How to Implement Half Wave Rectifiers for Voltage Regulation?

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectification Background and Objectives

Half wave rectification is a fundamental technique in electrical engineering that has been instrumental in the development of power electronics and voltage regulation systems. This method of converting alternating current (AC) to pulsating direct current (DC) has its roots in the early 20th century, coinciding with the widespread adoption of AC power distribution systems. The primary objective of half wave rectification in voltage regulation is to provide a stable, unidirectional current flow from an AC source, which is essential for powering various electronic devices and systems.

The evolution of half wave rectification technology has been closely tied to advancements in semiconductor materials and device fabrication. Initially, vacuum tube diodes were used for rectification, but these were gradually replaced by solid-state semiconductor diodes in the mid-20th century. This transition marked a significant improvement in efficiency, reliability, and miniaturization of rectification circuits. The development of silicon-based diodes, in particular, revolutionized the field, offering superior performance characteristics and enabling the widespread application of half wave rectifiers in consumer electronics, industrial equipment, and power supply systems.

In the context of voltage regulation, half wave rectifiers serve as a crucial first step in converting AC to DC. However, the pulsating nature of the output from a half wave rectifier presents challenges in achieving stable voltage levels. This has led to the development of various smoothing and filtering techniques, often used in conjunction with half wave rectification, to produce a more consistent DC output. The ongoing technological goal is to improve the efficiency of the rectification process, minimize power losses, and enhance the quality of the DC output.

Recent trends in half wave rectification for voltage regulation focus on addressing the limitations of traditional designs. These include efforts to reduce voltage drops across rectifying elements, improve the power factor, and minimize electromagnetic interference. Additionally, there is a growing emphasis on developing rectification systems that can handle higher frequencies and power levels, driven by the demands of modern power electronics applications such as switch-mode power supplies and renewable energy systems.

The future objectives for half wave rectification technology in voltage regulation are multifaceted. They include the development of more efficient and compact rectifier designs, the integration of advanced control algorithms for improved regulation, and the exploration of novel materials and device structures to enhance performance. There is also a push towards creating more versatile rectification systems that can adapt to varying input conditions and load requirements, thereby improving overall system reliability and efficiency.

The evolution of half wave rectification technology has been closely tied to advancements in semiconductor materials and device fabrication. Initially, vacuum tube diodes were used for rectification, but these were gradually replaced by solid-state semiconductor diodes in the mid-20th century. This transition marked a significant improvement in efficiency, reliability, and miniaturization of rectification circuits. The development of silicon-based diodes, in particular, revolutionized the field, offering superior performance characteristics and enabling the widespread application of half wave rectifiers in consumer electronics, industrial equipment, and power supply systems.

In the context of voltage regulation, half wave rectifiers serve as a crucial first step in converting AC to DC. However, the pulsating nature of the output from a half wave rectifier presents challenges in achieving stable voltage levels. This has led to the development of various smoothing and filtering techniques, often used in conjunction with half wave rectification, to produce a more consistent DC output. The ongoing technological goal is to improve the efficiency of the rectification process, minimize power losses, and enhance the quality of the DC output.

Recent trends in half wave rectification for voltage regulation focus on addressing the limitations of traditional designs. These include efforts to reduce voltage drops across rectifying elements, improve the power factor, and minimize electromagnetic interference. Additionally, there is a growing emphasis on developing rectification systems that can handle higher frequencies and power levels, driven by the demands of modern power electronics applications such as switch-mode power supplies and renewable energy systems.

The future objectives for half wave rectification technology in voltage regulation are multifaceted. They include the development of more efficient and compact rectifier designs, the integration of advanced control algorithms for improved regulation, and the exploration of novel materials and device structures to enhance performance. There is also a push towards creating more versatile rectification systems that can adapt to varying input conditions and load requirements, thereby improving overall system reliability and efficiency.

Market Demand for Voltage Regulation Solutions

The market demand for voltage regulation solutions has been steadily increasing across various industries due to the growing need for reliable and efficient power management systems. Half-wave rectifiers, as a fundamental component in voltage regulation circuits, play a crucial role in meeting this demand.

In the industrial sector, the rise of automation and smart manufacturing has led to a surge in demand for precise voltage control. Manufacturing equipment, robotics, and process control systems require stable power supplies to ensure optimal performance and prevent costly downtime. This has created a significant market opportunity for voltage regulation solutions incorporating half-wave rectifiers.

The automotive industry has also become a major driver of demand for voltage regulation technologies. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for efficient power conversion and management systems. Half-wave rectifiers are essential components in these vehicles' onboard chargers and power distribution units, contributing to improved energy efficiency and extended battery life.

In the consumer electronics sector, the proliferation of portable devices and smart home appliances has fueled the demand for compact and energy-efficient voltage regulation solutions. Half-wave rectifiers are widely used in power adapters, chargers, and power management integrated circuits (PMICs) to ensure stable power delivery and protect sensitive electronic components.

The renewable energy sector has emerged as another significant market for voltage regulation technologies. Solar and wind power systems require efficient power conversion and regulation to integrate with the grid and provide stable electricity output. Half-wave rectifiers are utilized in inverters and power conditioning units to help manage the variable nature of renewable energy sources.

Telecommunications infrastructure, including 5G networks and data centers, represents a growing market for voltage regulation solutions. The need for reliable power supplies in these critical systems has increased the demand for advanced rectification and voltage control technologies.

The healthcare industry has also seen a rise in demand for voltage regulation solutions, particularly in medical imaging equipment and patient monitoring systems. These devices require precise and stable power supplies to ensure accurate diagnostics and patient safety.

As the Internet of Things (IoT) continues to expand, the demand for low-power voltage regulation solutions has grown significantly. IoT devices often operate on battery power or energy harvesting systems, necessitating efficient voltage regulation to extend device lifespan and improve overall performance.

The global market for voltage regulation solutions is expected to continue its growth trajectory, driven by technological advancements, increasing electrification across industries, and the ongoing push for energy efficiency. As a result, the demand for half-wave rectifiers and related voltage regulation technologies is likely to remain strong in the foreseeable future.

In the industrial sector, the rise of automation and smart manufacturing has led to a surge in demand for precise voltage control. Manufacturing equipment, robotics, and process control systems require stable power supplies to ensure optimal performance and prevent costly downtime. This has created a significant market opportunity for voltage regulation solutions incorporating half-wave rectifiers.

The automotive industry has also become a major driver of demand for voltage regulation technologies. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for efficient power conversion and management systems. Half-wave rectifiers are essential components in these vehicles' onboard chargers and power distribution units, contributing to improved energy efficiency and extended battery life.

In the consumer electronics sector, the proliferation of portable devices and smart home appliances has fueled the demand for compact and energy-efficient voltage regulation solutions. Half-wave rectifiers are widely used in power adapters, chargers, and power management integrated circuits (PMICs) to ensure stable power delivery and protect sensitive electronic components.

The renewable energy sector has emerged as another significant market for voltage regulation technologies. Solar and wind power systems require efficient power conversion and regulation to integrate with the grid and provide stable electricity output. Half-wave rectifiers are utilized in inverters and power conditioning units to help manage the variable nature of renewable energy sources.

Telecommunications infrastructure, including 5G networks and data centers, represents a growing market for voltage regulation solutions. The need for reliable power supplies in these critical systems has increased the demand for advanced rectification and voltage control technologies.

The healthcare industry has also seen a rise in demand for voltage regulation solutions, particularly in medical imaging equipment and patient monitoring systems. These devices require precise and stable power supplies to ensure accurate diagnostics and patient safety.

As the Internet of Things (IoT) continues to expand, the demand for low-power voltage regulation solutions has grown significantly. IoT devices often operate on battery power or energy harvesting systems, necessitating efficient voltage regulation to extend device lifespan and improve overall performance.

The global market for voltage regulation solutions is expected to continue its growth trajectory, driven by technological advancements, increasing electrification across industries, and the ongoing push for energy efficiency. As a result, the demand for half-wave rectifiers and related voltage regulation technologies is likely to remain strong in the foreseeable future.

Current Challenges in Half Wave Rectifier Implementation

The implementation of half-wave rectifiers for voltage regulation faces several significant challenges in today's technological landscape. One of the primary issues is the inherent inefficiency of half-wave rectification. This process only utilizes one half of the AC cycle, resulting in a lower overall power output compared to full-wave rectification. This inefficiency can lead to increased power consumption and heat generation, which are critical concerns in modern electronic devices where energy efficiency is paramount.

Another challenge lies in the ripple voltage produced by half-wave rectifiers. The pulsating DC output contains a significant AC component, which can introduce noise and instability in sensitive electronic circuits. This ripple effect necessitates additional filtering components, increasing the complexity and cost of the overall system. The design of effective smoothing circuits to mitigate this ripple becomes crucial, especially in applications requiring stable and clean DC voltage.

The non-linear behavior of diodes used in half-wave rectifiers presents another hurdle. Diodes have a forward voltage drop, which can be significant in low-voltage applications. This voltage drop reduces the overall efficiency of the rectifier and can cause distortion in the output waveform. Additionally, the temperature sensitivity of diodes can lead to variations in performance across different operating conditions, making it challenging to maintain consistent voltage regulation.

Electromagnetic interference (EMI) is a growing concern in half-wave rectifier implementations. The abrupt current flow during the conduction phase of the rectifier can generate high-frequency harmonics, potentially causing interference with other electronic systems. This issue is particularly problematic in densely packed electronic environments, where multiple devices operate in close proximity.

Scaling half-wave rectifiers for high-power applications presents its own set of challenges. As power requirements increase, the stress on individual components, particularly the rectifying diode, becomes more severe. This can lead to reliability issues and reduced lifespan of the rectifier circuit. Designing robust thermal management solutions and selecting appropriate components capable of handling high currents and voltages become critical considerations.

The advent of high-frequency power supplies and switch-mode power converters has also introduced new challenges for half-wave rectifier implementations. These systems often operate at frequencies much higher than traditional line frequencies, requiring rectifiers with faster switching capabilities and lower recovery times. The selection of diodes with appropriate reverse recovery characteristics becomes crucial to maintain efficiency and prevent excessive power dissipation.

Lastly, the integration of half-wave rectifiers into miniaturized and portable devices poses significant design challenges. The need for compact form factors often conflicts with the requirements for adequate heat dissipation and filtering components. Balancing these competing demands while maintaining performance and reliability is a complex task that requires innovative design approaches and careful component selection.

Another challenge lies in the ripple voltage produced by half-wave rectifiers. The pulsating DC output contains a significant AC component, which can introduce noise and instability in sensitive electronic circuits. This ripple effect necessitates additional filtering components, increasing the complexity and cost of the overall system. The design of effective smoothing circuits to mitigate this ripple becomes crucial, especially in applications requiring stable and clean DC voltage.

The non-linear behavior of diodes used in half-wave rectifiers presents another hurdle. Diodes have a forward voltage drop, which can be significant in low-voltage applications. This voltage drop reduces the overall efficiency of the rectifier and can cause distortion in the output waveform. Additionally, the temperature sensitivity of diodes can lead to variations in performance across different operating conditions, making it challenging to maintain consistent voltage regulation.

Electromagnetic interference (EMI) is a growing concern in half-wave rectifier implementations. The abrupt current flow during the conduction phase of the rectifier can generate high-frequency harmonics, potentially causing interference with other electronic systems. This issue is particularly problematic in densely packed electronic environments, where multiple devices operate in close proximity.

Scaling half-wave rectifiers for high-power applications presents its own set of challenges. As power requirements increase, the stress on individual components, particularly the rectifying diode, becomes more severe. This can lead to reliability issues and reduced lifespan of the rectifier circuit. Designing robust thermal management solutions and selecting appropriate components capable of handling high currents and voltages become critical considerations.

The advent of high-frequency power supplies and switch-mode power converters has also introduced new challenges for half-wave rectifier implementations. These systems often operate at frequencies much higher than traditional line frequencies, requiring rectifiers with faster switching capabilities and lower recovery times. The selection of diodes with appropriate reverse recovery characteristics becomes crucial to maintain efficiency and prevent excessive power dissipation.

Lastly, the integration of half-wave rectifiers into miniaturized and portable devices poses significant design challenges. The need for compact form factors often conflicts with the requirements for adequate heat dissipation and filtering components. Balancing these competing demands while maintaining performance and reliability is a complex task that requires innovative design approaches and careful component selection.

Existing Half Wave Rectifier Circuit Designs

01 Circuit design for half-wave rectifiers

Half-wave rectifiers are designed to convert alternating current (AC) to pulsating direct current (DC). The circuit typically includes a diode that allows current to flow in only one direction during each AC cycle. This design is fundamental to many power supply applications and can be optimized for specific voltage requirements.- Circuit design for half-wave rectifiers: Half-wave rectifiers are designed to convert alternating current (AC) to pulsating direct current (DC). The circuit typically includes a diode that allows current to flow in only one direction during each AC cycle. This design is fundamental to many power supply applications and can be optimized for specific voltage requirements.

- Voltage regulation in half-wave rectifier systems: Voltage regulation is crucial in half-wave rectifier systems to maintain a stable output voltage. Various techniques are employed, such as using voltage regulators, feedback loops, or capacitive filtering. These methods help to smooth out the pulsating DC and provide a more consistent voltage output for different load conditions.

- Efficiency improvements in half-wave rectification: Enhancing the efficiency of half-wave rectifiers involves minimizing power losses and improving the overall power conversion process. This can be achieved through the use of advanced semiconductor materials, optimized circuit layouts, and innovative cooling solutions. Improved efficiency leads to better performance and reduced energy consumption in various applications.

- Integration of half-wave rectifiers in power supply systems: Half-wave rectifiers are often integrated into larger power supply systems. This integration involves considerations such as input and output filtering, protection circuits, and compatibility with other power conversion stages. The design aims to provide a reliable and efficient power source for various electronic devices and industrial applications.

- Control and monitoring of half-wave rectifier voltage: Advanced control and monitoring techniques are implemented to manage the voltage output of half-wave rectifiers. These may include digital control systems, real-time voltage sensing, and adaptive algorithms to adjust the rectification process based on load demands or input variations. Such systems ensure optimal performance and protection of the rectifier and connected devices.

02 Voltage regulation in half-wave rectifier systems

Voltage regulation is crucial in half-wave rectifier systems to maintain a stable output voltage. This can be achieved through various methods, including the use of capacitors for smoothing, voltage dividers for adjustment, and feedback loops for automatic regulation. Advanced control circuits can be implemented to improve the overall efficiency and stability of the rectified voltage.Expand Specific Solutions03 Efficiency improvements in half-wave rectification

Enhancing the efficiency of half-wave rectifiers involves minimizing power losses and improving the quality of the output voltage. This can be achieved through the use of high-performance diodes, optimized circuit layouts, and advanced filtering techniques. Some designs incorporate synchronous rectification or active power factor correction to further improve efficiency.Expand Specific Solutions04 Application-specific half-wave rectifier designs

Half-wave rectifiers can be tailored for specific applications such as battery charging, LED driving, or power supply units for electronic devices. These designs may incorporate additional features like overcurrent protection, temperature compensation, or multiple output voltages to meet the requirements of different applications.Expand Specific Solutions05 Integration of half-wave rectifiers in complex systems

Half-wave rectifiers are often integrated into larger power management systems or electronic devices. This integration may involve combining the rectifier with other power conversion stages, control circuits, or monitoring systems. Advanced designs may incorporate microcontrollers or digital signal processors for intelligent power management and improved performance.Expand Specific Solutions

Key Players in Power Electronics Industry

The implementation of half wave rectifiers for voltage regulation is in a mature stage of development, with a well-established market and widespread application across various industries. The global power electronics market, which includes voltage regulation technologies, is projected to reach significant size in the coming years. Major players in this field include TE Connectivity Corp., Panasonic Holdings Corp., and Infineon Technologies AG, who have demonstrated advanced capabilities in semiconductor and electronic component manufacturing. These companies, along with others like STMicroelectronics and Texas Instruments, continue to innovate in power management solutions, driving the technology's evolution towards higher efficiency and miniaturization. The competitive landscape is characterized by ongoing research and development efforts to improve performance and reduce costs in voltage regulation applications.

Sanken Electric Co., Ltd.

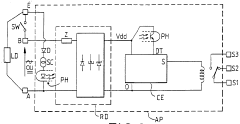

Technical Solution: Sanken Electric specializes in power semiconductor devices and implements half-wave rectifiers for voltage regulation with a focus on high reliability and efficiency. Their approach often involves the use of proprietary diode structures optimized for low forward voltage drop and high surge current capability. Sanken's half-wave rectifier solutions frequently incorporate advanced thermal management techniques, including innovative package designs for improved heat dissipation [7]. They also emphasize robust designs capable of withstanding harsh environmental conditions, making their solutions suitable for automotive and industrial applications. Sanken's designs often feature integrated protection circuits and are optimized for low EMI emissions [8].

Strengths: High reliability, robust designs suitable for harsh environments, and advanced thermal management. Weaknesses: May have a more limited product range compared to larger competitors, potentially higher cost for specialized applications.

Infineon Technologies AG

Technical Solution: Infineon's approach to half-wave rectifiers for voltage regulation focuses on high-performance power semiconductor devices. They utilize advanced silicon and wide-bandgap materials like silicon carbide (SiC) to create efficient rectifying diodes. Infineon's solutions often incorporate smart gate driver ICs and sophisticated control algorithms to optimize switching behavior and reduce electromagnetic interference (EMI) [2]. Their half-wave rectifier designs frequently include integrated current sensing and temperature monitoring for improved reliability and safety. Infineon also emphasizes compact designs, enabling higher power density in voltage regulation applications [4].

Strengths: High-performance semiconductors, advanced materials usage, and integrated smart features. Weaknesses: Potentially higher initial cost, may require specialized knowledge for implementation.

Core Innovations in Rectification Techniques

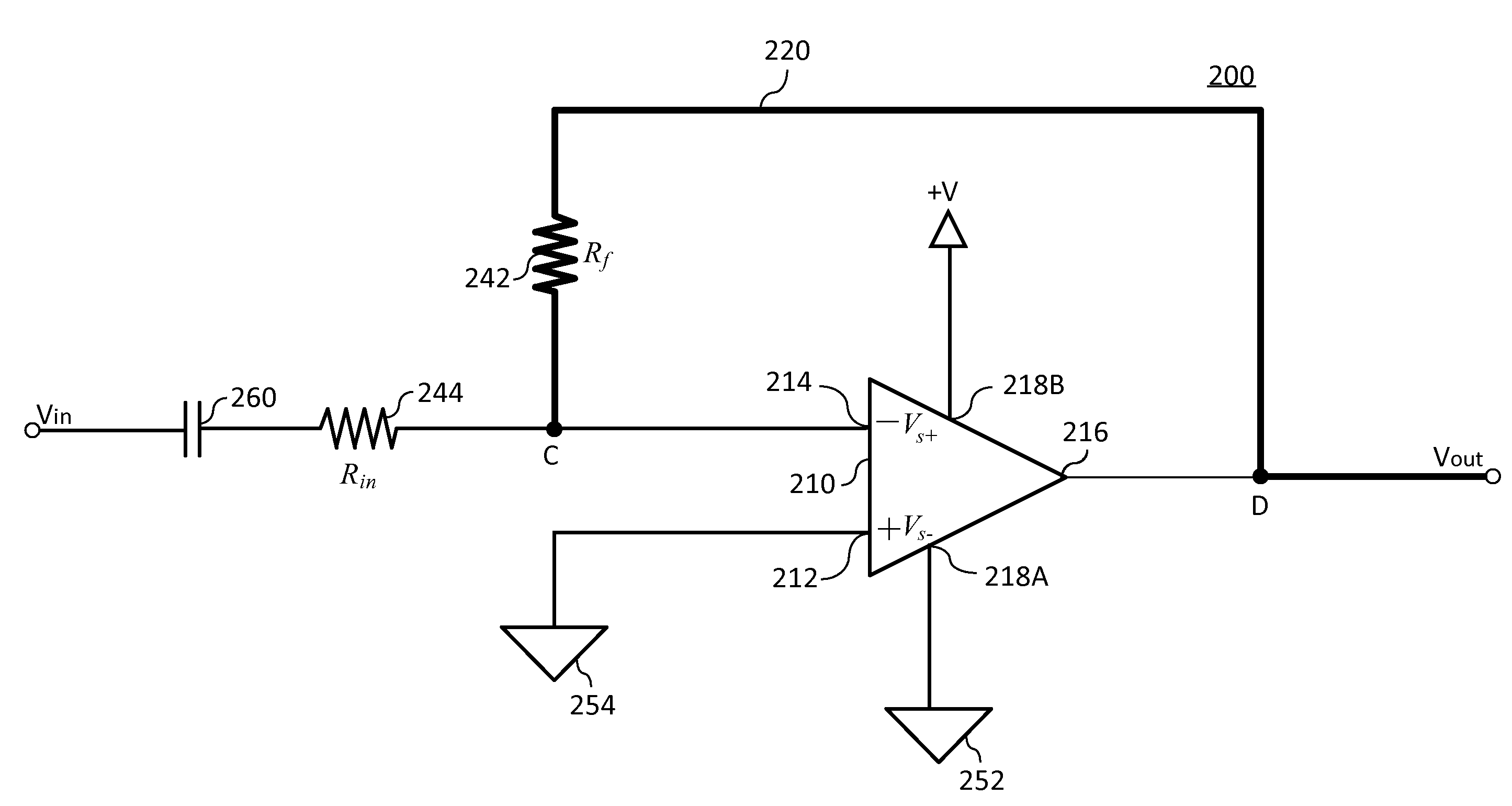

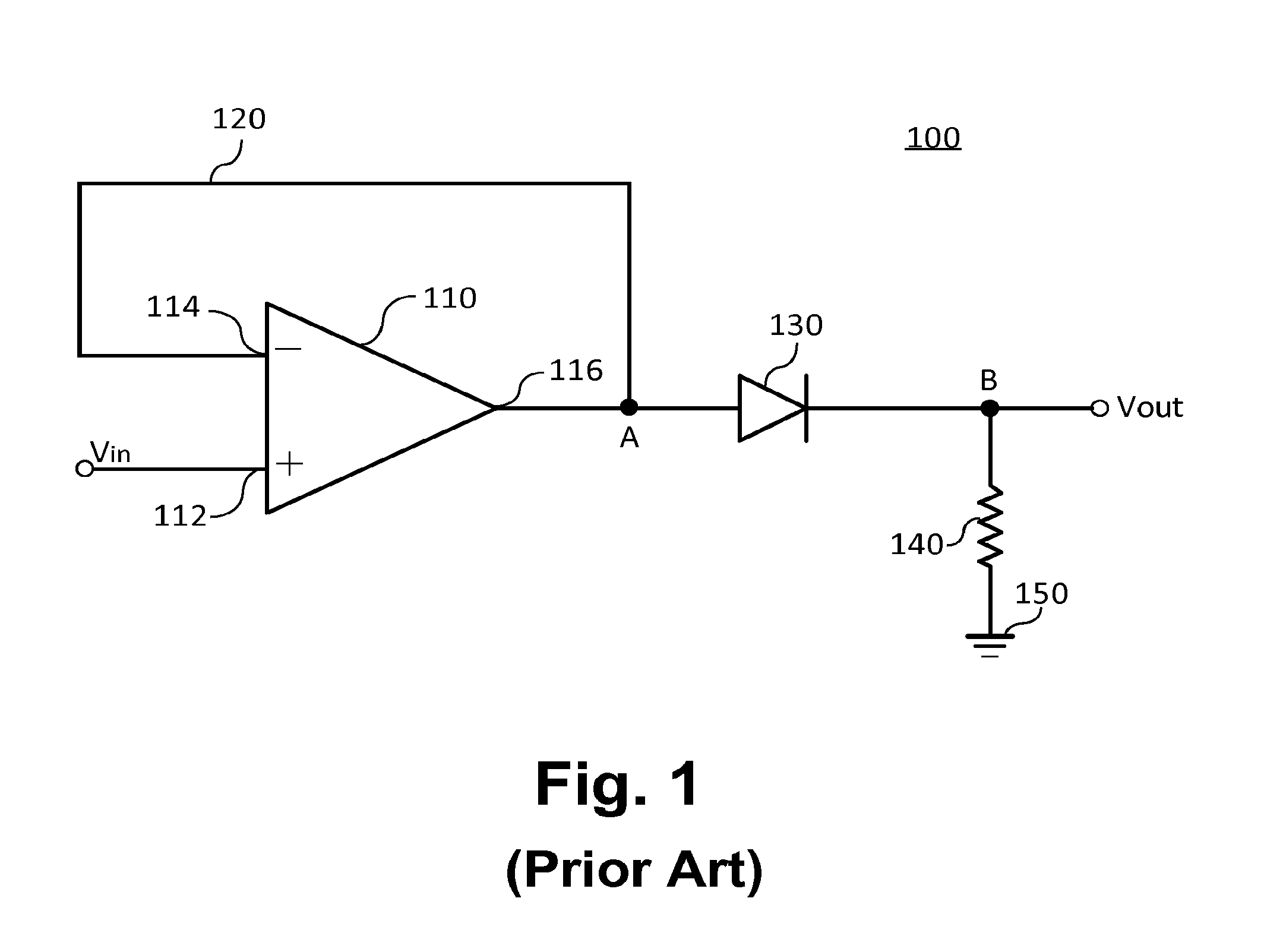

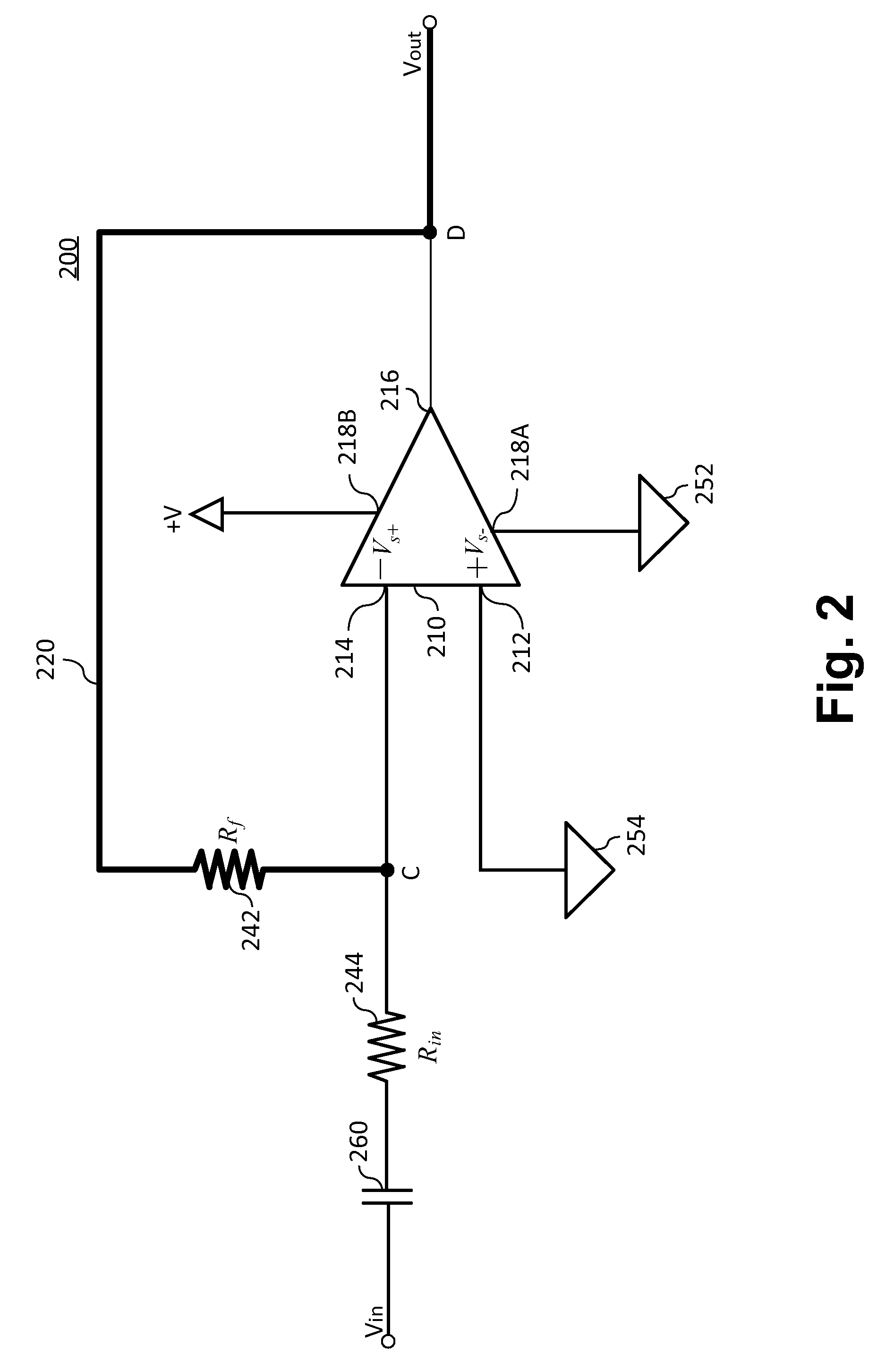

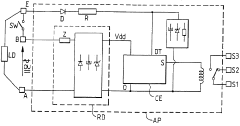

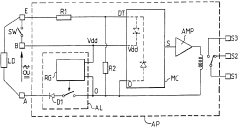

AC to DC conversion circuit

PatentActiveUS7764528B2

Innovation

- A diode-less half-wave rectifier circuit utilizing an operational amplifier with a capacitor and resistors in a negative feedback loop, allowing low-level signals to be converted to half-wave rectified DC signals, thereby extending the dynamic range of rectification.

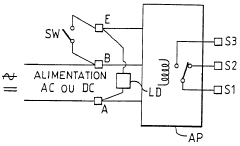

Electric apparatus with supply voltage control, operating in alternating or direct current

PatentWO2000016174A1

Innovation

- A control circuit using a half-wave rectifier and resistive divider bridge to generate a low DC voltage, with a microcontroller to detect the state of the control input signal, allowing operation across a wide range of supply voltages without the need for optocouplers, and maintaining detection accuracy even with external loads present.

Efficiency and Power Loss Considerations

Efficiency and power loss considerations are crucial aspects in the implementation of half-wave rectifiers for voltage regulation. The primary challenge lies in balancing the need for effective voltage conversion with the minimization of energy waste. Half-wave rectifiers, while simpler in design compared to full-wave counterparts, inherently suffer from lower efficiency due to their operational principle of utilizing only one half of the AC cycle.

The efficiency of a half-wave rectifier is typically limited to a theoretical maximum of 40.6%, which is significantly lower than that of full-wave rectifiers. This limitation arises from the fact that half-wave rectifiers only conduct current during one half of the AC cycle, effectively wasting the energy available in the other half. As a result, the power delivered to the load is reduced, and a larger transformer may be required to achieve the same output power as a full-wave rectifier.

Power losses in half-wave rectifiers occur through various mechanisms. The most significant source of loss is the non-conduction period during the negative half-cycle of the AC input. During this time, no power is transferred to the load, resulting in a pulsating DC output that requires additional filtering. The diode used in the rectifier also contributes to power loss through its forward voltage drop and reverse recovery characteristics.

To mitigate these efficiency issues and reduce power losses, several strategies can be employed. Implementing Schottky diodes instead of standard silicon diodes can decrease the forward voltage drop, thereby improving efficiency. Additionally, the use of synchronous rectification, where the diode is replaced with a controlled switch (such as a MOSFET), can significantly reduce conduction losses.

Proper thermal management is essential in half-wave rectifier designs to address power loss concerns. Heat sinks and adequate ventilation should be incorporated to dissipate the heat generated by power losses, particularly in higher power applications. This not only improves efficiency but also enhances the reliability and longevity of the rectifier circuit.

Another consideration is the selection of appropriate filter components. While larger capacitors can help smooth the output voltage and reduce ripple, they can also increase the peak current through the rectifier, potentially leading to higher losses. Careful selection of inductor-capacitor (LC) filter components can optimize the trade-off between output quality and efficiency.

In voltage regulation applications, the choice between linear and switching regulators following the half-wave rectifier stage can significantly impact overall system efficiency. While linear regulators are simpler and produce less noise, they are inherently less efficient than switching regulators, especially when there is a large difference between input and output voltages.

The efficiency of a half-wave rectifier is typically limited to a theoretical maximum of 40.6%, which is significantly lower than that of full-wave rectifiers. This limitation arises from the fact that half-wave rectifiers only conduct current during one half of the AC cycle, effectively wasting the energy available in the other half. As a result, the power delivered to the load is reduced, and a larger transformer may be required to achieve the same output power as a full-wave rectifier.

Power losses in half-wave rectifiers occur through various mechanisms. The most significant source of loss is the non-conduction period during the negative half-cycle of the AC input. During this time, no power is transferred to the load, resulting in a pulsating DC output that requires additional filtering. The diode used in the rectifier also contributes to power loss through its forward voltage drop and reverse recovery characteristics.

To mitigate these efficiency issues and reduce power losses, several strategies can be employed. Implementing Schottky diodes instead of standard silicon diodes can decrease the forward voltage drop, thereby improving efficiency. Additionally, the use of synchronous rectification, where the diode is replaced with a controlled switch (such as a MOSFET), can significantly reduce conduction losses.

Proper thermal management is essential in half-wave rectifier designs to address power loss concerns. Heat sinks and adequate ventilation should be incorporated to dissipate the heat generated by power losses, particularly in higher power applications. This not only improves efficiency but also enhances the reliability and longevity of the rectifier circuit.

Another consideration is the selection of appropriate filter components. While larger capacitors can help smooth the output voltage and reduce ripple, they can also increase the peak current through the rectifier, potentially leading to higher losses. Careful selection of inductor-capacitor (LC) filter components can optimize the trade-off between output quality and efficiency.

In voltage regulation applications, the choice between linear and switching regulators following the half-wave rectifier stage can significantly impact overall system efficiency. While linear regulators are simpler and produce less noise, they are inherently less efficient than switching regulators, especially when there is a large difference between input and output voltages.

Thermal Management in Rectifier Circuits

Thermal management is a critical aspect of rectifier circuit design, particularly in half-wave rectifiers used for voltage regulation. As these circuits handle significant power levels, they generate substantial heat that must be effectively dissipated to ensure optimal performance and longevity of the components. The primary sources of heat in rectifier circuits are the diodes and any voltage-dropping or current-limiting resistors.

Diodes, being semiconductor devices, exhibit a forward voltage drop that results in power dissipation. In half-wave rectifiers, this power dissipation occurs during the conduction phase of each cycle. The amount of heat generated is proportional to the forward current and the forward voltage drop of the diode. High-power applications may require the use of heat sinks or forced-air cooling to maintain safe operating temperatures.

Resistors used for voltage dropping or current limiting in rectifier circuits also contribute to heat generation. The power dissipated in a resistor is given by P = I²R, where I is the current flowing through the resistor and R is its resistance. In high-current applications, these resistors can become significant heat sources and may require special consideration in the thermal design.

The layout of components on the printed circuit board (PCB) plays a crucial role in thermal management. Proper placement of heat-generating components, such as diodes and power resistors, away from heat-sensitive components is essential. Additionally, the use of thermal vias and copper pours can help distribute heat more evenly across the PCB, improving overall thermal performance.

In some cases, the use of thermally conductive materials, such as thermal pads or thermal interface materials (TIMs), may be necessary to enhance heat transfer between components and heat sinks or the PCB itself. These materials help to fill air gaps and improve thermal conductivity, resulting in more efficient heat dissipation.

For high-power applications, active cooling methods may be employed. These can include forced-air cooling using fans or blowers, or even liquid cooling systems in extreme cases. The choice of cooling method depends on the specific power requirements, environmental conditions, and design constraints of the application.

Temperature monitoring and protection circuits are often incorporated into rectifier designs to prevent thermal runaway and component failure. These may include temperature sensors, thermal shutdown circuits, or current-limiting features that activate when predetermined temperature thresholds are exceeded.

In conclusion, effective thermal management in rectifier circuits, especially those employing half-wave rectifiers for voltage regulation, is crucial for ensuring reliability, efficiency, and longevity of the system. A comprehensive approach considering component selection, PCB layout, heat dissipation techniques, and protective measures is necessary to address the thermal challenges inherent in these power-handling circuits.

Diodes, being semiconductor devices, exhibit a forward voltage drop that results in power dissipation. In half-wave rectifiers, this power dissipation occurs during the conduction phase of each cycle. The amount of heat generated is proportional to the forward current and the forward voltage drop of the diode. High-power applications may require the use of heat sinks or forced-air cooling to maintain safe operating temperatures.

Resistors used for voltage dropping or current limiting in rectifier circuits also contribute to heat generation. The power dissipated in a resistor is given by P = I²R, where I is the current flowing through the resistor and R is its resistance. In high-current applications, these resistors can become significant heat sources and may require special consideration in the thermal design.

The layout of components on the printed circuit board (PCB) plays a crucial role in thermal management. Proper placement of heat-generating components, such as diodes and power resistors, away from heat-sensitive components is essential. Additionally, the use of thermal vias and copper pours can help distribute heat more evenly across the PCB, improving overall thermal performance.

In some cases, the use of thermally conductive materials, such as thermal pads or thermal interface materials (TIMs), may be necessary to enhance heat transfer between components and heat sinks or the PCB itself. These materials help to fill air gaps and improve thermal conductivity, resulting in more efficient heat dissipation.

For high-power applications, active cooling methods may be employed. These can include forced-air cooling using fans or blowers, or even liquid cooling systems in extreme cases. The choice of cooling method depends on the specific power requirements, environmental conditions, and design constraints of the application.

Temperature monitoring and protection circuits are often incorporated into rectifier designs to prevent thermal runaway and component failure. These may include temperature sensors, thermal shutdown circuits, or current-limiting features that activate when predetermined temperature thresholds are exceeded.

In conclusion, effective thermal management in rectifier circuits, especially those employing half-wave rectifiers for voltage regulation, is crucial for ensuring reliability, efficiency, and longevity of the system. A comprehensive approach considering component selection, PCB layout, heat dissipation techniques, and protective measures is necessary to address the thermal challenges inherent in these power-handling circuits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!