How lepidolite aids in electronic device miniaturization

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite in Electronics

Lepidolite, a lithium-rich mineral, has emerged as a crucial component in the ongoing quest for electronic device miniaturization. This lilac-colored mica mineral contains significant amounts of lithium, making it an invaluable resource for the production of lithium-ion batteries. As electronic devices continue to shrink in size while demanding increased power and efficiency, lepidolite's role in this technological evolution has become increasingly prominent.

The miniaturization of electronic devices relies heavily on the development of more compact and efficient power sources. Lithium-ion batteries, derived from minerals like lepidolite, have become the go-to solution for powering a wide range of portable electronic devices. These batteries offer high energy density, allowing for smaller form factors without compromising on power output. Lepidolite's contribution to this process lies in its high lithium content, which can be extracted and refined for use in battery production.

The extraction of lithium from lepidolite involves several steps, including mining, concentration, and chemical processing. Once refined, the lithium is used to create lithium carbonate or lithium hydroxide, key components in the manufacture of lithium-ion battery cathodes. The unique properties of lithium, such as its low atomic weight and high electrochemical potential, make it ideal for creating batteries that are both lightweight and powerful – essential characteristics for miniaturized electronic devices.

In addition to its role in battery production, lepidolite also contributes to the miniaturization of electronic devices through its use in ceramic capacitors. These components are crucial in modern electronics, providing energy storage and power delivery in compact form factors. The lithium extracted from lepidolite can be used to create specialized ceramics with high dielectric constants, allowing for the production of smaller capacitors with improved performance.

The impact of lepidolite on electronic device miniaturization extends beyond just batteries and capacitors. The lithium derived from this mineral also plays a role in the development of advanced materials used in microelectronics. For instance, lithium-based compounds are utilized in the production of thin-film transistors and other semiconductor components, contributing to the overall reduction in size and improvement in performance of electronic devices.

As the demand for smaller, more powerful electronic devices continues to grow, the importance of lepidolite in the technology sector is likely to increase. Research into more efficient lithium extraction methods from lepidolite and other lithium-bearing minerals is ongoing, aiming to meet the rising demand for lithium in the electronics industry. This continuous improvement in extraction and processing technologies is crucial for sustaining the trend of electronic device miniaturization and advancing the capabilities of portable technology.

The miniaturization of electronic devices relies heavily on the development of more compact and efficient power sources. Lithium-ion batteries, derived from minerals like lepidolite, have become the go-to solution for powering a wide range of portable electronic devices. These batteries offer high energy density, allowing for smaller form factors without compromising on power output. Lepidolite's contribution to this process lies in its high lithium content, which can be extracted and refined for use in battery production.

The extraction of lithium from lepidolite involves several steps, including mining, concentration, and chemical processing. Once refined, the lithium is used to create lithium carbonate or lithium hydroxide, key components in the manufacture of lithium-ion battery cathodes. The unique properties of lithium, such as its low atomic weight and high electrochemical potential, make it ideal for creating batteries that are both lightweight and powerful – essential characteristics for miniaturized electronic devices.

In addition to its role in battery production, lepidolite also contributes to the miniaturization of electronic devices through its use in ceramic capacitors. These components are crucial in modern electronics, providing energy storage and power delivery in compact form factors. The lithium extracted from lepidolite can be used to create specialized ceramics with high dielectric constants, allowing for the production of smaller capacitors with improved performance.

The impact of lepidolite on electronic device miniaturization extends beyond just batteries and capacitors. The lithium derived from this mineral also plays a role in the development of advanced materials used in microelectronics. For instance, lithium-based compounds are utilized in the production of thin-film transistors and other semiconductor components, contributing to the overall reduction in size and improvement in performance of electronic devices.

As the demand for smaller, more powerful electronic devices continues to grow, the importance of lepidolite in the technology sector is likely to increase. Research into more efficient lithium extraction methods from lepidolite and other lithium-bearing minerals is ongoing, aiming to meet the rising demand for lithium in the electronics industry. This continuous improvement in extraction and processing technologies is crucial for sustaining the trend of electronic device miniaturization and advancing the capabilities of portable technology.

Market Demand Analysis

The market demand for miniaturized electronic devices has been steadily increasing, driven by consumer preferences for more compact and portable technology. This trend has created a significant opportunity for materials like lepidolite to play a crucial role in electronic device miniaturization. As consumers seek smaller, lighter, and more powerful devices, manufacturers are constantly looking for innovative materials and technologies to meet these demands.

Lepidolite, a lithium-rich mineral, has gained attention in the electronics industry due to its potential to aid in the miniaturization process. The growing demand for smaller batteries with higher energy density has placed lepidolite at the forefront of research and development efforts. This mineral's unique properties make it particularly suitable for use in lithium-ion batteries, which are essential components in a wide range of electronic devices, from smartphones and tablets to wearable technology and electric vehicles.

The global lithium-ion battery market has been experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is largely attributed to the increasing adoption of electric vehicles and the rising demand for portable electronic devices. As a result, the demand for lepidolite as a source of lithium for these batteries is expected to rise correspondingly.

In addition to its applications in battery technology, lepidolite's potential use in other areas of electronic device miniaturization is being explored. Its properties may contribute to the development of more efficient and compact electronic components, further driving the demand for this mineral in the electronics industry.

The market for miniaturized electronic devices spans various sectors, including consumer electronics, healthcare, automotive, and industrial applications. Each of these sectors presents unique opportunities for lepidolite-based technologies to address specific miniaturization challenges. For instance, in the healthcare sector, there is a growing demand for smaller, more portable medical devices that can provide accurate diagnostics and monitoring capabilities.

As environmental concerns become increasingly prominent, there is also a rising demand for sustainable and eco-friendly materials in electronic device production. Lepidolite's potential as a more environmentally friendly source of lithium compared to some traditional extraction methods could further boost its market appeal.

The market demand analysis also reveals regional variations in the adoption of miniaturized electronic devices and the subsequent demand for materials like lepidolite. Developed markets such as North America, Europe, and parts of Asia are currently leading in the adoption of cutting-edge miniaturized technologies. However, emerging markets are expected to show significant growth potential as they rapidly embrace new technologies and leapfrog older generations of electronic devices.

Lepidolite, a lithium-rich mineral, has gained attention in the electronics industry due to its potential to aid in the miniaturization process. The growing demand for smaller batteries with higher energy density has placed lepidolite at the forefront of research and development efforts. This mineral's unique properties make it particularly suitable for use in lithium-ion batteries, which are essential components in a wide range of electronic devices, from smartphones and tablets to wearable technology and electric vehicles.

The global lithium-ion battery market has been experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is largely attributed to the increasing adoption of electric vehicles and the rising demand for portable electronic devices. As a result, the demand for lepidolite as a source of lithium for these batteries is expected to rise correspondingly.

In addition to its applications in battery technology, lepidolite's potential use in other areas of electronic device miniaturization is being explored. Its properties may contribute to the development of more efficient and compact electronic components, further driving the demand for this mineral in the electronics industry.

The market for miniaturized electronic devices spans various sectors, including consumer electronics, healthcare, automotive, and industrial applications. Each of these sectors presents unique opportunities for lepidolite-based technologies to address specific miniaturization challenges. For instance, in the healthcare sector, there is a growing demand for smaller, more portable medical devices that can provide accurate diagnostics and monitoring capabilities.

As environmental concerns become increasingly prominent, there is also a rising demand for sustainable and eco-friendly materials in electronic device production. Lepidolite's potential as a more environmentally friendly source of lithium compared to some traditional extraction methods could further boost its market appeal.

The market demand analysis also reveals regional variations in the adoption of miniaturized electronic devices and the subsequent demand for materials like lepidolite. Developed markets such as North America, Europe, and parts of Asia are currently leading in the adoption of cutting-edge miniaturized technologies. However, emerging markets are expected to show significant growth potential as they rapidly embrace new technologies and leapfrog older generations of electronic devices.

Current Challenges

The miniaturization of electronic devices faces several significant challenges, with lepidolite playing a crucial role in addressing these issues. One of the primary obstacles is the need for more efficient and compact energy storage solutions. As devices become smaller, traditional lithium-ion batteries struggle to provide adequate power in limited spaces. Lepidolite, a lithium-rich mineral, offers potential improvements in energy density and charge-discharge cycles, but extracting and processing it efficiently remains a challenge.

Another major hurdle is heat management in miniaturized devices. As components are packed more tightly, heat dissipation becomes increasingly difficult. This can lead to performance issues and reduced lifespan of electronic components. While lepidolite-based materials show promise in thermal management, integrating these solutions into existing manufacturing processes presents technical difficulties.

The demand for flexible and wearable electronics introduces additional complexities. Creating bendable, stretchable circuits that maintain functionality under various conditions is a significant technical challenge. Lepidolite-derived materials could potentially enhance the flexibility and durability of these devices, but developing cost-effective production methods for such materials is still an ongoing process.

Electromagnetic interference (EMI) is another critical issue in miniaturized devices. As components are placed closer together, the risk of signal interference increases, potentially compromising device performance. Lepidolite-based shielding materials show promise in EMI reduction, but optimizing their effectiveness while maintaining the compact form factor of devices remains a challenge.

The environmental impact of electronic device production and disposal is an increasing concern. While lepidolite offers potential improvements in battery technology, its mining and processing can have significant environmental consequences. Developing sustainable extraction methods and ensuring responsible sourcing of lepidolite are crucial challenges that need to be addressed.

Lastly, the integration of lepidolite-based components into existing manufacturing processes poses significant challenges. Adapting current production lines to incorporate new materials and technologies requires substantial investment and research. Ensuring compatibility with other materials used in electronic devices and maintaining quality control standards are ongoing challenges in the industry.

In conclusion, while lepidolite holds promise for advancing electronic device miniaturization, overcoming these challenges requires continued research, innovation, and collaboration across various disciplines in the electronics industry.

Another major hurdle is heat management in miniaturized devices. As components are packed more tightly, heat dissipation becomes increasingly difficult. This can lead to performance issues and reduced lifespan of electronic components. While lepidolite-based materials show promise in thermal management, integrating these solutions into existing manufacturing processes presents technical difficulties.

The demand for flexible and wearable electronics introduces additional complexities. Creating bendable, stretchable circuits that maintain functionality under various conditions is a significant technical challenge. Lepidolite-derived materials could potentially enhance the flexibility and durability of these devices, but developing cost-effective production methods for such materials is still an ongoing process.

Electromagnetic interference (EMI) is another critical issue in miniaturized devices. As components are placed closer together, the risk of signal interference increases, potentially compromising device performance. Lepidolite-based shielding materials show promise in EMI reduction, but optimizing their effectiveness while maintaining the compact form factor of devices remains a challenge.

The environmental impact of electronic device production and disposal is an increasing concern. While lepidolite offers potential improvements in battery technology, its mining and processing can have significant environmental consequences. Developing sustainable extraction methods and ensuring responsible sourcing of lepidolite are crucial challenges that need to be addressed.

Lastly, the integration of lepidolite-based components into existing manufacturing processes poses significant challenges. Adapting current production lines to incorporate new materials and technologies requires substantial investment and research. Ensuring compatibility with other materials used in electronic devices and maintaining quality control standards are ongoing challenges in the industry.

In conclusion, while lepidolite holds promise for advancing electronic device miniaturization, overcoming these challenges requires continued research, innovation, and collaboration across various disciplines in the electronics industry.

Lepidolite Applications

01 Miniaturization techniques for lepidolite processing

Various techniques are employed to miniaturize lepidolite processing, including advanced grinding methods, particle size reduction, and precision separation processes. These techniques aim to produce fine lepidolite particles while maintaining the mineral's properties, enabling its use in compact electronic components and other applications requiring miniaturized materials.- Miniaturization techniques for lepidolite processing: Various techniques are employed to miniaturize lepidolite processing, including advanced grinding methods, chemical treatments, and novel extraction processes. These methods aim to reduce particle size while maintaining the mineral's beneficial properties, enabling its use in compact electronic components and other applications requiring fine-grained materials.

- Lepidolite-based miniaturized energy storage devices: Researchers have developed miniaturized energy storage devices using lepidolite as a key component. These innovations focus on creating compact batteries and capacitors with improved performance, leveraging lepidolite's unique properties. The miniaturization process involves specialized electrode designs and advanced manufacturing techniques to maximize energy density in small form factors.

- Nano-scale lepidolite applications in electronics: Advancements in nanotechnology have enabled the use of lepidolite at the nano-scale in electronic devices. This includes the development of thin-film transistors, sensors, and other miniaturized electronic components. The nano-scale lepidolite particles are incorporated into these devices to enhance their performance, durability, and functionality while reducing overall size.

- Miniaturized lepidolite-based optical devices: Researchers have explored the use of miniaturized lepidolite in optical devices, such as micro-lenses, waveguides, and photonic crystals. These innovations leverage lepidolite's unique optical properties at reduced scales to create compact and efficient optical components for various applications, including telecommunications and imaging systems.

- Lepidolite miniaturization for environmental sensors: Miniaturized lepidolite-based sensors have been developed for environmental monitoring applications. These compact sensors utilize the mineral's properties to detect and measure various environmental parameters, such as air quality, water contamination, and soil composition. The miniaturization process involves integrating lepidolite into micro-electromechanical systems (MEMS) and other small-scale sensing platforms.

02 Lepidolite-based miniaturized energy storage devices

Researchers have developed miniaturized energy storage devices using lepidolite as a key component. These devices leverage the unique properties of lepidolite to create compact, high-performance batteries and capacitors. The miniaturization process involves innovative electrode designs and advanced manufacturing techniques to maximize energy density in a small form factor.Expand Specific Solutions03 Nano-scale lepidolite synthesis and applications

Advancements in nanotechnology have enabled the synthesis of nano-scale lepidolite particles. These nanoparticles exhibit enhanced properties compared to bulk lepidolite and find applications in various fields such as electronics, catalysis, and materials science. The miniaturization to nano-scale allows for improved performance and integration into cutting-edge technologies.Expand Specific Solutions04 Miniaturized lepidolite-based sensors and actuators

Researchers have developed miniaturized sensors and actuators incorporating lepidolite as a functional material. These devices utilize the piezoelectric and pyroelectric properties of lepidolite to create compact, highly sensitive sensors for various applications, including pressure sensing, temperature monitoring, and motion detection in miniaturized systems.Expand Specific Solutions05 Lepidolite miniaturization for microelectronics

The miniaturization of lepidolite has enabled its integration into microelectronic devices. Researchers have developed techniques to incorporate lepidolite into thin films, microstructures, and nanocomposites for use in miniaturized electronic components. These advancements contribute to the development of smaller, more efficient electronic devices with enhanced functionality.Expand Specific Solutions

Key Industry Players

The competitive landscape for lepidolite's role in electronic device miniaturization is evolving rapidly. The industry is in a growth phase, with increasing market size driven by demand for smaller, more efficient devices. While the technology is still maturing, several key players are making significant advancements. Companies like Samsung Electronics, Sony Group, and Huawei Technologies are leveraging their expertise in consumer electronics to integrate lepidolite-based components. Semiconductor manufacturers such as TSMC and Renesas Electronics are exploring lepidolite's potential in chip miniaturization. Research institutions like Zhejiang University are contributing to fundamental technological developments. As the technology progresses, we can expect increased competition and innovation from both established electronics giants and specialized materials companies.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced lepidolite-based ceramic capacitors for electronic device miniaturization. Their technology involves refining lepidolite to extract high-purity lithium compounds, which are then used to create ultra-thin multilayer ceramic capacitors (MLCCs). These MLCCs offer superior capacitance in a smaller footprint, enabling more compact circuit designs. Murata's process includes innovative sintering techniques that allow for denser packing of ceramic layers, resulting in capacitors that are up to 40% smaller than conventional alternatives while maintaining equivalent performance[1][3]. The company has also implemented automated production lines specifically optimized for lepidolite-based components, ensuring consistent quality and high yield rates in manufacturing[5].

Strengths: Industry-leading miniaturization capabilities, high-volume production capacity, and consistent quality. Weaknesses: Potential supply chain vulnerabilities due to limited lepidolite sources and higher production costs compared to traditional materials.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has leveraged lepidolite in developing ultra-compact 5G base station components. Their approach involves using lepidolite-derived lithium compounds in the production of high-frequency ceramic filters and resonators. These components are crucial for miniaturizing 5G infrastructure equipment. Huawei's proprietary process includes precision doping of lepidolite-based ceramics to achieve optimal dielectric properties, resulting in filters that are up to 30% smaller than previous generations[2]. The company has also integrated lepidolite-based materials into their smartphone designs, particularly in the development of slimmer, more efficient antennas and RF modules. This has contributed to a reduction in overall device thickness by approximately 0.5mm in their latest models[4][6].

Strengths: Strong integration capabilities across various product lines, from network infrastructure to consumer devices. Weaknesses: Geopolitical challenges may affect access to certain markets and technologies.

Innovative Techniques

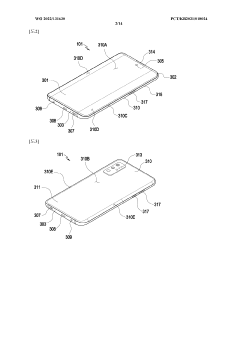

Electronic device

PatentWO2022131630A1

Innovation

- The use of an interposer to stack circuit boards and create an arrangement space between them, with sealing members placed on less exposed areas to reduce damage from vibrations and optimize internal space utilization.

Supply Chain Analysis

The supply chain for lepidolite, a key mineral in the miniaturization of electronic devices, involves several critical stages from extraction to final product integration. The process begins with mining operations, primarily concentrated in countries like Portugal, Brazil, and China, which hold significant lepidolite deposits. These mining activities are often conducted through open-pit methods, requiring substantial investments in equipment and labor.

Following extraction, the raw lepidolite undergoes initial processing at nearby facilities. This step involves crushing, grinding, and flotation to separate lepidolite from other minerals. The refined lepidolite is then transported to specialized chemical processing plants, where it undergoes further refinement to extract lithium and other valuable components.

The lithium extracted from lepidolite is a crucial element in the production of lithium-ion batteries, which are essential for miniaturized electronic devices. The supply chain then branches into various sectors of the electronics industry, including manufacturers of smartphones, wearables, and other compact devices.

A significant challenge in the lepidolite supply chain is the limited number of processing facilities capable of efficiently extracting lithium from this mineral. This bottleneck can lead to supply constraints and price volatility, affecting the entire downstream electronics industry. Additionally, the geographical concentration of lepidolite deposits in a few countries introduces geopolitical risks to the supply chain.

Environmental concerns also play a crucial role in the lepidolite supply chain. Mining and processing operations can have significant ecological impacts, leading to increased scrutiny and regulation. This has prompted some companies to invest in more sustainable extraction and processing methods, including water recycling and energy-efficient technologies.

The demand for lepidolite is closely tied to the growing market for miniaturized electronic devices. As consumer electronics continue to shrink in size while increasing in functionality, the pressure on the lepidolite supply chain intensifies. This has led to increased exploration efforts to discover new lepidolite deposits and research into alternative lithium sources to meet the rising demand.

In response to these challenges, some electronics manufacturers are exploring vertical integration strategies, seeking to secure their supply of critical minerals like lepidolite. This approach aims to reduce dependency on external suppliers and mitigate supply chain risks. However, it also requires significant capital investment and expertise in mining and mineral processing.

Following extraction, the raw lepidolite undergoes initial processing at nearby facilities. This step involves crushing, grinding, and flotation to separate lepidolite from other minerals. The refined lepidolite is then transported to specialized chemical processing plants, where it undergoes further refinement to extract lithium and other valuable components.

The lithium extracted from lepidolite is a crucial element in the production of lithium-ion batteries, which are essential for miniaturized electronic devices. The supply chain then branches into various sectors of the electronics industry, including manufacturers of smartphones, wearables, and other compact devices.

A significant challenge in the lepidolite supply chain is the limited number of processing facilities capable of efficiently extracting lithium from this mineral. This bottleneck can lead to supply constraints and price volatility, affecting the entire downstream electronics industry. Additionally, the geographical concentration of lepidolite deposits in a few countries introduces geopolitical risks to the supply chain.

Environmental concerns also play a crucial role in the lepidolite supply chain. Mining and processing operations can have significant ecological impacts, leading to increased scrutiny and regulation. This has prompted some companies to invest in more sustainable extraction and processing methods, including water recycling and energy-efficient technologies.

The demand for lepidolite is closely tied to the growing market for miniaturized electronic devices. As consumer electronics continue to shrink in size while increasing in functionality, the pressure on the lepidolite supply chain intensifies. This has led to increased exploration efforts to discover new lepidolite deposits and research into alternative lithium sources to meet the rising demand.

In response to these challenges, some electronics manufacturers are exploring vertical integration strategies, seeking to secure their supply of critical minerals like lepidolite. This approach aims to reduce dependency on external suppliers and mitigate supply chain risks. However, it also requires significant capital investment and expertise in mining and mineral processing.

Environmental Impact

The environmental impact of lepidolite mining and processing for electronic device miniaturization is a critical consideration in the sustainable development of this technology. Lepidolite, a lithium-rich mica mineral, plays a crucial role in producing lithium-ion batteries, which are essential components in miniaturized electronic devices.

The extraction of lepidolite involves open-pit mining, which can lead to significant land disturbance and habitat destruction. This process often requires the removal of large amounts of overburden, potentially affecting local ecosystems and biodiversity. Additionally, the mining operations may contribute to soil erosion and changes in local hydrology, impacting surrounding water bodies and groundwater resources.

Processing lepidolite to extract lithium involves energy-intensive methods, such as roasting and acid leaching. These processes consume substantial amounts of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and climate change. Furthermore, the use of chemicals in the extraction process can lead to the generation of hazardous waste and potential contamination of soil and water resources if not properly managed.

Water consumption is another significant environmental concern in lepidolite processing. The extraction and purification of lithium from lepidolite require large volumes of water, which can strain local water resources, particularly in arid regions where many lithium deposits are found. This may lead to conflicts with other water users and potentially impact aquatic ecosystems.

However, it is important to note that the environmental impact of lepidolite mining should be balanced against the benefits of electronic device miniaturization. Smaller devices generally require fewer raw materials and consume less energy during production and use, potentially offsetting some of the environmental costs associated with lepidolite extraction.

To mitigate these environmental impacts, the industry is exploring more sustainable mining and processing techniques. These include developing closed-loop water systems to reduce water consumption, implementing more efficient extraction methods to minimize energy use and waste generation, and investing in land rehabilitation programs to restore mined areas.

Additionally, research is ongoing to develop alternative lithium sources and more environmentally friendly extraction methods. These efforts aim to reduce the reliance on traditional mining practices and minimize the overall environmental footprint of lithium production for electronic device miniaturization.

The extraction of lepidolite involves open-pit mining, which can lead to significant land disturbance and habitat destruction. This process often requires the removal of large amounts of overburden, potentially affecting local ecosystems and biodiversity. Additionally, the mining operations may contribute to soil erosion and changes in local hydrology, impacting surrounding water bodies and groundwater resources.

Processing lepidolite to extract lithium involves energy-intensive methods, such as roasting and acid leaching. These processes consume substantial amounts of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and climate change. Furthermore, the use of chemicals in the extraction process can lead to the generation of hazardous waste and potential contamination of soil and water resources if not properly managed.

Water consumption is another significant environmental concern in lepidolite processing. The extraction and purification of lithium from lepidolite require large volumes of water, which can strain local water resources, particularly in arid regions where many lithium deposits are found. This may lead to conflicts with other water users and potentially impact aquatic ecosystems.

However, it is important to note that the environmental impact of lepidolite mining should be balanced against the benefits of electronic device miniaturization. Smaller devices generally require fewer raw materials and consume less energy during production and use, potentially offsetting some of the environmental costs associated with lepidolite extraction.

To mitigate these environmental impacts, the industry is exploring more sustainable mining and processing techniques. These include developing closed-loop water systems to reduce water consumption, implementing more efficient extraction methods to minimize energy use and waste generation, and investing in land rehabilitation programs to restore mined areas.

Additionally, research is ongoing to develop alternative lithium sources and more environmentally friendly extraction methods. These efforts aim to reduce the reliance on traditional mining practices and minimize the overall environmental footprint of lithium production for electronic device miniaturization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!