Challenges in Flexible Piezoelectric Sensor Development

JUL 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Evolution and Objectives

Piezoelectric sensors have undergone significant evolution since their inception, driven by the growing demand for flexible and wearable electronics. The journey of these sensors began with rigid, ceramic-based devices and has progressed towards more adaptable, polymer-based structures. This technological progression aims to address the limitations of traditional piezoelectric materials, particularly in applications requiring conformability and durability.

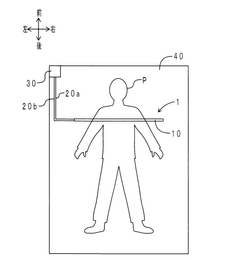

The primary objective in the development of flexible piezoelectric sensors is to create devices that can maintain high sensitivity and reliability while conforming to complex, non-planar surfaces. This goal is crucial for expanding the application scope of piezoelectric sensors in fields such as healthcare monitoring, soft robotics, and human-machine interfaces. Researchers are focusing on enhancing the mechanical flexibility of these sensors without compromising their electrical output or long-term stability.

Another key objective is to improve the energy harvesting capabilities of flexible piezoelectric sensors. As the Internet of Things (IoT) continues to expand, there is a growing need for self-powered sensing devices. Flexible piezoelectric sensors have the potential to harvest energy from ambient vibrations, body movements, or other mechanical stimuli, thus enabling autonomous operation in various environments.

Miniaturization is also a critical goal in the evolution of piezoelectric sensors. The trend towards smaller, more integrated devices necessitates the development of fabrication techniques that can produce ultra-thin, highly sensitive piezoelectric layers. This miniaturization effort is closely tied to the broader objective of creating multifunctional sensors that can detect multiple stimuli simultaneously, such as pressure, strain, and temperature.

The development of biocompatible and environmentally friendly piezoelectric materials is another important objective. As these sensors find increasing applications in biomedical and environmental monitoring, there is a growing emphasis on using non-toxic, biodegradable materials that can safely interface with biological systems and minimize environmental impact.

Lastly, the integration of flexible piezoelectric sensors with other emerging technologies, such as artificial intelligence and 5G networks, is a forward-looking objective. This integration aims to create smart sensing systems capable of real-time data processing and communication, opening up new possibilities in predictive maintenance, personalized healthcare, and smart infrastructure.

The primary objective in the development of flexible piezoelectric sensors is to create devices that can maintain high sensitivity and reliability while conforming to complex, non-planar surfaces. This goal is crucial for expanding the application scope of piezoelectric sensors in fields such as healthcare monitoring, soft robotics, and human-machine interfaces. Researchers are focusing on enhancing the mechanical flexibility of these sensors without compromising their electrical output or long-term stability.

Another key objective is to improve the energy harvesting capabilities of flexible piezoelectric sensors. As the Internet of Things (IoT) continues to expand, there is a growing need for self-powered sensing devices. Flexible piezoelectric sensors have the potential to harvest energy from ambient vibrations, body movements, or other mechanical stimuli, thus enabling autonomous operation in various environments.

Miniaturization is also a critical goal in the evolution of piezoelectric sensors. The trend towards smaller, more integrated devices necessitates the development of fabrication techniques that can produce ultra-thin, highly sensitive piezoelectric layers. This miniaturization effort is closely tied to the broader objective of creating multifunctional sensors that can detect multiple stimuli simultaneously, such as pressure, strain, and temperature.

The development of biocompatible and environmentally friendly piezoelectric materials is another important objective. As these sensors find increasing applications in biomedical and environmental monitoring, there is a growing emphasis on using non-toxic, biodegradable materials that can safely interface with biological systems and minimize environmental impact.

Lastly, the integration of flexible piezoelectric sensors with other emerging technologies, such as artificial intelligence and 5G networks, is a forward-looking objective. This integration aims to create smart sensing systems capable of real-time data processing and communication, opening up new possibilities in predictive maintenance, personalized healthcare, and smart infrastructure.

Market Demand Analysis for Flexible Sensors

The market demand for flexible piezoelectric sensors has been experiencing significant growth in recent years, driven by the increasing need for wearable devices, healthcare monitoring systems, and smart textiles. These sensors offer unique advantages in terms of flexibility, conformability, and sensitivity, making them ideal for applications where traditional rigid sensors fall short.

In the consumer electronics sector, there is a growing demand for flexible sensors in wearable devices such as smartwatches, fitness trackers, and health monitoring bands. These sensors enable continuous and non-invasive monitoring of vital signs, physical activities, and gestures, enhancing user experience and providing valuable health insights. The market for wearable devices is projected to expand rapidly, creating a substantial opportunity for flexible piezoelectric sensors.

The healthcare industry represents another significant market for flexible sensors. There is an increasing focus on remote patient monitoring and personalized healthcare, driving the demand for comfortable, unobtrusive sensors that can be integrated into clothing or directly adhered to the skin. Flexible piezoelectric sensors can monitor various physiological parameters, including heart rate, respiration, and body temperature, enabling long-term health tracking and early detection of medical conditions.

In the automotive sector, flexible sensors are gaining traction for applications in smart interiors and driver monitoring systems. These sensors can be seamlessly integrated into vehicle seats, steering wheels, and dashboards to detect driver fatigue, monitor posture, and enhance overall safety. As the automotive industry moves towards autonomous vehicles, the demand for advanced sensing technologies, including flexible piezoelectric sensors, is expected to rise.

The sports and fitness industry is another area where flexible sensors are finding increasing applications. These sensors can be incorporated into athletic wear to monitor performance metrics, analyze movement patterns, and prevent injuries. The ability to integrate sensors directly into fabrics without compromising comfort or flexibility is a key driver for adoption in this sector.

Industrial applications of flexible piezoelectric sensors are also on the rise. In structural health monitoring, these sensors can be used to detect vibrations, strains, and deformations in buildings, bridges, and other infrastructure. Their flexibility allows for easy installation on curved or irregular surfaces, providing more comprehensive monitoring capabilities compared to traditional rigid sensors.

The market for flexible piezoelectric sensors is expected to grow substantially in the coming years, with emerging applications in robotics, human-machine interfaces, and smart packaging further driving demand. However, challenges such as durability, long-term stability, and cost-effective manufacturing processes need to be addressed to fully realize the market potential of these sensors.

In the consumer electronics sector, there is a growing demand for flexible sensors in wearable devices such as smartwatches, fitness trackers, and health monitoring bands. These sensors enable continuous and non-invasive monitoring of vital signs, physical activities, and gestures, enhancing user experience and providing valuable health insights. The market for wearable devices is projected to expand rapidly, creating a substantial opportunity for flexible piezoelectric sensors.

The healthcare industry represents another significant market for flexible sensors. There is an increasing focus on remote patient monitoring and personalized healthcare, driving the demand for comfortable, unobtrusive sensors that can be integrated into clothing or directly adhered to the skin. Flexible piezoelectric sensors can monitor various physiological parameters, including heart rate, respiration, and body temperature, enabling long-term health tracking and early detection of medical conditions.

In the automotive sector, flexible sensors are gaining traction for applications in smart interiors and driver monitoring systems. These sensors can be seamlessly integrated into vehicle seats, steering wheels, and dashboards to detect driver fatigue, monitor posture, and enhance overall safety. As the automotive industry moves towards autonomous vehicles, the demand for advanced sensing technologies, including flexible piezoelectric sensors, is expected to rise.

The sports and fitness industry is another area where flexible sensors are finding increasing applications. These sensors can be incorporated into athletic wear to monitor performance metrics, analyze movement patterns, and prevent injuries. The ability to integrate sensors directly into fabrics without compromising comfort or flexibility is a key driver for adoption in this sector.

Industrial applications of flexible piezoelectric sensors are also on the rise. In structural health monitoring, these sensors can be used to detect vibrations, strains, and deformations in buildings, bridges, and other infrastructure. Their flexibility allows for easy installation on curved or irregular surfaces, providing more comprehensive monitoring capabilities compared to traditional rigid sensors.

The market for flexible piezoelectric sensors is expected to grow substantially in the coming years, with emerging applications in robotics, human-machine interfaces, and smart packaging further driving demand. However, challenges such as durability, long-term stability, and cost-effective manufacturing processes need to be addressed to fully realize the market potential of these sensors.

Flexible Piezoelectric Materials: State and Challenges

Flexible piezoelectric materials have emerged as a critical component in the development of advanced sensing technologies, particularly in the realm of wearable electronics and biomedical devices. These materials possess the unique ability to generate an electrical charge in response to mechanical stress, making them ideal for applications requiring precise and responsive sensing capabilities. However, the development and implementation of flexible piezoelectric sensors face several significant challenges that researchers and engineers must address.

One of the primary obstacles in flexible piezoelectric sensor development is achieving a balance between flexibility and performance. Traditional piezoelectric materials, such as lead zirconate titanate (PZT), exhibit excellent piezoelectric properties but are inherently rigid and brittle. This characteristic limits their applicability in flexible and conformable devices. Researchers have been exploring alternative materials and composite structures to overcome this limitation, including polymer-based piezoelectrics like polyvinylidene fluoride (PVDF) and its copolymers. While these materials offer improved flexibility, they often suffer from reduced piezoelectric coefficients compared to their ceramic counterparts.

Another challenge lies in the integration of flexible piezoelectric materials with other device components. The interface between the piezoelectric layer and electrodes, as well as the substrate, plays a crucial role in the overall performance and durability of the sensor. Ensuring robust adhesion and electrical connectivity while maintaining flexibility is a complex task that requires careful material selection and fabrication techniques. Additionally, the development of flexible interconnects and circuitry that can withstand repeated deformation without degradation in performance remains an ongoing area of research.

The long-term stability and reliability of flexible piezoelectric sensors present further challenges. Environmental factors such as temperature, humidity, and mechanical stress can significantly impact the performance and lifespan of these devices. Developing encapsulation methods and protective layers that preserve the sensor's flexibility while shielding it from external influences is essential for practical applications. Moreover, the potential for fatigue and degradation of piezoelectric properties over time due to repeated mechanical deformation must be addressed to ensure consistent and reliable sensor operation.

Scalability and manufacturability are also critical considerations in the development of flexible piezoelectric sensors. While laboratory-scale fabrication techniques have demonstrated promising results, translating these methods to large-scale, cost-effective production processes remains a significant hurdle. Techniques such as roll-to-roll manufacturing and printing technologies offer potential solutions but require further refinement to achieve the necessary precision and consistency for high-performance sensors.

In conclusion, while flexible piezoelectric materials hold great promise for next-generation sensing applications, several challenges must be overcome to fully realize their potential. Addressing these issues requires interdisciplinary collaboration and innovative approaches in materials science, device engineering, and manufacturing processes. As research in this field progresses, we can expect to see significant advancements that will pave the way for more versatile, reliable, and high-performance flexible piezoelectric sensors.

One of the primary obstacles in flexible piezoelectric sensor development is achieving a balance between flexibility and performance. Traditional piezoelectric materials, such as lead zirconate titanate (PZT), exhibit excellent piezoelectric properties but are inherently rigid and brittle. This characteristic limits their applicability in flexible and conformable devices. Researchers have been exploring alternative materials and composite structures to overcome this limitation, including polymer-based piezoelectrics like polyvinylidene fluoride (PVDF) and its copolymers. While these materials offer improved flexibility, they often suffer from reduced piezoelectric coefficients compared to their ceramic counterparts.

Another challenge lies in the integration of flexible piezoelectric materials with other device components. The interface between the piezoelectric layer and electrodes, as well as the substrate, plays a crucial role in the overall performance and durability of the sensor. Ensuring robust adhesion and electrical connectivity while maintaining flexibility is a complex task that requires careful material selection and fabrication techniques. Additionally, the development of flexible interconnects and circuitry that can withstand repeated deformation without degradation in performance remains an ongoing area of research.

The long-term stability and reliability of flexible piezoelectric sensors present further challenges. Environmental factors such as temperature, humidity, and mechanical stress can significantly impact the performance and lifespan of these devices. Developing encapsulation methods and protective layers that preserve the sensor's flexibility while shielding it from external influences is essential for practical applications. Moreover, the potential for fatigue and degradation of piezoelectric properties over time due to repeated mechanical deformation must be addressed to ensure consistent and reliable sensor operation.

Scalability and manufacturability are also critical considerations in the development of flexible piezoelectric sensors. While laboratory-scale fabrication techniques have demonstrated promising results, translating these methods to large-scale, cost-effective production processes remains a significant hurdle. Techniques such as roll-to-roll manufacturing and printing technologies offer potential solutions but require further refinement to achieve the necessary precision and consistency for high-performance sensors.

In conclusion, while flexible piezoelectric materials hold great promise for next-generation sensing applications, several challenges must be overcome to fully realize their potential. Addressing these issues requires interdisciplinary collaboration and innovative approaches in materials science, device engineering, and manufacturing processes. As research in this field progresses, we can expect to see significant advancements that will pave the way for more versatile, reliable, and high-performance flexible piezoelectric sensors.

Current Flexible Piezoelectric Sensor Solutions

01 Flexible piezoelectric materials

Development of flexible piezoelectric materials that can maintain their performance under bending or stretching conditions. These materials often include polymers or composite structures that combine flexibility with piezoelectric properties, allowing for the creation of sensors that can conform to various shapes and surfaces.- Flexible piezoelectric materials: Development of flexible piezoelectric materials that can maintain their piezoelectric properties while being bent or stretched. These materials often include polymers or composite structures that allow for greater flexibility compared to traditional ceramic piezoelectrics.

- Substrate and electrode design: Innovative designs for flexible substrates and electrodes that can accommodate bending and stretching without compromising the sensor's performance. This includes the use of stretchable electrodes and thin-film technologies to enhance overall flexibility.

- Nanostructured piezoelectric sensors: Incorporation of nanostructures such as nanowires, nanofibers, or nanoparticles to enhance the flexibility and sensitivity of piezoelectric sensors. These nanostructures can improve the mechanical properties and increase the active surface area of the sensor.

- Fabrication techniques for flexible sensors: Advanced manufacturing methods tailored for producing flexible piezoelectric sensors, including printing technologies, roll-to-roll processing, and other scalable techniques that enable the creation of thin, bendable devices.

- Integration with flexible electronics: Strategies for integrating flexible piezoelectric sensors with other flexible electronic components to create complete, bendable sensing systems. This includes the development of flexible circuits, interconnects, and packaging solutions that maintain flexibility throughout the entire device.

02 Nanostructured piezoelectric sensors

Utilization of nanostructures such as nanowires, nanofibers, or nanoparticles to enhance the flexibility and sensitivity of piezoelectric sensors. These nanostructures can be incorporated into flexible substrates or formed into thin films, providing improved mechanical properties and increased surface area for sensing.Expand Specific Solutions03 Substrate and electrode design

Innovative designs for flexible substrates and electrodes that can withstand repeated bending or stretching without compromising the sensor's performance. This includes the use of stretchable electrodes, serpentine patterns, or mesh structures to maintain electrical connectivity during deformation.Expand Specific Solutions04 Multilayer and composite structures

Development of multilayer or composite structures that combine different materials to achieve both flexibility and piezoelectric functionality. These structures may include alternating layers of piezoelectric materials and flexible polymers or the integration of piezoelectric elements within a flexible matrix.Expand Specific Solutions05 Application-specific designs

Tailored designs of flexible piezoelectric sensors for specific applications such as wearable devices, structural health monitoring, or energy harvesting. These designs consider factors like durability, sensitivity, and form factor to meet the requirements of different use cases while maintaining flexibility.Expand Specific Solutions

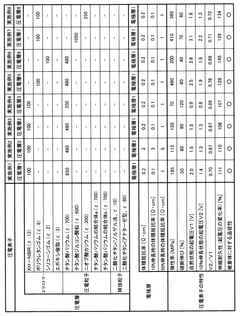

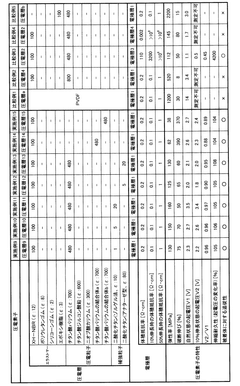

Key Players in Flexible Sensor Industry

The development of flexible piezoelectric sensors is currently in a transitional phase, moving from early-stage research to emerging commercial applications. The market size is expanding, driven by growing demand in wearable technology, healthcare, and industrial sectors. However, technical challenges persist in achieving consistent performance and durability. Companies like Sumitomo Riko, Canon, and Panasonic are at the forefront, leveraging their expertise in materials and electronics to advance the technology. Academic institutions such as Shanghai Jiao Tong University and Fraunhofer-Gesellschaft are contributing significant research. While progress is being made, the technology is not yet fully mature, with ongoing efforts to improve sensitivity, flexibility, and integration capabilities.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a flexible piezoelectric sensor technology that combines organic and inorganic materials to create a hybrid sensor with enhanced performance. Their approach involves depositing piezoelectric ceramic nanoparticles onto a flexible polymer substrate, creating a thin film that retains good piezoelectric properties while remaining bendable. Panasonic's design incorporates a unique electrode configuration that maximizes the active area and improves charge collection efficiency. To address the challenge of maintaining sensor performance under repeated bending, Panasonic has implemented a proprietary stress relief layer that helps to distribute mechanical stress and prevent cracking of the piezoelectric material[10][12]. The company has also developed advanced signal processing algorithms to compensate for non-linear behavior and improve the sensor's accuracy across a wide range of operating conditions[11].

Strengths: Good balance between flexibility and piezoelectric performance, potential for high sensitivity. Suitable for a wide range of applications. Weaknesses: Manufacturing complexity due to the hybrid nature of the sensor, potential issues with long-term stability of the interface between organic and inorganic components.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed a flexible piezoelectric sensor using PVDF (polyvinylidene fluoride) film as the base material. Their approach involves creating a thin, bendable sensor that can detect pressure, vibration, and deformation. The sensor utilizes the piezoelectric effect of PVDF, which generates an electrical charge when mechanically stressed. Murata's design incorporates electrodes on both sides of the PVDF film, allowing for the collection and measurement of the generated charge. The company has also developed proprietary signal processing techniques to enhance sensitivity and reduce noise, enabling the sensor to detect subtle changes in pressure or vibration[1][3]. To address the challenge of maintaining performance under repeated bending, Murata has implemented a unique lamination process that enhances the durability of the sensor while preserving its flexibility[5].

Strengths: High flexibility, good sensitivity, and durability. Suitable for wearable devices and IoT applications. Weaknesses: May have temperature sensitivity issues and potential long-term stability concerns in harsh environments.

Core Innovations in Flexible Piezoelectric Technology

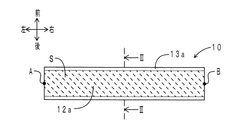

Piezoelectric sensor and method for manufacturing same

PatentWO2020157999A1

Innovation

- A flexible piezoelectric sensor design featuring a piezoelectric layer with elastomer and piezoelectric particles, and an electrode layer made of elastomer with flaky conductive material, oriented to maintain high conductivity and flexibility, even when elongated, by aligning flaky conductive materials in the length direction and pressure bonding with the piezoelectric layer before crosslinking.

Piezoelectric sensor

PatentWO2017010135A1

Innovation

- A piezoelectric sensor with a piezoelectric element featuring a layer composed of an elastomer and piezoelectric particles, along with an electrode layer made of elastomer and conductive material, allowing for elongation at break of 10% or more and maintaining high conductivity even when stretched up to 10% in the uniaxial direction, enabling accurate load detection on deformed adherends.

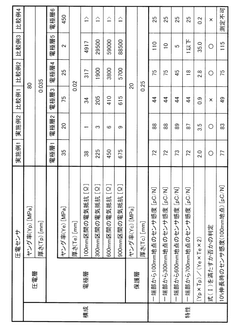

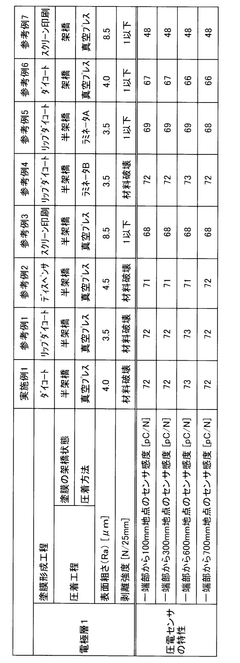

Manufacturing Processes for Flexible Sensors

The manufacturing processes for flexible piezoelectric sensors present unique challenges and opportunities in the development of these advanced devices. Traditional fabrication methods often struggle to meet the demands of flexibility, durability, and performance required for these sensors. As a result, innovative manufacturing techniques have emerged to address these specific needs.

One of the primary manufacturing processes for flexible piezoelectric sensors is screen printing. This method allows for the deposition of piezoelectric materials onto flexible substrates in precise patterns. Screen printing offers advantages in terms of scalability and cost-effectiveness, making it suitable for large-scale production. However, achieving uniform thickness and consistent performance across the printed area remains a challenge.

Another promising approach is inkjet printing, which enables the precise deposition of piezoelectric materials in droplet form. This technique offers high resolution and the ability to create complex patterns, but it requires careful control of ink properties and substrate interactions to ensure optimal sensor performance.

Electrospinning has gained attention for its ability to produce nanofiber-based piezoelectric sensors. This process involves drawing charged polymer solutions into ultra-thin fibers, which can be collected as non-woven mats or aligned arrays. Electrospun piezoelectric sensors offer high sensitivity due to their large surface area, but controlling fiber uniformity and scaling up production remain ongoing challenges.

Roll-to-roll manufacturing processes have shown great potential for the mass production of flexible piezoelectric sensors. This continuous fabrication method allows for the deposition of piezoelectric materials onto flexible substrates in a high-throughput manner. However, maintaining consistent quality and performance across large areas can be challenging, particularly when integrating multiple layers or components.

Transfer printing techniques have also been developed to fabricate flexible piezoelectric sensors. This approach involves creating the sensor structure on a rigid substrate and then transferring it onto a flexible substrate. While this method allows for high-precision fabrication, the transfer process itself can introduce defects or alter the sensor's properties.

Additive manufacturing, or 3D printing, is emerging as a versatile tool for creating custom-designed flexible piezoelectric sensors. This technique allows for the fabrication of complex 3D structures with embedded piezoelectric properties. However, the limited range of printable piezoelectric materials and challenges in achieving high-performance devices currently restrict its widespread adoption.

As the field of flexible piezoelectric sensors continues to evolve, researchers and manufacturers are exploring hybrid approaches that combine multiple fabrication techniques. These hybrid processes aim to leverage the strengths of different methods while mitigating their individual limitations, potentially leading to more robust and efficient manufacturing solutions for next-generation flexible piezoelectric sensors.

One of the primary manufacturing processes for flexible piezoelectric sensors is screen printing. This method allows for the deposition of piezoelectric materials onto flexible substrates in precise patterns. Screen printing offers advantages in terms of scalability and cost-effectiveness, making it suitable for large-scale production. However, achieving uniform thickness and consistent performance across the printed area remains a challenge.

Another promising approach is inkjet printing, which enables the precise deposition of piezoelectric materials in droplet form. This technique offers high resolution and the ability to create complex patterns, but it requires careful control of ink properties and substrate interactions to ensure optimal sensor performance.

Electrospinning has gained attention for its ability to produce nanofiber-based piezoelectric sensors. This process involves drawing charged polymer solutions into ultra-thin fibers, which can be collected as non-woven mats or aligned arrays. Electrospun piezoelectric sensors offer high sensitivity due to their large surface area, but controlling fiber uniformity and scaling up production remain ongoing challenges.

Roll-to-roll manufacturing processes have shown great potential for the mass production of flexible piezoelectric sensors. This continuous fabrication method allows for the deposition of piezoelectric materials onto flexible substrates in a high-throughput manner. However, maintaining consistent quality and performance across large areas can be challenging, particularly when integrating multiple layers or components.

Transfer printing techniques have also been developed to fabricate flexible piezoelectric sensors. This approach involves creating the sensor structure on a rigid substrate and then transferring it onto a flexible substrate. While this method allows for high-precision fabrication, the transfer process itself can introduce defects or alter the sensor's properties.

Additive manufacturing, or 3D printing, is emerging as a versatile tool for creating custom-designed flexible piezoelectric sensors. This technique allows for the fabrication of complex 3D structures with embedded piezoelectric properties. However, the limited range of printable piezoelectric materials and challenges in achieving high-performance devices currently restrict its widespread adoption.

As the field of flexible piezoelectric sensors continues to evolve, researchers and manufacturers are exploring hybrid approaches that combine multiple fabrication techniques. These hybrid processes aim to leverage the strengths of different methods while mitigating their individual limitations, potentially leading to more robust and efficient manufacturing solutions for next-generation flexible piezoelectric sensors.

Environmental Impact of Piezoelectric Materials

The development of flexible piezoelectric sensors has raised concerns about the environmental impact of piezoelectric materials. As these sensors become more prevalent in various applications, it is crucial to assess their potential effects on ecosystems and human health throughout their lifecycle.

Piezoelectric materials commonly used in flexible sensors, such as lead zirconate titanate (PZT), contain heavy metals that can pose environmental risks if not properly managed. The production process of these materials often involves energy-intensive methods and the use of toxic chemicals, contributing to air and water pollution. Additionally, the mining and extraction of raw materials for piezoelectric components can lead to habitat destruction and soil contamination.

During the operational phase, flexible piezoelectric sensors generally have a low environmental impact due to their energy-efficient nature. However, the increasing integration of these sensors into consumer electronics and wearable devices raises concerns about electronic waste accumulation. The complex composition of flexible sensors makes recycling challenging, potentially leading to improper disposal and environmental contamination.

End-of-life management of flexible piezoelectric sensors is a critical environmental consideration. The presence of heavy metals and other hazardous substances in these devices necessitates specialized recycling processes to prevent soil and water pollution. However, the current recycling infrastructure for such materials is limited, increasing the risk of environmental contamination when these sensors are discarded.

Research efforts are underway to develop more environmentally friendly piezoelectric materials for flexible sensors. Bio-based piezoelectric materials, such as cellulose nanofibrils and peptide nanotubes, show promise as sustainable alternatives. These materials offer biodegradability and reduced toxicity compared to traditional piezoelectric compounds, potentially mitigating environmental concerns associated with sensor production and disposal.

The miniaturization trend in flexible piezoelectric sensor design may have both positive and negative environmental implications. While smaller sensors require fewer raw materials, their reduced size can make them more challenging to recover and recycle, potentially exacerbating e-waste issues. Balancing these factors is crucial for minimizing the overall environmental footprint of flexible piezoelectric sensor technologies.

As the adoption of flexible piezoelectric sensors continues to grow, it is essential to implement comprehensive lifecycle assessments and develop sustainable manufacturing practices. This includes exploring eco-friendly material alternatives, improving recycling technologies, and establishing effective take-back programs for end-of-life sensors. By addressing these environmental challenges, the flexible piezoelectric sensor industry can work towards more sustainable and responsible innovation.

Piezoelectric materials commonly used in flexible sensors, such as lead zirconate titanate (PZT), contain heavy metals that can pose environmental risks if not properly managed. The production process of these materials often involves energy-intensive methods and the use of toxic chemicals, contributing to air and water pollution. Additionally, the mining and extraction of raw materials for piezoelectric components can lead to habitat destruction and soil contamination.

During the operational phase, flexible piezoelectric sensors generally have a low environmental impact due to their energy-efficient nature. However, the increasing integration of these sensors into consumer electronics and wearable devices raises concerns about electronic waste accumulation. The complex composition of flexible sensors makes recycling challenging, potentially leading to improper disposal and environmental contamination.

End-of-life management of flexible piezoelectric sensors is a critical environmental consideration. The presence of heavy metals and other hazardous substances in these devices necessitates specialized recycling processes to prevent soil and water pollution. However, the current recycling infrastructure for such materials is limited, increasing the risk of environmental contamination when these sensors are discarded.

Research efforts are underway to develop more environmentally friendly piezoelectric materials for flexible sensors. Bio-based piezoelectric materials, such as cellulose nanofibrils and peptide nanotubes, show promise as sustainable alternatives. These materials offer biodegradability and reduced toxicity compared to traditional piezoelectric compounds, potentially mitigating environmental concerns associated with sensor production and disposal.

The miniaturization trend in flexible piezoelectric sensor design may have both positive and negative environmental implications. While smaller sensors require fewer raw materials, their reduced size can make them more challenging to recover and recycle, potentially exacerbating e-waste issues. Balancing these factors is crucial for minimizing the overall environmental footprint of flexible piezoelectric sensor technologies.

As the adoption of flexible piezoelectric sensors continues to grow, it is essential to implement comprehensive lifecycle assessments and develop sustainable manufacturing practices. This includes exploring eco-friendly material alternatives, improving recycling technologies, and establishing effective take-back programs for end-of-life sensors. By addressing these environmental challenges, the flexible piezoelectric sensor industry can work towards more sustainable and responsible innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!