How lepidolite supports green chemistry in pharmaceutical industry

AUG 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite in Pharma: Background and Objectives

Lepidolite, a lithium-rich mineral, has emerged as a significant player in the pharmaceutical industry's pursuit of green chemistry principles. This mineral's unique properties and composition make it an ideal candidate for supporting sustainable practices in drug development and manufacturing processes. The evolution of lepidolite's role in pharmaceuticals can be traced back to the growing awareness of environmental concerns and the need for more sustainable practices in the industry.

The primary objective of incorporating lepidolite into pharmaceutical processes is to reduce the environmental impact of drug production while maintaining or improving the efficacy and safety of medications. This aligns with the broader goals of green chemistry, which seeks to design chemical products and processes that minimize the use and generation of hazardous substances. By leveraging lepidolite's properties, the pharmaceutical industry aims to develop more environmentally friendly synthesis routes, reduce waste generation, and decrease the overall carbon footprint of drug manufacturing.

Lepidolite's potential in green chemistry stems from its rich lithium content and unique crystal structure. Lithium, a key component of lepidolite, has gained significant attention in the pharmaceutical sector due to its applications in various medications, particularly those used in treating mental health disorders. The mineral's composition also includes other elements such as potassium, aluminum, and fluorine, which can contribute to its versatility in chemical processes.

The technological trajectory of lepidolite in pharmaceuticals has been shaped by advancements in extraction and processing techniques. Early applications were limited by the challenges of efficiently separating lithium from the mineral matrix. However, recent innovations in hydrometallurgy and other extraction methods have made it more feasible to utilize lepidolite as a sustainable source of lithium and other valuable components for pharmaceutical applications.

As the pharmaceutical industry faces increasing pressure to adopt more sustainable practices, lepidolite presents an opportunity to address several key challenges. These include reducing dependence on petrochemical-based raw materials, minimizing the use of toxic solvents, and developing more energy-efficient synthesis processes. The integration of lepidolite into pharmaceutical green chemistry aligns with the industry's long-term goals of improving sustainability, reducing environmental impact, and meeting stringent regulatory requirements.

Looking ahead, the objectives for lepidolite in pharmaceutical green chemistry include expanding its applications beyond lithium extraction to leverage its full potential as a multifunctional mineral resource. This involves exploring novel catalytic properties, developing new synthetic methodologies, and investigating its role in drug delivery systems. By fully understanding and harnessing lepidolite's capabilities, the pharmaceutical industry aims to create a more sustainable and environmentally responsible approach to drug discovery and production.

The primary objective of incorporating lepidolite into pharmaceutical processes is to reduce the environmental impact of drug production while maintaining or improving the efficacy and safety of medications. This aligns with the broader goals of green chemistry, which seeks to design chemical products and processes that minimize the use and generation of hazardous substances. By leveraging lepidolite's properties, the pharmaceutical industry aims to develop more environmentally friendly synthesis routes, reduce waste generation, and decrease the overall carbon footprint of drug manufacturing.

Lepidolite's potential in green chemistry stems from its rich lithium content and unique crystal structure. Lithium, a key component of lepidolite, has gained significant attention in the pharmaceutical sector due to its applications in various medications, particularly those used in treating mental health disorders. The mineral's composition also includes other elements such as potassium, aluminum, and fluorine, which can contribute to its versatility in chemical processes.

The technological trajectory of lepidolite in pharmaceuticals has been shaped by advancements in extraction and processing techniques. Early applications were limited by the challenges of efficiently separating lithium from the mineral matrix. However, recent innovations in hydrometallurgy and other extraction methods have made it more feasible to utilize lepidolite as a sustainable source of lithium and other valuable components for pharmaceutical applications.

As the pharmaceutical industry faces increasing pressure to adopt more sustainable practices, lepidolite presents an opportunity to address several key challenges. These include reducing dependence on petrochemical-based raw materials, minimizing the use of toxic solvents, and developing more energy-efficient synthesis processes. The integration of lepidolite into pharmaceutical green chemistry aligns with the industry's long-term goals of improving sustainability, reducing environmental impact, and meeting stringent regulatory requirements.

Looking ahead, the objectives for lepidolite in pharmaceutical green chemistry include expanding its applications beyond lithium extraction to leverage its full potential as a multifunctional mineral resource. This involves exploring novel catalytic properties, developing new synthetic methodologies, and investigating its role in drug delivery systems. By fully understanding and harnessing lepidolite's capabilities, the pharmaceutical industry aims to create a more sustainable and environmentally responsible approach to drug discovery and production.

Green Chemistry Market Demand in Pharmaceuticals

The pharmaceutical industry is experiencing a significant shift towards green chemistry practices, driven by increasing environmental concerns, regulatory pressures, and the need for sustainable manufacturing processes. This growing market demand for green chemistry in pharmaceuticals is reflected in several key trends and factors.

Firstly, there is a rising awareness among pharmaceutical companies about the environmental impact of their operations. This has led to a surge in demand for greener alternatives to traditional chemical processes, including the use of more environmentally friendly solvents, catalysts, and reagents. The industry is actively seeking ways to reduce waste, minimize energy consumption, and decrease the use of hazardous substances throughout the drug development and manufacturing lifecycle.

Regulatory bodies worldwide are also playing a crucial role in driving the adoption of green chemistry principles. Stringent environmental regulations and guidelines are pushing pharmaceutical companies to invest in cleaner technologies and sustainable practices. This regulatory landscape is creating a strong market pull for green chemistry solutions, as companies strive to comply with evolving standards while maintaining their competitive edge.

Moreover, there is a growing consumer preference for sustainably produced pharmaceuticals. Patients and healthcare providers are becoming increasingly conscious of the environmental footprint of medications, leading to a demand for drugs manufactured using green chemistry principles. This consumer-driven trend is compelling pharmaceutical companies to adopt greener practices as a means of enhancing their brand image and meeting customer expectations.

The economic benefits associated with green chemistry are also fueling market demand. Many pharmaceutical companies are recognizing that implementing green chemistry practices can lead to cost savings through reduced waste generation, improved resource efficiency, and lower energy consumption. These economic incentives are driving investments in green chemistry research and development, as well as the adoption of sustainable manufacturing processes.

In terms of specific applications, there is a notable demand for green chemistry solutions in various stages of pharmaceutical production. This includes the development of bio-based solvents, the use of catalytic reactions to reduce waste, and the implementation of continuous flow chemistry for more efficient and environmentally friendly synthesis processes. Additionally, there is a growing interest in the application of green chemistry principles in drug discovery, formulation development, and packaging.

The market demand for green chemistry in pharmaceuticals is also reflected in the increasing collaborations between pharmaceutical companies, academic institutions, and technology providers. These partnerships aim to develop innovative green chemistry solutions and accelerate their implementation in industrial settings. Such collaborations are fostering a rich ecosystem of research and development, driving further advancements in sustainable pharmaceutical manufacturing.

Firstly, there is a rising awareness among pharmaceutical companies about the environmental impact of their operations. This has led to a surge in demand for greener alternatives to traditional chemical processes, including the use of more environmentally friendly solvents, catalysts, and reagents. The industry is actively seeking ways to reduce waste, minimize energy consumption, and decrease the use of hazardous substances throughout the drug development and manufacturing lifecycle.

Regulatory bodies worldwide are also playing a crucial role in driving the adoption of green chemistry principles. Stringent environmental regulations and guidelines are pushing pharmaceutical companies to invest in cleaner technologies and sustainable practices. This regulatory landscape is creating a strong market pull for green chemistry solutions, as companies strive to comply with evolving standards while maintaining their competitive edge.

Moreover, there is a growing consumer preference for sustainably produced pharmaceuticals. Patients and healthcare providers are becoming increasingly conscious of the environmental footprint of medications, leading to a demand for drugs manufactured using green chemistry principles. This consumer-driven trend is compelling pharmaceutical companies to adopt greener practices as a means of enhancing their brand image and meeting customer expectations.

The economic benefits associated with green chemistry are also fueling market demand. Many pharmaceutical companies are recognizing that implementing green chemistry practices can lead to cost savings through reduced waste generation, improved resource efficiency, and lower energy consumption. These economic incentives are driving investments in green chemistry research and development, as well as the adoption of sustainable manufacturing processes.

In terms of specific applications, there is a notable demand for green chemistry solutions in various stages of pharmaceutical production. This includes the development of bio-based solvents, the use of catalytic reactions to reduce waste, and the implementation of continuous flow chemistry for more efficient and environmentally friendly synthesis processes. Additionally, there is a growing interest in the application of green chemistry principles in drug discovery, formulation development, and packaging.

The market demand for green chemistry in pharmaceuticals is also reflected in the increasing collaborations between pharmaceutical companies, academic institutions, and technology providers. These partnerships aim to develop innovative green chemistry solutions and accelerate their implementation in industrial settings. Such collaborations are fostering a rich ecosystem of research and development, driving further advancements in sustainable pharmaceutical manufacturing.

Lepidolite: Current Applications and Challenges

Lepidolite, a lithium-rich mica mineral, has gained significant attention in recent years due to its potential applications in various industries, including pharmaceuticals. In the context of green chemistry in the pharmaceutical sector, lepidolite offers several promising avenues for sustainable practices and innovative solutions.

Currently, lepidolite is primarily utilized as a source of lithium, which is crucial for the production of lithium-based pharmaceuticals and as a component in certain drug formulations. Its high lithium content makes it an attractive alternative to traditional lithium sources, potentially reducing the environmental impact of lithium extraction processes.

In the pharmaceutical industry, lepidolite-derived lithium compounds are employed in the synthesis of mood stabilizers and antidepressants. These medications play a vital role in treating various mental health conditions, including bipolar disorder and major depressive disorder. The use of lepidolite in this context aligns with green chemistry principles by potentially offering a more sustainable source of lithium for pharmaceutical production.

Another emerging application of lepidolite in the pharmaceutical sector is its potential use as a catalyst support in organic synthesis reactions. The unique crystal structure and chemical properties of lepidolite make it an interesting candidate for developing heterogeneous catalysts, which could lead to more efficient and environmentally friendly synthetic processes for drug manufacturing.

Despite these promising applications, several challenges hinder the widespread adoption of lepidolite in pharmaceutical green chemistry. One significant obstacle is the need for efficient and cost-effective extraction methods to isolate high-purity lithium and other valuable components from lepidolite ore. Current extraction processes often involve energy-intensive and chemically harsh techniques, which can offset the potential environmental benefits.

Additionally, the variability in lepidolite composition from different geological sources poses challenges for standardization and quality control in pharmaceutical applications. Ensuring consistent purity and performance of lepidolite-derived materials across different batches is crucial for meeting stringent regulatory requirements in drug manufacturing.

Furthermore, the limited availability of high-grade lepidolite deposits and competition from other industries (such as battery manufacturing) for this resource may impact its long-term viability as a sustainable option for the pharmaceutical sector. Developing alternative sources or improving the efficiency of lepidolite utilization will be essential to address these supply chain concerns.

In conclusion, while lepidolite shows promise in supporting green chemistry initiatives in the pharmaceutical industry, particularly in lithium-based drug production and as a potential catalyst support, significant research and development efforts are still required to overcome existing challenges and fully realize its potential in this field.

Currently, lepidolite is primarily utilized as a source of lithium, which is crucial for the production of lithium-based pharmaceuticals and as a component in certain drug formulations. Its high lithium content makes it an attractive alternative to traditional lithium sources, potentially reducing the environmental impact of lithium extraction processes.

In the pharmaceutical industry, lepidolite-derived lithium compounds are employed in the synthesis of mood stabilizers and antidepressants. These medications play a vital role in treating various mental health conditions, including bipolar disorder and major depressive disorder. The use of lepidolite in this context aligns with green chemistry principles by potentially offering a more sustainable source of lithium for pharmaceutical production.

Another emerging application of lepidolite in the pharmaceutical sector is its potential use as a catalyst support in organic synthesis reactions. The unique crystal structure and chemical properties of lepidolite make it an interesting candidate for developing heterogeneous catalysts, which could lead to more efficient and environmentally friendly synthetic processes for drug manufacturing.

Despite these promising applications, several challenges hinder the widespread adoption of lepidolite in pharmaceutical green chemistry. One significant obstacle is the need for efficient and cost-effective extraction methods to isolate high-purity lithium and other valuable components from lepidolite ore. Current extraction processes often involve energy-intensive and chemically harsh techniques, which can offset the potential environmental benefits.

Additionally, the variability in lepidolite composition from different geological sources poses challenges for standardization and quality control in pharmaceutical applications. Ensuring consistent purity and performance of lepidolite-derived materials across different batches is crucial for meeting stringent regulatory requirements in drug manufacturing.

Furthermore, the limited availability of high-grade lepidolite deposits and competition from other industries (such as battery manufacturing) for this resource may impact its long-term viability as a sustainable option for the pharmaceutical sector. Developing alternative sources or improving the efficiency of lepidolite utilization will be essential to address these supply chain concerns.

In conclusion, while lepidolite shows promise in supporting green chemistry initiatives in the pharmaceutical industry, particularly in lithium-based drug production and as a potential catalyst support, significant research and development efforts are still required to overcome existing challenges and fully realize its potential in this field.

Current Green Chemistry Solutions Using Lepidolite

01 Lepidolite as a lithium source

Lepidolite is utilized as a valuable source of lithium in various industrial applications. It is processed to extract lithium for use in batteries, ceramics, and other products. The mineral's high lithium content makes it an important raw material in the growing lithium market.- Lepidolite in lithium extraction and processing: Lepidolite is used as a source for lithium extraction and processing. Various methods are employed to extract lithium from lepidolite, including acid leaching, roasting, and other chemical processes. These techniques aim to efficiently separate lithium from other minerals present in lepidolite ore.

- Lepidolite in energy storage applications: Lepidolite and its derivatives are utilized in energy storage applications, particularly in the development of lithium-ion batteries. The lithium extracted from lepidolite can be used to produce battery components, contributing to the advancement of renewable energy technologies and electric vehicles.

- Lepidolite in ceramic and glass production: Lepidolite is employed in the production of ceramics and glass. Its unique chemical composition and properties make it suitable for enhancing the strength, durability, and thermal resistance of ceramic and glass products. It can also be used to create specialized glazes and coatings.

- Lepidolite in environmental applications: Lepidolite finds applications in environmental remediation and water treatment processes. Its ion-exchange properties make it effective in removing heavy metals and other contaminants from water and soil. It can also be used in the development of eco-friendly materials and products.

- Lepidolite in alternative medicine and wellness: Lepidolite is used in alternative medicine and wellness practices. It is believed to have calming and stress-relieving properties, and is sometimes incorporated into holistic therapies, meditation aids, and wellness products. Some applications include the creation of jewelry, crystals, and other personal items for therapeutic purposes.

02 Lepidolite in cosmetic and skincare products

Lepidolite is incorporated into cosmetic and skincare formulations due to its beneficial properties. It is used in products such as face masks, creams, and lotions to provide soothing and calming effects on the skin. The mineral's composition is believed to offer potential anti-inflammatory and stress-reducing benefits.Expand Specific Solutions03 Lepidolite in water treatment and purification

Lepidolite is employed in water treatment and purification processes. Its unique chemical properties allow it to effectively remove certain contaminants from water, making it useful in both industrial and environmental applications. The mineral can be used in filtration systems or as an adsorbent material.Expand Specific Solutions04 Lepidolite in energy storage and conversion devices

Lepidolite is utilized in the development of advanced energy storage and conversion devices. Its lithium content and other properties make it suitable for use in lithium-ion batteries, fuel cells, and other energy-related applications. Research is ongoing to optimize its performance in these technologies.Expand Specific Solutions05 Lepidolite in ceramic and glass production

Lepidolite is used as an additive in ceramic and glass production processes. It can improve the properties of these materials, such as strength, durability, and thermal resistance. The mineral's unique composition contributes to the development of specialized ceramic and glass products for various industries.Expand Specific Solutions

Key Players in Lepidolite and Green Pharma

The green chemistry application of lepidolite in the pharmaceutical industry is in an emerging stage, with growing market potential as sustainability becomes a priority. The technology's maturity is still developing, with research institutions like Chengdu University of Technology, Wuhan University of Technology, and Central South University leading academic efforts. Companies such as ARIBIO Co., Ltd. and UCB Pharma SA are exploring industrial applications. The competitive landscape is characterized by collaboration between academia and industry, focusing on optimizing extraction processes, improving purity, and developing novel applications for lepidolite-derived compounds in pharmaceutical synthesis and formulation.

UCB Pharma SA (Belgium)

Technical Solution: UCB Pharma SA has developed a green chemistry approach using lepidolite as a sustainable source of lithium for pharmaceutical applications. Their process involves extracting lithium from lepidolite using supercritical carbon dioxide, which is environmentally friendly and reduces the use of harsh chemicals[1]. This method allows for the production of high-purity lithium compounds essential for drug synthesis while minimizing waste and environmental impact. UCB has also implemented a continuous flow chemistry system that incorporates lepidolite-derived lithium, enabling more efficient and sustainable drug manufacturing processes[2].

Strengths: Sustainable lithium source, reduced environmental impact, high-purity product. Weaknesses: Potentially higher initial costs, limited to lithium-based pharmaceuticals.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed an innovative approach to utilizing lepidolite in green pharmaceutical chemistry. They have created a lepidolite-derived heterogeneous catalyst that facilitates more environmentally friendly organic transformations[5]. This catalyst system reduces the need for toxic metal catalysts and allows for easier product separation and catalyst recycling. MIT has also pioneered a microfluidic platform that incorporates lepidolite-based materials for continuous-flow synthesis of pharmaceutical intermediates, significantly reducing solvent use and improving reaction efficiency[6]. Furthermore, they have explored the use of lepidolite as a source of rubidium for specialized pharmaceutical applications, expanding its potential in the industry[7].

Strengths: Reduced use of toxic catalysts, improved reaction efficiency, potential for new pharmaceutical applications. Weaknesses: Early-stage technology, may require significant investment for industrial implementation.

Innovative Lepidolite-based Green Chemistry Techniques

Benzylation process in aqueous medium for controlling donepezil benzyl chloride impurity in manufacture of donepezil hydrochloride

PatentInactiveIN1877MUM2013A

Innovation

- A green process utilizing an aqueous medium for benzylation of 2,3-dihydro-5,6-dimethoxy-2-(4-piperidinylmethyl)-1H-inden-1-one 4-methylbenzenesulfonate with benzyl halide, followed by treatment with a mixture of ethyl acetate and hexane to control the donepezil benzyl chloride impurity to less than 0.02%, thereby reducing solvent usage and achieving pharmaceutically acceptable grade donepezil hydrochloride.

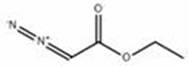

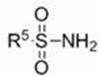

Method for preparing n-sulfimide

PatentWO2022261992A1

Innovation

- 采用酰胺、重氮乙酸乙酯和磺酰胺在硫酸铁催化下进行反应,反应温度为25~100℃,时间为12~48小时,使用硫酸铁和硫酸氢钾作为催化剂和助剂,反应在空气中进行,通过饱和氯化钠溶液淬灭、乙酸乙酯萃取和柱层析得到产物。

Environmental Impact Assessment

The use of lepidolite in green chemistry within the pharmaceutical industry has significant environmental implications that warrant careful assessment. Lepidolite, a lithium-rich mica mineral, offers potential benefits in reducing the environmental footprint of pharmaceutical manufacturing processes.

One of the primary environmental advantages of lepidolite-based processes is the reduction in hazardous waste generation. Traditional pharmaceutical synthesis often involves the use of toxic solvents and reagents, which can lead to substantial amounts of harmful byproducts. Lepidolite-catalyzed reactions typically operate under milder conditions, resulting in fewer side reactions and less waste production.

Water consumption is another critical environmental factor in pharmaceutical manufacturing. Lepidolite-based processes often require less water for reaction media and purification steps, contributing to water conservation efforts. This is particularly significant in regions facing water scarcity issues, where pharmaceutical production can strain local water resources.

Energy efficiency is a key consideration in environmental impact assessments. Lepidolite-catalyzed reactions frequently occur at lower temperatures and pressures compared to conventional methods. This translates to reduced energy requirements for heating, cooling, and maintaining reaction conditions, leading to a lower carbon footprint for pharmaceutical production facilities.

The sourcing and extraction of lepidolite itself must be considered in the overall environmental impact. While mining operations can have localized environmental effects, the long-term benefits of using lepidolite in green chemistry applications may outweigh these initial impacts. Sustainable mining practices and efficient extraction techniques can further mitigate environmental concerns associated with lepidolite procurement.

Biodegradability and ecotoxicity of pharmaceutical intermediates and final products are crucial aspects of environmental assessment. Lepidolite-based synthetic routes often lead to compounds with improved biodegradability profiles, reducing the potential for long-term environmental accumulation and adverse effects on ecosystems.

Air quality is another important factor to consider. The use of lepidolite in pharmaceutical processes can lead to reduced emissions of volatile organic compounds (VOCs) and other air pollutants commonly associated with traditional chemical synthesis. This contributes to improved air quality both within manufacturing facilities and in surrounding communities.

In terms of life cycle assessment, lepidolite-supported green chemistry in pharmaceuticals shows promise in reducing overall environmental impact from raw material extraction to product disposal. The potential for increased recyclability of catalysts and solvents, coupled with more efficient synthetic pathways, can lead to a more sustainable pharmaceutical supply chain.

One of the primary environmental advantages of lepidolite-based processes is the reduction in hazardous waste generation. Traditional pharmaceutical synthesis often involves the use of toxic solvents and reagents, which can lead to substantial amounts of harmful byproducts. Lepidolite-catalyzed reactions typically operate under milder conditions, resulting in fewer side reactions and less waste production.

Water consumption is another critical environmental factor in pharmaceutical manufacturing. Lepidolite-based processes often require less water for reaction media and purification steps, contributing to water conservation efforts. This is particularly significant in regions facing water scarcity issues, where pharmaceutical production can strain local water resources.

Energy efficiency is a key consideration in environmental impact assessments. Lepidolite-catalyzed reactions frequently occur at lower temperatures and pressures compared to conventional methods. This translates to reduced energy requirements for heating, cooling, and maintaining reaction conditions, leading to a lower carbon footprint for pharmaceutical production facilities.

The sourcing and extraction of lepidolite itself must be considered in the overall environmental impact. While mining operations can have localized environmental effects, the long-term benefits of using lepidolite in green chemistry applications may outweigh these initial impacts. Sustainable mining practices and efficient extraction techniques can further mitigate environmental concerns associated with lepidolite procurement.

Biodegradability and ecotoxicity of pharmaceutical intermediates and final products are crucial aspects of environmental assessment. Lepidolite-based synthetic routes often lead to compounds with improved biodegradability profiles, reducing the potential for long-term environmental accumulation and adverse effects on ecosystems.

Air quality is another important factor to consider. The use of lepidolite in pharmaceutical processes can lead to reduced emissions of volatile organic compounds (VOCs) and other air pollutants commonly associated with traditional chemical synthesis. This contributes to improved air quality both within manufacturing facilities and in surrounding communities.

In terms of life cycle assessment, lepidolite-supported green chemistry in pharmaceuticals shows promise in reducing overall environmental impact from raw material extraction to product disposal. The potential for increased recyclability of catalysts and solvents, coupled with more efficient synthetic pathways, can lead to a more sustainable pharmaceutical supply chain.

Regulatory Framework for Green Pharmaceutical Processes

The regulatory framework for green pharmaceutical processes is evolving rapidly to support the integration of sustainable practices in the pharmaceutical industry. Governments and regulatory bodies worldwide are recognizing the importance of green chemistry principles in drug development and manufacturing.

In the United States, the Environmental Protection Agency (EPA) has implemented the Green Chemistry Program, which promotes the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. This program provides guidelines and incentives for pharmaceutical companies to adopt greener practices throughout their production processes.

The European Union has established the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to improve the protection of human health and the environment from the risks posed by chemicals. This regulation encourages the use of alternative substances and technologies, aligning with the principles of green chemistry in pharmaceutical manufacturing.

In addition, the International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has developed guidelines that address environmental risk assessment for pharmaceuticals. These guidelines encourage pharmaceutical companies to consider the environmental impact of their products throughout the drug lifecycle.

Many countries have also implemented specific regulations to promote the use of green solvents and reduce the environmental footprint of pharmaceutical manufacturing. For instance, Japan's Chemical Substances Control Law requires manufacturers to assess the environmental and health risks of new chemical substances before their introduction to the market.

The pharmaceutical industry is responding to these regulatory changes by developing internal policies and guidelines for green chemistry implementation. Companies are increasingly adopting metrics to measure the environmental impact of their processes, such as the Process Mass Intensity (PMI) and E-factor, which quantify the efficiency of resource use in pharmaceutical production.

Regulatory bodies are also encouraging the adoption of continuous manufacturing processes, which can significantly reduce waste and energy consumption compared to traditional batch processing. The FDA has issued guidance documents to support the implementation of continuous manufacturing in the pharmaceutical industry, recognizing its potential to improve product quality and reduce environmental impact.

As the regulatory landscape continues to evolve, pharmaceutical companies are expected to face more stringent requirements for demonstrating the environmental sustainability of their processes. This regulatory pressure is likely to drive further innovation in green chemistry applications, including the use of alternative raw materials like lepidolite in pharmaceutical manufacturing.

In the United States, the Environmental Protection Agency (EPA) has implemented the Green Chemistry Program, which promotes the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. This program provides guidelines and incentives for pharmaceutical companies to adopt greener practices throughout their production processes.

The European Union has established the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to improve the protection of human health and the environment from the risks posed by chemicals. This regulation encourages the use of alternative substances and technologies, aligning with the principles of green chemistry in pharmaceutical manufacturing.

In addition, the International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has developed guidelines that address environmental risk assessment for pharmaceuticals. These guidelines encourage pharmaceutical companies to consider the environmental impact of their products throughout the drug lifecycle.

Many countries have also implemented specific regulations to promote the use of green solvents and reduce the environmental footprint of pharmaceutical manufacturing. For instance, Japan's Chemical Substances Control Law requires manufacturers to assess the environmental and health risks of new chemical substances before their introduction to the market.

The pharmaceutical industry is responding to these regulatory changes by developing internal policies and guidelines for green chemistry implementation. Companies are increasingly adopting metrics to measure the environmental impact of their processes, such as the Process Mass Intensity (PMI) and E-factor, which quantify the efficiency of resource use in pharmaceutical production.

Regulatory bodies are also encouraging the adoption of continuous manufacturing processes, which can significantly reduce waste and energy consumption compared to traditional batch processing. The FDA has issued guidance documents to support the implementation of continuous manufacturing in the pharmaceutical industry, recognizing its potential to improve product quality and reduce environmental impact.

As the regulatory landscape continues to evolve, pharmaceutical companies are expected to face more stringent requirements for demonstrating the environmental sustainability of their processes. This regulatory pressure is likely to drive further innovation in green chemistry applications, including the use of alternative raw materials like lepidolite in pharmaceutical manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!