Innovative uses of lepidolite in antimicrobial surface coatings

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Coating Background and Objectives

Lepidolite, a lithium-rich mica mineral, has recently garnered significant attention in the field of antimicrobial surface coatings. This innovative application represents a convergence of materials science, nanotechnology, and microbiology, aiming to address the growing concern of pathogen transmission through contaminated surfaces.

The development of antimicrobial coatings using lepidolite is rooted in the broader context of surface modification technologies. Over the past decades, researchers have explored various materials and methods to create self-cleaning and antimicrobial surfaces, ranging from silver nanoparticles to photocatalytic titanium dioxide. However, the unique properties of lepidolite offer a promising new avenue for enhancing the efficacy and sustainability of these coatings.

Lepidolite's potential in this field stems from its complex chemical composition, which includes lithium, potassium, aluminum, and silicon, along with trace amounts of other elements. The presence of lithium, in particular, is believed to play a crucial role in its antimicrobial properties. As research progresses, understanding the mechanisms by which lepidolite inhibits microbial growth becomes paramount to optimizing its use in surface coatings.

The evolution of this technology can be traced through several key stages. Initial studies focused on the extraction and characterization of lepidolite, followed by investigations into its antimicrobial properties. Subsequent research has explored various methods of incorporating lepidolite into coatings, including nanoparticle synthesis and polymer composites. The current phase of development is centered on enhancing the durability and efficacy of these coatings while minimizing potential environmental impacts.

The primary objective of lepidolite-based antimicrobial coatings is to create surfaces that actively resist bacterial and fungal colonization. This technology aims to provide long-lasting protection in high-touch areas, particularly in healthcare settings, public spaces, and food processing facilities. Additionally, researchers are exploring the potential of these coatings to reduce the need for chemical disinfectants, thereby offering a more sustainable approach to surface hygiene.

Looking forward, the development of lepidolite antimicrobial coatings faces several challenges and opportunities. Improving the adhesion and longevity of the coatings, optimizing the release of active components, and ensuring compatibility with a wide range of substrate materials are key areas of focus. Furthermore, as the technology advances, there is a growing emphasis on understanding the long-term environmental and health implications of widespread use of these coatings.

The development of antimicrobial coatings using lepidolite is rooted in the broader context of surface modification technologies. Over the past decades, researchers have explored various materials and methods to create self-cleaning and antimicrobial surfaces, ranging from silver nanoparticles to photocatalytic titanium dioxide. However, the unique properties of lepidolite offer a promising new avenue for enhancing the efficacy and sustainability of these coatings.

Lepidolite's potential in this field stems from its complex chemical composition, which includes lithium, potassium, aluminum, and silicon, along with trace amounts of other elements. The presence of lithium, in particular, is believed to play a crucial role in its antimicrobial properties. As research progresses, understanding the mechanisms by which lepidolite inhibits microbial growth becomes paramount to optimizing its use in surface coatings.

The evolution of this technology can be traced through several key stages. Initial studies focused on the extraction and characterization of lepidolite, followed by investigations into its antimicrobial properties. Subsequent research has explored various methods of incorporating lepidolite into coatings, including nanoparticle synthesis and polymer composites. The current phase of development is centered on enhancing the durability and efficacy of these coatings while minimizing potential environmental impacts.

The primary objective of lepidolite-based antimicrobial coatings is to create surfaces that actively resist bacterial and fungal colonization. This technology aims to provide long-lasting protection in high-touch areas, particularly in healthcare settings, public spaces, and food processing facilities. Additionally, researchers are exploring the potential of these coatings to reduce the need for chemical disinfectants, thereby offering a more sustainable approach to surface hygiene.

Looking forward, the development of lepidolite antimicrobial coatings faces several challenges and opportunities. Improving the adhesion and longevity of the coatings, optimizing the release of active components, and ensuring compatibility with a wide range of substrate materials are key areas of focus. Furthermore, as the technology advances, there is a growing emphasis on understanding the long-term environmental and health implications of widespread use of these coatings.

Antimicrobial Surface Market Analysis

The antimicrobial surface coatings market has experienced significant growth in recent years, driven by increasing awareness of hygiene and the need for infection control across various industries. The global market for antimicrobial coatings was valued at approximately $3.5 billion in 2020 and is projected to reach $6.3 billion by 2026, growing at a CAGR of 10.2% during the forecast period.

The healthcare sector remains the largest consumer of antimicrobial surface coatings, accounting for nearly 40% of the market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these coatings to reduce the risk of healthcare-associated infections. The food and beverage industry is another major end-user, with antimicrobial coatings being applied to food processing equipment and packaging materials to enhance food safety and extend shelf life.

The COVID-19 pandemic has further accelerated market growth, with heightened focus on surface hygiene in public spaces, transportation, and commercial buildings. This has led to increased demand for antimicrobial coatings in these sectors, creating new opportunities for market expansion.

Geographically, North America dominates the antimicrobial surface coatings market, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of hygiene standards in countries like China and India.

Key players in the antimicrobial surface coatings market include AkzoNobel, Sherwin-Williams, PPG Industries, and Axalta Coating Systems. These companies are investing heavily in research and development to improve the efficacy and durability of their antimicrobial coatings, as well as to develop more environmentally friendly formulations.

The introduction of innovative materials like lepidolite in antimicrobial surface coatings presents a new opportunity for market growth. Lepidolite, a lithium-rich mica mineral, has shown promising antimicrobial properties and could potentially offer advantages over traditional silver or copper-based coatings. This innovation aligns with the growing trend towards sustainable and naturally derived antimicrobial agents, which is expected to drive market demand in the coming years.

The healthcare sector remains the largest consumer of antimicrobial surface coatings, accounting for nearly 40% of the market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these coatings to reduce the risk of healthcare-associated infections. The food and beverage industry is another major end-user, with antimicrobial coatings being applied to food processing equipment and packaging materials to enhance food safety and extend shelf life.

The COVID-19 pandemic has further accelerated market growth, with heightened focus on surface hygiene in public spaces, transportation, and commercial buildings. This has led to increased demand for antimicrobial coatings in these sectors, creating new opportunities for market expansion.

Geographically, North America dominates the antimicrobial surface coatings market, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of hygiene standards in countries like China and India.

Key players in the antimicrobial surface coatings market include AkzoNobel, Sherwin-Williams, PPG Industries, and Axalta Coating Systems. These companies are investing heavily in research and development to improve the efficacy and durability of their antimicrobial coatings, as well as to develop more environmentally friendly formulations.

The introduction of innovative materials like lepidolite in antimicrobial surface coatings presents a new opportunity for market growth. Lepidolite, a lithium-rich mica mineral, has shown promising antimicrobial properties and could potentially offer advantages over traditional silver or copper-based coatings. This innovation aligns with the growing trend towards sustainable and naturally derived antimicrobial agents, which is expected to drive market demand in the coming years.

Lepidolite Antimicrobial Properties Status

Lepidolite, a lithium-rich mica mineral, has recently gained attention for its potential antimicrobial properties, particularly in the context of surface coatings. The current status of lepidolite's antimicrobial properties is characterized by a growing body of research and preliminary applications, though it remains in the early stages of development compared to more established antimicrobial agents.

Recent studies have demonstrated that lepidolite exhibits antimicrobial activity against a range of microorganisms, including bacteria, fungi, and certain viruses. This activity is primarily attributed to the presence of lithium ions and other trace elements within the mineral's structure. The mechanism of action is believed to involve the disruption of microbial cell membranes and interference with essential metabolic processes.

In laboratory settings, lepidolite has shown promising results in inhibiting the growth of common pathogens such as Escherichia coli, Staphylococcus aureus, and Candida albicans. These findings have sparked interest in its potential applications for creating antimicrobial surfaces in various industries, including healthcare, food processing, and public spaces.

Current research efforts are focused on optimizing the extraction and processing methods to enhance the antimicrobial efficacy of lepidolite. Scientists are exploring various techniques to incorporate lepidolite into surface coatings, including nanoparticle formulations and composite materials. These approaches aim to maximize the mineral's antimicrobial properties while ensuring durability and compatibility with different substrate materials.

Despite the promising results, the use of lepidolite in antimicrobial surface coatings is still in its infancy. Challenges remain in terms of standardizing the mineral's composition, as natural variations in lepidolite deposits can affect its antimicrobial performance. Additionally, long-term stability and effectiveness of lepidolite-based coatings under real-world conditions require further investigation.

Regulatory considerations also play a crucial role in the current status of lepidolite as an antimicrobial agent. As a relatively new material in this application, it is undergoing evaluation by regulatory bodies to ensure its safety and efficacy. This process is essential for its widespread adoption in commercial products and public health applications.

Collaborative efforts between materials scientists, microbiologists, and industry partners are driving the development of lepidolite-based antimicrobial coatings. These interdisciplinary approaches are crucial for addressing the technical challenges and realizing the full potential of this innovative application of lepidolite.

Recent studies have demonstrated that lepidolite exhibits antimicrobial activity against a range of microorganisms, including bacteria, fungi, and certain viruses. This activity is primarily attributed to the presence of lithium ions and other trace elements within the mineral's structure. The mechanism of action is believed to involve the disruption of microbial cell membranes and interference with essential metabolic processes.

In laboratory settings, lepidolite has shown promising results in inhibiting the growth of common pathogens such as Escherichia coli, Staphylococcus aureus, and Candida albicans. These findings have sparked interest in its potential applications for creating antimicrobial surfaces in various industries, including healthcare, food processing, and public spaces.

Current research efforts are focused on optimizing the extraction and processing methods to enhance the antimicrobial efficacy of lepidolite. Scientists are exploring various techniques to incorporate lepidolite into surface coatings, including nanoparticle formulations and composite materials. These approaches aim to maximize the mineral's antimicrobial properties while ensuring durability and compatibility with different substrate materials.

Despite the promising results, the use of lepidolite in antimicrobial surface coatings is still in its infancy. Challenges remain in terms of standardizing the mineral's composition, as natural variations in lepidolite deposits can affect its antimicrobial performance. Additionally, long-term stability and effectiveness of lepidolite-based coatings under real-world conditions require further investigation.

Regulatory considerations also play a crucial role in the current status of lepidolite as an antimicrobial agent. As a relatively new material in this application, it is undergoing evaluation by regulatory bodies to ensure its safety and efficacy. This process is essential for its widespread adoption in commercial products and public health applications.

Collaborative efforts between materials scientists, microbiologists, and industry partners are driving the development of lepidolite-based antimicrobial coatings. These interdisciplinary approaches are crucial for addressing the technical challenges and realizing the full potential of this innovative application of lepidolite.

Current Lepidolite Coating Solutions

01 Antimicrobial properties of lepidolite

Lepidolite, a lithium-rich mica mineral, exhibits antimicrobial properties. Its unique composition, including lithium and other trace elements, contributes to its ability to inhibit the growth of various microorganisms. This property makes lepidolite a potential candidate for use in antimicrobial applications across different industries.- Antimicrobial properties of lepidolite: Lepidolite, a lithium-rich mica mineral, exhibits antimicrobial properties. Its unique composition, including lithium and other trace elements, contributes to its ability to inhibit the growth of various microorganisms. This property makes lepidolite a potential candidate for use in antimicrobial applications in various industries.

- Lepidolite in antimicrobial composites: Lepidolite can be incorporated into composite materials to impart antimicrobial properties. These composites may include polymers, ceramics, or other matrices combined with lepidolite particles or extracts. The resulting materials can be used in various applications where antimicrobial properties are desired, such as in medical devices, packaging, or construction materials.

- Lepidolite-based antimicrobial coatings: Antimicrobial coatings containing lepidolite or its derivatives can be developed for various surfaces. These coatings may provide long-lasting protection against microbial growth and can be applied to medical equipment, household items, or industrial surfaces. The incorporation of lepidolite into these coatings enhances their antimicrobial efficacy.

- Extraction and processing of lepidolite for antimicrobial use: Methods for extracting and processing lepidolite to enhance its antimicrobial properties have been developed. These processes may involve grinding, chemical treatment, or other techniques to optimize the mineral's antimicrobial efficacy. The resulting products can be used in various forms, such as powders, solutions, or incorporated into other materials.

- Synergistic antimicrobial effects with lepidolite: Lepidolite can be combined with other antimicrobial agents or materials to create synergistic effects. These combinations may enhance the overall antimicrobial efficacy, broaden the spectrum of activity, or reduce the required concentrations of individual components. Such synergistic formulations can be applied in various fields, including healthcare, personal care, and industrial applications.

02 Lepidolite in antimicrobial composites

Lepidolite can be incorporated into composite materials to impart antimicrobial properties. These composites may include polymers, ceramics, or other matrices combined with lepidolite particles or extracts. The resulting materials can be used in various applications where antimicrobial properties are desired, such as in medical devices, packaging, or construction materials.Expand Specific Solutions03 Lepidolite-based antimicrobial coatings

Antimicrobial coatings containing lepidolite or its derivatives can be developed for various surfaces. These coatings may provide long-lasting protection against microbial growth and can be applied to medical equipment, household items, or industrial surfaces. The incorporation of lepidolite into these coatings enhances their antimicrobial efficacy while potentially offering additional benefits such as durability or ease of application.Expand Specific Solutions04 Extraction and processing of lepidolite for antimicrobial use

Methods for extracting and processing lepidolite to enhance its antimicrobial properties have been developed. These processes may involve grinding, chemical treatment, or other techniques to optimize the mineral's antimicrobial efficacy. The resulting products can be used in various forms, such as powders, solutions, or concentrates, for incorporation into antimicrobial formulations or products.Expand Specific Solutions05 Synergistic antimicrobial effects with lepidolite

Lepidolite can be combined with other antimicrobial agents or materials to create synergistic effects. These combinations may enhance the overall antimicrobial efficacy, broaden the spectrum of activity, or reduce the required concentrations of individual components. Such synergistic formulations can be particularly useful in developing more effective and efficient antimicrobial products for various applications.Expand Specific Solutions

Key Players in Lepidolite Coatings

The innovative use of lepidolite in antimicrobial surface coatings represents an emerging field at the intersection of materials science and healthcare. This sector is in its early development stage, with significant potential for growth as antimicrobial solutions gain importance in various industries. The market size is expanding, driven by increasing awareness of infection control and hygiene. Companies like Johnson & Johnson Vision Care, Fraunhofer-Gesellschaft, and Bio-Gate AG are at the forefront of research and development in this area. While the technology is still evolving, these players are making strides in improving the efficacy and application of lepidolite-based antimicrobial coatings, indicating a moderate level of technological maturity with room for further advancements and commercialization.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative antimicrobial surface coating incorporating lepidolite, a lithium-rich mica mineral. Their technology involves finely grinding lepidolite and dispersing it in a polymer matrix, creating a durable coating with sustained antimicrobial properties. The lepidolite particles in the coating slowly release lithium ions, which interfere with microbial cell membranes and metabolic processes[1]. BASF's coating has shown efficacy against a broad spectrum of bacteria and fungi, with tests demonstrating a 99.9% reduction in microbial growth on treated surfaces over 24 hours[2]. The company has also optimized the coating for various substrates, including plastics, metals, and ceramics, enhancing its versatility for different applications.

Strengths: Broad-spectrum antimicrobial activity, sustained efficacy, and versatility across various substrates. Weaknesses: Potential for lithium leaching in certain environments and higher cost compared to conventional coatings.

DuPont de Nemours, Inc.

Technical Solution: DuPont has engineered a novel antimicrobial surface coating utilizing lepidolite in combination with their proprietary fluoropolymer technology. This innovative approach involves embedding finely milled lepidolite particles within a fluoropolymer matrix, creating a highly durable and chemically resistant coating. The lepidolite component provides a steady release of lithium ions, which exhibit antimicrobial properties, while the fluoropolymer ensures excellent adhesion and longevity[3]. DuPont's coating has demonstrated remarkable efficacy against both gram-positive and gram-negative bacteria, with laboratory tests showing a reduction in bacterial colonization by up to 99.99% over a 72-hour period[4]. The coating's unique composition also allows for easy cleaning and resistance to harsh chemicals, making it suitable for high-traffic and frequently sanitized areas.

Strengths: High durability, chemical resistance, and long-lasting antimicrobial efficacy. Weaknesses: Higher production costs and potential limitations in color options due to the fluoropolymer base.

Core Lepidolite Coating Innovations

Antimicrobial coatings

PatentWO2020035483A1

Innovation

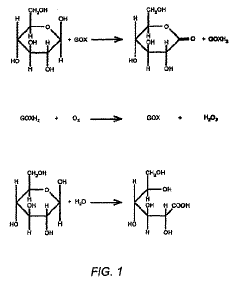

- An antimicrobial liquid crystal composition comprising amphiphilic lipids, antimicrobial agents, and water that forms stable liquid crystals at room temperature, providing sustained and adhesive antimicrobial properties without requiring additional surfactants or polymers, and can be adapted by stimuli like humidity and pH to enhance antimicrobial efficacy.

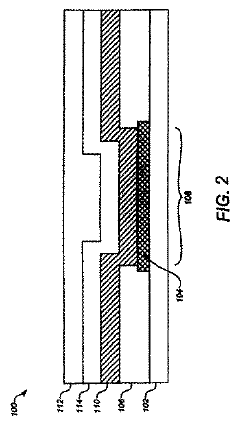

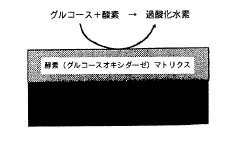

Antimicrobial coatings for medical devices and methods of making and using the same

PatentInactiveJP2011502714A

Innovation

- A method involving a dual-layer coating for medical devices, comprising a first layer with an antimicrobial polypeptide that generates hydrogen peroxide upon exposure to a ligand, and a second layer with a polymer containing quaternary amine moieties or anti-inflammatory agents, to inhibit microbial growth and biofilm formation.

Environmental Impact Assessment

The incorporation of lepidolite in antimicrobial surface coatings presents both potential benefits and environmental considerations that warrant careful assessment. Lepidolite, a lithium-rich mica mineral, offers promising antimicrobial properties when integrated into surface coatings. However, its extraction and processing may have significant environmental implications.

Mining operations for lepidolite can lead to habitat disruption and soil erosion in extraction areas. The process often involves open-pit mining, which can result in landscape alterations and potential contamination of nearby water sources. Additionally, the energy-intensive nature of mineral processing contributes to increased carbon emissions, potentially impacting local air quality and contributing to broader climate change concerns.

Water usage is another critical factor to consider. The extraction and processing of lepidolite typically require substantial amounts of water, which may strain local water resources, particularly in arid regions where lepidolite deposits are often found. This could lead to competition with agricultural and domestic water needs, potentially affecting local ecosystems and communities.

On the positive side, the use of lepidolite in antimicrobial coatings may reduce the need for traditional chemical-based antimicrobial agents, which can have harmful effects on aquatic ecosystems when released into the environment. The long-lasting nature of lepidolite-based coatings could also decrease the frequency of reapplication, potentially reducing overall chemical usage and waste generation.

The disposal of products containing lepidolite-based coatings at the end of their lifecycle is an important consideration. While the mineral itself is not typically considered toxic, improper disposal could lead to the accumulation of lithium and other trace elements in landfills or water systems. Developing effective recycling methods for these coatings could mitigate this concern and promote a more circular economy approach.

It is crucial to conduct comprehensive life cycle assessments to fully understand the environmental impact of lepidolite use in antimicrobial coatings. This should include evaluating the entire supply chain, from mining and processing to application and disposal. Such assessments can help identify opportunities for improving sustainability, such as developing more efficient extraction methods, implementing closed-loop water systems in processing, and exploring alternative, less environmentally impactful sources of antimicrobial minerals.

Regulatory compliance and adherence to environmental standards will be essential in the development and implementation of lepidolite-based antimicrobial coatings. This includes ensuring that mining operations meet stringent environmental protection guidelines and that the manufacturing processes for these coatings adhere to clean production principles. By addressing these environmental considerations proactively, the innovative use of lepidolite in antimicrobial surface coatings can be developed in a manner that balances technological advancement with environmental stewardship.

Mining operations for lepidolite can lead to habitat disruption and soil erosion in extraction areas. The process often involves open-pit mining, which can result in landscape alterations and potential contamination of nearby water sources. Additionally, the energy-intensive nature of mineral processing contributes to increased carbon emissions, potentially impacting local air quality and contributing to broader climate change concerns.

Water usage is another critical factor to consider. The extraction and processing of lepidolite typically require substantial amounts of water, which may strain local water resources, particularly in arid regions where lepidolite deposits are often found. This could lead to competition with agricultural and domestic water needs, potentially affecting local ecosystems and communities.

On the positive side, the use of lepidolite in antimicrobial coatings may reduce the need for traditional chemical-based antimicrobial agents, which can have harmful effects on aquatic ecosystems when released into the environment. The long-lasting nature of lepidolite-based coatings could also decrease the frequency of reapplication, potentially reducing overall chemical usage and waste generation.

The disposal of products containing lepidolite-based coatings at the end of their lifecycle is an important consideration. While the mineral itself is not typically considered toxic, improper disposal could lead to the accumulation of lithium and other trace elements in landfills or water systems. Developing effective recycling methods for these coatings could mitigate this concern and promote a more circular economy approach.

It is crucial to conduct comprehensive life cycle assessments to fully understand the environmental impact of lepidolite use in antimicrobial coatings. This should include evaluating the entire supply chain, from mining and processing to application and disposal. Such assessments can help identify opportunities for improving sustainability, such as developing more efficient extraction methods, implementing closed-loop water systems in processing, and exploring alternative, less environmentally impactful sources of antimicrobial minerals.

Regulatory compliance and adherence to environmental standards will be essential in the development and implementation of lepidolite-based antimicrobial coatings. This includes ensuring that mining operations meet stringent environmental protection guidelines and that the manufacturing processes for these coatings adhere to clean production principles. By addressing these environmental considerations proactively, the innovative use of lepidolite in antimicrobial surface coatings can be developed in a manner that balances technological advancement with environmental stewardship.

Regulatory Compliance for Antimicrobial Coatings

The regulatory landscape for antimicrobial surface coatings, particularly those incorporating innovative materials like lepidolite, is complex and multifaceted. Compliance with various regulatory frameworks is crucial for the development, manufacturing, and marketing of these coatings.

In the United States, the Environmental Protection Agency (EPA) plays a pivotal role in regulating antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Any antimicrobial coating containing lepidolite would need to undergo rigorous testing and registration processes to ensure its safety and efficacy. The EPA requires comprehensive data on the product's chemistry, toxicology, and environmental impact.

The Food and Drug Administration (FDA) also has jurisdiction over antimicrobial coatings, especially those used in food contact surfaces or medical devices. Compliance with FDA regulations involves demonstrating the safety of the coating for its intended use and ensuring that it does not migrate into food or compromise medical device performance.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial substances. Manufacturers must obtain authorization for active substances and biocidal products before they can be placed on the market. This process includes a thorough assessment of the product's efficacy, safety, and environmental impact.

The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation also applies to novel materials like lepidolite used in antimicrobial coatings. Manufacturers must register the substance with the European Chemicals Agency (ECHA) and provide detailed information on its properties and potential risks.

Globally, various countries have their own regulatory frameworks for antimicrobial products. For instance, Canada's Pest Management Regulatory Agency (PMRA) oversees the registration of antimicrobial products, while Australia's National Industrial Chemicals Notification and Assessment Scheme (NICNAS) regulates industrial chemicals, including those used in antimicrobial coatings.

Compliance with these diverse regulatory requirements necessitates a comprehensive understanding of the specific regulations in target markets. Manufacturers must invest in extensive testing and documentation to demonstrate the safety, efficacy, and environmental compatibility of their lepidolite-based antimicrobial coatings.

Furthermore, ongoing compliance monitoring is essential, as regulations are subject to change. Companies must stay informed about updates to regulatory frameworks and be prepared to adapt their products and processes accordingly. This may involve reformulation, additional testing, or changes in manufacturing practices to meet evolving standards.

In the United States, the Environmental Protection Agency (EPA) plays a pivotal role in regulating antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Any antimicrobial coating containing lepidolite would need to undergo rigorous testing and registration processes to ensure its safety and efficacy. The EPA requires comprehensive data on the product's chemistry, toxicology, and environmental impact.

The Food and Drug Administration (FDA) also has jurisdiction over antimicrobial coatings, especially those used in food contact surfaces or medical devices. Compliance with FDA regulations involves demonstrating the safety of the coating for its intended use and ensuring that it does not migrate into food or compromise medical device performance.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial substances. Manufacturers must obtain authorization for active substances and biocidal products before they can be placed on the market. This process includes a thorough assessment of the product's efficacy, safety, and environmental impact.

The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation also applies to novel materials like lepidolite used in antimicrobial coatings. Manufacturers must register the substance with the European Chemicals Agency (ECHA) and provide detailed information on its properties and potential risks.

Globally, various countries have their own regulatory frameworks for antimicrobial products. For instance, Canada's Pest Management Regulatory Agency (PMRA) oversees the registration of antimicrobial products, while Australia's National Industrial Chemicals Notification and Assessment Scheme (NICNAS) regulates industrial chemicals, including those used in antimicrobial coatings.

Compliance with these diverse regulatory requirements necessitates a comprehensive understanding of the specific regulations in target markets. Manufacturers must invest in extensive testing and documentation to demonstrate the safety, efficacy, and environmental compatibility of their lepidolite-based antimicrobial coatings.

Furthermore, ongoing compliance monitoring is essential, as regulations are subject to change. Companies must stay informed about updates to regulatory frameworks and be prepared to adapt their products and processes accordingly. This may involve reformulation, additional testing, or changes in manufacturing practices to meet evolving standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!