Comparative environmental footprints of lepidolite versus brine lithium sources

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Background and Objectives

Lithium extraction has become a critical focus in the global transition towards sustainable energy solutions. The increasing demand for lithium-ion batteries in electric vehicles and renewable energy storage systems has propelled the lithium industry into the spotlight. Historically, lithium extraction has primarily relied on two main sources: brine deposits and hard rock mining, with the latter predominantly focusing on spodumene.

In recent years, lepidolite, a lithium-bearing mica mineral, has emerged as a potential alternative source for lithium extraction. This shift in focus has led to a growing interest in comparing the environmental impacts of lepidolite-based extraction methods with traditional brine-based approaches. The objective of this technical research is to conduct a comprehensive analysis of the comparative environmental footprints associated with lepidolite and brine lithium sources.

The evolution of lithium extraction technologies has been driven by the need for more efficient and environmentally friendly processes. Brine extraction, which has been the dominant method, involves pumping lithium-rich brine from underground reservoirs and concentrating it through evaporation. This process, while well-established, faces challenges related to water consumption and potential ecosystem disruption in arid regions where most brine deposits are located.

Lepidolite extraction, on the other hand, represents a newer approach to lithium production. As a hard rock source, lepidolite mining and processing methods differ significantly from brine extraction. The technical goals of this research include evaluating the energy requirements, water usage, land disturbance, and greenhouse gas emissions associated with both lepidolite and brine extraction processes.

Furthermore, this study aims to assess the scalability and long-term sustainability of lepidolite extraction compared to brine sources. As global lithium demand continues to surge, understanding the environmental implications of different extraction methods becomes crucial for informed decision-making in the industry. This research will also explore potential technological advancements that could mitigate the environmental impacts of both extraction methods.

By conducting this comparative analysis, we seek to provide valuable insights into the future direction of lithium extraction technologies. The findings will contribute to the ongoing dialogue about sustainable resource management and help guide policy decisions and industry practices towards more environmentally responsible lithium production methods.

In recent years, lepidolite, a lithium-bearing mica mineral, has emerged as a potential alternative source for lithium extraction. This shift in focus has led to a growing interest in comparing the environmental impacts of lepidolite-based extraction methods with traditional brine-based approaches. The objective of this technical research is to conduct a comprehensive analysis of the comparative environmental footprints associated with lepidolite and brine lithium sources.

The evolution of lithium extraction technologies has been driven by the need for more efficient and environmentally friendly processes. Brine extraction, which has been the dominant method, involves pumping lithium-rich brine from underground reservoirs and concentrating it through evaporation. This process, while well-established, faces challenges related to water consumption and potential ecosystem disruption in arid regions where most brine deposits are located.

Lepidolite extraction, on the other hand, represents a newer approach to lithium production. As a hard rock source, lepidolite mining and processing methods differ significantly from brine extraction. The technical goals of this research include evaluating the energy requirements, water usage, land disturbance, and greenhouse gas emissions associated with both lepidolite and brine extraction processes.

Furthermore, this study aims to assess the scalability and long-term sustainability of lepidolite extraction compared to brine sources. As global lithium demand continues to surge, understanding the environmental implications of different extraction methods becomes crucial for informed decision-making in the industry. This research will also explore potential technological advancements that could mitigate the environmental impacts of both extraction methods.

By conducting this comparative analysis, we seek to provide valuable insights into the future direction of lithium extraction technologies. The findings will contribute to the ongoing dialogue about sustainable resource management and help guide policy decisions and industry practices towards more environmentally responsible lithium production methods.

Market Demand Analysis for Lithium

The global lithium market has experienced significant growth in recent years, driven primarily by the increasing demand for lithium-ion batteries in electric vehicles (EVs) and energy storage systems. This surge in demand has led to a substantial increase in lithium production and exploration activities worldwide.

The EV market, in particular, has been a major driver of lithium demand. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, automakers are rapidly expanding their electric vehicle lineups. This trend has resulted in a sharp increase in the demand for lithium-ion batteries, which in turn has boosted the demand for lithium carbonate and lithium hydroxide, the key lithium compounds used in battery production.

In addition to the automotive sector, the growing adoption of renewable energy sources has created a significant market for large-scale energy storage systems, further driving the demand for lithium. The portable electronics industry, including smartphones, laptops, and tablets, continues to be a steady consumer of lithium-ion batteries, contributing to the overall market growth.

The lithium market is expected to continue its upward trajectory in the coming years. Industry analysts project that the global lithium demand could triple by 2025 compared to 2019 levels. This growth is primarily attributed to the anticipated expansion of the EV market and the increasing deployment of grid-scale energy storage systems.

However, the lithium market faces challenges in meeting this growing demand. Traditional lithium extraction methods, particularly from brine sources, are time-consuming and water-intensive. This has led to increased interest in alternative lithium sources, such as hard rock deposits like lepidolite, which offer potentially faster extraction times and reduced environmental impact.

The comparison between lepidolite and brine lithium sources has become increasingly relevant in the context of market demand analysis. Lepidolite, a lithium-bearing mica mineral, presents an opportunity to diversify lithium supply and potentially address some of the environmental concerns associated with brine extraction. As the market continues to grow, the ability to efficiently and sustainably extract lithium from various sources will be crucial in meeting the escalating demand.

The geographical distribution of lithium resources also plays a significant role in market dynamics. While traditional brine operations are concentrated in South America's "Lithium Triangle," lepidolite and other hard rock lithium sources are more widely distributed globally. This distribution could lead to a shift in the lithium supply chain and potentially impact market prices and availability.

The EV market, in particular, has been a major driver of lithium demand. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, automakers are rapidly expanding their electric vehicle lineups. This trend has resulted in a sharp increase in the demand for lithium-ion batteries, which in turn has boosted the demand for lithium carbonate and lithium hydroxide, the key lithium compounds used in battery production.

In addition to the automotive sector, the growing adoption of renewable energy sources has created a significant market for large-scale energy storage systems, further driving the demand for lithium. The portable electronics industry, including smartphones, laptops, and tablets, continues to be a steady consumer of lithium-ion batteries, contributing to the overall market growth.

The lithium market is expected to continue its upward trajectory in the coming years. Industry analysts project that the global lithium demand could triple by 2025 compared to 2019 levels. This growth is primarily attributed to the anticipated expansion of the EV market and the increasing deployment of grid-scale energy storage systems.

However, the lithium market faces challenges in meeting this growing demand. Traditional lithium extraction methods, particularly from brine sources, are time-consuming and water-intensive. This has led to increased interest in alternative lithium sources, such as hard rock deposits like lepidolite, which offer potentially faster extraction times and reduced environmental impact.

The comparison between lepidolite and brine lithium sources has become increasingly relevant in the context of market demand analysis. Lepidolite, a lithium-bearing mica mineral, presents an opportunity to diversify lithium supply and potentially address some of the environmental concerns associated with brine extraction. As the market continues to grow, the ability to efficiently and sustainably extract lithium from various sources will be crucial in meeting the escalating demand.

The geographical distribution of lithium resources also plays a significant role in market dynamics. While traditional brine operations are concentrated in South America's "Lithium Triangle," lepidolite and other hard rock lithium sources are more widely distributed globally. This distribution could lead to a shift in the lithium supply chain and potentially impact market prices and availability.

Current Challenges in Lithium Extraction Methods

The lithium extraction industry currently faces several significant challenges that impact both lepidolite and brine sources. One of the primary concerns is the environmental impact of extraction processes. For lepidolite, the main challenges include energy-intensive mining and processing operations, which contribute to greenhouse gas emissions and potential habitat disruption. The extraction process often involves open-pit mining, crushing, and chemical processing, all of which can have substantial environmental footprints.

Brine extraction, while generally considered less environmentally disruptive than hard rock mining, also faces its own set of challenges. The most pressing issue is water consumption and potential groundwater depletion, particularly in arid regions where many lithium-rich brines are located. The evaporation process used in traditional brine extraction methods can lead to significant water loss, affecting local ecosystems and communities.

Both extraction methods struggle with efficiency and yield optimization. Lepidolite processing often results in lower lithium recovery rates compared to high-grade brine operations, leading to increased waste generation. Brine extraction, on the other hand, is time-consuming due to the reliance on solar evaporation, which can take several months to concentrate lithium sufficiently.

The management of waste and by-products poses another significant challenge. Lepidolite mining generates substantial amounts of tailings that require proper disposal and management to prevent environmental contamination. Brine operations produce salt wastes and other minerals that need to be handled responsibly to minimize ecological impact.

Technological limitations also hinder the advancement of more sustainable extraction methods. For lepidolite, developing more efficient and environmentally friendly processing techniques remains a challenge. In brine extraction, the industry is seeking alternatives to traditional evaporation ponds, such as direct lithium extraction (DLE) technologies, but these are still in various stages of development and face scalability issues.

The economic viability of extraction methods is another crucial factor. Fluctuating lithium prices and market demands can impact the feasibility of both lepidolite and brine operations. This economic uncertainty can hinder investments in more sustainable technologies and practices, as companies may prioritize short-term profitability over long-term environmental considerations.

Regulatory compliance and obtaining necessary permits present additional challenges, particularly as environmental regulations become more stringent globally. Both lepidolite and brine operations must navigate complex regulatory landscapes, which can vary significantly between regions and countries, adding to the operational complexities and costs.

Brine extraction, while generally considered less environmentally disruptive than hard rock mining, also faces its own set of challenges. The most pressing issue is water consumption and potential groundwater depletion, particularly in arid regions where many lithium-rich brines are located. The evaporation process used in traditional brine extraction methods can lead to significant water loss, affecting local ecosystems and communities.

Both extraction methods struggle with efficiency and yield optimization. Lepidolite processing often results in lower lithium recovery rates compared to high-grade brine operations, leading to increased waste generation. Brine extraction, on the other hand, is time-consuming due to the reliance on solar evaporation, which can take several months to concentrate lithium sufficiently.

The management of waste and by-products poses another significant challenge. Lepidolite mining generates substantial amounts of tailings that require proper disposal and management to prevent environmental contamination. Brine operations produce salt wastes and other minerals that need to be handled responsibly to minimize ecological impact.

Technological limitations also hinder the advancement of more sustainable extraction methods. For lepidolite, developing more efficient and environmentally friendly processing techniques remains a challenge. In brine extraction, the industry is seeking alternatives to traditional evaporation ponds, such as direct lithium extraction (DLE) technologies, but these are still in various stages of development and face scalability issues.

The economic viability of extraction methods is another crucial factor. Fluctuating lithium prices and market demands can impact the feasibility of both lepidolite and brine operations. This economic uncertainty can hinder investments in more sustainable technologies and practices, as companies may prioritize short-term profitability over long-term environmental considerations.

Regulatory compliance and obtaining necessary permits present additional challenges, particularly as environmental regulations become more stringent globally. Both lepidolite and brine operations must navigate complex regulatory landscapes, which can vary significantly between regions and countries, adding to the operational complexities and costs.

Existing Extraction Methods: Lepidolite vs Brine

01 Environmental impact assessment of lithium extraction

Evaluating the environmental footprint of lithium extraction from both lepidolite and brine sources. This includes assessing factors such as water usage, energy consumption, and greenhouse gas emissions associated with different extraction methods. The assessment helps in comparing the sustainability of various lithium sources and informs decision-making for more environmentally friendly extraction processes.- Environmental impact assessment of lithium extraction: Methods and systems for assessing the environmental footprint of lithium extraction from various sources, including lepidolite and brine. These assessments consider factors such as water usage, energy consumption, and greenhouse gas emissions associated with different extraction processes.

- Sustainable lithium extraction from brine: Techniques for extracting lithium from brine sources with reduced environmental impact. These methods focus on minimizing water consumption, optimizing energy use, and implementing closed-loop systems to reduce waste and emissions in the extraction process.

- Eco-friendly processing of lepidolite: Innovative approaches to processing lepidolite for lithium extraction with a focus on reducing the environmental footprint. These methods include improved ore beneficiation techniques, energy-efficient roasting processes, and the use of green solvents for lithium recovery.

- Comparative analysis of lithium sources: Studies and methodologies for comparing the environmental impacts of different lithium sources, including lepidolite and brine. These analyses consider factors such as land use, water consumption, energy requirements, and carbon emissions throughout the entire extraction and processing lifecycle.

- Mitigation strategies for environmental impacts: Development of strategies and technologies to mitigate the environmental impacts of lithium extraction from both lepidolite and brine sources. These include water recycling systems, renewable energy integration, and habitat restoration techniques to minimize the ecological footprint of lithium production.

02 Water management in brine-based lithium extraction

Addressing water-related challenges in lithium extraction from brine sources. This involves developing techniques for efficient water use, recycling, and minimizing freshwater consumption in arid regions where many lithium brine deposits are located. Improved water management strategies aim to reduce the environmental impact of brine-based lithium production.Expand Specific Solutions03 Sustainable processing of lepidolite for lithium extraction

Developing environmentally friendly methods for processing lepidolite to extract lithium. This includes innovative techniques to reduce energy consumption, minimize waste generation, and decrease the use of harmful chemicals in the extraction process. The focus is on creating more sustainable and eco-friendly approaches to hard rock lithium mining.Expand Specific Solutions04 Life cycle analysis of lithium production

Conducting comprehensive life cycle analyses of lithium production from both lepidolite and brine sources. This involves examining the environmental impacts throughout the entire production chain, from extraction to processing and refining. The analysis helps identify areas for improvement and enables a more accurate comparison of the overall environmental footprint of different lithium sources.Expand Specific Solutions05 Technological innovations for reducing environmental impact

Implementing new technologies and processes to minimize the environmental footprint of lithium extraction. This includes developing more efficient extraction methods, utilizing renewable energy sources in production, and creating closed-loop systems to reduce waste and emissions. These innovations aim to make lithium production more sustainable and environmentally friendly.Expand Specific Solutions

Key Players in Lithium Mining Industry

The comparative environmental footprints of lepidolite versus brine lithium sources present a complex competitive landscape in the lithium industry. The market is in a growth phase, with increasing demand for lithium in battery technologies driving expansion. The global lithium market size is projected to reach significant volumes in the coming years. Technologically, both lepidolite and brine extraction methods are evolving, with companies like Energy Exploration Technologies, Inc. and Novalith Technologies Pty Ltd. developing innovative direct lithium extraction technologies. Established players such as LANXESS Deutschland GmbH and Rockwood Lithium are also active in this space. Research institutions like Qinghai Institute of Salt Lakes and universities including Central South University are contributing to advancements in extraction techniques, indicating a dynamic and competitive environment in lithium sourcing technologies.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has developed an innovative approach to lithium extraction from salt lake brines, focusing on environmental sustainability. Their method utilizes a selective adsorption process that significantly reduces water consumption and minimizes chemical usage[1]. The institute has implemented a closed-loop system that recycles and reuses process water, reducing freshwater intake by up to 65% compared to traditional brine extraction methods[2]. Additionally, they have integrated solar evaporation techniques to minimize energy consumption, leveraging the natural conditions of the Qinghai-Tibet Plateau[3]. This approach not only improves efficiency but also reduces the carbon footprint of lithium production.

Strengths: Significantly reduced water consumption, minimized chemical usage, and lower carbon footprint. Weaknesses: May have limited applicability in regions without suitable solar evaporation conditions.

Energy Exploration Technologies, Inc.

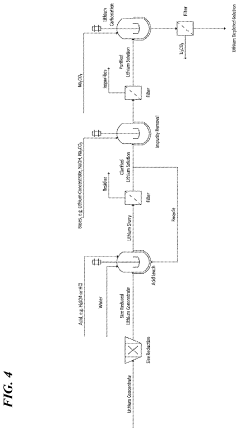

Technical Solution: Energy Exploration Technologies (EnergyX) has developed a novel lithium extraction technology called Lithium-Ion Transport and Separation (LiTAS). This direct lithium extraction (DLE) method uses a highly selective membrane that allows for the efficient separation of lithium ions from brine solutions[4]. The LiTAS process can extract lithium from various brine sources, including geothermal and oilfield brines, with minimal environmental impact. EnergyX claims their technology can recover up to 90% of available lithium in brine resources, compared to 30-50% for traditional evaporation methods[5]. The process is also significantly faster, reducing extraction time from months to hours, and requires a much smaller land footprint than evaporation ponds[6].

Strengths: High lithium recovery rate, faster extraction process, and reduced land use. Weaknesses: May require higher initial capital investment compared to traditional methods.

Core Innovations in Lithium Extraction Processes

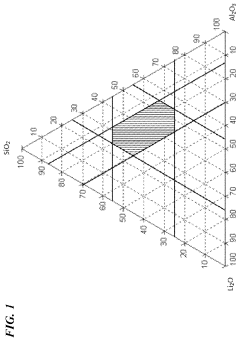

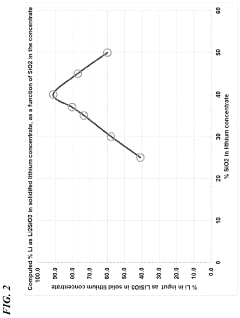

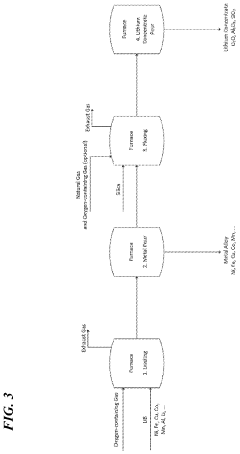

Method for producing battery grade lithium hydroxide monohydrate

PatentWO2021228936A1

Innovation

- A solvent extraction process using chloride/hydroxide anion exchange to convert technical-grade lithium chloride into high-purity lithium hydroxide monohydrate, involving dissolution in organic solvents, addition of alkali metal hydroxide, optional non-aqueous ion exchange, solvent removal, and subsequent aqueous dissolution for chloride-to-hydroxide conversion.

Lithium-rich compositions

PatentPendingUS20230411722A1

Innovation

- A process involving the production of high-concentration lithium concentrates through pyrometallurgical recycling, where lithium batteries are smelted in a furnace with oxygen injection to separate a metal phase and a lithium concentrate phase, followed by acidification and filtration to extract lithium, resulting in a lithium-enriched solution with minimal aluminum and impurity extraction.

Environmental Impact Assessment Methodologies

Environmental Impact Assessment (EIA) methodologies play a crucial role in evaluating the comparative environmental footprints of lepidolite and brine lithium sources. These methodologies provide a structured approach to assessing the potential environmental consequences of lithium extraction from different sources.

Life Cycle Assessment (LCA) is a widely used methodology in this context. It examines the environmental impacts associated with all stages of a product's life, from raw material extraction to disposal. For lithium production, LCA considers factors such as energy consumption, water usage, greenhouse gas emissions, and land use changes throughout the entire production process.

Water Footprint Assessment is particularly relevant when comparing lepidolite and brine lithium sources. This methodology quantifies the volume of freshwater used in production and assesses the impact on local water resources. It is especially important for brine extraction, which often occurs in water-scarce regions.

Carbon Footprint Analysis focuses specifically on greenhouse gas emissions associated with lithium production. This methodology calculates the total amount of carbon dioxide and other greenhouse gases emitted throughout the production process, allowing for a direct comparison between lepidolite and brine sources in terms of climate impact.

Ecosystem Services Valuation is another important methodology that assesses the impact of lithium extraction on local ecosystems. It quantifies the value of services provided by ecosystems, such as water purification or biodiversity support, and how these services may be affected by different extraction methods.

Environmental Risk Assessment is used to identify and evaluate potential environmental hazards associated with lithium extraction. This methodology considers factors such as the likelihood and severity of environmental incidents, helping to compare the relative risks of lepidolite mining and brine extraction.

Material Flow Analysis tracks the flow of materials and energy through the production system. This methodology is particularly useful for comparing the resource efficiency of lepidolite and brine lithium sources, highlighting areas where waste reduction or process optimization could be implemented.

Lastly, Social Impact Assessment, while not strictly environmental, is often included in comprehensive EIAs. This methodology evaluates the social consequences of lithium extraction, including impacts on local communities, labor conditions, and cultural heritage. It provides a more holistic view of the overall sustainability of different lithium sources.

These methodologies, when applied systematically, provide a comprehensive framework for comparing the environmental footprints of lepidolite and brine lithium sources. They enable decision-makers to make informed choices based on a thorough understanding of the environmental implications of different extraction methods.

Life Cycle Assessment (LCA) is a widely used methodology in this context. It examines the environmental impacts associated with all stages of a product's life, from raw material extraction to disposal. For lithium production, LCA considers factors such as energy consumption, water usage, greenhouse gas emissions, and land use changes throughout the entire production process.

Water Footprint Assessment is particularly relevant when comparing lepidolite and brine lithium sources. This methodology quantifies the volume of freshwater used in production and assesses the impact on local water resources. It is especially important for brine extraction, which often occurs in water-scarce regions.

Carbon Footprint Analysis focuses specifically on greenhouse gas emissions associated with lithium production. This methodology calculates the total amount of carbon dioxide and other greenhouse gases emitted throughout the production process, allowing for a direct comparison between lepidolite and brine sources in terms of climate impact.

Ecosystem Services Valuation is another important methodology that assesses the impact of lithium extraction on local ecosystems. It quantifies the value of services provided by ecosystems, such as water purification or biodiversity support, and how these services may be affected by different extraction methods.

Environmental Risk Assessment is used to identify and evaluate potential environmental hazards associated with lithium extraction. This methodology considers factors such as the likelihood and severity of environmental incidents, helping to compare the relative risks of lepidolite mining and brine extraction.

Material Flow Analysis tracks the flow of materials and energy through the production system. This methodology is particularly useful for comparing the resource efficiency of lepidolite and brine lithium sources, highlighting areas where waste reduction or process optimization could be implemented.

Lastly, Social Impact Assessment, while not strictly environmental, is often included in comprehensive EIAs. This methodology evaluates the social consequences of lithium extraction, including impacts on local communities, labor conditions, and cultural heritage. It provides a more holistic view of the overall sustainability of different lithium sources.

These methodologies, when applied systematically, provide a comprehensive framework for comparing the environmental footprints of lepidolite and brine lithium sources. They enable decision-makers to make informed choices based on a thorough understanding of the environmental implications of different extraction methods.

Regulatory Framework for Lithium Mining Operations

The regulatory framework for lithium mining operations is a complex and evolving landscape that varies significantly across different jurisdictions. In many countries, lithium extraction is subject to both general mining regulations and specific rules tailored to the unique characteristics of lithium production.

At the federal level, environmental protection agencies often play a crucial role in overseeing lithium mining activities. These agencies typically enforce regulations related to air and water quality, waste management, and ecosystem preservation. For instance, in the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act and Clean Water Act, which directly impact lithium mining operations.

Land use and permitting processes are often managed at the state or provincial level. These regulations govern aspects such as exploration rights, mining claims, and land reclamation requirements. In Australia, for example, each state has its own mining act that outlines the procedures for obtaining mining leases and environmental approvals.

Water management is a critical aspect of lithium mining regulations, particularly for brine extraction methods. In water-scarce regions like Chile's Atacama Desert, strict quotas on water usage are enforced to protect local ecosystems and communities. Similarly, regulations often require mining companies to implement water recycling and conservation measures.

Occupational health and safety regulations are another important component of the regulatory framework. These rules aim to protect workers from the potential hazards associated with lithium mining, including exposure to chemicals and dust. In Canada, for instance, the Mining Association of Canada's Towards Sustainable Mining initiative sets industry standards for safety and environmental performance.

Indigenous rights and community engagement are increasingly emphasized in regulatory frameworks for lithium mining. In many jurisdictions, mining companies are required to consult with local communities and obtain their consent before commencing operations. This aspect is particularly relevant in countries like Bolivia, where lithium-rich areas often overlap with indigenous territories.

As the demand for lithium continues to grow, driven by the electric vehicle and renewable energy storage sectors, regulatory frameworks are adapting to address new challenges. Many countries are developing or updating their regulations to ensure sustainable lithium production practices. This includes stricter environmental impact assessment requirements, more comprehensive monitoring systems, and enhanced provisions for mine closure and site rehabilitation.

International standards and guidelines also influence national regulatory frameworks. Organizations such as the International Council on Mining and Metals (ICMM) provide best practice guidelines that many countries incorporate into their regulatory approaches. These standards often go beyond legal requirements, addressing issues such as biodiversity conservation and social responsibility.

At the federal level, environmental protection agencies often play a crucial role in overseeing lithium mining activities. These agencies typically enforce regulations related to air and water quality, waste management, and ecosystem preservation. For instance, in the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act and Clean Water Act, which directly impact lithium mining operations.

Land use and permitting processes are often managed at the state or provincial level. These regulations govern aspects such as exploration rights, mining claims, and land reclamation requirements. In Australia, for example, each state has its own mining act that outlines the procedures for obtaining mining leases and environmental approvals.

Water management is a critical aspect of lithium mining regulations, particularly for brine extraction methods. In water-scarce regions like Chile's Atacama Desert, strict quotas on water usage are enforced to protect local ecosystems and communities. Similarly, regulations often require mining companies to implement water recycling and conservation measures.

Occupational health and safety regulations are another important component of the regulatory framework. These rules aim to protect workers from the potential hazards associated with lithium mining, including exposure to chemicals and dust. In Canada, for instance, the Mining Association of Canada's Towards Sustainable Mining initiative sets industry standards for safety and environmental performance.

Indigenous rights and community engagement are increasingly emphasized in regulatory frameworks for lithium mining. In many jurisdictions, mining companies are required to consult with local communities and obtain their consent before commencing operations. This aspect is particularly relevant in countries like Bolivia, where lithium-rich areas often overlap with indigenous territories.

As the demand for lithium continues to grow, driven by the electric vehicle and renewable energy storage sectors, regulatory frameworks are adapting to address new challenges. Many countries are developing or updating their regulations to ensure sustainable lithium production practices. This includes stricter environmental impact assessment requirements, more comprehensive monitoring systems, and enhanced provisions for mine closure and site rehabilitation.

International standards and guidelines also influence national regulatory frameworks. Organizations such as the International Council on Mining and Metals (ICMM) provide best practice guidelines that many countries incorporate into their regulatory approaches. These standards often go beyond legal requirements, addressing issues such as biodiversity conservation and social responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!