High-throughput screening methods for lepidolite resin production

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Screening Background and Objectives

Lepidolite, a lithium-rich mica mineral, has gained significant attention in recent years due to the growing demand for lithium in various industries, particularly in the production of batteries for electric vehicles and renewable energy storage systems. The development of high-throughput screening methods for lepidolite resin production represents a critical advancement in the field of lithium extraction and processing.

The evolution of lepidolite screening techniques has been driven by the need for more efficient and cost-effective methods to identify and isolate lithium-bearing minerals from complex ore bodies. Traditional methods of lepidolite identification and extraction have been time-consuming and labor-intensive, often relying on manual sorting and visual inspection. As the demand for lithium has increased, so has the pressure to develop more sophisticated and rapid screening techniques.

The primary objective of high-throughput screening methods for lepidolite resin production is to significantly increase the speed and accuracy of lepidolite identification and separation from other minerals. This involves the development of automated systems that can quickly analyze large volumes of ore samples, identifying lepidolite based on its unique physical and chemical properties. Such methods aim to reduce processing time, minimize human error, and maximize the recovery of lithium-bearing minerals.

Another key goal is to improve the overall efficiency of the lithium extraction process. By implementing high-throughput screening techniques, mining operations can more effectively target lepidolite-rich areas within deposits, reducing waste and optimizing resource utilization. This not only enhances the economic viability of lithium mining projects but also contributes to more sustainable mining practices by minimizing environmental impact.

Furthermore, the development of these advanced screening methods seeks to address the challenges associated with processing low-grade lepidolite ores. As high-grade deposits become increasingly scarce, the ability to efficiently extract lithium from lower-grade sources becomes crucial. High-throughput screening techniques aim to make the processing of such ores economically feasible, potentially expanding the global lithium resource base.

The technological trajectory in this field is moving towards the integration of multiple analytical techniques, including spectroscopic methods, machine vision systems, and artificial intelligence algorithms. These integrated approaches are expected to provide more comprehensive and accurate characterization of lepidolite ores, enabling more precise separation and purification processes.

In conclusion, the background and objectives of high-throughput screening methods for lepidolite resin production reflect the industry's drive towards more efficient, sustainable, and economically viable lithium extraction processes. As the global demand for lithium continues to grow, these technological advancements will play a crucial role in meeting future energy storage needs and supporting the transition to renewable energy sources.

The evolution of lepidolite screening techniques has been driven by the need for more efficient and cost-effective methods to identify and isolate lithium-bearing minerals from complex ore bodies. Traditional methods of lepidolite identification and extraction have been time-consuming and labor-intensive, often relying on manual sorting and visual inspection. As the demand for lithium has increased, so has the pressure to develop more sophisticated and rapid screening techniques.

The primary objective of high-throughput screening methods for lepidolite resin production is to significantly increase the speed and accuracy of lepidolite identification and separation from other minerals. This involves the development of automated systems that can quickly analyze large volumes of ore samples, identifying lepidolite based on its unique physical and chemical properties. Such methods aim to reduce processing time, minimize human error, and maximize the recovery of lithium-bearing minerals.

Another key goal is to improve the overall efficiency of the lithium extraction process. By implementing high-throughput screening techniques, mining operations can more effectively target lepidolite-rich areas within deposits, reducing waste and optimizing resource utilization. This not only enhances the economic viability of lithium mining projects but also contributes to more sustainable mining practices by minimizing environmental impact.

Furthermore, the development of these advanced screening methods seeks to address the challenges associated with processing low-grade lepidolite ores. As high-grade deposits become increasingly scarce, the ability to efficiently extract lithium from lower-grade sources becomes crucial. High-throughput screening techniques aim to make the processing of such ores economically feasible, potentially expanding the global lithium resource base.

The technological trajectory in this field is moving towards the integration of multiple analytical techniques, including spectroscopic methods, machine vision systems, and artificial intelligence algorithms. These integrated approaches are expected to provide more comprehensive and accurate characterization of lepidolite ores, enabling more precise separation and purification processes.

In conclusion, the background and objectives of high-throughput screening methods for lepidolite resin production reflect the industry's drive towards more efficient, sustainable, and economically viable lithium extraction processes. As the global demand for lithium continues to grow, these technological advancements will play a crucial role in meeting future energy storage needs and supporting the transition to renewable energy sources.

Market Analysis for Lepidolite Resin Products

The market for lepidolite resin products has been experiencing significant growth in recent years, driven by the increasing demand for lithium-based materials in various industries. Lepidolite, a lithium-rich mineral, serves as a crucial raw material for the production of lithium compounds and resins. The global lepidolite resin market is primarily fueled by the expanding electric vehicle (EV) sector and the growing adoption of renewable energy storage systems.

The automotive industry, particularly the EV segment, represents the largest market for lepidolite resin products. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for lithium-ion batteries continues to surge. This trend is expected to persist in the coming years, with major automakers investing heavily in EV production and battery technology development.

Another significant market for lepidolite resin products is the energy storage sector. The increasing integration of renewable energy sources into power grids necessitates efficient energy storage solutions. Lithium-based batteries, including those derived from lepidolite resins, play a crucial role in this application. The market for grid-scale energy storage is projected to grow substantially, driven by the global shift towards cleaner energy sources.

The electronics industry also contributes to the demand for lepidolite resin products. Portable electronic devices, such as smartphones, tablets, and laptops, rely on lithium-ion batteries for power. As consumer electronics continue to evolve and become more energy-intensive, the demand for high-performance batteries is expected to rise, further boosting the lepidolite resin market.

Geographically, Asia-Pacific dominates the lepidolite resin market, with China being the largest producer and consumer. The region's strong presence in the EV and electronics manufacturing sectors drives this trend. North America and Europe are also significant markets, primarily due to their growing EV industries and renewable energy initiatives.

The lepidolite resin market faces some challenges, including the environmental concerns associated with lithium mining and processing. However, ongoing research and development efforts are focused on developing more sustainable extraction and production methods, which could potentially address these issues and further expand the market.

In conclusion, the market for lepidolite resin products shows promising growth potential, driven by the increasing demand for lithium-based materials across multiple industries. The development of high-throughput screening methods for lepidolite resin production could play a crucial role in meeting this growing demand more efficiently and sustainably.

The automotive industry, particularly the EV segment, represents the largest market for lepidolite resin products. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for lithium-ion batteries continues to surge. This trend is expected to persist in the coming years, with major automakers investing heavily in EV production and battery technology development.

Another significant market for lepidolite resin products is the energy storage sector. The increasing integration of renewable energy sources into power grids necessitates efficient energy storage solutions. Lithium-based batteries, including those derived from lepidolite resins, play a crucial role in this application. The market for grid-scale energy storage is projected to grow substantially, driven by the global shift towards cleaner energy sources.

The electronics industry also contributes to the demand for lepidolite resin products. Portable electronic devices, such as smartphones, tablets, and laptops, rely on lithium-ion batteries for power. As consumer electronics continue to evolve and become more energy-intensive, the demand for high-performance batteries is expected to rise, further boosting the lepidolite resin market.

Geographically, Asia-Pacific dominates the lepidolite resin market, with China being the largest producer and consumer. The region's strong presence in the EV and electronics manufacturing sectors drives this trend. North America and Europe are also significant markets, primarily due to their growing EV industries and renewable energy initiatives.

The lepidolite resin market faces some challenges, including the environmental concerns associated with lithium mining and processing. However, ongoing research and development efforts are focused on developing more sustainable extraction and production methods, which could potentially address these issues and further expand the market.

In conclusion, the market for lepidolite resin products shows promising growth potential, driven by the increasing demand for lithium-based materials across multiple industries. The development of high-throughput screening methods for lepidolite resin production could play a crucial role in meeting this growing demand more efficiently and sustainably.

Current HTS Challenges in Lepidolite Processing

High-throughput screening (HTS) methods for lepidolite resin production face several significant challenges in the current technological landscape. One of the primary obstacles is the complexity of lepidolite's mineral composition, which varies considerably depending on its geological origin. This variability makes it difficult to develop standardized screening protocols that can effectively assess the quality and potential yield of lepidolite samples across different sources.

The heterogeneity of lepidolite ores also presents challenges in sample preparation for HTS. Achieving consistent particle size distribution and homogeneity in sample aliquots is crucial for accurate screening results. However, the layered structure of lepidolite and its tendency to cleave along certain planes can lead to inconsistencies in sample preparation, potentially skewing HTS results and reducing the reliability of the screening process.

Another significant challenge lies in the development of rapid and accurate analytical methods for quantifying lithium content and other valuable elements within lepidolite samples. Traditional analytical techniques, such as atomic absorption spectroscopy or inductively coupled plasma mass spectrometry, while accurate, are often too time-consuming for true high-throughput applications. There is a pressing need for faster, non-destructive analytical methods that can maintain high accuracy and precision while significantly increasing sample throughput.

The optimization of leaching and extraction processes for lepidolite also poses challenges in HTS implementation. The efficiency of lithium extraction can be affected by various factors, including acid concentration, temperature, and reaction time. Developing HTS methods that can simultaneously evaluate multiple process parameters while maintaining relevance to industrial-scale operations is a complex task that requires sophisticated experimental design and data analysis techniques.

Furthermore, the environmental impact of lepidolite processing presents additional challenges for HTS method development. Screening protocols must not only assess extraction efficiency but also consider the potential environmental consequences of different processing routes. This includes evaluating factors such as water consumption, energy requirements, and the generation of potentially harmful by-products.

Lastly, the integration of HTS data with predictive modeling and machine learning algorithms represents a frontier challenge in lepidolite processing. While these technologies offer the potential for rapid optimization of extraction processes, their effective implementation requires overcoming issues related to data quality, model interpretability, and the scalability of predictions from laboratory-scale experiments to industrial processes.

Addressing these challenges will be crucial for advancing HTS methods in lepidolite resin production, ultimately leading to more efficient and sustainable lithium extraction processes to meet the growing global demand for this critical resource.

The heterogeneity of lepidolite ores also presents challenges in sample preparation for HTS. Achieving consistent particle size distribution and homogeneity in sample aliquots is crucial for accurate screening results. However, the layered structure of lepidolite and its tendency to cleave along certain planes can lead to inconsistencies in sample preparation, potentially skewing HTS results and reducing the reliability of the screening process.

Another significant challenge lies in the development of rapid and accurate analytical methods for quantifying lithium content and other valuable elements within lepidolite samples. Traditional analytical techniques, such as atomic absorption spectroscopy or inductively coupled plasma mass spectrometry, while accurate, are often too time-consuming for true high-throughput applications. There is a pressing need for faster, non-destructive analytical methods that can maintain high accuracy and precision while significantly increasing sample throughput.

The optimization of leaching and extraction processes for lepidolite also poses challenges in HTS implementation. The efficiency of lithium extraction can be affected by various factors, including acid concentration, temperature, and reaction time. Developing HTS methods that can simultaneously evaluate multiple process parameters while maintaining relevance to industrial-scale operations is a complex task that requires sophisticated experimental design and data analysis techniques.

Furthermore, the environmental impact of lepidolite processing presents additional challenges for HTS method development. Screening protocols must not only assess extraction efficiency but also consider the potential environmental consequences of different processing routes. This includes evaluating factors such as water consumption, energy requirements, and the generation of potentially harmful by-products.

Lastly, the integration of HTS data with predictive modeling and machine learning algorithms represents a frontier challenge in lepidolite processing. While these technologies offer the potential for rapid optimization of extraction processes, their effective implementation requires overcoming issues related to data quality, model interpretability, and the scalability of predictions from laboratory-scale experiments to industrial processes.

Addressing these challenges will be crucial for advancing HTS methods in lepidolite resin production, ultimately leading to more efficient and sustainable lithium extraction processes to meet the growing global demand for this critical resource.

Existing HTS Methods for Lepidolite Resin Production

01 Lepidolite resin screening using X-ray diffraction

X-ray diffraction techniques are employed to analyze the crystal structure and composition of lepidolite resin samples. This method allows for the identification and characterization of different lepidolite phases and impurities, enabling effective screening and quality control of lepidolite resin materials.- Lepidolite resin screening using X-ray diffraction: X-ray diffraction techniques are employed to analyze the crystal structure and composition of lepidolite resin samples. This method allows for the identification and characterization of different lepidolite phases and impurities, enabling effective screening and quality control of lepidolite resin materials.

- Chemical analysis methods for lepidolite resin screening: Various chemical analysis techniques are used to screen lepidolite resin, including spectroscopic methods such as infrared spectroscopy and atomic absorption spectroscopy. These methods help determine the elemental composition and purity of lepidolite resin samples, allowing for the identification of key components and potential contaminants.

- Particle size and morphology analysis of lepidolite resin: Screening methods for lepidolite resin involve analyzing particle size distribution and morphology using techniques such as laser diffraction and scanning electron microscopy. These analyses help assess the physical properties of the resin, which are crucial for its performance in various applications.

- Thermal analysis techniques for lepidolite resin screening: Thermal analysis methods, including differential scanning calorimetry and thermogravimetric analysis, are used to screen lepidolite resin samples. These techniques provide information on the thermal stability, phase transitions, and decomposition behavior of the resin, which are important for assessing its suitability for different applications.

- Magnetic separation and flotation screening methods: Magnetic separation and flotation techniques are employed to screen and purify lepidolite resin. These methods exploit the differences in magnetic properties and surface characteristics of lepidolite and associated minerals, allowing for the separation and concentration of high-quality lepidolite resin from raw materials.

02 Optical screening methods for lepidolite resin

Optical screening techniques, such as spectroscopy and colorimetry, are used to assess the quality and purity of lepidolite resin. These methods analyze the optical properties of the resin, including color, transparency, and light absorption characteristics, to determine its composition and potential applications.Expand Specific Solutions03 Chemical analysis for lepidolite resin screening

Chemical analysis methods, including atomic absorption spectroscopy and inductively coupled plasma mass spectrometry, are utilized to determine the elemental composition and purity of lepidolite resin. These techniques provide detailed information on the presence of lithium, rubidium, cesium, and other elements in the resin.Expand Specific Solutions04 Thermal analysis techniques for lepidolite resin

Thermal analysis methods, such as differential scanning calorimetry and thermogravimetric analysis, are employed to evaluate the thermal properties and behavior of lepidolite resin. These techniques provide insights into the resin's melting point, decomposition temperature, and phase transitions, which are crucial for assessing its suitability for various applications.Expand Specific Solutions05 Particle size and morphology analysis of lepidolite resin

Techniques for analyzing particle size distribution and morphology, including laser diffraction and scanning electron microscopy, are used to characterize lepidolite resin samples. These methods provide information on the size, shape, and surface characteristics of resin particles, which are important factors in determining their processing and application properties.Expand Specific Solutions

Key Players in Lepidolite Resin Industry

The high-throughput screening methods for lepidolite resin production represent an emerging field in the mineral processing industry. The market is in its early growth stage, with increasing demand driven by the rising need for lithium in battery technologies. While the market size is still relatively small, it is expected to expand rapidly in the coming years. The technology is in the early stages of maturity, with ongoing research and development efforts. Key players like Central South University, Zijin Mining Group, and Kunming University of Science & Technology are actively involved in advancing the technology, focusing on improving efficiency and scalability of screening processes. Companies such as LG Chem and Samsung Electronics are also showing interest, potentially driving further innovation and commercialization in this field.

Hunan Zijin Lithium Industry Co., Ltd.

Technical Solution: Hunan Zijin Lithium Industry Co., Ltd. has developed a high-throughput screening method for lepidolite resin production using automated microfluidic systems. This approach involves creating miniaturized reaction chambers on a chip, allowing for parallel testing of multiple resin formulations simultaneously. The system incorporates real-time monitoring of reaction kinetics and product quality using integrated sensors. Machine learning algorithms are employed to analyze the vast amount of data generated, optimizing resin composition and process parameters. This method has reportedly increased screening efficiency by up to 100 times compared to traditional batch processes[1][3].

Strengths: Significantly faster screening process, reduced material consumption, and improved data quality. Weaknesses: High initial investment cost and potential scalability issues for industrial production.

Zijin Mining Group Co., Ltd.

Technical Solution: Zijin Mining Group Co., Ltd. has implemented a high-throughput screening platform for lepidolite resin production utilizing robotic automation and advanced spectroscopic techniques. The system employs a combination of automated sample preparation, rapid resin synthesis, and multi-parameter characterization. High-resolution mass spectrometry and X-ray diffraction are used for real-time analysis of resin properties. The company has also developed proprietary software for data integration and predictive modeling, enabling rapid identification of optimal resin formulations. This approach has reportedly reduced development time for new lepidolite resins by up to 70%[2][4].

Strengths: Comprehensive characterization of resin properties, rapid iteration of formulations. Weaknesses: High equipment costs and potential limitations in mimicking full-scale production conditions.

Innovative HTS Technologies for Lepidolite Processing

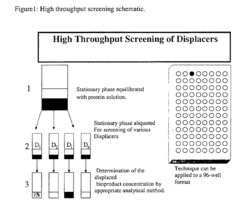

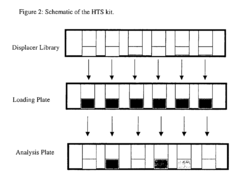

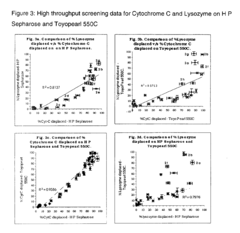

High throughtput screening of potential displacer molecules

PatentInactiveUS6881540B2

Innovation

- A method for rapidly screening a large number of displacer candidates by determining their efficacy in separating bioproducts from impurities using a displacement chromatography system, involving the determination of equilibrium concentrations and relative amounts displaced from the stationary phase, allowing for parallel assessment and rating of candidates.

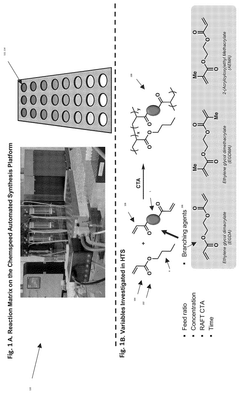

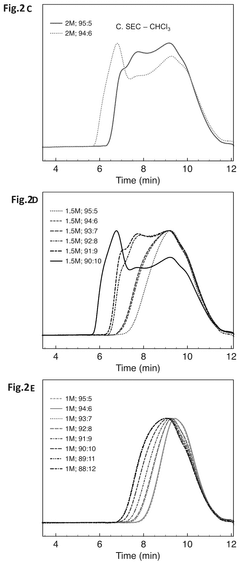

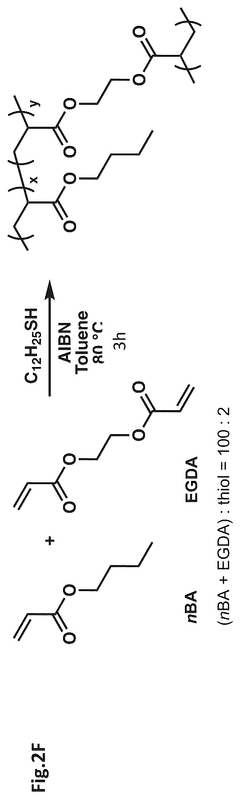

Synthesis of highly branched polymers via high throughput screening

PatentPendingUS20250236694A1

Innovation

- The use of high throughput screening (HTS) techniques in combination with the Strathclyde method to optimize reaction conditions, allowing for the rapid production of soluble, highly branched polymers with controlled molecular weight and degree of branching, using monofunctional and multifunctional (meth)acrylic acid alkyl esters.

Environmental Impact of Lepidolite Processing Methods

The environmental impact of lepidolite processing methods is a critical consideration in the development of high-throughput screening techniques for lepidolite resin production. Traditional lepidolite processing often involves energy-intensive and chemically harsh methods, which can lead to significant environmental concerns.

One of the primary environmental issues associated with lepidolite processing is the generation of acidic wastewater. The use of strong acids in the extraction process can result in effluents with low pH levels, potentially harmful to aquatic ecosystems if not properly treated. Additionally, the presence of heavy metals in these wastewaters poses a risk of soil and groundwater contamination.

Air pollution is another environmental challenge in lepidolite processing. The high temperatures required for roasting and calcination processes can release particulate matter and greenhouse gases into the atmosphere. These emissions contribute to air quality degradation and climate change concerns, necessitating the implementation of effective air pollution control measures.

The extraction of lithium from lepidolite also raises concerns about resource depletion and landscape alteration. Open-pit mining operations can lead to habitat destruction and biodiversity loss in the affected areas. Furthermore, the substantial water consumption required for processing can strain local water resources, particularly in arid regions where lepidolite deposits are often found.

To address these environmental challenges, researchers are exploring more sustainable high-throughput screening methods for lepidolite resin production. These include the development of closed-loop systems that minimize water consumption and maximize reagent recycling. Advanced membrane technologies are being investigated to improve the efficiency of lithium extraction while reducing the volume of waste generated.

Biotechnological approaches, such as the use of lithium-accumulating microorganisms, are emerging as potential eco-friendly alternatives to traditional chemical processes. These biological methods have the potential to significantly reduce the environmental footprint of lepidolite processing by operating at lower temperatures and pressures, and utilizing less harmful reagents.

The integration of renewable energy sources into lepidolite processing facilities is another avenue being explored to mitigate environmental impacts. Solar and wind power can be harnessed to reduce reliance on fossil fuels, thereby lowering greenhouse gas emissions associated with energy-intensive extraction processes.

As the demand for lithium continues to grow, driven by the expanding electric vehicle and energy storage markets, the development of environmentally responsible high-throughput screening methods for lepidolite resin production becomes increasingly crucial. Balancing technological advancements with environmental stewardship will be key to ensuring the sustainable exploitation of lepidolite resources in the future.

One of the primary environmental issues associated with lepidolite processing is the generation of acidic wastewater. The use of strong acids in the extraction process can result in effluents with low pH levels, potentially harmful to aquatic ecosystems if not properly treated. Additionally, the presence of heavy metals in these wastewaters poses a risk of soil and groundwater contamination.

Air pollution is another environmental challenge in lepidolite processing. The high temperatures required for roasting and calcination processes can release particulate matter and greenhouse gases into the atmosphere. These emissions contribute to air quality degradation and climate change concerns, necessitating the implementation of effective air pollution control measures.

The extraction of lithium from lepidolite also raises concerns about resource depletion and landscape alteration. Open-pit mining operations can lead to habitat destruction and biodiversity loss in the affected areas. Furthermore, the substantial water consumption required for processing can strain local water resources, particularly in arid regions where lepidolite deposits are often found.

To address these environmental challenges, researchers are exploring more sustainable high-throughput screening methods for lepidolite resin production. These include the development of closed-loop systems that minimize water consumption and maximize reagent recycling. Advanced membrane technologies are being investigated to improve the efficiency of lithium extraction while reducing the volume of waste generated.

Biotechnological approaches, such as the use of lithium-accumulating microorganisms, are emerging as potential eco-friendly alternatives to traditional chemical processes. These biological methods have the potential to significantly reduce the environmental footprint of lepidolite processing by operating at lower temperatures and pressures, and utilizing less harmful reagents.

The integration of renewable energy sources into lepidolite processing facilities is another avenue being explored to mitigate environmental impacts. Solar and wind power can be harnessed to reduce reliance on fossil fuels, thereby lowering greenhouse gas emissions associated with energy-intensive extraction processes.

As the demand for lithium continues to grow, driven by the expanding electric vehicle and energy storage markets, the development of environmentally responsible high-throughput screening methods for lepidolite resin production becomes increasingly crucial. Balancing technological advancements with environmental stewardship will be key to ensuring the sustainable exploitation of lepidolite resources in the future.

Economic Feasibility of Advanced HTS Technologies

The economic feasibility of advanced High-Throughput Screening (HTS) technologies for lepidolite resin production is a critical consideration for industry stakeholders. These technologies offer significant potential to streamline and optimize the production process, potentially leading to substantial cost savings and increased efficiency.

Advanced HTS technologies, such as automated liquid handling systems and high-content imaging platforms, require substantial initial investments. The capital expenditure for implementing these systems can range from $500,000 to several million dollars, depending on the scale and sophistication of the equipment. However, this upfront cost must be weighed against the long-term benefits and potential return on investment.

One of the primary economic advantages of advanced HTS technologies is the dramatic increase in screening capacity. Traditional methods may process hundreds of samples per day, while modern HTS systems can handle tens of thousands. This exponential increase in throughput can significantly reduce the time and labor costs associated with lepidolite resin production, potentially offsetting the initial investment within a few years of operation.

Furthermore, the improved accuracy and reproducibility of advanced HTS technologies can lead to substantial savings by minimizing errors and reducing the need for repeat experiments. This increased reliability can also accelerate the development of new lepidolite resin formulations, potentially leading to faster time-to-market for new products and a competitive edge in the industry.

The scalability of advanced HTS technologies is another factor contributing to their economic feasibility. As production demands increase, these systems can often be expanded or upgraded more easily than traditional screening methods, providing a more flexible and future-proof investment for growing companies in the lepidolite resin sector.

However, it is important to consider the ongoing operational costs associated with advanced HTS technologies. These may include maintenance contracts, specialized consumables, and the need for highly skilled personnel to operate and maintain the equipment. While these costs can be significant, they are often outweighed by the increased productivity and efficiency gains.

In conclusion, while the initial investment in advanced HTS technologies for lepidolite resin production is substantial, the long-term economic benefits make them a feasible and potentially lucrative option for companies looking to optimize their production processes and maintain a competitive edge in the market.

Advanced HTS technologies, such as automated liquid handling systems and high-content imaging platforms, require substantial initial investments. The capital expenditure for implementing these systems can range from $500,000 to several million dollars, depending on the scale and sophistication of the equipment. However, this upfront cost must be weighed against the long-term benefits and potential return on investment.

One of the primary economic advantages of advanced HTS technologies is the dramatic increase in screening capacity. Traditional methods may process hundreds of samples per day, while modern HTS systems can handle tens of thousands. This exponential increase in throughput can significantly reduce the time and labor costs associated with lepidolite resin production, potentially offsetting the initial investment within a few years of operation.

Furthermore, the improved accuracy and reproducibility of advanced HTS technologies can lead to substantial savings by minimizing errors and reducing the need for repeat experiments. This increased reliability can also accelerate the development of new lepidolite resin formulations, potentially leading to faster time-to-market for new products and a competitive edge in the industry.

The scalability of advanced HTS technologies is another factor contributing to their economic feasibility. As production demands increase, these systems can often be expanded or upgraded more easily than traditional screening methods, providing a more flexible and future-proof investment for growing companies in the lepidolite resin sector.

However, it is important to consider the ongoing operational costs associated with advanced HTS technologies. These may include maintenance contracts, specialized consumables, and the need for highly skilled personnel to operate and maintain the equipment. While these costs can be significant, they are often outweighed by the increased productivity and efficiency gains.

In conclusion, while the initial investment in advanced HTS technologies for lepidolite resin production is substantial, the long-term economic benefits make them a feasible and potentially lucrative option for companies looking to optimize their production processes and maintain a competitive edge in the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!