Strategies for Enhancing Half Wave Rectifier Performance

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half wave rectifiers have been a fundamental component in electronic circuits since the early days of electrical engineering. These devices play a crucial role in converting alternating current (AC) to pulsating direct current (DC), making them essential in various applications, from power supplies to signal processing. The evolution of half wave rectifiers has been closely tied to the advancement of semiconductor technology, with significant improvements in efficiency and performance over the years.

The primary objective of enhancing half wave rectifier performance is to increase the overall efficiency of power conversion while minimizing power losses and distortion. This goal is driven by the growing demand for more energy-efficient and compact electronic devices across multiple industries. Improved half wave rectifier performance can lead to reduced energy consumption, extended battery life in portable devices, and enhanced reliability in power systems.

One of the key trends in half wave rectifier development is the focus on reducing forward voltage drop and reverse recovery time. These improvements directly contribute to increased efficiency and reduced power dissipation. Additionally, there is a growing emphasis on developing rectifiers capable of handling higher frequencies and power levels, which is particularly important in emerging applications such as wireless power transfer and high-frequency power converters.

The technological progression of half wave rectifiers has seen a shift from vacuum tube diodes to semiconductor diodes, and more recently, to advanced materials like silicon carbide (SiC) and gallium nitride (GaN). These wide-bandgap semiconductors offer superior performance characteristics, including higher breakdown voltages, faster switching speeds, and better thermal conductivity, all of which contribute to enhanced rectifier performance.

Another significant trend is the integration of smart features and control mechanisms into rectifier circuits. This includes the development of adaptive rectification techniques that can optimize performance based on varying load conditions and input voltages. Such advancements are particularly relevant in renewable energy systems and smart grid applications, where input voltages can fluctuate significantly.

As we look towards the future, the objectives for half wave rectifier enhancement are likely to focus on further improving efficiency, reducing size and weight, and increasing power density. There is also a growing interest in developing rectifiers that can operate effectively in harsh environments, such as high-temperature and high-radiation conditions, to meet the demands of aerospace and industrial applications.

The primary objective of enhancing half wave rectifier performance is to increase the overall efficiency of power conversion while minimizing power losses and distortion. This goal is driven by the growing demand for more energy-efficient and compact electronic devices across multiple industries. Improved half wave rectifier performance can lead to reduced energy consumption, extended battery life in portable devices, and enhanced reliability in power systems.

One of the key trends in half wave rectifier development is the focus on reducing forward voltage drop and reverse recovery time. These improvements directly contribute to increased efficiency and reduced power dissipation. Additionally, there is a growing emphasis on developing rectifiers capable of handling higher frequencies and power levels, which is particularly important in emerging applications such as wireless power transfer and high-frequency power converters.

The technological progression of half wave rectifiers has seen a shift from vacuum tube diodes to semiconductor diodes, and more recently, to advanced materials like silicon carbide (SiC) and gallium nitride (GaN). These wide-bandgap semiconductors offer superior performance characteristics, including higher breakdown voltages, faster switching speeds, and better thermal conductivity, all of which contribute to enhanced rectifier performance.

Another significant trend is the integration of smart features and control mechanisms into rectifier circuits. This includes the development of adaptive rectification techniques that can optimize performance based on varying load conditions and input voltages. Such advancements are particularly relevant in renewable energy systems and smart grid applications, where input voltages can fluctuate significantly.

As we look towards the future, the objectives for half wave rectifier enhancement are likely to focus on further improving efficiency, reducing size and weight, and increasing power density. There is also a growing interest in developing rectifiers that can operate effectively in harsh environments, such as high-temperature and high-radiation conditions, to meet the demands of aerospace and industrial applications.

Market Analysis for Improved Rectification

The market for improved rectification technologies, particularly in the context of half-wave rectifiers, has shown significant growth potential in recent years. This growth is primarily driven by the increasing demand for more efficient power conversion systems across various industries. The global power electronics market, which includes rectifiers, is projected to reach a substantial market value in the coming years, with a compound annual growth rate (CAGR) that outpaces many other electronic component sectors.

One of the key factors driving this market growth is the rising adoption of renewable energy sources, such as solar and wind power. These energy sources require efficient power conversion systems, including high-performance rectifiers, to integrate with existing power grids. As governments worldwide push for cleaner energy solutions, the demand for advanced rectification technologies is expected to surge.

The automotive industry represents another significant market for improved rectification technologies. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for efficient power conversion systems. Half-wave rectifiers, when enhanced, can play a crucial role in improving the overall efficiency of EV charging systems and onboard power management.

In the consumer electronics sector, the trend towards miniaturization and increased power efficiency is creating new opportunities for enhanced half-wave rectifier technologies. Smartphones, laptops, and other portable devices require compact and efficient power conversion solutions, driving innovation in rectifier design and performance.

The industrial automation sector is also contributing to the growing demand for improved rectification technologies. As factories become more automated and digitalized, the need for reliable and efficient power conversion systems increases. Enhanced half-wave rectifiers can contribute to better energy management and reduced operational costs in industrial settings.

Geographically, Asia-Pacific is expected to dominate the market for improved rectification technologies, driven by the region's robust electronics manufacturing industry and rapid industrialization. North America and Europe are also significant markets, particularly in sectors such as renewable energy and automotive.

However, the market faces challenges such as the high initial costs associated with implementing advanced rectification technologies and the complexity of integrating these solutions into existing systems. Despite these challenges, the long-term benefits of improved efficiency and performance are expected to drive continued market growth and innovation in half-wave rectifier technologies.

One of the key factors driving this market growth is the rising adoption of renewable energy sources, such as solar and wind power. These energy sources require efficient power conversion systems, including high-performance rectifiers, to integrate with existing power grids. As governments worldwide push for cleaner energy solutions, the demand for advanced rectification technologies is expected to surge.

The automotive industry represents another significant market for improved rectification technologies. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increasing need for efficient power conversion systems. Half-wave rectifiers, when enhanced, can play a crucial role in improving the overall efficiency of EV charging systems and onboard power management.

In the consumer electronics sector, the trend towards miniaturization and increased power efficiency is creating new opportunities for enhanced half-wave rectifier technologies. Smartphones, laptops, and other portable devices require compact and efficient power conversion solutions, driving innovation in rectifier design and performance.

The industrial automation sector is also contributing to the growing demand for improved rectification technologies. As factories become more automated and digitalized, the need for reliable and efficient power conversion systems increases. Enhanced half-wave rectifiers can contribute to better energy management and reduced operational costs in industrial settings.

Geographically, Asia-Pacific is expected to dominate the market for improved rectification technologies, driven by the region's robust electronics manufacturing industry and rapid industrialization. North America and Europe are also significant markets, particularly in sectors such as renewable energy and automotive.

However, the market faces challenges such as the high initial costs associated with implementing advanced rectification technologies and the complexity of integrating these solutions into existing systems. Despite these challenges, the long-term benefits of improved efficiency and performance are expected to drive continued market growth and innovation in half-wave rectifier technologies.

Current Challenges in Half Wave Rectification

Half wave rectifiers, while fundamental in AC to DC conversion, face several challenges that limit their performance and efficiency. One of the primary issues is the low output voltage and power efficiency. Due to the rectification of only one half of the AC waveform, the average DC output voltage is significantly lower than the peak input voltage, resulting in substantial power loss.

Another critical challenge is the high ripple content in the output voltage. The pulsating nature of the half-wave rectified output leads to a considerable amount of AC ripple superimposed on the DC level. This ripple can cause unwanted noise and interference in sensitive electronic circuits, necessitating additional filtering stages that further reduce efficiency and increase complexity.

The presence of harmonics in the input current waveform poses a significant problem for half-wave rectifiers. These harmonics can lead to electromagnetic interference (EMI) and power quality issues, potentially affecting other equipment connected to the same power source. Moreover, the non-linear current draw can cause distortion in the voltage waveform of the AC supply, which may violate power quality standards in certain applications.

Reverse recovery time of the rectifying diode presents another challenge, particularly in high-frequency applications. During the transition from forward to reverse bias, the diode requires a finite time to stop conducting, leading to switching losses and reduced efficiency. This effect becomes more pronounced as operating frequencies increase, limiting the use of half-wave rectifiers in high-speed switching applications.

Temperature sensitivity of semiconductor devices used in half-wave rectifiers also poses a significant challenge. As temperature increases, the forward voltage drop of the diode changes, affecting the rectifier's performance and efficiency. This temperature dependence can lead to stability issues and reduced reliability in varying environmental conditions.

The inherent inefficiency of half-wave rectifiers in terms of transformer utilization is another notable challenge. Since only one half of the AC cycle is used, the transformer core is not fully utilized, leading to a larger and more expensive transformer for a given power rating compared to full-wave rectification schemes.

Addressing these challenges is crucial for enhancing the performance of half-wave rectifiers and expanding their applicability in modern electronic systems. Innovative solutions are needed to improve efficiency, reduce ripple, mitigate harmonics, and overcome the limitations imposed by component characteristics and operating conditions.

Another critical challenge is the high ripple content in the output voltage. The pulsating nature of the half-wave rectified output leads to a considerable amount of AC ripple superimposed on the DC level. This ripple can cause unwanted noise and interference in sensitive electronic circuits, necessitating additional filtering stages that further reduce efficiency and increase complexity.

The presence of harmonics in the input current waveform poses a significant problem for half-wave rectifiers. These harmonics can lead to electromagnetic interference (EMI) and power quality issues, potentially affecting other equipment connected to the same power source. Moreover, the non-linear current draw can cause distortion in the voltage waveform of the AC supply, which may violate power quality standards in certain applications.

Reverse recovery time of the rectifying diode presents another challenge, particularly in high-frequency applications. During the transition from forward to reverse bias, the diode requires a finite time to stop conducting, leading to switching losses and reduced efficiency. This effect becomes more pronounced as operating frequencies increase, limiting the use of half-wave rectifiers in high-speed switching applications.

Temperature sensitivity of semiconductor devices used in half-wave rectifiers also poses a significant challenge. As temperature increases, the forward voltage drop of the diode changes, affecting the rectifier's performance and efficiency. This temperature dependence can lead to stability issues and reduced reliability in varying environmental conditions.

The inherent inefficiency of half-wave rectifiers in terms of transformer utilization is another notable challenge. Since only one half of the AC cycle is used, the transformer core is not fully utilized, leading to a larger and more expensive transformer for a given power rating compared to full-wave rectification schemes.

Addressing these challenges is crucial for enhancing the performance of half-wave rectifiers and expanding their applicability in modern electronic systems. Innovative solutions are needed to improve efficiency, reduce ripple, mitigate harmonics, and overcome the limitations imposed by component characteristics and operating conditions.

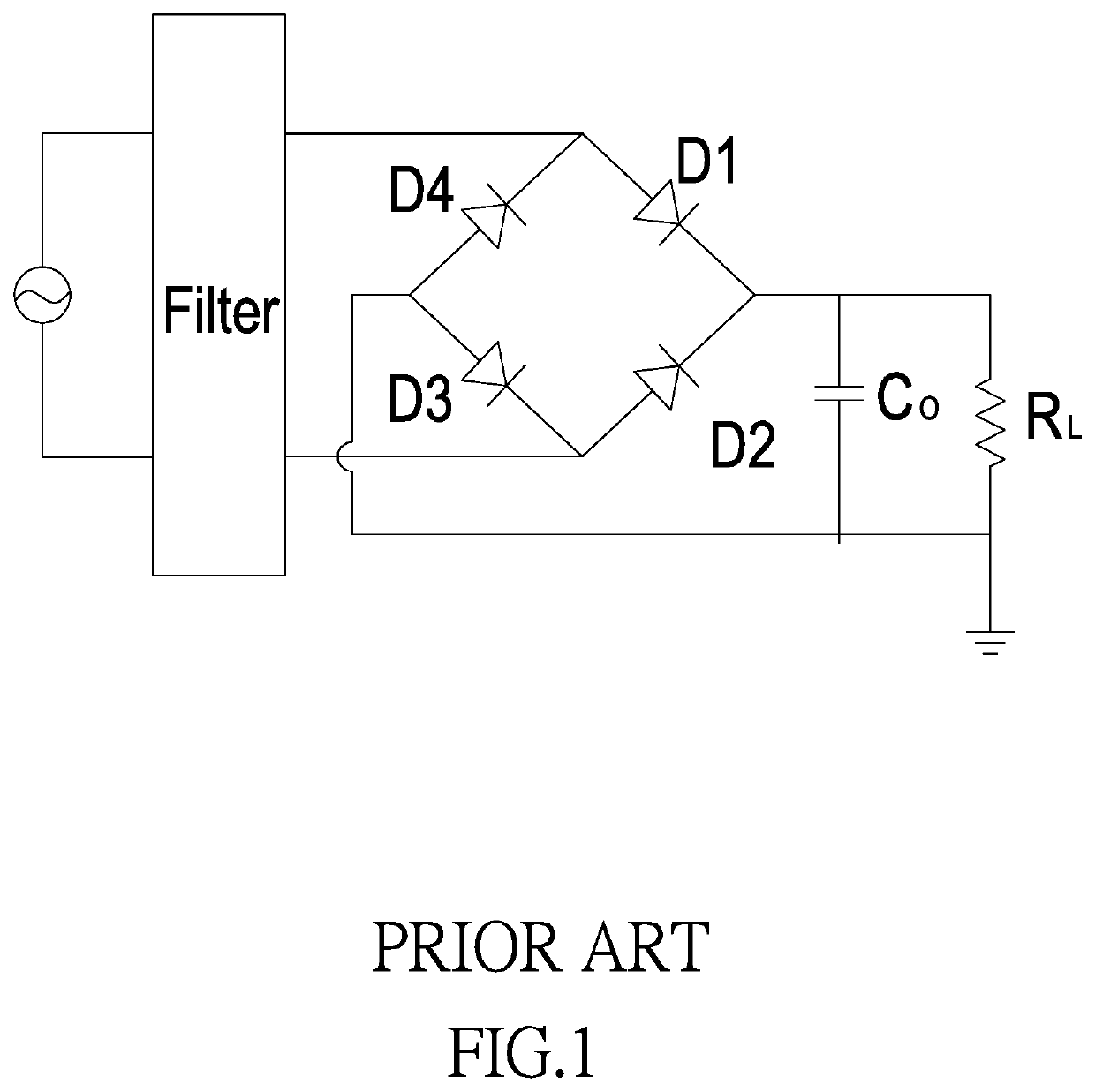

Existing Half Wave Rectifier Enhancements

01 Circuit design for improved efficiency

Half-wave rectifiers can be optimized through improved circuit designs. This includes the use of advanced components and topologies to reduce power losses and increase overall efficiency. Such designs may incorporate features like snubber circuits, soft-switching techniques, or resonant configurations to enhance performance.- Efficiency improvement techniques: Various methods are employed to enhance the performance of half-wave rectifiers. These include optimizing circuit design, using advanced semiconductor materials, and implementing filtering techniques to reduce ripple and improve output quality. Such improvements lead to better power conversion efficiency and overall system performance.

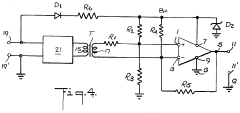

- Control and regulation mechanisms: Half-wave rectifier performance can be improved through the implementation of control and regulation mechanisms. These may include feedback loops, voltage sensing circuits, and adaptive control systems that adjust rectifier operation based on load conditions or input variations, resulting in more stable and reliable output.

- Integration with power factor correction: Combining half-wave rectifiers with power factor correction (PFC) circuits can significantly enhance overall performance. PFC techniques help reduce harmonic distortion, improve power quality, and increase energy efficiency. This integration is particularly beneficial in applications where compliance with power quality standards is required.

- Thermal management and protection: Effective thermal management is crucial for maintaining optimal half-wave rectifier performance. This includes the use of heat sinks, thermal sensors, and protection circuits to prevent overheating and ensure reliable operation under various load conditions. Proper thermal design can extend the lifespan of the rectifier and improve its overall efficiency.

- Application-specific optimizations: Half-wave rectifier performance can be tailored to specific applications through custom design and optimization. This may involve adjusting component values, implementing specialized filtering, or integrating additional features to meet the unique requirements of different industries or use cases, such as in telecommunications, automotive, or renewable energy systems.

02 Voltage regulation and stabilization

Enhancing voltage regulation and stabilization is crucial for half-wave rectifier performance. This can be achieved through the implementation of feedback control systems, voltage clamping circuits, or advanced filtering techniques. These methods help maintain a stable output voltage under varying load conditions and input fluctuations.Expand Specific Solutions03 Reduction of electromagnetic interference

Minimizing electromagnetic interference (EMI) is essential for improving half-wave rectifier performance. This can be accomplished through proper shielding, layout optimization, and the use of EMI suppression components. Advanced filtering techniques and careful component selection can also contribute to reduced EMI emissions and improved overall system performance.Expand Specific Solutions04 Thermal management and heat dissipation

Effective thermal management is crucial for maintaining optimal half-wave rectifier performance. This involves the use of heat sinks, thermal compounds, and improved component layouts to enhance heat dissipation. Advanced cooling techniques, such as forced air or liquid cooling, may also be employed in high-power applications to ensure stable operation and extend component lifespan.Expand Specific Solutions05 Integration of protection features

Incorporating protection features enhances the reliability and longevity of half-wave rectifier circuits. This includes overvoltage protection, overcurrent protection, and reverse polarity protection. Advanced protection schemes may utilize fast-acting semiconductor devices or intelligent control systems to prevent damage to the rectifier and connected loads under fault conditions.Expand Specific Solutions

Key Players in Power Electronics Industry

The market for half wave rectifier performance enhancement strategies is in a mature stage, with ongoing research and development efforts focused on incremental improvements. The global power electronics market, which includes rectifiers, is projected to reach $40 billion by 2027, driven by increasing demand for energy-efficient devices. Technologically, half wave rectifiers are well-established, but companies like Texas Instruments, Infineon Technologies, and Renesas Electronics continue to innovate in areas such as efficiency, miniaturization, and integration with other power management components. Universities like Southwest Jiaotong University and Harbin Institute of Technology are also contributing to advancements in this field through academic research and industry collaborations.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed strategies for enhancing half-wave rectifier performance in various applications, particularly in wireless power transfer and energy harvesting systems. Their approach includes the use of high-efficiency Schottky diodes with ultra-low forward voltage drop, specifically designed for rectification in near-field communication (NFC) and wireless charging applications[9]. Samsung has also implemented active rectification techniques using MOSFETs controlled by specialized ICs, achieving higher efficiency in medium to high power wireless charging systems. Their rectifier designs often incorporate adaptive power management features to optimize performance across varying input power levels and load conditions. Additionally, Samsung has explored the use of flexible and printed electronics technologies to create novel form factors for rectifier circuits in wearable and IoT devices[10].

Strengths: Optimized for mobile and IoT applications, innovative form factors, and integration with wireless power systems. Weaknesses: May be less focused on high-power industrial applications.

Infineon Technologies Austria AG

Technical Solution: Infineon has developed innovative half-wave rectifier solutions focusing on high efficiency and power density. Their approach includes the use of CoolMOS™ superjunction MOSFETs in synchronous rectification circuits, which significantly reduce conduction losses compared to traditional diode-based rectifiers[4]. Infineon also implements digital control techniques to optimize the timing of MOSFET switching, minimizing both conduction and switching losses. Their rectifier designs often incorporate advanced packaging technologies, such as TO-Leadless packages, to improve thermal performance and reduce parasitic inductances[5]. Furthermore, Infineon has introduced silicon carbide (SiC) diodes for high-voltage rectification applications, offering faster switching speeds and lower reverse recovery losses[6].

Strengths: High efficiency, excellent thermal management, and advanced semiconductor technologies. Weaknesses: Higher initial cost and potential complexity in control systems.

Innovative Rectification Techniques

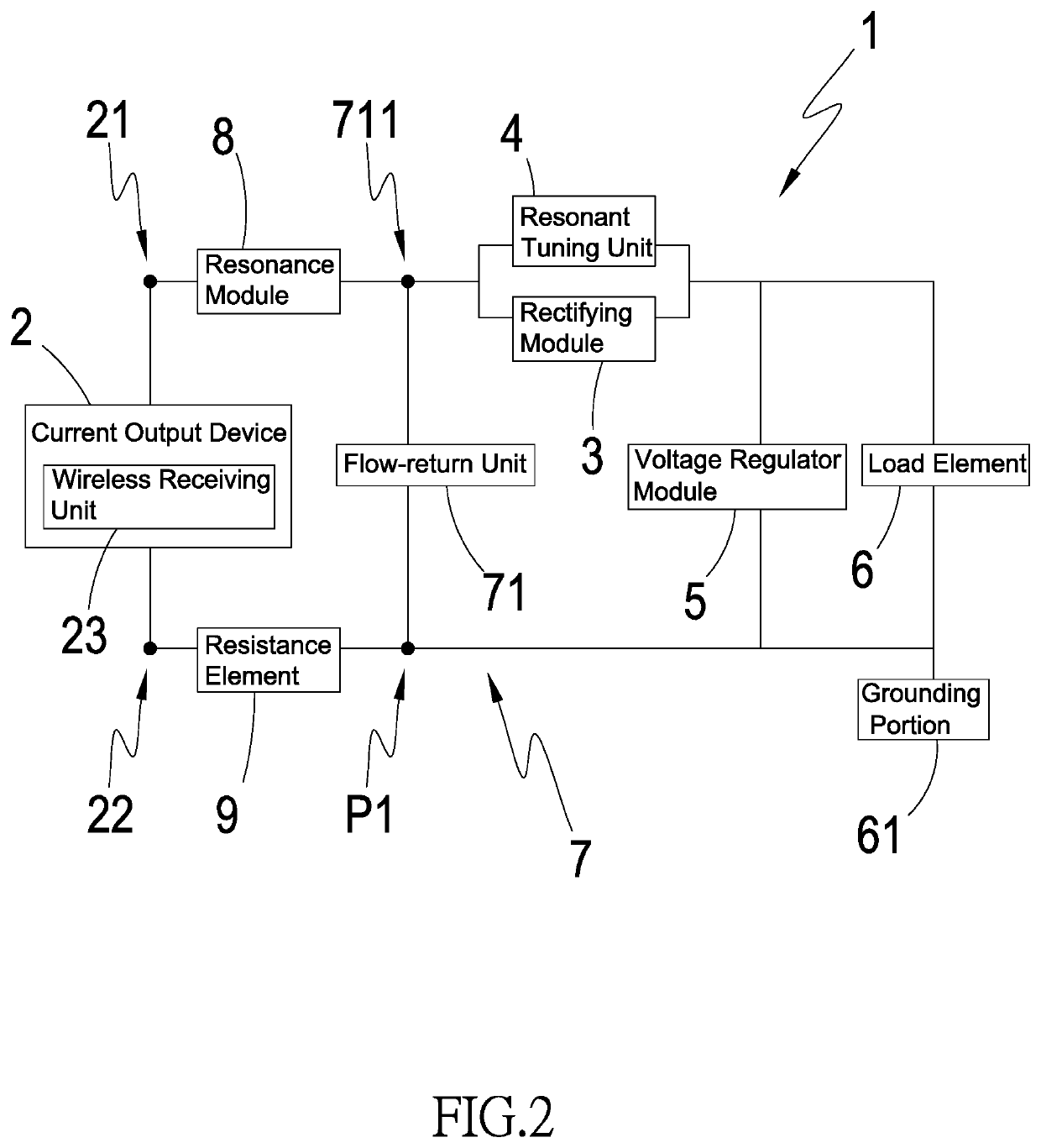

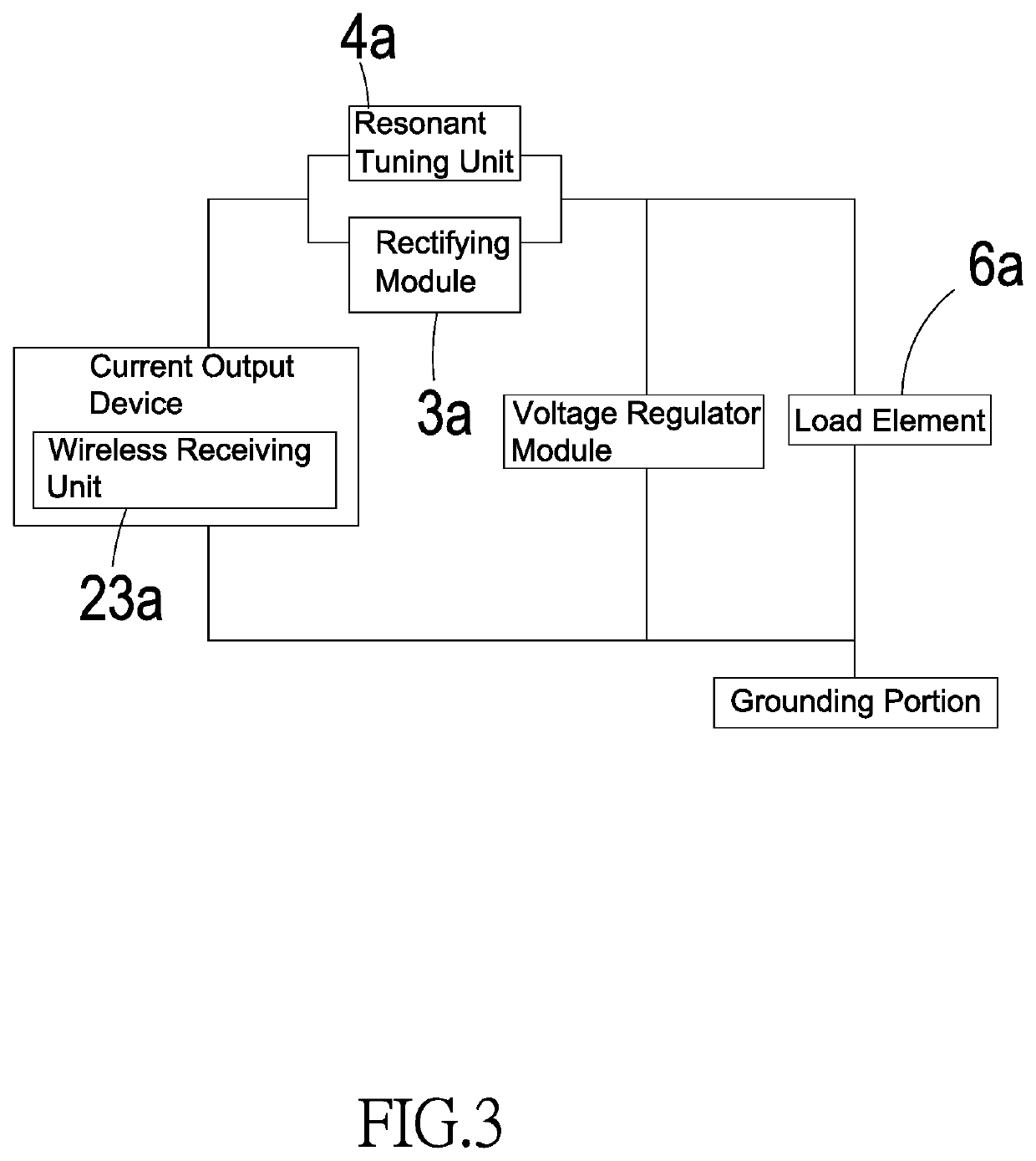

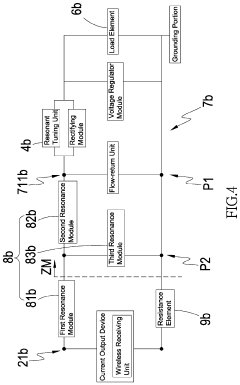

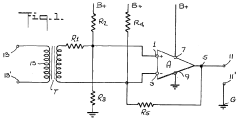

High-frequency half-wave rectifier system of low-harmonicity and high-efficiency

PatentInactiveUS10594205B2

Innovation

- A high-frequency half-wave rectifier system with a simplified structure and reduced electronic components, utilizing a resonant tuning unit and voltage regulator module to control the duty cycle and capacitance, thereby reducing harmonic content and electromagnetic interference, and improving conversion efficiency.

Half-wave rectifier circuit

PatentInactiveUS3936720A

Innovation

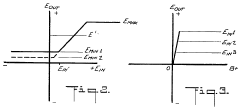

- A high-gain differential amplifier-based half-wave rectifier circuit operating from a single power supply, eliminating the need for voltage regulation and reducing temperature dependence, with resistor ratios optimized to minimize errors and achieve minimal output voltage drop.

Efficiency and Power Quality Considerations

Efficiency and power quality are critical considerations in enhancing the performance of half-wave rectifiers. These factors directly impact the overall effectiveness and reliability of power conversion systems, making them essential areas of focus for engineers and researchers in the field.

The efficiency of a half-wave rectifier is primarily determined by its ability to convert AC input into usable DC output with minimal power loss. Traditional half-wave rectifiers suffer from relatively low efficiency due to the inherent nature of their operation, where only one half of the AC cycle is utilized. This results in significant power wastage and increased heat generation. To address this issue, various strategies have been developed to improve the efficiency of half-wave rectifiers.

One approach involves the implementation of advanced semiconductor materials and device structures. Silicon carbide (SiC) and gallium nitride (GaN) based devices have shown promising results in reducing conduction and switching losses, thereby enhancing overall efficiency. These wide-bandgap semiconductors offer superior electrical properties compared to conventional silicon-based components, allowing for higher operating frequencies and improved thermal management.

Another strategy focuses on optimizing the rectifier circuit topology. By incorporating additional components such as snubber circuits and resonant networks, designers can minimize switching losses and improve the overall power conversion efficiency. Furthermore, the integration of synchronous rectification techniques can significantly reduce conduction losses by replacing diodes with actively controlled switches.

Power quality is equally important in half-wave rectifier applications, as it directly affects the performance and longevity of connected loads. The pulsating nature of half-wave rectified output introduces harmonic distortion and ripple, which can lead to electromagnetic interference (EMI) and reduced power factor. To mitigate these issues, several techniques have been developed to enhance power quality.

Passive filtering methods, such as the use of LC filters, remain a popular choice for smoothing the rectified output and reducing harmonic content. However, more advanced active power factor correction (PFC) circuits are increasingly being employed to achieve near-unity power factor and comply with stringent regulatory standards. These PFC circuits dynamically adjust the input current waveform to match the voltage waveform, resulting in improved power quality and reduced stress on the power distribution system.

The implementation of digital control algorithms has also proven effective in enhancing both efficiency and power quality. Microcontroller-based systems can continuously monitor and adjust rectifier parameters in real-time, optimizing performance across varying load conditions and input voltages. This adaptive approach allows for more precise control of the rectification process, leading to improved overall system performance.

As the demand for more efficient and reliable power conversion solutions continues to grow, ongoing research and development efforts are focused on pushing the boundaries of half-wave rectifier performance. The integration of wide-bandgap semiconductors, advanced circuit topologies, and intelligent control strategies promises to deliver significant improvements in both efficiency and power quality, paving the way for more sustainable and high-performance power electronics systems.

The efficiency of a half-wave rectifier is primarily determined by its ability to convert AC input into usable DC output with minimal power loss. Traditional half-wave rectifiers suffer from relatively low efficiency due to the inherent nature of their operation, where only one half of the AC cycle is utilized. This results in significant power wastage and increased heat generation. To address this issue, various strategies have been developed to improve the efficiency of half-wave rectifiers.

One approach involves the implementation of advanced semiconductor materials and device structures. Silicon carbide (SiC) and gallium nitride (GaN) based devices have shown promising results in reducing conduction and switching losses, thereby enhancing overall efficiency. These wide-bandgap semiconductors offer superior electrical properties compared to conventional silicon-based components, allowing for higher operating frequencies and improved thermal management.

Another strategy focuses on optimizing the rectifier circuit topology. By incorporating additional components such as snubber circuits and resonant networks, designers can minimize switching losses and improve the overall power conversion efficiency. Furthermore, the integration of synchronous rectification techniques can significantly reduce conduction losses by replacing diodes with actively controlled switches.

Power quality is equally important in half-wave rectifier applications, as it directly affects the performance and longevity of connected loads. The pulsating nature of half-wave rectified output introduces harmonic distortion and ripple, which can lead to electromagnetic interference (EMI) and reduced power factor. To mitigate these issues, several techniques have been developed to enhance power quality.

Passive filtering methods, such as the use of LC filters, remain a popular choice for smoothing the rectified output and reducing harmonic content. However, more advanced active power factor correction (PFC) circuits are increasingly being employed to achieve near-unity power factor and comply with stringent regulatory standards. These PFC circuits dynamically adjust the input current waveform to match the voltage waveform, resulting in improved power quality and reduced stress on the power distribution system.

The implementation of digital control algorithms has also proven effective in enhancing both efficiency and power quality. Microcontroller-based systems can continuously monitor and adjust rectifier parameters in real-time, optimizing performance across varying load conditions and input voltages. This adaptive approach allows for more precise control of the rectification process, leading to improved overall system performance.

As the demand for more efficient and reliable power conversion solutions continues to grow, ongoing research and development efforts are focused on pushing the boundaries of half-wave rectifier performance. The integration of wide-bandgap semiconductors, advanced circuit topologies, and intelligent control strategies promises to deliver significant improvements in both efficiency and power quality, paving the way for more sustainable and high-performance power electronics systems.

Thermal Management Strategies

Thermal management is a critical aspect of enhancing half wave rectifier performance. As power electronic devices continue to shrink in size while handling higher power densities, effective heat dissipation becomes increasingly important. Proper thermal management strategies can significantly improve the efficiency, reliability, and longevity of half wave rectifiers.

One of the primary thermal management techniques for half wave rectifiers is the use of heat sinks. These passive cooling devices increase the surface area available for heat dissipation, allowing for more efficient transfer of thermal energy to the surrounding environment. Heat sinks can be designed with various fin configurations and materials to optimize their performance based on specific application requirements.

Active cooling methods, such as forced air cooling and liquid cooling, can be employed for more demanding applications. Forced air cooling utilizes fans or blowers to increase air circulation around the rectifier components, enhancing convective heat transfer. Liquid cooling systems, while more complex, offer superior heat dissipation capabilities by circulating a coolant through channels or plates in direct contact with the heat-generating components.

Thermal interface materials (TIMs) play a crucial role in improving heat transfer between the rectifier components and cooling solutions. These materials, such as thermal greases, pads, or phase change materials, fill microscopic air gaps and ensure efficient thermal conduction across interfaces.

Advanced packaging techniques can also contribute to better thermal management. For instance, direct bonded copper (DBC) substrates provide excellent thermal conductivity and electrical isolation, allowing for more efficient heat dissipation from semiconductor devices to the cooling system.

Thermal simulation and modeling tools are invaluable for optimizing thermal management strategies. These tools enable engineers to predict temperature distributions, identify hotspots, and evaluate the effectiveness of various cooling solutions before physical prototyping. This approach can significantly reduce development time and costs while ensuring optimal thermal performance.

Implementing temperature monitoring and control systems can further enhance the thermal management of half wave rectifiers. These systems can dynamically adjust cooling parameters or even initiate protective measures in response to temperature fluctuations, ensuring safe and reliable operation under varying load conditions.

By employing a combination of these thermal management strategies, designers can effectively mitigate heat-related issues in half wave rectifiers, leading to improved performance, increased power handling capabilities, and extended operational lifetimes.

One of the primary thermal management techniques for half wave rectifiers is the use of heat sinks. These passive cooling devices increase the surface area available for heat dissipation, allowing for more efficient transfer of thermal energy to the surrounding environment. Heat sinks can be designed with various fin configurations and materials to optimize their performance based on specific application requirements.

Active cooling methods, such as forced air cooling and liquid cooling, can be employed for more demanding applications. Forced air cooling utilizes fans or blowers to increase air circulation around the rectifier components, enhancing convective heat transfer. Liquid cooling systems, while more complex, offer superior heat dissipation capabilities by circulating a coolant through channels or plates in direct contact with the heat-generating components.

Thermal interface materials (TIMs) play a crucial role in improving heat transfer between the rectifier components and cooling solutions. These materials, such as thermal greases, pads, or phase change materials, fill microscopic air gaps and ensure efficient thermal conduction across interfaces.

Advanced packaging techniques can also contribute to better thermal management. For instance, direct bonded copper (DBC) substrates provide excellent thermal conductivity and electrical isolation, allowing for more efficient heat dissipation from semiconductor devices to the cooling system.

Thermal simulation and modeling tools are invaluable for optimizing thermal management strategies. These tools enable engineers to predict temperature distributions, identify hotspots, and evaluate the effectiveness of various cooling solutions before physical prototyping. This approach can significantly reduce development time and costs while ensuring optimal thermal performance.

Implementing temperature monitoring and control systems can further enhance the thermal management of half wave rectifiers. These systems can dynamically adjust cooling parameters or even initiate protective measures in response to temperature fluctuations, ensuring safe and reliable operation under varying load conditions.

By employing a combination of these thermal management strategies, designers can effectively mitigate heat-related issues in half wave rectifiers, leading to improved performance, increased power handling capabilities, and extended operational lifetimes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!