolers, which offer superior heat removal capabilities compared to traditional air cooling methods.

Thermal simulation tools can be valuable in the design process, allowing engineers to predict temperature distributions and identify potential thermal issues before physical prototyping. These tools can help optimize component placement, heat sink design, and overall thermal management strategies.

By carefully considering thermal management aspects in the design of a half-wave rectifier, engineers can ensure optimal performance, improved reliability, and extended component life. This approach contributes to achieving maximum output while maintaining safe operating temperatures and preventing thermal-related failures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!