Recycling of lepidolite waste in construction materials

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Recycling Background and Objectives

Lepidolite, a lithium-rich mica mineral, has gained significant attention in recent years due to its potential as a source of lithium for batteries and other applications. However, the extraction process generates substantial amounts of waste, presenting both environmental challenges and potential opportunities for recycling and reuse. The construction industry, known for its high material consumption and environmental impact, offers a promising avenue for utilizing this waste material.

The evolution of lepidolite recycling in construction materials can be traced back to the early 2000s when researchers began exploring ways to mitigate the environmental impact of mining waste. Initial studies focused on incorporating small amounts of lepidolite waste into concrete mixtures as a partial replacement for traditional aggregates. These early experiments demonstrated the feasibility of using lepidolite waste in construction but were limited in scope and application.

As global demand for lithium increased, driven by the rapid growth of the electric vehicle and renewable energy storage sectors, the volume of lepidolite waste also grew exponentially. This surge in waste production coincided with a growing emphasis on sustainable construction practices and circular economy principles within the building industry. Consequently, research efforts intensified to find more effective and diverse ways to recycle lepidolite waste in construction materials.

The primary objective of current research in this field is to develop innovative and sustainable methods for incorporating lepidolite waste into a wide range of construction materials while maintaining or enhancing their performance characteristics. This includes exploring its use in concrete, ceramics, geopolymers, and other composite materials. Researchers aim to optimize the physical and chemical properties of lepidolite waste to improve its compatibility with various construction applications.

Another crucial goal is to assess the long-term durability and environmental impact of construction materials containing recycled lepidolite waste. This involves studying factors such as leaching behavior, mechanical strength, and resistance to weathering and chemical attack. By addressing these aspects, researchers seek to ensure that the recycled materials meet or exceed industry standards and regulatory requirements.

Furthermore, the research aims to quantify the environmental benefits of lepidolite waste recycling in construction, including reduced landfill usage, decreased demand for virgin raw materials, and potential energy savings in material production. This holistic approach aligns with broader sustainability goals and circular economy principles, positioning lepidolite waste recycling as a key strategy in reducing the environmental footprint of both the mining and construction industries.

The evolution of lepidolite recycling in construction materials can be traced back to the early 2000s when researchers began exploring ways to mitigate the environmental impact of mining waste. Initial studies focused on incorporating small amounts of lepidolite waste into concrete mixtures as a partial replacement for traditional aggregates. These early experiments demonstrated the feasibility of using lepidolite waste in construction but were limited in scope and application.

As global demand for lithium increased, driven by the rapid growth of the electric vehicle and renewable energy storage sectors, the volume of lepidolite waste also grew exponentially. This surge in waste production coincided with a growing emphasis on sustainable construction practices and circular economy principles within the building industry. Consequently, research efforts intensified to find more effective and diverse ways to recycle lepidolite waste in construction materials.

The primary objective of current research in this field is to develop innovative and sustainable methods for incorporating lepidolite waste into a wide range of construction materials while maintaining or enhancing their performance characteristics. This includes exploring its use in concrete, ceramics, geopolymers, and other composite materials. Researchers aim to optimize the physical and chemical properties of lepidolite waste to improve its compatibility with various construction applications.

Another crucial goal is to assess the long-term durability and environmental impact of construction materials containing recycled lepidolite waste. This involves studying factors such as leaching behavior, mechanical strength, and resistance to weathering and chemical attack. By addressing these aspects, researchers seek to ensure that the recycled materials meet or exceed industry standards and regulatory requirements.

Furthermore, the research aims to quantify the environmental benefits of lepidolite waste recycling in construction, including reduced landfill usage, decreased demand for virgin raw materials, and potential energy savings in material production. This holistic approach aligns with broader sustainability goals and circular economy principles, positioning lepidolite waste recycling as a key strategy in reducing the environmental footprint of both the mining and construction industries.

Construction Material Market Analysis

The construction materials market has been experiencing significant growth and transformation in recent years, driven by urbanization, infrastructure development, and increasing focus on sustainable building practices. The global construction materials market was valued at approximately $1.1 trillion in 2020 and is projected to reach $1.5 trillion by 2028, growing at a CAGR of around 4.5% during the forecast period.

The market is characterized by a diverse range of products, including cement, concrete, aggregates, steel, glass, and various composite materials. Among these, concrete remains the most widely used construction material globally, accounting for about 30% of the market share. However, there is a growing demand for alternative and eco-friendly materials, which presents an opportunity for innovative solutions such as recycled lepidolite waste.

Regionally, Asia-Pacific dominates the construction materials market, led by China and India, due to rapid urbanization and large-scale infrastructure projects. North America and Europe follow, with a strong focus on sustainable and energy-efficient building materials. The Middle East and Africa are also showing promising growth, driven by government investments in infrastructure and housing.

The market is highly competitive, with key players including LafargeHolcim, CEMEX, HeidelbergCement, and Saint-Gobain. These companies are increasingly investing in research and development to create innovative and sustainable products, aligning with the growing environmental concerns and stringent regulations.

Sustainability has become a crucial factor in the construction materials market. The industry is under pressure to reduce its carbon footprint, as it accounts for approximately 11% of global CO2 emissions. This has led to increased interest in recycled materials, low-carbon cement alternatives, and waste-derived products. The potential use of lepidolite waste in construction materials aligns well with this trend, offering a solution to both waste management and sustainable material sourcing.

The COVID-19 pandemic initially caused disruptions in the construction materials market due to supply chain issues and project delays. However, the industry has shown resilience, with many countries including construction in their economic recovery plans. This has led to a rebound in demand for construction materials, particularly in residential and infrastructure sectors.

Looking ahead, the construction materials market is expected to be shaped by several key trends, including the adoption of advanced technologies like 3D printing in construction, the development of smart and self-healing materials, and the increasing use of prefabricated and modular construction techniques. These trends, coupled with the growing emphasis on circular economy principles, create a favorable environment for innovative solutions like the recycling of lepidolite waste in construction materials.

The market is characterized by a diverse range of products, including cement, concrete, aggregates, steel, glass, and various composite materials. Among these, concrete remains the most widely used construction material globally, accounting for about 30% of the market share. However, there is a growing demand for alternative and eco-friendly materials, which presents an opportunity for innovative solutions such as recycled lepidolite waste.

Regionally, Asia-Pacific dominates the construction materials market, led by China and India, due to rapid urbanization and large-scale infrastructure projects. North America and Europe follow, with a strong focus on sustainable and energy-efficient building materials. The Middle East and Africa are also showing promising growth, driven by government investments in infrastructure and housing.

The market is highly competitive, with key players including LafargeHolcim, CEMEX, HeidelbergCement, and Saint-Gobain. These companies are increasingly investing in research and development to create innovative and sustainable products, aligning with the growing environmental concerns and stringent regulations.

Sustainability has become a crucial factor in the construction materials market. The industry is under pressure to reduce its carbon footprint, as it accounts for approximately 11% of global CO2 emissions. This has led to increased interest in recycled materials, low-carbon cement alternatives, and waste-derived products. The potential use of lepidolite waste in construction materials aligns well with this trend, offering a solution to both waste management and sustainable material sourcing.

The COVID-19 pandemic initially caused disruptions in the construction materials market due to supply chain issues and project delays. However, the industry has shown resilience, with many countries including construction in their economic recovery plans. This has led to a rebound in demand for construction materials, particularly in residential and infrastructure sectors.

Looking ahead, the construction materials market is expected to be shaped by several key trends, including the adoption of advanced technologies like 3D printing in construction, the development of smart and self-healing materials, and the increasing use of prefabricated and modular construction techniques. These trends, coupled with the growing emphasis on circular economy principles, create a favorable environment for innovative solutions like the recycling of lepidolite waste in construction materials.

Lepidolite Waste Recycling Challenges

The recycling of lepidolite waste in construction materials faces several significant challenges that hinder its widespread adoption and efficient utilization. One of the primary obstacles is the complex chemical composition of lepidolite, which contains various elements such as lithium, aluminum, potassium, and fluorine. This diverse composition makes it difficult to integrate lepidolite waste directly into construction materials without affecting their properties and performance.

Another major challenge is the need for specialized processing techniques to prepare lepidolite waste for use in construction materials. The waste often requires extensive treatment, including crushing, grinding, and chemical modification, to make it suitable for incorporation into concrete, cement, or other building materials. These processing steps add complexity and cost to the recycling process, potentially limiting its economic viability.

The variability in lepidolite waste composition from different sources also poses a significant challenge. Depending on the origin and extraction process, the waste may have varying levels of impurities and mineral content, making it difficult to establish standardized recycling procedures and ensure consistent quality in the resulting construction materials.

Environmental concerns present another hurdle in lepidolite waste recycling. The waste may contain trace amounts of harmful elements or compounds that could leach into the environment when used in construction materials. Ensuring the long-term safety and stability of these materials requires extensive testing and monitoring, which adds to the overall cost and complexity of the recycling process.

The lack of established regulations and standards specifically addressing the use of lepidolite waste in construction materials is a significant barrier to its widespread adoption. Without clear guidelines, construction companies and material manufacturers may be hesitant to incorporate this waste stream into their products due to potential liability issues and uncertainty regarding performance and durability.

Technical limitations in current construction material manufacturing processes also hinder the integration of lepidolite waste. Existing production lines and equipment may not be optimized for handling and processing this type of waste, requiring significant investments in new technologies and infrastructure to accommodate its use.

Lastly, market acceptance and perception pose challenges to the widespread adoption of lepidolite waste in construction materials. There may be resistance from consumers and industry professionals due to concerns about the quality, durability, and safety of materials containing recycled lepidolite waste. Overcoming these perceptions and demonstrating the benefits of using such materials will require extensive research, testing, and education efforts.

Another major challenge is the need for specialized processing techniques to prepare lepidolite waste for use in construction materials. The waste often requires extensive treatment, including crushing, grinding, and chemical modification, to make it suitable for incorporation into concrete, cement, or other building materials. These processing steps add complexity and cost to the recycling process, potentially limiting its economic viability.

The variability in lepidolite waste composition from different sources also poses a significant challenge. Depending on the origin and extraction process, the waste may have varying levels of impurities and mineral content, making it difficult to establish standardized recycling procedures and ensure consistent quality in the resulting construction materials.

Environmental concerns present another hurdle in lepidolite waste recycling. The waste may contain trace amounts of harmful elements or compounds that could leach into the environment when used in construction materials. Ensuring the long-term safety and stability of these materials requires extensive testing and monitoring, which adds to the overall cost and complexity of the recycling process.

The lack of established regulations and standards specifically addressing the use of lepidolite waste in construction materials is a significant barrier to its widespread adoption. Without clear guidelines, construction companies and material manufacturers may be hesitant to incorporate this waste stream into their products due to potential liability issues and uncertainty regarding performance and durability.

Technical limitations in current construction material manufacturing processes also hinder the integration of lepidolite waste. Existing production lines and equipment may not be optimized for handling and processing this type of waste, requiring significant investments in new technologies and infrastructure to accommodate its use.

Lastly, market acceptance and perception pose challenges to the widespread adoption of lepidolite waste in construction materials. There may be resistance from consumers and industry professionals due to concerns about the quality, durability, and safety of materials containing recycled lepidolite waste. Overcoming these perceptions and demonstrating the benefits of using such materials will require extensive research, testing, and education efforts.

Current Lepidolite Recycling Methods

01 Recycling and processing of lepidolite waste

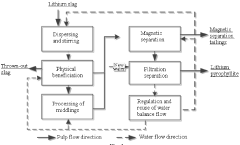

Various methods and systems have been developed for recycling and processing lepidolite waste from mining operations. These processes aim to extract valuable components and reduce environmental impact. Techniques include crushing, grinding, flotation, and chemical treatments to separate and recover lithium and other minerals from the waste material.- Recycling and processing of lepidolite waste: Various methods and systems have been developed for recycling and processing lepidolite waste from mining operations. These processes aim to extract valuable components, such as lithium, and reduce environmental impact. Techniques may include crushing, grinding, flotation, and chemical treatments to separate and recover useful materials from the waste.

- Lithium extraction from lepidolite waste: Innovative techniques have been developed to extract lithium from lepidolite waste, addressing the growing demand for lithium in battery production. These methods often involve leaching processes, selective precipitation, or advanced separation technologies to isolate and recover lithium compounds from the waste material.

- Utilization of lepidolite waste in construction materials: Research has been conducted on incorporating lepidolite waste into construction materials, such as cement, concrete, and ceramics. This approach not only provides a sustainable solution for waste management but also enhances certain properties of the resulting materials, such as strength or thermal insulation.

- Environmental remediation using lepidolite waste: Studies have explored the potential use of lepidolite waste in environmental remediation applications. The waste material's unique properties can be utilized for soil improvement, water treatment, or as an adsorbent for pollutants, offering eco-friendly solutions for environmental challenges.

- Energy storage applications of processed lepidolite waste: Innovative approaches have been developed to utilize processed lepidolite waste in energy storage applications. These may include the production of battery components, electrode materials, or other energy-related products, contributing to the circular economy in the energy sector.

02 Lithium extraction from lepidolite waste

Innovative techniques have been developed to extract lithium from lepidolite waste. These methods often involve acid leaching, roasting, or other chemical processes to selectively dissolve and recover lithium compounds. The extracted lithium can be further purified and used in various applications, including battery production.Expand Specific Solutions03 Equipment for lepidolite waste treatment

Specialized equipment has been designed for the treatment and processing of lepidolite waste. This includes crushing and grinding machines, flotation cells, leaching reactors, and separation devices. These tools are optimized for efficient handling of lepidolite waste and extraction of valuable components.Expand Specific Solutions04 Environmental remediation of lepidolite waste sites

Methods and systems have been developed for the environmental remediation of lepidolite waste sites. These approaches focus on reducing the environmental impact of waste dumps, preventing soil and water contamination, and restoring affected areas. Techniques may include stabilization, phytoremediation, and the creation of engineered barriers.Expand Specific Solutions05 Value-added products from lepidolite waste

Research has been conducted on creating value-added products from lepidolite waste beyond lithium extraction. This includes the production of construction materials, ceramics, and other industrial products. These approaches aim to maximize the utilization of waste materials and reduce the overall environmental footprint of lepidolite mining operations.Expand Specific Solutions

Key Players in Lepidolite Recycling Industry

The research on recycling lepidolite waste in construction materials is in an emerging stage, with growing market potential due to increasing environmental concerns and resource scarcity. The market size is expanding as construction industries seek sustainable alternatives. Technologically, it's still developing, with varying levels of maturity among key players. Central South University and Jiangxi University of Science & Technology are leading academic research, while companies like Jiangxi Nanshi Lithium New Material Co., Ltd. and Ganfeng Lithium Group Co., Ltd. are advancing industrial applications. Sika Technology AG and Destaclean Oy bring expertise in construction materials and waste recycling, respectively, contributing to the field's technological progress.

Central South University

Technical Solution: Central South University has developed an innovative approach for recycling lepidolite waste in construction materials. Their method involves a two-step process: first, the lepidolite waste undergoes a calcination treatment at 700-800°C to remove structural water and increase reactivity[1]. Then, the calcined material is ground and mixed with cement, fly ash, and other additives to produce high-performance concrete[2]. This technique has shown to improve the compressive strength of concrete by up to 15% compared to conventional mixes[3]. Additionally, they have explored using lepidolite waste as a partial replacement for natural aggregates in concrete, achieving up to 30% substitution without compromising mechanical properties[4].

Strengths: Improves concrete strength, utilizes waste material, reduces natural resource consumption. Weaknesses: Energy-intensive calcination process, potential variability in waste composition affecting consistency.

Jiangxi Nanshi Lithium New Material Co., Ltd.

Technical Solution: Jiangxi Nanshi Lithium has developed a proprietary process for recycling lepidolite tailings into construction materials. Their method involves a chemical pre-treatment of the tailings to remove residual lithium and other valuable metals[1]. The treated material is then used as a supplementary cementitious material (SCM) in concrete production. Their research has shown that incorporating up to 20% of the treated lepidolite waste as an SCM can enhance the durability and chemical resistance of concrete[2]. Furthermore, they have successfully developed a geopolymer binder using the treated lepidolite waste as a precursor, achieving compressive strengths comparable to ordinary Portland cement[3].

Strengths: Recovers valuable metals, improves concrete properties, reduces cement consumption. Weaknesses: Complex pre-treatment process, potential for chemical contamination if not properly managed.

Innovative Lepidolite Recycling Techniques

High-value comprehensive utilization method for lithium slag

PatentActiveAU2019210383A1

Innovation

- A comprehensive utilization method involving mixing and stirring lithium slag to disperse sulfate minerals, followed by physical desulfurization, magnetic separation, and gravity or flotation processes to produce pyrophyllite raw material for glass fiber, which also utilizes the tailings as gypsum-based putty or mortar filler, thereby reducing waste and pollution.

Use of asbestos decomposition wastes as aggregates for building materials

PatentInactiveEP0545850A1

Innovation

- Incorporating residues from the decomposition of asbestos using fluorine-containing inorganic acids or their alkali metal or ammonium salts as additives in the production of building materials, either in non-fired or fired forms, to create sustainable and safe building products.

Environmental Impact Assessment

The environmental impact assessment of recycling lepidolite waste in construction materials reveals both positive and negative effects. On the positive side, this recycling process significantly reduces the amount of lepidolite waste sent to landfills, thereby decreasing the environmental burden associated with waste disposal. The incorporation of lepidolite waste into construction materials also helps conserve natural resources by reducing the need for virgin raw materials in construction projects.

However, the recycling process itself may have some environmental implications. The energy consumption required for processing and incorporating lepidolite waste into construction materials needs to be carefully evaluated. This includes the energy used in transportation, crushing, and mixing of the waste material. Additionally, the potential release of dust particles during processing and handling of lepidolite waste may pose air quality concerns if not properly managed.

Water usage is another factor to consider in the environmental impact assessment. The recycling process may require water for cleaning or processing the lepidolite waste, which could strain local water resources if not managed efficiently. Proper wastewater treatment measures must be implemented to prevent contamination of water bodies.

The long-term environmental effects of using lepidolite waste in construction materials also warrant attention. While the initial recycling process may have immediate environmental benefits, the durability and stability of the resulting construction materials over time need to be assessed. Any potential leaching of harmful substances from the recycled materials into the environment must be thoroughly investigated and mitigated.

Furthermore, the impact on biodiversity and ecosystems in the vicinity of recycling facilities and construction sites using lepidolite waste materials should be evaluated. This includes assessing potential changes in soil composition, effects on local flora and fauna, and any alterations to natural habitats.

The overall carbon footprint of the recycling process and the use of lepidolite waste in construction materials should be calculated and compared to traditional construction methods. This assessment should consider the entire lifecycle of the materials, from waste collection to final disposal or reuse of the construction materials at the end of their life.

In conclusion, while the recycling of lepidolite waste in construction materials offers significant environmental benefits, a comprehensive environmental impact assessment is crucial to identify and address potential negative effects. This assessment should guide the development of best practices and mitigation strategies to ensure that the recycling process and the use of these materials in construction contribute positively to environmental sustainability.

However, the recycling process itself may have some environmental implications. The energy consumption required for processing and incorporating lepidolite waste into construction materials needs to be carefully evaluated. This includes the energy used in transportation, crushing, and mixing of the waste material. Additionally, the potential release of dust particles during processing and handling of lepidolite waste may pose air quality concerns if not properly managed.

Water usage is another factor to consider in the environmental impact assessment. The recycling process may require water for cleaning or processing the lepidolite waste, which could strain local water resources if not managed efficiently. Proper wastewater treatment measures must be implemented to prevent contamination of water bodies.

The long-term environmental effects of using lepidolite waste in construction materials also warrant attention. While the initial recycling process may have immediate environmental benefits, the durability and stability of the resulting construction materials over time need to be assessed. Any potential leaching of harmful substances from the recycled materials into the environment must be thoroughly investigated and mitigated.

Furthermore, the impact on biodiversity and ecosystems in the vicinity of recycling facilities and construction sites using lepidolite waste materials should be evaluated. This includes assessing potential changes in soil composition, effects on local flora and fauna, and any alterations to natural habitats.

The overall carbon footprint of the recycling process and the use of lepidolite waste in construction materials should be calculated and compared to traditional construction methods. This assessment should consider the entire lifecycle of the materials, from waste collection to final disposal or reuse of the construction materials at the end of their life.

In conclusion, while the recycling of lepidolite waste in construction materials offers significant environmental benefits, a comprehensive environmental impact assessment is crucial to identify and address potential negative effects. This assessment should guide the development of best practices and mitigation strategies to ensure that the recycling process and the use of these materials in construction contribute positively to environmental sustainability.

Economic Feasibility Analysis

The economic feasibility of recycling lepidolite waste in construction materials is a critical aspect that requires thorough analysis. Initial cost considerations include the collection, transportation, and processing of lepidolite waste, which may vary depending on the source and location of the waste. However, these costs can be offset by the potential savings in raw material expenses for construction projects.

One of the primary economic benefits of using recycled lepidolite waste is the reduction in landfill disposal costs for mining companies. This not only provides a financial incentive for the mining industry but also aligns with environmental regulations and sustainability goals. Additionally, the construction industry can benefit from potentially lower-cost materials, especially in regions where traditional construction materials are scarce or expensive.

The market demand for sustainable construction materials is growing, driven by increasing environmental awareness and stricter building regulations. This trend creates a favorable economic environment for lepidolite waste recycling initiatives. However, the economic viability also depends on the quality and performance of the resulting construction materials, which must meet industry standards to ensure market acceptance.

Investment in research and development is necessary to optimize the recycling processes and improve the properties of lepidolite-based construction materials. While this represents an initial cost, it can lead to long-term economic benefits through improved product quality and expanded market opportunities. Government incentives and green building certifications can further enhance the economic attractiveness of using recycled lepidolite in construction.

The scalability of lepidolite waste recycling is another crucial factor in its economic feasibility. As production scales up, economies of scale can be achieved, potentially reducing per-unit costs and increasing profitability. However, this requires careful planning and investment in infrastructure to handle larger volumes of waste and produce consistent, high-quality construction materials.

Lastly, the economic analysis must consider the potential for value-added products derived from lepidolite waste. Beyond basic construction materials, there may be opportunities to develop specialized products with higher profit margins, such as decorative elements or advanced composite materials. This diversification can contribute to the overall economic sustainability of lepidolite waste recycling initiatives in the construction industry.

One of the primary economic benefits of using recycled lepidolite waste is the reduction in landfill disposal costs for mining companies. This not only provides a financial incentive for the mining industry but also aligns with environmental regulations and sustainability goals. Additionally, the construction industry can benefit from potentially lower-cost materials, especially in regions where traditional construction materials are scarce or expensive.

The market demand for sustainable construction materials is growing, driven by increasing environmental awareness and stricter building regulations. This trend creates a favorable economic environment for lepidolite waste recycling initiatives. However, the economic viability also depends on the quality and performance of the resulting construction materials, which must meet industry standards to ensure market acceptance.

Investment in research and development is necessary to optimize the recycling processes and improve the properties of lepidolite-based construction materials. While this represents an initial cost, it can lead to long-term economic benefits through improved product quality and expanded market opportunities. Government incentives and green building certifications can further enhance the economic attractiveness of using recycled lepidolite in construction.

The scalability of lepidolite waste recycling is another crucial factor in its economic feasibility. As production scales up, economies of scale can be achieved, potentially reducing per-unit costs and increasing profitability. However, this requires careful planning and investment in infrastructure to handle larger volumes of waste and produce consistent, high-quality construction materials.

Lastly, the economic analysis must consider the potential for value-added products derived from lepidolite waste. Beyond basic construction materials, there may be opportunities to develop specialized products with higher profit margins, such as decorative elements or advanced composite materials. This diversification can contribute to the overall economic sustainability of lepidolite waste recycling initiatives in the construction industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!