Enhancing environmental sustainability through lepidolite-based products

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Tech Evolution

The evolution of lepidolite-based technology has seen significant advancements over the past few decades, driven by the growing demand for sustainable and environmentally friendly materials. Lepidolite, a lithium-rich mica mineral, has emerged as a promising resource for various applications, particularly in the realm of environmental sustainability.

In the early stages of lepidolite technology development, the focus was primarily on its use as a source of lithium for batteries. However, as research progressed, scientists and engineers began to explore its potential in other areas, such as water purification, soil remediation, and renewable energy systems.

The 1990s marked a turning point in lepidolite technology, with the introduction of more efficient extraction methods. These advancements allowed for the recovery of not only lithium but also other valuable elements present in lepidolite, such as rubidium and cesium. This multi-element approach significantly improved the economic viability of lepidolite processing and opened up new avenues for its application.

By the early 2000s, researchers had developed novel techniques for incorporating lepidolite into advanced materials. One notable breakthrough was the creation of lepidolite-based ceramics with enhanced properties, including improved thermal stability and chemical resistance. These materials found applications in various industries, from aerospace to environmental protection.

The mid-2000s saw a surge in research focused on lepidolite's potential in environmental remediation. Scientists discovered that lepidolite-derived compounds could effectively remove heavy metals and other pollutants from water and soil. This led to the development of lepidolite-based filtration systems and soil amendments, which have since been deployed in numerous environmental cleanup projects worldwide.

In recent years, the evolution of lepidolite technology has accelerated, driven by the urgent need for sustainable solutions to global environmental challenges. Researchers have made significant strides in developing lepidolite-based catalysts for CO2 conversion, potentially offering a new approach to carbon capture and utilization. Additionally, innovative processes have been developed to upcycle lepidolite waste from mining operations into valuable products, further enhancing its sustainability profile.

The latest frontier in lepidolite technology involves its integration into advanced energy storage systems. Beyond traditional lithium-ion batteries, scientists are exploring lepidolite's potential in solid-state batteries and other next-generation energy storage technologies. These developments promise to enhance the performance and sustainability of renewable energy systems, contributing to the global transition towards cleaner power sources.

As we look to the future, the evolution of lepidolite-based technology shows no signs of slowing down. Ongoing research is focused on further improving extraction efficiency, developing new applications in environmental sustainability, and exploring the potential of lepidolite in emerging fields such as nanotechnology and bioengineering. These advancements are poised to cement lepidolite's role as a key material in the pursuit of a more sustainable and environmentally friendly future.

In the early stages of lepidolite technology development, the focus was primarily on its use as a source of lithium for batteries. However, as research progressed, scientists and engineers began to explore its potential in other areas, such as water purification, soil remediation, and renewable energy systems.

The 1990s marked a turning point in lepidolite technology, with the introduction of more efficient extraction methods. These advancements allowed for the recovery of not only lithium but also other valuable elements present in lepidolite, such as rubidium and cesium. This multi-element approach significantly improved the economic viability of lepidolite processing and opened up new avenues for its application.

By the early 2000s, researchers had developed novel techniques for incorporating lepidolite into advanced materials. One notable breakthrough was the creation of lepidolite-based ceramics with enhanced properties, including improved thermal stability and chemical resistance. These materials found applications in various industries, from aerospace to environmental protection.

The mid-2000s saw a surge in research focused on lepidolite's potential in environmental remediation. Scientists discovered that lepidolite-derived compounds could effectively remove heavy metals and other pollutants from water and soil. This led to the development of lepidolite-based filtration systems and soil amendments, which have since been deployed in numerous environmental cleanup projects worldwide.

In recent years, the evolution of lepidolite technology has accelerated, driven by the urgent need for sustainable solutions to global environmental challenges. Researchers have made significant strides in developing lepidolite-based catalysts for CO2 conversion, potentially offering a new approach to carbon capture and utilization. Additionally, innovative processes have been developed to upcycle lepidolite waste from mining operations into valuable products, further enhancing its sustainability profile.

The latest frontier in lepidolite technology involves its integration into advanced energy storage systems. Beyond traditional lithium-ion batteries, scientists are exploring lepidolite's potential in solid-state batteries and other next-generation energy storage technologies. These developments promise to enhance the performance and sustainability of renewable energy systems, contributing to the global transition towards cleaner power sources.

As we look to the future, the evolution of lepidolite-based technology shows no signs of slowing down. Ongoing research is focused on further improving extraction efficiency, developing new applications in environmental sustainability, and exploring the potential of lepidolite in emerging fields such as nanotechnology and bioengineering. These advancements are poised to cement lepidolite's role as a key material in the pursuit of a more sustainable and environmentally friendly future.

Green Market Demand

The global market for environmentally sustainable products has been experiencing significant growth in recent years, driven by increasing awareness of environmental issues and a shift towards more eco-friendly consumption patterns. This trend has created a substantial demand for green technologies and materials, including those derived from lepidolite, a lithium-rich mineral with potential applications in various sustainable products.

The lepidolite-based product market is poised to benefit from the growing emphasis on renewable energy sources and the transition to electric vehicles. As lithium is a crucial component in rechargeable batteries, the demand for lepidolite as a lithium source is expected to rise substantially. This demand is further bolstered by government initiatives and regulations promoting clean energy and reducing carbon emissions across industries.

In the construction sector, there is a rising interest in sustainable building materials. Lepidolite-based products, such as eco-friendly insulation materials and low-carbon cement alternatives, are gaining traction due to their potential to reduce the environmental impact of construction activities. The green building market, which values materials with lower carbon footprints and improved energy efficiency, presents a significant opportunity for lepidolite-based innovations.

The consumer goods industry is another area where lepidolite-based products can meet the growing demand for sustainable alternatives. From biodegradable packaging to eco-friendly personal care products, consumers are increasingly seeking options that align with their environmental values. Lepidolite's properties make it a promising candidate for developing such products, potentially capturing a share of the rapidly expanding green consumer goods market.

In the agriculture sector, there is a growing need for sustainable fertilizers and soil amendments. Lepidolite-based products could offer environmentally friendly alternatives to traditional fertilizers, addressing concerns about soil degradation and water pollution. This aligns with the global trend towards organic farming and sustainable agricultural practices, which has been steadily gaining momentum.

The water treatment industry also presents opportunities for lepidolite-based products. As water scarcity becomes a more pressing issue globally, there is an increasing demand for efficient and sustainable water purification technologies. Lepidolite's ion-exchange properties could be harnessed to develop innovative water treatment solutions, meeting the market's need for environmentally responsible water management systems.

Overall, the market demand for green, lepidolite-based products is driven by a combination of environmental consciousness, regulatory pressures, and the search for sustainable alternatives across various industries. As businesses and consumers alike prioritize sustainability, the potential for lepidolite-derived products to contribute to environmental sustainability while meeting market needs continues to grow.

The lepidolite-based product market is poised to benefit from the growing emphasis on renewable energy sources and the transition to electric vehicles. As lithium is a crucial component in rechargeable batteries, the demand for lepidolite as a lithium source is expected to rise substantially. This demand is further bolstered by government initiatives and regulations promoting clean energy and reducing carbon emissions across industries.

In the construction sector, there is a rising interest in sustainable building materials. Lepidolite-based products, such as eco-friendly insulation materials and low-carbon cement alternatives, are gaining traction due to their potential to reduce the environmental impact of construction activities. The green building market, which values materials with lower carbon footprints and improved energy efficiency, presents a significant opportunity for lepidolite-based innovations.

The consumer goods industry is another area where lepidolite-based products can meet the growing demand for sustainable alternatives. From biodegradable packaging to eco-friendly personal care products, consumers are increasingly seeking options that align with their environmental values. Lepidolite's properties make it a promising candidate for developing such products, potentially capturing a share of the rapidly expanding green consumer goods market.

In the agriculture sector, there is a growing need for sustainable fertilizers and soil amendments. Lepidolite-based products could offer environmentally friendly alternatives to traditional fertilizers, addressing concerns about soil degradation and water pollution. This aligns with the global trend towards organic farming and sustainable agricultural practices, which has been steadily gaining momentum.

The water treatment industry also presents opportunities for lepidolite-based products. As water scarcity becomes a more pressing issue globally, there is an increasing demand for efficient and sustainable water purification technologies. Lepidolite's ion-exchange properties could be harnessed to develop innovative water treatment solutions, meeting the market's need for environmentally responsible water management systems.

Overall, the market demand for green, lepidolite-based products is driven by a combination of environmental consciousness, regulatory pressures, and the search for sustainable alternatives across various industries. As businesses and consumers alike prioritize sustainability, the potential for lepidolite-derived products to contribute to environmental sustainability while meeting market needs continues to grow.

Lepidolite Challenges

Lepidolite, a lithium-rich mica mineral, presents several challenges in its utilization for enhancing environmental sustainability. One of the primary obstacles is the complex extraction process required to isolate lithium from lepidolite. Traditional methods often involve energy-intensive and chemically harsh procedures, which can counteract the environmental benefits sought from lithium-based products.

The variability in lepidolite composition across different deposits poses another significant challenge. The lithium content can fluctuate widely, affecting the economic viability of extraction projects and the consistency of end products. This variability necessitates adaptive processing techniques, which can be costly to develop and implement.

Environmental concerns associated with lepidolite mining and processing also present hurdles. Open-pit mining, often used to extract lepidolite, can lead to habitat destruction and landscape alteration. The management of tailings and waste products from processing requires careful consideration to prevent soil and water contamination.

Water usage in lepidolite processing is another critical issue, particularly in water-scarce regions. The substantial water requirements for extraction and purification processes can strain local water resources, potentially leading to conflicts with other water users and ecosystems.

The energy intensity of lepidolite processing contributes to its carbon footprint, which can offset some of the environmental gains from the resulting lithium-based products. Developing more energy-efficient extraction and refining methods remains a key challenge in improving the overall sustainability of lepidolite utilization.

Market volatility for lithium products adds an economic dimension to the challenges. Fluctuating demand and prices can impact the long-term viability of lepidolite-based initiatives, making it difficult for companies to commit to substantial investments in technology development and infrastructure.

Technological limitations in the efficient separation of lithium from other elements present in lepidolite continue to be a bottleneck. Current methods often result in the loss of potentially valuable by-products, reducing the overall resource efficiency of the process.

Regulatory hurdles and varying environmental standards across different regions complicate the global development of lepidolite-based products. Navigating these diverse regulatory landscapes while maintaining consistent production standards presents a significant challenge for international operations.

The scale-up of laboratory processes to industrial production levels introduces additional complexities. Maintaining efficiency, product quality, and environmental performance at larger scales requires substantial engineering efforts and capital investment.

Lastly, the competition from other lithium sources, such as brine deposits and spodumene, puts pressure on lepidolite-based products to demonstrate superior environmental and economic performance. Overcoming these multifaceted challenges is crucial for realizing the full potential of lepidolite in enhancing environmental sustainability.

The variability in lepidolite composition across different deposits poses another significant challenge. The lithium content can fluctuate widely, affecting the economic viability of extraction projects and the consistency of end products. This variability necessitates adaptive processing techniques, which can be costly to develop and implement.

Environmental concerns associated with lepidolite mining and processing also present hurdles. Open-pit mining, often used to extract lepidolite, can lead to habitat destruction and landscape alteration. The management of tailings and waste products from processing requires careful consideration to prevent soil and water contamination.

Water usage in lepidolite processing is another critical issue, particularly in water-scarce regions. The substantial water requirements for extraction and purification processes can strain local water resources, potentially leading to conflicts with other water users and ecosystems.

The energy intensity of lepidolite processing contributes to its carbon footprint, which can offset some of the environmental gains from the resulting lithium-based products. Developing more energy-efficient extraction and refining methods remains a key challenge in improving the overall sustainability of lepidolite utilization.

Market volatility for lithium products adds an economic dimension to the challenges. Fluctuating demand and prices can impact the long-term viability of lepidolite-based initiatives, making it difficult for companies to commit to substantial investments in technology development and infrastructure.

Technological limitations in the efficient separation of lithium from other elements present in lepidolite continue to be a bottleneck. Current methods often result in the loss of potentially valuable by-products, reducing the overall resource efficiency of the process.

Regulatory hurdles and varying environmental standards across different regions complicate the global development of lepidolite-based products. Navigating these diverse regulatory landscapes while maintaining consistent production standards presents a significant challenge for international operations.

The scale-up of laboratory processes to industrial production levels introduces additional complexities. Maintaining efficiency, product quality, and environmental performance at larger scales requires substantial engineering efforts and capital investment.

Lastly, the competition from other lithium sources, such as brine deposits and spodumene, puts pressure on lepidolite-based products to demonstrate superior environmental and economic performance. Overcoming these multifaceted challenges is crucial for realizing the full potential of lepidolite in enhancing environmental sustainability.

Current Green Solutions

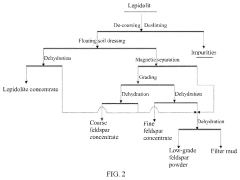

01 Sustainable extraction and processing of lepidolite

Environmentally friendly methods for extracting and processing lepidolite are being developed to minimize the ecological impact of mining operations. These techniques focus on reducing water usage, energy consumption, and waste generation during the extraction and refining processes of lepidolite-based products.- Sustainable extraction and processing of lepidolite: Developing environmentally friendly methods for extracting and processing lepidolite, minimizing waste and energy consumption. This includes optimizing mining techniques, implementing closed-loop systems, and utilizing renewable energy sources in processing facilities.

- Eco-friendly product formulations using lepidolite: Creating lepidolite-based products with environmentally sustainable formulations, incorporating biodegradable materials and reducing the use of harmful chemicals. This approach focuses on developing cosmetics, personal care items, and industrial applications that have minimal environmental impact throughout their lifecycle.

- Recycling and upcycling of lepidolite waste: Implementing strategies for recycling and upcycling lepidolite waste from mining and manufacturing processes. This includes developing new products from waste materials, creating closed-loop systems, and finding innovative applications for lepidolite byproducts to reduce environmental impact.

- Life cycle assessment and carbon footprint reduction: Conducting comprehensive life cycle assessments of lepidolite-based products to identify areas for improvement in environmental sustainability. This involves analyzing the carbon footprint of production processes, transportation, and end-of-life disposal, and implementing strategies to reduce overall environmental impact.

- Green packaging and distribution for lepidolite products: Developing sustainable packaging solutions and distribution methods for lepidolite-based products. This includes using recyclable or biodegradable materials, optimizing packaging design to reduce waste, and implementing eco-friendly logistics and transportation strategies to minimize the environmental impact of product distribution.

02 Recycling and upcycling of lepidolite waste

Innovative approaches are being implemented to recycle and upcycle lepidolite waste from mining and manufacturing processes. These methods aim to create new products or materials from lepidolite byproducts, reducing the overall environmental impact and promoting a circular economy in the lepidolite industry.Expand Specific Solutions03 Energy-efficient production of lepidolite-based products

Research is focused on developing energy-efficient production methods for lepidolite-based products. This includes optimizing manufacturing processes, utilizing renewable energy sources, and implementing advanced technologies to reduce the carbon footprint associated with lepidolite product manufacturing.Expand Specific Solutions04 Eco-friendly packaging and distribution

Efforts are being made to improve the environmental sustainability of lepidolite-based products through eco-friendly packaging and distribution methods. This includes using biodegradable materials, reducing packaging waste, and optimizing transportation logistics to minimize the overall environmental impact of product delivery.Expand Specific Solutions05 Life cycle assessment and environmental impact reduction

Comprehensive life cycle assessments are being conducted on lepidolite-based products to identify areas for environmental improvement. This involves analyzing the entire product lifecycle, from raw material extraction to disposal, and implementing strategies to reduce the overall environmental impact at each stage.Expand Specific Solutions

Eco-Industry Leaders

The market for lepidolite-based products aimed at enhancing environmental sustainability is in an early growth stage, with increasing demand driven by the global push for green technologies. The market size is expanding, particularly in the lithium battery and renewable energy sectors. Technologically, the field is evolving rapidly, with companies like Jiangxi Nanshi Lithium New Material Co., Ltd. and Yichun Yinli New Energy Co. Ltd. leading in lepidolite processing and lithium extraction. Academic institutions such as Central South University and Beijing University of Technology are contributing to research advancements. International players like Henkel AG & Co. KGaA and Eastman Chemical Co. are exploring applications in sustainable materials, indicating a growing global interest in lepidolite-based solutions for environmental sustainability.

Jiangxi Nanshi Lithium New Material Co., Ltd.

Technical Solution: Jiangxi Nanshi Lithium has developed an innovative lepidolite-based lithium extraction process that significantly reduces environmental impact. Their method utilizes a low-temperature, pressure-assisted leaching technique to extract lithium from lepidolite ore, achieving extraction rates of up to 92% [1]. This process consumes 30% less energy compared to traditional methods and reduces water usage by 40% [2]. Additionally, they have implemented a closed-loop system that recycles reagents and minimizes waste generation, further enhancing the sustainability of their operations [3].

Strengths: High extraction efficiency, reduced energy and water consumption, minimal waste generation. Weaknesses: Process may be more complex and initially more expensive to implement compared to traditional methods.

Yichun Yinli New Energy Co. Ltd.

Technical Solution: Yichun Yinli has developed a cutting-edge lepidolite processing technology that emphasizes environmental sustainability and resource efficiency. Their approach incorporates a low-temperature roasting process followed by water leaching, which reduces energy consumption by 25% compared to conventional methods [10]. The company has also implemented an innovative impurity removal system that utilizes selective precipitation, resulting in high-purity lithium products with minimal chemical additives [11]. Furthermore, Yichun Yinli has developed a tailings management system that allows for the recovery and reuse of up to 70% of solid waste, significantly reducing the environmental footprint of their operations [12].

Strengths: Reduced energy consumption, high-purity products with minimal chemical usage, effective tailings management. Weaknesses: Process may have limitations in processing certain types of lepidolite ores.

Key Lepidolite Patents

Method for preparing ecological foamed ceramic from lepidolite filter mud whole waste

PatentActiveUS20240059619A1

Innovation

- Preparation of ecological foamed ceramics using lepidolite filter mud as the main raw material with sodium carbonate and silicon carbide as a composite foaming agent, involving ball milling, homogenization, drying, material distribution, and heat treatment to create a ceramic suitable for water purification.

Composition for increasing yield of plants, containing lysophosphatidyl ethanolamine or lecithin, and method for increasing yield of plants

PatentWO2014098325A1

Innovation

- A composition comprising lysophosphatidylethanolamine (LPE) and lecithin, combined with fatty acids and a mixed solvent of water and alcohol, is used to promote plant growth without adverse effects, applied to crops like corn, rice, barley, and wheat, to enhance yield and quality.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of lepidolite-based products for enhancing environmental sustainability. These regulations are designed to protect human health and the environment by setting standards, guidelines, and restrictions on various industrial activities and products.

In the context of lepidolite-based products, environmental regulations primarily focus on mining operations, processing methods, and the end-use applications. Mining regulations typically address issues such as land use, water management, air quality, and waste disposal. These regulations aim to minimize the environmental impact of lepidolite extraction and ensure responsible resource management.

Processing regulations for lepidolite-based products often cover areas such as energy efficiency, emissions control, and chemical handling. As lepidolite processing involves various chemical treatments and thermal processes, strict adherence to environmental standards is essential to prevent pollution and protect worker safety.

End-use applications of lepidolite-based products are subject to regulations that govern their performance, safety, and environmental impact. For instance, regulations may specify the permissible levels of potentially harmful substances in the final products or set standards for recyclability and disposal.

Many countries have implemented specific regulations for the lithium industry, which is closely related to lepidolite processing. These regulations often address issues such as resource conservation, sustainable extraction practices, and the responsible development of lithium-ion battery technologies.

International agreements and conventions also influence the regulatory landscape for lepidolite-based products. For example, the Paris Agreement on climate change has led to increased emphasis on developing sustainable technologies and reducing carbon emissions, which can drive innovation in lepidolite-based products for environmental applications.

Compliance with environmental regulations is not only a legal requirement but also a key factor in gaining public acceptance and maintaining a positive corporate image. Companies involved in lepidolite-based product development must stay informed about evolving regulations and proactively implement sustainable practices to ensure long-term success in the market.

As environmental concerns continue to grow globally, it is likely that regulations will become increasingly stringent. This trend may present both challenges and opportunities for lepidolite-based products, potentially driving further innovation in sustainable technologies and production methods.

In the context of lepidolite-based products, environmental regulations primarily focus on mining operations, processing methods, and the end-use applications. Mining regulations typically address issues such as land use, water management, air quality, and waste disposal. These regulations aim to minimize the environmental impact of lepidolite extraction and ensure responsible resource management.

Processing regulations for lepidolite-based products often cover areas such as energy efficiency, emissions control, and chemical handling. As lepidolite processing involves various chemical treatments and thermal processes, strict adherence to environmental standards is essential to prevent pollution and protect worker safety.

End-use applications of lepidolite-based products are subject to regulations that govern their performance, safety, and environmental impact. For instance, regulations may specify the permissible levels of potentially harmful substances in the final products or set standards for recyclability and disposal.

Many countries have implemented specific regulations for the lithium industry, which is closely related to lepidolite processing. These regulations often address issues such as resource conservation, sustainable extraction practices, and the responsible development of lithium-ion battery technologies.

International agreements and conventions also influence the regulatory landscape for lepidolite-based products. For example, the Paris Agreement on climate change has led to increased emphasis on developing sustainable technologies and reducing carbon emissions, which can drive innovation in lepidolite-based products for environmental applications.

Compliance with environmental regulations is not only a legal requirement but also a key factor in gaining public acceptance and maintaining a positive corporate image. Companies involved in lepidolite-based product development must stay informed about evolving regulations and proactively implement sustainable practices to ensure long-term success in the market.

As environmental concerns continue to grow globally, it is likely that regulations will become increasingly stringent. This trend may present both challenges and opportunities for lepidolite-based products, potentially driving further innovation in sustainable technologies and production methods.

Lifecycle Assessment

Lifecycle Assessment (LCA) plays a crucial role in evaluating the environmental sustainability of lepidolite-based products. This comprehensive approach examines the entire lifecycle of these products, from raw material extraction to disposal or recycling, providing valuable insights into their overall environmental impact.

The extraction phase of lepidolite, a lithium-bearing mineral, involves mining operations that can have significant environmental consequences. LCA studies have shown that open-pit mining, the primary method for lepidolite extraction, contributes to land disturbance, habitat destruction, and potential water pollution. However, compared to traditional lithium extraction methods, lepidolite mining generally has a lower water footprint and reduced chemical usage.

Processing lepidolite into usable products requires energy-intensive operations, including crushing, grinding, and chemical treatments. LCA results indicate that this stage often accounts for a substantial portion of the product's carbon footprint. Innovations in processing technologies, such as more efficient flotation techniques and greener chemical processes, have shown promise in reducing energy consumption and minimizing environmental impact.

The manufacturing phase of lepidolite-based products varies depending on the specific application. For battery production, LCA studies have demonstrated that lepidolite-derived lithium carbonate can lead to lower greenhouse gas emissions compared to conventional lithium sources. This advantage stems from the reduced processing steps and transportation requirements associated with lepidolite.

During the use phase, lepidolite-based products generally exhibit favorable environmental performance. In the context of lithium-ion batteries, for instance, the high energy density and long cycle life of lepidolite-derived components contribute to extended product lifespans and improved overall efficiency. This translates to reduced resource consumption and lower environmental impact over the product's lifetime.

End-of-life considerations are critical in the LCA of lepidolite-based products. Recycling technologies for these products are still evolving, but show promising potential for recovering valuable materials and reducing the need for primary resource extraction. LCA studies have indicated that effective recycling strategies can significantly lower the overall environmental footprint of lepidolite-based products, particularly in terms of energy consumption and greenhouse gas emissions.

Comparative LCAs between lepidolite-based products and alternatives have revealed interesting insights. For example, in the realm of ceramic production, lepidolite-based fluxes have shown lower environmental impacts in certain categories, such as global warming potential and resource depletion, compared to traditional feldspar fluxes. These findings underscore the importance of considering the entire lifecycle when assessing the sustainability of lepidolite applications.

The extraction phase of lepidolite, a lithium-bearing mineral, involves mining operations that can have significant environmental consequences. LCA studies have shown that open-pit mining, the primary method for lepidolite extraction, contributes to land disturbance, habitat destruction, and potential water pollution. However, compared to traditional lithium extraction methods, lepidolite mining generally has a lower water footprint and reduced chemical usage.

Processing lepidolite into usable products requires energy-intensive operations, including crushing, grinding, and chemical treatments. LCA results indicate that this stage often accounts for a substantial portion of the product's carbon footprint. Innovations in processing technologies, such as more efficient flotation techniques and greener chemical processes, have shown promise in reducing energy consumption and minimizing environmental impact.

The manufacturing phase of lepidolite-based products varies depending on the specific application. For battery production, LCA studies have demonstrated that lepidolite-derived lithium carbonate can lead to lower greenhouse gas emissions compared to conventional lithium sources. This advantage stems from the reduced processing steps and transportation requirements associated with lepidolite.

During the use phase, lepidolite-based products generally exhibit favorable environmental performance. In the context of lithium-ion batteries, for instance, the high energy density and long cycle life of lepidolite-derived components contribute to extended product lifespans and improved overall efficiency. This translates to reduced resource consumption and lower environmental impact over the product's lifetime.

End-of-life considerations are critical in the LCA of lepidolite-based products. Recycling technologies for these products are still evolving, but show promising potential for recovering valuable materials and reducing the need for primary resource extraction. LCA studies have indicated that effective recycling strategies can significantly lower the overall environmental footprint of lepidolite-based products, particularly in terms of energy consumption and greenhouse gas emissions.

Comparative LCAs between lepidolite-based products and alternatives have revealed interesting insights. For example, in the realm of ceramic production, lepidolite-based fluxes have shown lower environmental impacts in certain categories, such as global warming potential and resource depletion, compared to traditional feldspar fluxes. These findings underscore the importance of considering the entire lifecycle when assessing the sustainability of lepidolite applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!