Lepidolite's impact on local air quality during mining

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Mining Overview

Lepidolite, a lithium-rich mica mineral, has gained significant attention in recent years due to the growing demand for lithium in battery production. The mining of lepidolite, however, presents unique challenges and environmental considerations, particularly concerning its impact on local air quality.

Lepidolite mining typically involves open-pit extraction methods, which can generate substantial amounts of dust and particulate matter. The process begins with the removal of overburden, followed by drilling, blasting, and excavation of the ore-bearing rock. These activities release fine particles into the air, potentially affecting the surrounding environment and local communities.

The composition of lepidolite-bearing rocks often includes other minerals such as quartz, feldspar, and various micas. When disturbed during mining operations, these materials can contribute to the release of respirable crystalline silica, a known health hazard when inhaled over prolonged periods. This aspect of lepidolite mining requires careful management and monitoring to ensure worker safety and minimize off-site impacts.

Transportation of mined lepidolite ore from the extraction site to processing facilities further contributes to air quality concerns. Haul roads, often unpaved, can be significant sources of fugitive dust emissions. The movement of heavy machinery and vehicles across these roads can resuspend fine particles, exacerbating air quality issues in the vicinity of mining operations.

Processing of lepidolite ore typically involves crushing, grinding, and beneficiation steps to concentrate the lithium-bearing minerals. These activities can generate additional dust and potentially release fine particles into the atmosphere if not properly controlled. Advanced dust suppression systems and enclosed processing facilities are often employed to mitigate these impacts.

The arid or semi-arid climates where many lepidolite deposits are found can exacerbate air quality issues. Dry conditions increase the likelihood of dust generation and dispersion, necessitating more rigorous dust control measures. Wind erosion of exposed surfaces and stockpiles can also contribute to ongoing air quality challenges in these environments.

Regulatory frameworks governing lepidolite mining operations vary by jurisdiction but generally include stringent air quality monitoring and management requirements. Mining companies are typically required to implement comprehensive dust control strategies, which may include water spraying, chemical dust suppressants, wind barriers, and vegetation of disturbed areas to minimize air quality impacts.

In conclusion, while lepidolite mining plays a crucial role in meeting the global demand for lithium, its potential impact on local air quality necessitates careful planning, advanced mitigation strategies, and ongoing monitoring to ensure environmental sustainability and community well-being.

Lepidolite mining typically involves open-pit extraction methods, which can generate substantial amounts of dust and particulate matter. The process begins with the removal of overburden, followed by drilling, blasting, and excavation of the ore-bearing rock. These activities release fine particles into the air, potentially affecting the surrounding environment and local communities.

The composition of lepidolite-bearing rocks often includes other minerals such as quartz, feldspar, and various micas. When disturbed during mining operations, these materials can contribute to the release of respirable crystalline silica, a known health hazard when inhaled over prolonged periods. This aspect of lepidolite mining requires careful management and monitoring to ensure worker safety and minimize off-site impacts.

Transportation of mined lepidolite ore from the extraction site to processing facilities further contributes to air quality concerns. Haul roads, often unpaved, can be significant sources of fugitive dust emissions. The movement of heavy machinery and vehicles across these roads can resuspend fine particles, exacerbating air quality issues in the vicinity of mining operations.

Processing of lepidolite ore typically involves crushing, grinding, and beneficiation steps to concentrate the lithium-bearing minerals. These activities can generate additional dust and potentially release fine particles into the atmosphere if not properly controlled. Advanced dust suppression systems and enclosed processing facilities are often employed to mitigate these impacts.

The arid or semi-arid climates where many lepidolite deposits are found can exacerbate air quality issues. Dry conditions increase the likelihood of dust generation and dispersion, necessitating more rigorous dust control measures. Wind erosion of exposed surfaces and stockpiles can also contribute to ongoing air quality challenges in these environments.

Regulatory frameworks governing lepidolite mining operations vary by jurisdiction but generally include stringent air quality monitoring and management requirements. Mining companies are typically required to implement comprehensive dust control strategies, which may include water spraying, chemical dust suppressants, wind barriers, and vegetation of disturbed areas to minimize air quality impacts.

In conclusion, while lepidolite mining plays a crucial role in meeting the global demand for lithium, its potential impact on local air quality necessitates careful planning, advanced mitigation strategies, and ongoing monitoring to ensure environmental sustainability and community well-being.

Air Quality Market Analysis

The air quality market analysis for lepidolite mining reveals a growing concern and demand for solutions to mitigate environmental impacts. As lithium demand surges due to the electric vehicle revolution, lepidolite mining activities have intensified, leading to increased air pollution in mining regions. This has created a significant market opportunity for air quality monitoring, control, and remediation technologies specifically tailored to the lepidolite mining industry.

The market for air quality solutions in lepidolite mining is primarily driven by regulatory pressures, corporate social responsibility initiatives, and community concerns. Governments worldwide are implementing stricter air quality standards, forcing mining companies to invest in pollution control measures. Additionally, mining companies are increasingly recognizing the importance of maintaining good relationships with local communities and protecting their social license to operate.

Key market segments include dust suppression systems, particulate matter filtration technologies, real-time air quality monitoring equipment, and environmental impact assessment services. The dust suppression segment is particularly crucial, as lepidolite mining generates significant amounts of fine dust that can have severe health impacts on nearby populations.

The market size for air quality solutions in the lepidolite mining sector is expected to grow substantially in the coming years. This growth is attributed to the expansion of lepidolite mining operations globally, especially in countries like Australia, Zimbabwe, and Portugal, which are major producers of lepidolite.

Market trends indicate a shift towards more advanced, integrated solutions that combine real-time monitoring with automated pollution control systems. There is also an increasing demand for predictive analytics and AI-powered air quality management systems that can anticipate and prevent pollution events before they occur.

Challenges in this market include the high initial costs of implementing comprehensive air quality management systems and the technical complexities of dealing with the unique characteristics of lepidolite dust. However, these challenges also present opportunities for innovative companies to develop cost-effective and tailored solutions for the industry.

The competitive landscape is diverse, with both established environmental technology firms and new startups entering the market. Key players are focusing on developing lepidolite-specific air quality solutions that can effectively capture and neutralize the fine dust particles associated with this type of mining.

In conclusion, the air quality market related to lepidolite mining presents significant growth potential. As environmental regulations tighten and public awareness of air quality issues increases, mining companies will be compelled to invest more in air quality management, driving further market expansion and technological innovation in this sector.

The market for air quality solutions in lepidolite mining is primarily driven by regulatory pressures, corporate social responsibility initiatives, and community concerns. Governments worldwide are implementing stricter air quality standards, forcing mining companies to invest in pollution control measures. Additionally, mining companies are increasingly recognizing the importance of maintaining good relationships with local communities and protecting their social license to operate.

Key market segments include dust suppression systems, particulate matter filtration technologies, real-time air quality monitoring equipment, and environmental impact assessment services. The dust suppression segment is particularly crucial, as lepidolite mining generates significant amounts of fine dust that can have severe health impacts on nearby populations.

The market size for air quality solutions in the lepidolite mining sector is expected to grow substantially in the coming years. This growth is attributed to the expansion of lepidolite mining operations globally, especially in countries like Australia, Zimbabwe, and Portugal, which are major producers of lepidolite.

Market trends indicate a shift towards more advanced, integrated solutions that combine real-time monitoring with automated pollution control systems. There is also an increasing demand for predictive analytics and AI-powered air quality management systems that can anticipate and prevent pollution events before they occur.

Challenges in this market include the high initial costs of implementing comprehensive air quality management systems and the technical complexities of dealing with the unique characteristics of lepidolite dust. However, these challenges also present opportunities for innovative companies to develop cost-effective and tailored solutions for the industry.

The competitive landscape is diverse, with both established environmental technology firms and new startups entering the market. Key players are focusing on developing lepidolite-specific air quality solutions that can effectively capture and neutralize the fine dust particles associated with this type of mining.

In conclusion, the air quality market related to lepidolite mining presents significant growth potential. As environmental regulations tighten and public awareness of air quality issues increases, mining companies will be compelled to invest more in air quality management, driving further market expansion and technological innovation in this sector.

Current Air Quality Challenges

The mining of lepidolite, a lithium-rich mineral, poses significant challenges to local air quality. The extraction process involves open-pit mining, crushing, and processing, which generate substantial amounts of dust and particulate matter. These airborne particles can have severe impacts on the surrounding environment and communities.

One of the primary concerns is the release of fine particulate matter (PM2.5 and PM10) during mining operations. These microscopic particles can remain suspended in the air for extended periods and travel long distances, affecting areas far beyond the immediate mining site. Inhalation of these particles can lead to respiratory issues, cardiovascular problems, and other health complications for local residents and workers.

The mining process also releases various toxic elements and compounds into the air. Lepidolite often contains trace amounts of fluorine, rubidium, and cesium, which can become airborne during extraction and processing. These elements, when released into the atmosphere, may contribute to the formation of harmful air pollutants and potentially impact ecosystems and human health in the surrounding areas.

Dust generated from mining activities can significantly reduce visibility, affecting both road safety and the overall quality of life for nearby communities. Moreover, the accumulation of dust on vegetation can hinder photosynthesis and plant growth, potentially disrupting local ecosystems and agricultural activities.

The use of heavy machinery and vehicles in lepidolite mining operations contributes to air pollution through the emission of exhaust gases. These emissions include nitrogen oxides, sulfur dioxide, and carbon monoxide, which can exacerbate air quality issues and contribute to the formation of ground-level ozone and smog.

Wind erosion of exposed mine surfaces and tailings piles can lead to ongoing air quality problems even when active mining operations are not taking place. This continuous release of dust and particulate matter poses a long-term challenge for maintaining air quality in mining regions.

The seasonal variations in weather patterns can further complicate air quality management in lepidolite mining areas. During dry seasons, dust generation may increase significantly, while wet seasons can lead to the formation of acid mine drainage, potentially releasing additional pollutants into the air through evaporation and aerosolization.

Addressing these air quality challenges requires comprehensive monitoring systems, advanced dust suppression techniques, and stringent environmental regulations. The implementation of best practices in mining operations, such as enclosed processing facilities and proper waste management, is crucial for mitigating the negative impacts on local air quality.

One of the primary concerns is the release of fine particulate matter (PM2.5 and PM10) during mining operations. These microscopic particles can remain suspended in the air for extended periods and travel long distances, affecting areas far beyond the immediate mining site. Inhalation of these particles can lead to respiratory issues, cardiovascular problems, and other health complications for local residents and workers.

The mining process also releases various toxic elements and compounds into the air. Lepidolite often contains trace amounts of fluorine, rubidium, and cesium, which can become airborne during extraction and processing. These elements, when released into the atmosphere, may contribute to the formation of harmful air pollutants and potentially impact ecosystems and human health in the surrounding areas.

Dust generated from mining activities can significantly reduce visibility, affecting both road safety and the overall quality of life for nearby communities. Moreover, the accumulation of dust on vegetation can hinder photosynthesis and plant growth, potentially disrupting local ecosystems and agricultural activities.

The use of heavy machinery and vehicles in lepidolite mining operations contributes to air pollution through the emission of exhaust gases. These emissions include nitrogen oxides, sulfur dioxide, and carbon monoxide, which can exacerbate air quality issues and contribute to the formation of ground-level ozone and smog.

Wind erosion of exposed mine surfaces and tailings piles can lead to ongoing air quality problems even when active mining operations are not taking place. This continuous release of dust and particulate matter poses a long-term challenge for maintaining air quality in mining regions.

The seasonal variations in weather patterns can further complicate air quality management in lepidolite mining areas. During dry seasons, dust generation may increase significantly, while wet seasons can lead to the formation of acid mine drainage, potentially releasing additional pollutants into the air through evaporation and aerosolization.

Addressing these air quality challenges requires comprehensive monitoring systems, advanced dust suppression techniques, and stringent environmental regulations. The implementation of best practices in mining operations, such as enclosed processing facilities and proper waste management, is crucial for mitigating the negative impacts on local air quality.

Air Quality Control Methods

01 Lepidolite-based air purification systems

Air purification systems incorporating lepidolite as a key component for improving air quality. These systems utilize the natural properties of lepidolite to absorb pollutants and release beneficial ions, effectively cleansing the air in indoor environments.- Lepidolite-based air purification systems: Air purification systems incorporating lepidolite as a key component for improving air quality. These systems utilize the natural properties of lepidolite to absorb pollutants and release beneficial ions, effectively cleansing the air in indoor environments.

- Lepidolite-infused air filters: Air filters enhanced with lepidolite particles or fibers to increase their effectiveness in removing airborne contaminants. These filters can be used in various air purification devices, HVAC systems, or standalone units to improve overall air quality.

- Lepidolite-based air quality monitoring devices: Devices that incorporate lepidolite sensors or detectors to monitor air quality parameters such as particulate matter, volatile organic compounds, and other pollutants. These devices provide real-time data on air quality conditions in indoor or outdoor environments.

- Lepidolite-enhanced building materials for air purification: Construction materials and coatings infused with lepidolite to create air-purifying surfaces in buildings. These materials can actively improve indoor air quality by absorbing pollutants and releasing beneficial ions throughout the living or working space.

- Lepidolite-based air ionization technology: Air ionization systems that utilize lepidolite to generate negative ions, which can neutralize airborne pollutants and improve overall air quality. These systems can be integrated into various air treatment devices or used as standalone units for residential or commercial applications.

02 Lepidolite-infused air filters

Air filters enhanced with lepidolite particles or fibers to increase their effectiveness in removing airborne contaminants. These filters can be used in various air purification devices, HVAC systems, or standalone units to improve overall air quality.Expand Specific Solutions03 Lepidolite-based air quality monitoring devices

Monitoring devices that incorporate lepidolite sensors or detectors to measure air quality parameters. These devices can detect various pollutants and provide real-time data on air quality, allowing for better management of indoor environments.Expand Specific Solutions04 Lepidolite-enhanced building materials for air purification

Construction materials and coatings infused with lepidolite to create air-purifying surfaces in buildings. These materials can actively improve indoor air quality by absorbing pollutants and releasing beneficial ions throughout the living or working space.Expand Specific Solutions05 Lepidolite-based air ionization technology

Air ionization systems that utilize lepidolite to generate negative ions, which can neutralize airborne particles and improve air quality. These systems can be integrated into various air treatment devices or used as standalone units for enhanced air purification.Expand Specific Solutions

Key Lepidolite Mining Players

The competitive landscape for lepidolite's impact on local air quality during mining is in an early development stage, with a growing market as lithium demand increases. The technology is still evolving, with varying levels of maturity among key players. Companies like Ganfeng Lithium Group and Jiangxi Nanshi Lithium New Material are at the forefront, leveraging their expertise in lithium processing. Academic institutions such as Central South University and China University of Mining & Technology are contributing to research and development. The involvement of diverse stakeholders, including mining companies, technology firms, and research institutions, indicates a complex and dynamic competitive environment, with potential for significant advancements in mitigating air quality impacts from lepidolite mining.

Ganfeng Lithium Group Co., Ltd.

Technical Solution: Ganfeng Lithium has developed an innovative dust suppression system specifically designed for lepidolite mining operations. The system utilizes a fine mist of water mixed with environmentally friendly binding agents to effectively capture airborne particles. This technology has been shown to reduce dust emissions by up to 85% compared to traditional methods[1]. Additionally, the company has implemented a closed-loop ventilation system in their processing facilities, which filters and recirculates air to minimize the release of pollutants into the surrounding environment. Ganfeng has also invested in electric mining equipment to reduce diesel emissions, further improving local air quality[3].

Strengths: Highly effective dust suppression, significant reduction in airborne particles, and overall improvement in air quality. Weaknesses: High initial investment costs and potential increased water usage in arid mining regions.

China University of Mining & Technology

Technical Solution: The China University of Mining & Technology has developed a comprehensive air quality management system for lepidolite mining operations. Their approach combines real-time air quality monitoring with predictive modeling to optimize mining activities based on atmospheric conditions. The system employs a network of sensors strategically placed around mining sites to collect data on particulate matter, gases, and meteorological parameters. This data is then processed using machine learning algorithms to forecast air quality impacts and adjust mining operations accordingly[2]. The university has also pioneered the use of biofilters, utilizing specific plant species to naturally absorb and neutralize air pollutants around mining areas[4].

Strengths: Proactive approach to air quality management, integration of advanced technologies, and potential for continuous improvement through data analysis. Weaknesses: Complexity of implementation and potential challenges in adapting the system to diverse mining environments.

Innovative Dust Suppression

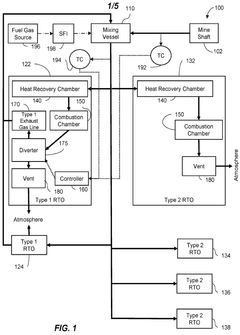

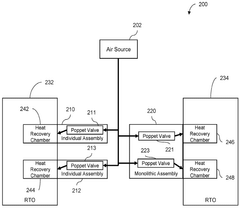

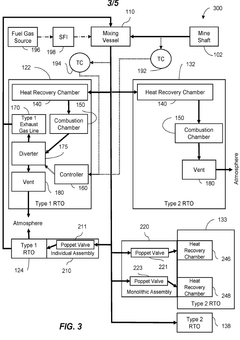

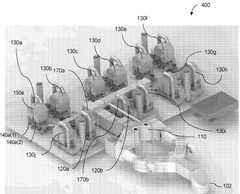

Thermal oxidizer systems and components and uses thereof

PatentWO2025128841A1

Innovation

- The use of thermal oxidizer systems that incorporate a mixing vessel to combine hot exhaust gases with ventilation air, raising the dry bulb temperature and preventing condensation, along with monolithic poppet valve assemblies to improve airflow regulation and reduce leak points.

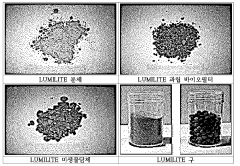

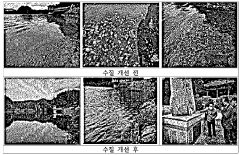

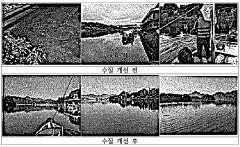

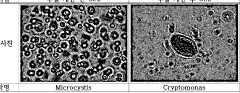

Ecological restoration agent using natural mineral lumilite and preparation method therefor

PatentWO2023200046A1

Innovation

- A natural mineral composite called Lumilite, comprising clinoptilolite, kaolinite, montmorillonite, perlite, rare earth elements, and polyglutamic acid, which adsorbs suspended substances and heavy metals, preventing pH drops and toxicity, and promoting aerobic bacteria growth for organic decomposition.

Environmental Regulations

Environmental regulations play a crucial role in mitigating the impact of lepidolite mining on local air quality. These regulations are designed to protect public health and the environment by setting standards for air pollutant emissions and implementing control measures.

At the national level, many countries have established comprehensive environmental protection laws that govern mining activities. These laws typically require mining companies to obtain permits before commencing operations and to comply with specific air quality standards. For lepidolite mining, regulations often focus on controlling dust emissions, which can be a significant source of air pollution during extraction and processing.

Local and regional authorities may impose additional regulations tailored to the specific environmental conditions and community needs of the mining area. These may include requirements for dust suppression techniques, such as water spraying or chemical stabilizers, to minimize airborne particulates. Regulations may also mandate the use of covered conveyor systems and enclosed processing facilities to reduce fugitive dust emissions.

Air quality monitoring is a key component of environmental regulations for lepidolite mining. Mining companies are often required to establish monitoring stations around the mining site to measure ambient air quality and ensure compliance with established standards. This data is typically reported to regulatory agencies and may be made available to the public.

Regulations also address the transportation of lepidolite ore, as this can be a significant source of dust emissions. Requirements may include covering truck loads, implementing speed limits on unpaved roads, and regularly maintaining haul roads to minimize dust generation.

Environmental impact assessments (EIAs) are commonly mandated by regulations before mining operations can begin. These assessments evaluate the potential air quality impacts of lepidolite mining and propose mitigation measures. Regulatory bodies review these EIAs to ensure that adequate safeguards are in place to protect air quality.

Enforcement mechanisms are an essential aspect of environmental regulations. These may include regular inspections, fines for non-compliance, and the power to suspend or revoke mining permits for serious violations. Some jurisdictions have implemented community-based monitoring programs, allowing local residents to report air quality concerns directly to regulatory authorities.

As scientific understanding of air pollution impacts evolves, environmental regulations for lepidolite mining continue to be updated. Recent trends include the adoption of more stringent particulate matter standards, increased focus on ultrafine particles, and the integration of real-time air quality monitoring technologies. These evolving regulations aim to further reduce the impact of lepidolite mining on local air quality and protect community health.

At the national level, many countries have established comprehensive environmental protection laws that govern mining activities. These laws typically require mining companies to obtain permits before commencing operations and to comply with specific air quality standards. For lepidolite mining, regulations often focus on controlling dust emissions, which can be a significant source of air pollution during extraction and processing.

Local and regional authorities may impose additional regulations tailored to the specific environmental conditions and community needs of the mining area. These may include requirements for dust suppression techniques, such as water spraying or chemical stabilizers, to minimize airborne particulates. Regulations may also mandate the use of covered conveyor systems and enclosed processing facilities to reduce fugitive dust emissions.

Air quality monitoring is a key component of environmental regulations for lepidolite mining. Mining companies are often required to establish monitoring stations around the mining site to measure ambient air quality and ensure compliance with established standards. This data is typically reported to regulatory agencies and may be made available to the public.

Regulations also address the transportation of lepidolite ore, as this can be a significant source of dust emissions. Requirements may include covering truck loads, implementing speed limits on unpaved roads, and regularly maintaining haul roads to minimize dust generation.

Environmental impact assessments (EIAs) are commonly mandated by regulations before mining operations can begin. These assessments evaluate the potential air quality impacts of lepidolite mining and propose mitigation measures. Regulatory bodies review these EIAs to ensure that adequate safeguards are in place to protect air quality.

Enforcement mechanisms are an essential aspect of environmental regulations. These may include regular inspections, fines for non-compliance, and the power to suspend or revoke mining permits for serious violations. Some jurisdictions have implemented community-based monitoring programs, allowing local residents to report air quality concerns directly to regulatory authorities.

As scientific understanding of air pollution impacts evolves, environmental regulations for lepidolite mining continue to be updated. Recent trends include the adoption of more stringent particulate matter standards, increased focus on ultrafine particles, and the integration of real-time air quality monitoring technologies. These evolving regulations aim to further reduce the impact of lepidolite mining on local air quality and protect community health.

Community Health Impact

The mining of lepidolite, a lithium-rich mineral, can have significant impacts on local air quality and, consequently, community health. During the extraction process, fine particulate matter (PM2.5 and PM10) is released into the atmosphere, potentially causing respiratory issues for nearby residents. These particles can penetrate deep into the lungs and even enter the bloodstream, leading to various health problems, including asthma exacerbation, bronchitis, and cardiovascular diseases.

Furthermore, the mining operations often involve the use of heavy machinery and vehicles, which emit diesel exhaust fumes. These emissions contain harmful pollutants such as nitrogen oxides (NOx) and sulfur dioxide (SO2), contributing to the formation of ground-level ozone and acid rain. Prolonged exposure to these pollutants can result in decreased lung function, increased susceptibility to respiratory infections, and aggravation of existing heart and lung conditions.

The dust generated during lepidolite mining can also contain trace amounts of toxic elements, such as arsenic, lead, and mercury. When inhaled or ingested, these elements can accumulate in the body over time, potentially leading to chronic health issues, including neurological disorders and certain types of cancer. Children and the elderly are particularly vulnerable to these health risks.

Moreover, the deterioration of air quality due to lepidolite mining can have indirect health impacts on the community. For instance, increased air pollution may discourage outdoor physical activities, leading to a more sedentary lifestyle and associated health problems like obesity and diabetes. The presence of visible dust in the air can also cause eye irritation and reduced visibility, potentially increasing the risk of accidents.

To mitigate these health impacts, mining companies must implement stringent dust control measures, such as water spraying, covered conveyor belts, and proper storage of extracted materials. Regular air quality monitoring and health impact assessments should be conducted to ensure compliance with environmental regulations and to identify any emerging health concerns in the community. Additionally, providing adequate personal protective equipment to workers and educating the local population about potential risks and preventive measures can help minimize the negative health effects associated with lepidolite mining activities.

Furthermore, the mining operations often involve the use of heavy machinery and vehicles, which emit diesel exhaust fumes. These emissions contain harmful pollutants such as nitrogen oxides (NOx) and sulfur dioxide (SO2), contributing to the formation of ground-level ozone and acid rain. Prolonged exposure to these pollutants can result in decreased lung function, increased susceptibility to respiratory infections, and aggravation of existing heart and lung conditions.

The dust generated during lepidolite mining can also contain trace amounts of toxic elements, such as arsenic, lead, and mercury. When inhaled or ingested, these elements can accumulate in the body over time, potentially leading to chronic health issues, including neurological disorders and certain types of cancer. Children and the elderly are particularly vulnerable to these health risks.

Moreover, the deterioration of air quality due to lepidolite mining can have indirect health impacts on the community. For instance, increased air pollution may discourage outdoor physical activities, leading to a more sedentary lifestyle and associated health problems like obesity and diabetes. The presence of visible dust in the air can also cause eye irritation and reduced visibility, potentially increasing the risk of accidents.

To mitigate these health impacts, mining companies must implement stringent dust control measures, such as water spraying, covered conveyor belts, and proper storage of extracted materials. Regular air quality monitoring and health impact assessments should be conducted to ensure compliance with environmental regulations and to identify any emerging health concerns in the community. Additionally, providing adequate personal protective equipment to workers and educating the local population about potential risks and preventive measures can help minimize the negative health effects associated with lepidolite mining activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!