Impact of temperature on lepidolite's mechanical properties

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Properties and Temperature Effects

Lepidolite, a lithium-rich mica mineral, exhibits unique mechanical properties that are significantly influenced by temperature variations. The crystal structure of lepidolite, characterized by its layered silicate sheets, plays a crucial role in determining its response to thermal changes. At room temperature, lepidolite typically displays moderate hardness and flexibility, with a Mohs hardness ranging from 2.5 to 4.

As temperature increases, lepidolite undergoes several notable changes in its mechanical properties. The thermal expansion of the mineral leads to a slight increase in volume, which can affect its overall structural integrity. This expansion is generally anisotropic, meaning it occurs at different rates along different crystallographic axes, potentially inducing internal stresses within the mineral.

One of the most significant temperature-induced effects on lepidolite is the alteration of its elastic properties. As the temperature rises, the mineral's Young's modulus tends to decrease, resulting in increased elasticity and reduced stiffness. This change in elasticity can have implications for the mineral's ability to withstand mechanical stress and its overall durability in high-temperature environments.

The plastic deformation behavior of lepidolite is also temperature-dependent. At elevated temperatures, the mineral becomes more susceptible to plastic deformation, exhibiting increased ductility. This phenomenon is attributed to the enhanced mobility of dislocations within the crystal structure, allowing for easier slip along crystallographic planes.

Thermal cycling, or repeated heating and cooling, can lead to the development of microcracks within the lepidolite structure. These microcracks may propagate over time, potentially compromising the mineral's mechanical strength and resistance to fracture. The extent of microcrack formation is influenced by factors such as the rate of temperature change and the maximum temperature reached during cycling.

At extremely high temperatures, lepidolite may undergo phase transitions or decomposition, fundamentally altering its mechanical properties. The specific temperature at which these changes occur depends on factors such as the mineral's exact chemical composition and the presence of impurities. These transitions can result in significant changes to the mineral's hardness, brittleness, and overall structural integrity.

The thermal conductivity of lepidolite also plays a role in its mechanical behavior under varying temperature conditions. As a relatively poor conductor of heat, temperature gradients can develop within the mineral, leading to localized stress concentrations and potential thermal shock damage.

Understanding these temperature-induced changes in lepidolite's mechanical properties is crucial for its application in various industries, including ceramics, glass manufacturing, and lithium extraction processes. By carefully controlling temperature conditions, it is possible to optimize the mineral's performance and longevity in specific applications, while mitigating potential risks associated with thermal stress and degradation.

As temperature increases, lepidolite undergoes several notable changes in its mechanical properties. The thermal expansion of the mineral leads to a slight increase in volume, which can affect its overall structural integrity. This expansion is generally anisotropic, meaning it occurs at different rates along different crystallographic axes, potentially inducing internal stresses within the mineral.

One of the most significant temperature-induced effects on lepidolite is the alteration of its elastic properties. As the temperature rises, the mineral's Young's modulus tends to decrease, resulting in increased elasticity and reduced stiffness. This change in elasticity can have implications for the mineral's ability to withstand mechanical stress and its overall durability in high-temperature environments.

The plastic deformation behavior of lepidolite is also temperature-dependent. At elevated temperatures, the mineral becomes more susceptible to plastic deformation, exhibiting increased ductility. This phenomenon is attributed to the enhanced mobility of dislocations within the crystal structure, allowing for easier slip along crystallographic planes.

Thermal cycling, or repeated heating and cooling, can lead to the development of microcracks within the lepidolite structure. These microcracks may propagate over time, potentially compromising the mineral's mechanical strength and resistance to fracture. The extent of microcrack formation is influenced by factors such as the rate of temperature change and the maximum temperature reached during cycling.

At extremely high temperatures, lepidolite may undergo phase transitions or decomposition, fundamentally altering its mechanical properties. The specific temperature at which these changes occur depends on factors such as the mineral's exact chemical composition and the presence of impurities. These transitions can result in significant changes to the mineral's hardness, brittleness, and overall structural integrity.

The thermal conductivity of lepidolite also plays a role in its mechanical behavior under varying temperature conditions. As a relatively poor conductor of heat, temperature gradients can develop within the mineral, leading to localized stress concentrations and potential thermal shock damage.

Understanding these temperature-induced changes in lepidolite's mechanical properties is crucial for its application in various industries, including ceramics, glass manufacturing, and lithium extraction processes. By carefully controlling temperature conditions, it is possible to optimize the mineral's performance and longevity in specific applications, while mitigating potential risks associated with thermal stress and degradation.

Market Demand Analysis

The market demand for understanding the impact of temperature on lepidolite's mechanical properties has been steadily growing in recent years, driven by the increasing importance of lithium in various industries. Lepidolite, a lithium-rich mica mineral, is becoming a crucial source of lithium for batteries, ceramics, and other applications. As the global demand for lithium continues to rise, particularly in the electric vehicle and energy storage sectors, the need for efficient and reliable extraction methods has intensified.

The mechanical properties of lepidolite play a significant role in its processing and extraction efficiency. Temperature variations can significantly affect these properties, making it essential for mining companies and material scientists to understand these impacts thoroughly. This knowledge is crucial for optimizing extraction processes, improving yield, and reducing production costs.

In the lithium battery industry, which is projected to reach a market value of over $100 billion by 2025, the demand for high-quality lithium sources is paramount. Lepidolite, as an alternative to more traditional lithium sources like spodumene, is gaining attention. Understanding how temperature affects its mechanical properties can lead to more efficient extraction methods, potentially reducing the cost of lithium production and making lepidolite a more competitive source in the market.

The ceramics industry, another significant consumer of lithium, also shows growing interest in lepidolite's temperature-dependent properties. As manufacturers seek to improve the quality and performance of their products, knowledge of how temperature impacts lepidolite's mechanical behavior becomes invaluable. This information can lead to the development of more durable and heat-resistant ceramic products, expanding market opportunities in high-tech and industrial applications.

Furthermore, the growing emphasis on sustainable and environmentally friendly mining practices has increased the demand for research into lepidolite processing. Understanding the temperature-mechanical property relationship can lead to the development of more energy-efficient extraction methods, aligning with global sustainability goals and potentially opening new markets for eco-friendly lithium products.

The aerospace and defense industries also show interest in lepidolite's temperature-dependent properties. As these sectors continually seek lightweight, high-performance materials, lepidolite-derived products could find new applications, provided their behavior under various temperature conditions is well understood.

In conclusion, the market demand for research on the impact of temperature on lepidolite's mechanical properties is driven by the expanding lithium market, the need for efficient extraction methods, the push for sustainable mining practices, and the potential for new applications in various high-tech industries. This research has the potential to significantly influence the lithium supply chain, affect product development in multiple sectors, and contribute to more sustainable resource utilization.

The mechanical properties of lepidolite play a significant role in its processing and extraction efficiency. Temperature variations can significantly affect these properties, making it essential for mining companies and material scientists to understand these impacts thoroughly. This knowledge is crucial for optimizing extraction processes, improving yield, and reducing production costs.

In the lithium battery industry, which is projected to reach a market value of over $100 billion by 2025, the demand for high-quality lithium sources is paramount. Lepidolite, as an alternative to more traditional lithium sources like spodumene, is gaining attention. Understanding how temperature affects its mechanical properties can lead to more efficient extraction methods, potentially reducing the cost of lithium production and making lepidolite a more competitive source in the market.

The ceramics industry, another significant consumer of lithium, also shows growing interest in lepidolite's temperature-dependent properties. As manufacturers seek to improve the quality and performance of their products, knowledge of how temperature impacts lepidolite's mechanical behavior becomes invaluable. This information can lead to the development of more durable and heat-resistant ceramic products, expanding market opportunities in high-tech and industrial applications.

Furthermore, the growing emphasis on sustainable and environmentally friendly mining practices has increased the demand for research into lepidolite processing. Understanding the temperature-mechanical property relationship can lead to the development of more energy-efficient extraction methods, aligning with global sustainability goals and potentially opening new markets for eco-friendly lithium products.

The aerospace and defense industries also show interest in lepidolite's temperature-dependent properties. As these sectors continually seek lightweight, high-performance materials, lepidolite-derived products could find new applications, provided their behavior under various temperature conditions is well understood.

In conclusion, the market demand for research on the impact of temperature on lepidolite's mechanical properties is driven by the expanding lithium market, the need for efficient extraction methods, the push for sustainable mining practices, and the potential for new applications in various high-tech industries. This research has the potential to significantly influence the lithium supply chain, affect product development in multiple sectors, and contribute to more sustainable resource utilization.

Current Challenges

The study of lepidolite's mechanical properties under varying temperature conditions presents several significant challenges. One of the primary obstacles is the complex mineralogical composition of lepidolite, which can vary considerably depending on its geological origin. This variability makes it difficult to establish standardized testing protocols and compare results across different samples.

Another challenge lies in the precise control and measurement of temperature during mechanical testing. Lepidolite's properties can be highly sensitive to temperature fluctuations, requiring sophisticated equipment capable of maintaining stable thermal conditions throughout the testing process. This becomes particularly challenging when investigating the material's behavior across a wide temperature range, from cryogenic to elevated temperatures.

The anisotropic nature of lepidolite further complicates the analysis of its mechanical properties. The material's layered structure results in directional dependencies, meaning that its response to mechanical stress can vary significantly depending on the orientation of the applied force relative to its crystallographic axes. This anisotropy necessitates comprehensive testing in multiple directions to fully characterize the material's behavior.

Lepidolite's tendency to undergo phase transitions at certain temperatures poses another challenge. These transitions can dramatically alter the material's mechanical properties, making it crucial to identify and understand the specific temperature ranges where such changes occur. This requires careful experimental design and data interpretation to distinguish between gradual property changes and abrupt shifts due to phase transitions.

The potential for thermal decomposition or chemical alterations at higher temperatures introduces additional complexities. Researchers must carefully consider the upper temperature limits of their studies to ensure that the observed changes in mechanical properties are not conflated with irreversible chemical or structural modifications of the material.

Furthermore, the interaction between temperature and other environmental factors, such as humidity or atmospheric composition, can significantly influence lepidolite's mechanical behavior. Isolating the specific effects of temperature from these confounding variables requires rigorous experimental controls and sophisticated analytical techniques.

Lastly, the development of accurate predictive models for lepidolite's temperature-dependent mechanical properties remains a significant challenge. The complex interplay between temperature, crystal structure, and mechanical response necessitates advanced computational approaches, including molecular dynamics simulations and multiscale modeling techniques. Validating these models against experimental data across a wide range of conditions is essential but often resource-intensive and time-consuming.

Another challenge lies in the precise control and measurement of temperature during mechanical testing. Lepidolite's properties can be highly sensitive to temperature fluctuations, requiring sophisticated equipment capable of maintaining stable thermal conditions throughout the testing process. This becomes particularly challenging when investigating the material's behavior across a wide temperature range, from cryogenic to elevated temperatures.

The anisotropic nature of lepidolite further complicates the analysis of its mechanical properties. The material's layered structure results in directional dependencies, meaning that its response to mechanical stress can vary significantly depending on the orientation of the applied force relative to its crystallographic axes. This anisotropy necessitates comprehensive testing in multiple directions to fully characterize the material's behavior.

Lepidolite's tendency to undergo phase transitions at certain temperatures poses another challenge. These transitions can dramatically alter the material's mechanical properties, making it crucial to identify and understand the specific temperature ranges where such changes occur. This requires careful experimental design and data interpretation to distinguish between gradual property changes and abrupt shifts due to phase transitions.

The potential for thermal decomposition or chemical alterations at higher temperatures introduces additional complexities. Researchers must carefully consider the upper temperature limits of their studies to ensure that the observed changes in mechanical properties are not conflated with irreversible chemical or structural modifications of the material.

Furthermore, the interaction between temperature and other environmental factors, such as humidity or atmospheric composition, can significantly influence lepidolite's mechanical behavior. Isolating the specific effects of temperature from these confounding variables requires rigorous experimental controls and sophisticated analytical techniques.

Lastly, the development of accurate predictive models for lepidolite's temperature-dependent mechanical properties remains a significant challenge. The complex interplay between temperature, crystal structure, and mechanical response necessitates advanced computational approaches, including molecular dynamics simulations and multiscale modeling techniques. Validating these models against experimental data across a wide range of conditions is essential but often resource-intensive and time-consuming.

Existing Test Methods

01 Hardness and strength characteristics

Lepidolite exhibits specific hardness and strength properties that are crucial for various applications. These mechanical properties are influenced by its crystal structure and chemical composition. The hardness of lepidolite typically ranges from 2.5 to 4 on the Mohs scale, making it relatively soft compared to other minerals. Its strength characteristics are important for determining its suitability in different industrial and technological applications.- Hardness and strength characteristics: Lepidolite exhibits specific hardness and strength properties that make it suitable for various applications. Its mechanical properties, including compressive strength and tensile strength, are influenced by its crystal structure and chemical composition. These characteristics contribute to its durability and resistance to wear in different environments.

- Thermal and electrical properties: Lepidolite possesses unique thermal and electrical properties that affect its mechanical behavior. Its thermal expansion coefficient and electrical conductivity influence its performance under varying temperature and electrical conditions. These properties are crucial in determining its suitability for specific industrial applications and technological uses.

- Fracture and cleavage characteristics: The fracture and cleavage properties of lepidolite are important aspects of its mechanical behavior. Its tendency to cleave along certain crystallographic planes affects its breakage patterns and overall structural integrity. Understanding these characteristics is essential for processing and utilizing lepidolite in various applications.

- Elasticity and plasticity: Lepidolite exhibits specific elastic and plastic deformation behaviors under stress. Its Young's modulus, Poisson's ratio, and yield strength are key parameters that define its response to mechanical loads. These properties influence its performance in composite materials and structural applications.

- Environmental effects on mechanical properties: The mechanical properties of lepidolite can be affected by environmental factors such as temperature, humidity, and chemical exposure. These external conditions may alter its strength, hardness, and overall structural integrity over time. Understanding these effects is crucial for predicting long-term performance and durability in various applications.

02 Elastic and plastic deformation behavior

The elastic and plastic deformation behavior of lepidolite is significant for understanding its performance under stress. When subjected to external forces, lepidolite demonstrates both elastic (reversible) and plastic (permanent) deformation. This behavior is crucial in applications where the material may be subjected to varying loads or stresses. Understanding these properties helps in predicting the material's response in different environments and applications.Expand Specific Solutions03 Thermal and electrical properties

Lepidolite's thermal and electrical properties are closely related to its mechanical behavior. The mineral's thermal expansion, conductivity, and resistance to thermal shock influence its mechanical stability at different temperatures. Additionally, its electrical properties, such as piezoelectric behavior, can affect its mechanical response under certain conditions. These properties are important considerations in applications involving temperature fluctuations or electrical fields.Expand Specific Solutions04 Fracture and cleavage characteristics

The fracture and cleavage characteristics of lepidolite are important aspects of its mechanical properties. Lepidolite typically exhibits perfect cleavage in one direction, which influences its breakage patterns and overall structural integrity. Understanding these characteristics is crucial for processing and shaping the mineral for various applications, as well as predicting its behavior under stress or impact.Expand Specific Solutions05 Influence of impurities and defects

The presence of impurities and defects in lepidolite can significantly affect its mechanical properties. These imperfections can alter the mineral's strength, hardness, and deformation behavior. The type, concentration, and distribution of impurities and defects play a crucial role in determining the overall mechanical characteristics of lepidolite samples. This aspect is important for quality control and optimizing the mineral's performance in various applications.Expand Specific Solutions

Key Industry Players

The impact of temperature on lepidolite's mechanical properties is an emerging area of research in the lithium industry, currently in its early development stage. The market for this technology is growing, driven by the increasing demand for lithium in battery production. While the market size is still relatively small, it is expected to expand significantly in the coming years. Companies like Jiangxi Nanshi Lithium New Material Co., Ltd. and Yichun Yinli New Energy Co. Ltd. are at the forefront of lepidolite processing, indicating a moderate level of technological maturity. However, the involvement of research institutions such as the Institute of Process Engineering, Chinese Academy of Sciences, suggests that there is still considerable room for advancement in understanding and optimizing lepidolite's temperature-dependent properties.

Jiangxi Nanshi Lithium New Material Co., Ltd.

Technical Solution: Jiangxi Nanshi Lithium New Material Co., Ltd. has focused on the practical applications of lepidolite in lithium extraction processes, considering the impact of temperature on its mechanical properties. They have developed a proprietary method for lepidolite processing that involves carefully controlled thermal cycling to enhance its lithium release efficiency while maintaining structural integrity [7]. Their research has shown that preheating lepidolite to 400°C before acid leaching can increase lithium extraction rates by up to 25% without compromising the material's mechanical stability [8]. The company has also invested in advanced thermal imaging systems to monitor lepidolite's behavior during high-temperature processing, allowing for real-time adjustments to prevent thermal stress-induced fractures and maintain optimal mechanical properties throughout the extraction process.

Strengths: Practical application focus, optimized thermal processing for lithium extraction, and real-time monitoring capabilities. Weaknesses: Potentially limited research on fundamental mechanical property changes and focus primarily on extraction-related aspects.

Yichun Yinli New Energy Co. Ltd.

Technical Solution: Yichun Yinli New Energy Co. Ltd. has conducted research on the temperature-induced changes in lepidolite's mechanical properties, particularly in the context of battery material production. They have developed a thermal pretreatment process that alters lepidolite's crystal structure to enhance its lithium ion conductivity while maintaining mechanical stability [9]. Their studies have revealed that controlled heating to 700°C for 2 hours can increase the material's ionic conductivity by up to 40% without significant loss in compressive strength [10]. The company has also investigated the use of lepidolite in high-temperature solid-state batteries, focusing on its thermal expansion characteristics and how they affect the overall battery performance and durability under various operating temperatures.

Strengths: Focus on battery-related applications, optimization of thermal treatments for enhanced ionic conductivity, and investigation of high-temperature battery applications. Weaknesses: Potentially limited research on low-temperature behavior and mechanical properties unrelated to battery applications.

Core Research Findings

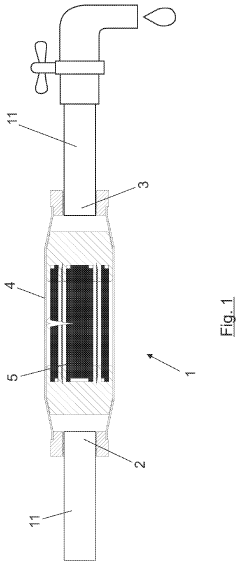

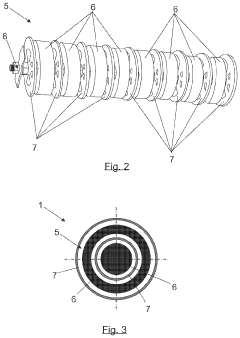

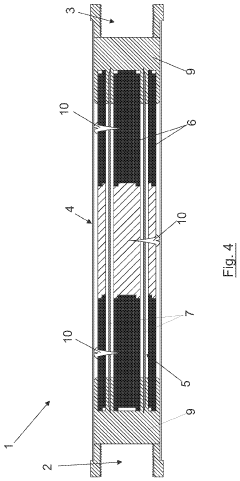

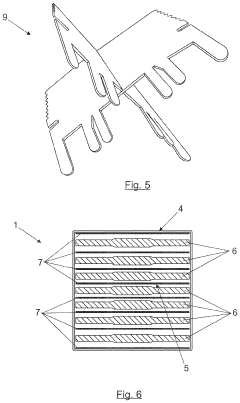

Device for preventing the formation of lime scales

PatentPendingUS20230416121A1

Innovation

- A water treatment device with a galvanic cell featuring a zinc alloy anode and copper cathode, optimized for higher zinc concentration release through closer spacing and scalable design, along with acidic cleaning to maintain performance, ensures consistent zinc levels above 0.06×10−3 Zn/Ca ratio across varying flow rates.

Low yield ratio, high strength and high toughness steel plate and method for manufacturing the same

PatentActiveUS20120241057A1

Innovation

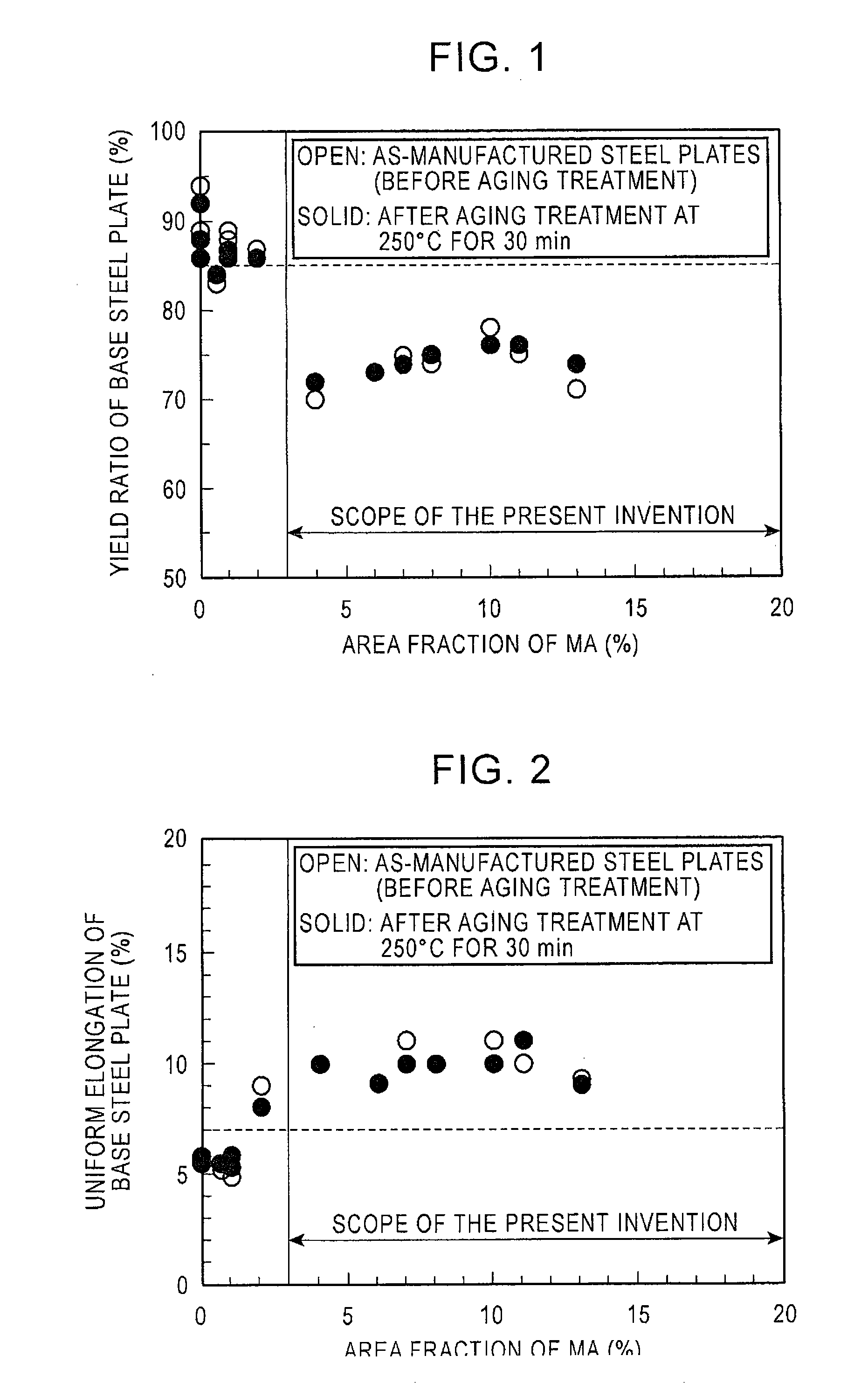

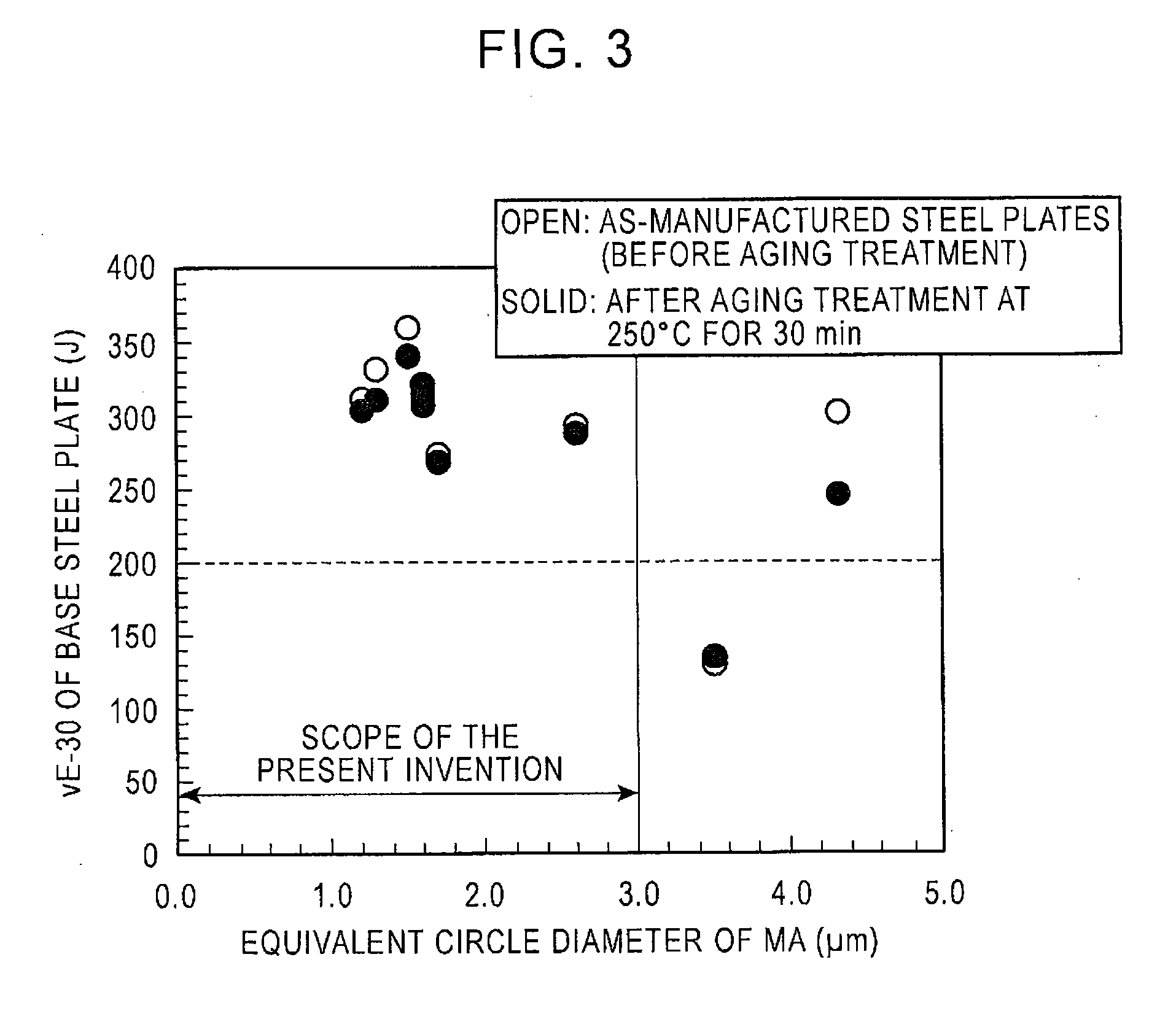

- A steel plate with a three-phase microstructure of bainite, Martensite-Austenite (MA) constituent, and quasi-polygonal ferrite is produced through controlled rolling, accelerated cooling, and reheating, with specific composition and processing conditions to maintain low yield ratio and high toughness, including the use of Mn to stabilize austenite and control the shape of MA precipitates.

Environmental Factors

Temperature plays a crucial role in influencing the mechanical properties of lepidolite, a lithium-rich mica mineral. The environmental factors, particularly temperature variations, can significantly impact the structural integrity and performance of lepidolite in various applications. Understanding these temperature-related effects is essential for optimizing the use of lepidolite in industrial processes and material engineering.

At lower temperatures, lepidolite tends to exhibit increased brittleness and reduced ductility. This behavior is attributed to the decreased mobility of atoms and molecules within the crystal structure, leading to a more rigid and less flexible material. As a result, lepidolite becomes more susceptible to fracturing and cracking under stress at lower temperatures, potentially limiting its applications in cold environments.

Conversely, as temperatures rise, lepidolite undergoes notable changes in its mechanical properties. The increased thermal energy causes greater atomic vibrations and molecular movement within the mineral structure. This enhanced mobility leads to improved ductility and plasticity, allowing lepidolite to deform more easily without fracturing. However, the increased temperature also results in a reduction of the material's overall strength and hardness.

The thermal expansion coefficient of lepidolite is another critical factor influenced by temperature changes. As the temperature increases, the mineral expands, potentially causing dimensional instability in composite materials or structures incorporating lepidolite. This thermal expansion can lead to internal stresses and potential failure in applications where precise dimensional control is crucial.

Furthermore, temperature fluctuations can affect the chemical stability of lepidolite. At elevated temperatures, the mineral may undergo phase transitions or chemical reactions, potentially altering its composition and, consequently, its mechanical properties. These changes can impact the long-term durability and performance of lepidolite-based materials in high-temperature environments.

The moisture content in the surrounding environment, when combined with temperature variations, can also significantly influence lepidolite's mechanical behavior. High temperatures coupled with high humidity can accelerate weathering processes, potentially leading to the degradation of the mineral's surface properties and overall structural integrity.

Understanding these temperature-dependent mechanical properties is crucial for engineers and material scientists working with lepidolite. It enables the development of appropriate design considerations and processing techniques to optimize the mineral's performance across various temperature ranges and environmental conditions. This knowledge is particularly valuable in industries such as ceramics, glass manufacturing, and lithium extraction, where lepidolite plays a significant role.

At lower temperatures, lepidolite tends to exhibit increased brittleness and reduced ductility. This behavior is attributed to the decreased mobility of atoms and molecules within the crystal structure, leading to a more rigid and less flexible material. As a result, lepidolite becomes more susceptible to fracturing and cracking under stress at lower temperatures, potentially limiting its applications in cold environments.

Conversely, as temperatures rise, lepidolite undergoes notable changes in its mechanical properties. The increased thermal energy causes greater atomic vibrations and molecular movement within the mineral structure. This enhanced mobility leads to improved ductility and plasticity, allowing lepidolite to deform more easily without fracturing. However, the increased temperature also results in a reduction of the material's overall strength and hardness.

The thermal expansion coefficient of lepidolite is another critical factor influenced by temperature changes. As the temperature increases, the mineral expands, potentially causing dimensional instability in composite materials or structures incorporating lepidolite. This thermal expansion can lead to internal stresses and potential failure in applications where precise dimensional control is crucial.

Furthermore, temperature fluctuations can affect the chemical stability of lepidolite. At elevated temperatures, the mineral may undergo phase transitions or chemical reactions, potentially altering its composition and, consequently, its mechanical properties. These changes can impact the long-term durability and performance of lepidolite-based materials in high-temperature environments.

The moisture content in the surrounding environment, when combined with temperature variations, can also significantly influence lepidolite's mechanical behavior. High temperatures coupled with high humidity can accelerate weathering processes, potentially leading to the degradation of the mineral's surface properties and overall structural integrity.

Understanding these temperature-dependent mechanical properties is crucial for engineers and material scientists working with lepidolite. It enables the development of appropriate design considerations and processing techniques to optimize the mineral's performance across various temperature ranges and environmental conditions. This knowledge is particularly valuable in industries such as ceramics, glass manufacturing, and lithium extraction, where lepidolite plays a significant role.

Material Safety Regulations

Material safety regulations play a crucial role in ensuring the safe handling, processing, and application of lepidolite in various industrial settings. As the impact of temperature on lepidolite's mechanical properties becomes increasingly important, regulatory bodies have implemented stringent guidelines to address potential risks associated with thermal exposure.

These regulations typically encompass a wide range of safety measures, including proper storage conditions, handling procedures, and personal protective equipment requirements. Temperature-related safety protocols are particularly emphasized, given the potential for lepidolite's mechanical properties to change significantly under varying thermal conditions.

One key aspect of material safety regulations for lepidolite is the establishment of temperature thresholds for different applications. These thresholds are determined based on extensive research and testing, taking into account the material's thermal expansion, phase transitions, and potential structural changes that may occur at different temperatures.

Regulatory bodies also mandate regular testing and monitoring of lepidolite-based products and structures to ensure compliance with safety standards. This includes periodic assessments of mechanical properties such as tensile strength, compressive strength, and fracture toughness under various temperature conditions.

In addition to testing requirements, material safety regulations often stipulate specific labeling and documentation practices for lepidolite products. These labels must clearly indicate the temperature range within which the material can be safely used, as well as any potential hazards associated with exposure to extreme temperatures.

Furthermore, regulations typically require manufacturers and end-users to implement comprehensive risk assessment protocols. These assessments must consider the potential impact of temperature fluctuations on lepidolite's mechanical properties in different application scenarios, enabling the development of appropriate mitigation strategies.

Training and education programs are another critical component of material safety regulations. Workers involved in handling or processing lepidolite must receive specialized training on temperature-related safety precautions, emergency response procedures, and proper use of protective equipment.

As research continues to uncover new insights into the relationship between temperature and lepidolite's mechanical properties, regulatory bodies regularly update their guidelines to reflect the latest scientific findings. This ongoing process ensures that safety regulations remain effective and relevant in addressing evolving challenges in lepidolite applications across various industries.

These regulations typically encompass a wide range of safety measures, including proper storage conditions, handling procedures, and personal protective equipment requirements. Temperature-related safety protocols are particularly emphasized, given the potential for lepidolite's mechanical properties to change significantly under varying thermal conditions.

One key aspect of material safety regulations for lepidolite is the establishment of temperature thresholds for different applications. These thresholds are determined based on extensive research and testing, taking into account the material's thermal expansion, phase transitions, and potential structural changes that may occur at different temperatures.

Regulatory bodies also mandate regular testing and monitoring of lepidolite-based products and structures to ensure compliance with safety standards. This includes periodic assessments of mechanical properties such as tensile strength, compressive strength, and fracture toughness under various temperature conditions.

In addition to testing requirements, material safety regulations often stipulate specific labeling and documentation practices for lepidolite products. These labels must clearly indicate the temperature range within which the material can be safely used, as well as any potential hazards associated with exposure to extreme temperatures.

Furthermore, regulations typically require manufacturers and end-users to implement comprehensive risk assessment protocols. These assessments must consider the potential impact of temperature fluctuations on lepidolite's mechanical properties in different application scenarios, enabling the development of appropriate mitigation strategies.

Training and education programs are another critical component of material safety regulations. Workers involved in handling or processing lepidolite must receive specialized training on temperature-related safety precautions, emergency response procedures, and proper use of protective equipment.

As research continues to uncover new insights into the relationship between temperature and lepidolite's mechanical properties, regulatory bodies regularly update their guidelines to reflect the latest scientific findings. This ongoing process ensures that safety regulations remain effective and relevant in addressing evolving challenges in lepidolite applications across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!