Conductive Polymer Inks for Flexible Electronics Applications

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Inks Background and Objectives

Conductive polymer inks represent a transformative technology in the field of flexible electronics, emerging from the convergence of materials science, chemistry, and electronic engineering. The evolution of these specialized inks can be traced back to the discovery of conductive polymers in the 1970s, which earned Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa the Nobel Prize in Chemistry in 2000. Since then, the field has witnessed remarkable advancements, transitioning from laboratory curiosities to commercially viable materials with diverse applications.

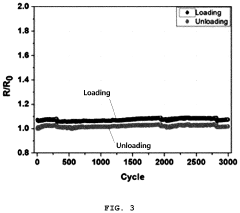

The technological trajectory of conductive polymer inks has been characterized by continuous improvements in electrical conductivity, mechanical flexibility, environmental stability, and processing compatibility. Early iterations faced significant limitations in conductivity and durability, but recent developments have yielded formulations with performance metrics approaching those of traditional metallic conductors while maintaining the inherent advantages of polymeric materials.

Current research trends focus on enhancing the intrinsic properties of conductive polymers through molecular engineering, developing novel composite formulations incorporating nanomaterials, and optimizing ink rheology for various deposition techniques. The integration of sustainability principles into ink development represents another emerging trend, with increasing emphasis on environmentally friendly solvents and biodegradable components.

The primary technical objectives for conductive polymer inks center on achieving specific performance benchmarks that enable their widespread adoption in flexible electronics. These include reaching conductivity values exceeding 10,000 S/cm while maintaining flexibility under mechanical strain, ensuring environmental stability across diverse operating conditions, and developing formulations compatible with high-throughput manufacturing processes such as roll-to-roll printing.

Additionally, there are objectives related to application-specific requirements, such as transparency for display technologies, biocompatibility for wearable health monitoring devices, and stretchability for conformable electronics. The development of multi-functional inks that combine conductivity with other properties like thermoelectric effects or sensing capabilities represents another frontier in this field.

The overarching goal of conductive polymer ink technology is to enable a new generation of electronic devices that transcend the limitations of rigid, silicon-based electronics. By providing cost-effective, scalable methods for fabricating flexible, lightweight, and potentially biodegradable electronic components, these materials aim to revolutionize sectors ranging from consumer electronics and healthcare to energy harvesting and smart packaging.

The technological trajectory of conductive polymer inks has been characterized by continuous improvements in electrical conductivity, mechanical flexibility, environmental stability, and processing compatibility. Early iterations faced significant limitations in conductivity and durability, but recent developments have yielded formulations with performance metrics approaching those of traditional metallic conductors while maintaining the inherent advantages of polymeric materials.

Current research trends focus on enhancing the intrinsic properties of conductive polymers through molecular engineering, developing novel composite formulations incorporating nanomaterials, and optimizing ink rheology for various deposition techniques. The integration of sustainability principles into ink development represents another emerging trend, with increasing emphasis on environmentally friendly solvents and biodegradable components.

The primary technical objectives for conductive polymer inks center on achieving specific performance benchmarks that enable their widespread adoption in flexible electronics. These include reaching conductivity values exceeding 10,000 S/cm while maintaining flexibility under mechanical strain, ensuring environmental stability across diverse operating conditions, and developing formulations compatible with high-throughput manufacturing processes such as roll-to-roll printing.

Additionally, there are objectives related to application-specific requirements, such as transparency for display technologies, biocompatibility for wearable health monitoring devices, and stretchability for conformable electronics. The development of multi-functional inks that combine conductivity with other properties like thermoelectric effects or sensing capabilities represents another frontier in this field.

The overarching goal of conductive polymer ink technology is to enable a new generation of electronic devices that transcend the limitations of rigid, silicon-based electronics. By providing cost-effective, scalable methods for fabricating flexible, lightweight, and potentially biodegradable electronic components, these materials aim to revolutionize sectors ranging from consumer electronics and healthcare to energy harvesting and smart packaging.

Market Analysis for Flexible Electronics Applications

The flexible electronics market has been experiencing robust growth, with a global market value reaching $31.6 billion in 2022 and projected to expand at a CAGR of 15.3% through 2030. This growth is primarily driven by increasing demand for lightweight, portable, and bendable electronic devices across various industries including consumer electronics, healthcare, automotive, and aerospace.

Conductive polymer inks represent a critical component within this ecosystem, with their market segment valued at approximately $3.2 billion in 2022. These materials enable the printing of electronic circuits directly onto flexible substrates such as plastic, paper, and textiles, facilitating the production of flexible displays, sensors, and wearable technology.

Consumer electronics remains the dominant application sector, accounting for 42% of the flexible electronics market. The proliferation of smartphones, tablets, and wearable devices has created substantial demand for flexible displays and touch panels that incorporate conductive polymer ink technology. Major manufacturers like Samsung and LG have already commercialized flexible OLED displays using these materials.

The healthcare sector presents the fastest-growing opportunity, with a projected CAGR of 18.7% for flexible electronics applications. Medical wearables, biosensors, and smart patches utilizing conductive polymer inks are revolutionizing patient monitoring and diagnostic capabilities. These devices offer advantages in comfort, conformability to body contours, and continuous data collection.

Automotive applications are gaining significant traction as vehicle manufacturers integrate more sophisticated human-machine interfaces and sensor systems. The automotive flexible electronics segment is expected to grow at 16.2% annually, with conductive polymer inks enabling printed heaters, lighting elements, and touch controls that conform to interior surfaces.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global consumption, followed by North America (28%) and Europe (22%). China, South Korea, and Japan lead manufacturing capacity, while significant R&D investments are concentrated in the United States and Germany.

Market challenges include price sensitivity, as conductive polymer inks remain more expensive than traditional rigid circuit manufacturing methods. Additionally, concerns regarding long-term durability and environmental stability under repeated flexing conditions persist among potential adopters.

The competitive landscape features specialized materials companies like Henkel, DuPont, and Heraeus providing high-performance conductive polymer formulations, alongside emerging startups developing novel ink compositions with enhanced conductivity and flexibility characteristics. Strategic partnerships between ink manufacturers and electronic device producers are increasingly common, accelerating commercialization timelines.

Conductive polymer inks represent a critical component within this ecosystem, with their market segment valued at approximately $3.2 billion in 2022. These materials enable the printing of electronic circuits directly onto flexible substrates such as plastic, paper, and textiles, facilitating the production of flexible displays, sensors, and wearable technology.

Consumer electronics remains the dominant application sector, accounting for 42% of the flexible electronics market. The proliferation of smartphones, tablets, and wearable devices has created substantial demand for flexible displays and touch panels that incorporate conductive polymer ink technology. Major manufacturers like Samsung and LG have already commercialized flexible OLED displays using these materials.

The healthcare sector presents the fastest-growing opportunity, with a projected CAGR of 18.7% for flexible electronics applications. Medical wearables, biosensors, and smart patches utilizing conductive polymer inks are revolutionizing patient monitoring and diagnostic capabilities. These devices offer advantages in comfort, conformability to body contours, and continuous data collection.

Automotive applications are gaining significant traction as vehicle manufacturers integrate more sophisticated human-machine interfaces and sensor systems. The automotive flexible electronics segment is expected to grow at 16.2% annually, with conductive polymer inks enabling printed heaters, lighting elements, and touch controls that conform to interior surfaces.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global consumption, followed by North America (28%) and Europe (22%). China, South Korea, and Japan lead manufacturing capacity, while significant R&D investments are concentrated in the United States and Germany.

Market challenges include price sensitivity, as conductive polymer inks remain more expensive than traditional rigid circuit manufacturing methods. Additionally, concerns regarding long-term durability and environmental stability under repeated flexing conditions persist among potential adopters.

The competitive landscape features specialized materials companies like Henkel, DuPont, and Heraeus providing high-performance conductive polymer formulations, alongside emerging startups developing novel ink compositions with enhanced conductivity and flexibility characteristics. Strategic partnerships between ink manufacturers and electronic device producers are increasingly common, accelerating commercialization timelines.

Current State and Technical Challenges of Conductive Polymer Inks

Conductive polymer inks have emerged as a pivotal technology in the flexible electronics landscape, with significant advancements achieved over the past decade. Currently, these inks primarily utilize polymers such as PEDOT:PSS, polyaniline, and polypyrrole, which offer electrical conductivity while maintaining flexibility. The global market has witnessed substantial growth, with major manufacturers in North America, Europe, and East Asia leading development efforts.

The current conductivity levels of polymer inks range from 1-10³ S/cm, significantly lower than metallic counterparts (10⁵-10⁶ S/cm), presenting a fundamental performance limitation. While sufficient for certain applications like touch sensors and simple circuits, this conductivity gap restricts their implementation in high-performance electronics requiring rapid signal transmission.

Environmental stability remains a critical challenge, as many conductive polymers exhibit performance degradation when exposed to oxygen, moisture, and UV radiation. Current solutions involve encapsulation techniques and stabilizing additives, though these often compromise other properties such as transparency or flexibility.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production methods frequently fail to translate to industrial-scale manufacturing without compromising ink quality and performance consistency. Variations in batch-to-batch properties create reliability issues that impede widespread commercial adoption.

The rheological properties of conductive polymer inks present complex engineering challenges. Achieving the optimal balance between viscosity, surface tension, and particle size distribution is essential for compatibility with various printing techniques (inkjet, screen, gravure). Current formulations often require trade-offs between printability and electrical performance.

Cost factors continue to constrain market expansion, with high-performance conductive polymers and specialized additives commanding premium prices. The complex synthesis processes and purification requirements contribute to production costs that exceed those of conventional electronic materials by 3-5 times on average.

Substrate compatibility issues persist across the industry. While adhesion to common flexible substrates like PET and PEN has improved, maintaining consistent electrical performance across different substrate materials remains problematic. Interface engineering between ink and substrate continues to be an active research area.

Recent technical developments have focused on hybrid systems incorporating nanomaterials (carbon nanotubes, graphene) to enhance conductivity while maintaining flexibility. These approaches show promise but introduce new challenges related to dispersion stability and increased production complexity.

The regulatory landscape adds another layer of complexity, with growing concerns about the environmental impact and potential toxicity of some conductive polymer components. This has accelerated research into greener alternatives and sustainable manufacturing processes, though these typically lag behind conventional options in performance metrics.

The current conductivity levels of polymer inks range from 1-10³ S/cm, significantly lower than metallic counterparts (10⁵-10⁶ S/cm), presenting a fundamental performance limitation. While sufficient for certain applications like touch sensors and simple circuits, this conductivity gap restricts their implementation in high-performance electronics requiring rapid signal transmission.

Environmental stability remains a critical challenge, as many conductive polymers exhibit performance degradation when exposed to oxygen, moisture, and UV radiation. Current solutions involve encapsulation techniques and stabilizing additives, though these often compromise other properties such as transparency or flexibility.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production methods frequently fail to translate to industrial-scale manufacturing without compromising ink quality and performance consistency. Variations in batch-to-batch properties create reliability issues that impede widespread commercial adoption.

The rheological properties of conductive polymer inks present complex engineering challenges. Achieving the optimal balance between viscosity, surface tension, and particle size distribution is essential for compatibility with various printing techniques (inkjet, screen, gravure). Current formulations often require trade-offs between printability and electrical performance.

Cost factors continue to constrain market expansion, with high-performance conductive polymers and specialized additives commanding premium prices. The complex synthesis processes and purification requirements contribute to production costs that exceed those of conventional electronic materials by 3-5 times on average.

Substrate compatibility issues persist across the industry. While adhesion to common flexible substrates like PET and PEN has improved, maintaining consistent electrical performance across different substrate materials remains problematic. Interface engineering between ink and substrate continues to be an active research area.

Recent technical developments have focused on hybrid systems incorporating nanomaterials (carbon nanotubes, graphene) to enhance conductivity while maintaining flexibility. These approaches show promise but introduce new challenges related to dispersion stability and increased production complexity.

The regulatory landscape adds another layer of complexity, with growing concerns about the environmental impact and potential toxicity of some conductive polymer components. This has accelerated research into greener alternatives and sustainable manufacturing processes, though these typically lag behind conventional options in performance metrics.

Current Technical Solutions for Flexible Electronics Printing

01 Conductive polymer compositions for printable electronics

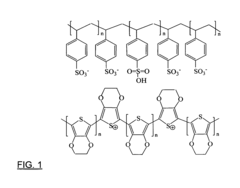

Conductive polymer inks can be formulated with specific polymers like PEDOT:PSS, polyaniline, or polythiophene derivatives to create printable electronic components. These formulations typically include solvents, binders, and additives that enhance conductivity while maintaining printability. The resulting inks can be used for flexible electronics, sensors, and printed circuit applications where traditional metal conductors may not be suitable.- Composition of conductive polymer inks: Conductive polymer inks typically consist of conductive polymers such as PEDOT:PSS, polyaniline, or polypyrrole combined with solvents and additives to enhance conductivity and printability. These formulations often include stabilizers to prevent aggregation and improve shelf life. The composition can be tailored to achieve specific viscosity, surface tension, and drying characteristics required for various printing methods such as inkjet, screen, or flexographic printing.

- Manufacturing processes for conductive polymer inks: Manufacturing processes for conductive polymer inks involve polymerization techniques, dispersion methods, and formulation strategies to ensure uniform particle distribution and stability. These processes may include in-situ polymerization, emulsion polymerization, or solution processing. Post-processing treatments such as filtration and sonication are often employed to achieve the desired particle size distribution and remove aggregates, ensuring consistent print quality and electrical performance.

- Applications of conductive polymer inks: Conductive polymer inks find applications in flexible electronics, printed circuit boards, RFID tags, sensors, and photovoltaic devices. They enable the fabrication of lightweight, flexible, and stretchable electronic components that can be integrated into wearable technology, smart packaging, and biomedical devices. These inks are particularly valuable for applications requiring low-temperature processing, mechanical flexibility, or large-area coverage on various substrates including plastics, paper, and textiles.

- Enhancement of electrical conductivity in polymer inks: Various methods are employed to enhance the electrical conductivity of polymer inks, including the addition of conductive fillers such as carbon nanotubes, graphene, or metal nanoparticles. Secondary doping with specific solvents or additives can significantly improve charge transport properties. Post-deposition treatments such as thermal annealing, solvent annealing, or acid treatment are also used to optimize the molecular arrangement and increase conductivity by several orders of magnitude.

- Stability and durability improvements for conductive polymer inks: Improving the stability and durability of conductive polymer inks involves incorporating stabilizers, cross-linking agents, and protective additives to enhance resistance against environmental factors such as humidity, UV radiation, and oxidation. Encapsulation techniques and barrier materials are used to protect the conductive layers from degradation. These improvements extend the functional lifetime of printed electronic devices and maintain consistent electrical performance under various operating conditions and environmental stresses.

02 Nanoparticle-enhanced conductive polymer inks

Incorporating conductive nanoparticles such as carbon nanotubes, graphene, or metal nanoparticles into polymer matrices significantly enhances the electrical conductivity of the ink. These hybrid formulations combine the flexibility and processability of polymers with the superior conductivity of nanomaterials. The synergistic effect results in inks with improved performance for applications requiring high conductivity while maintaining the advantages of polymer-based systems.Expand Specific Solutions03 Processing techniques for conductive polymer inks

Various processing techniques can be employed to optimize the performance of conductive polymer inks, including solvent selection, curing methods, and post-deposition treatments. Techniques such as thermal annealing, UV curing, or chemical treatments can significantly enhance conductivity by improving polymer chain alignment or removing insulating components. The viscosity and surface tension of the ink can be tailored for specific deposition methods like screen printing, inkjet printing, or roll-to-roll processing.Expand Specific Solutions04 Environmental stability and durability enhancements

Formulations that improve the environmental stability and durability of conductive polymer inks are crucial for commercial applications. Additives such as stabilizers, cross-linking agents, and encapsulants can protect the conductive polymers from degradation due to oxygen, moisture, UV light, and mechanical stress. These enhancements extend the functional lifetime of printed electronic components and enable their use in more demanding environments.Expand Specific Solutions05 Application-specific conductive polymer ink formulations

Specialized conductive polymer ink formulations can be tailored for specific applications such as transparent electrodes, electromagnetic shielding, antistatic coatings, or biomedical devices. These formulations balance conductivity requirements with other properties like transparency, flexibility, biocompatibility, or adhesion to specific substrates. The composition can be optimized to meet the unique demands of each application while maintaining processability and cost-effectiveness.Expand Specific Solutions

Key Industry Players in Conductive Polymer Ink Development

Conductive polymer inks for flexible electronics are currently in a growth phase, with the market expanding rapidly due to increasing demand for wearable technology, IoT devices, and printed electronics. The global market size is projected to reach significant value by 2030, driven by applications in consumer electronics, automotive, and healthcare sectors. Technologically, the field is advancing from early commercial adoption toward maturity, with companies like Henkel AG, DuPont, and LG Chem leading commercial development. Research institutions including Karlsruher Institut für Technologie and South China University of Technology are pushing boundaries in material science, while specialized players like Nanotech Energy and InkTec focus on niche applications. The ecosystem shows a balance between established chemical companies diversifying into this space and specialized startups developing proprietary formulations.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed LOCTITE ECI 8000 series, a portfolio of conductive polymer inks specifically designed for flexible electronics applications. These inks utilize a proprietary blend of conductive polymers (primarily PEDOT:PSS) modified with silver nanoparticles to enhance conductivity while maintaining flexibility. The formulation includes specialized additives that improve adhesion to various substrates including PET, TPU, and polyimide films. Henkel's technology enables printing at temperatures as low as 80°C, making it compatible with heat-sensitive substrates. Their inks achieve sheet resistance values of 10-50 ohms/square with stretchability up to 100% strain without significant conductivity loss. The company has also developed a patented encapsulation technology that enhances the environmental stability of their conductive polymer inks, providing resistance to humidity and oxidation for extended product lifetimes in wearable applications.

Strengths: Superior flexibility and stretchability compared to traditional silver inks; excellent adhesion to multiple substrates; low temperature processing capability; good environmental stability. Weaknesses: Lower conductivity compared to pure metal-based inks; higher cost than conventional carbon-based inks; limited shelf life requiring refrigerated storage.

Wacker Chemie AG

Technical Solution: Wacker Chemie has pioneered ELASTOSIL® Film, a silicone-based platform for conductive polymer ink integration in flexible electronics. Their approach combines silicone elastomers with specially formulated conductive polymers to create ultra-stretchable electronic circuits. The technology utilizes a proprietary cross-linking mechanism that maintains electrical conductivity even under extreme deformation (up to 300% strain). Wacker's formulation includes specialized silicone-compatible surfactants that enable homogeneous dispersion of conductive polymers within the silicone matrix. Their manufacturing process employs screen printing techniques followed by a rapid thermal curing step at moderate temperatures (120-150°C). The resulting films exhibit excellent adhesion between the conductive layers and silicone substrate, with minimal delamination during repeated stretching cycles. Wacker has also developed specialized encapsulation materials that protect the conductive traces from environmental factors while maintaining the overall flexibility of the system.

Strengths: Exceptional stretchability and durability; excellent chemical resistance; good thermal stability; compatible with existing screen printing processes. Weaknesses: Higher material costs compared to conventional polymer substrates; specialized processing equipment required; limited electrical conductivity compared to metal-based alternatives.

Core Patents and Innovations in Conductive Polymer Formulations

Flexible aqueous soluble conductive polymer compositions

PatentInactiveUS20110309305A1

Innovation

- A conductive, flexible polymer composition is formed by blending an electrically conductive polymer mixture with a peelable polymer blend, comprising a water-soluble polymer, polyoxyalkene polymer, and alkyl glycol, which synergistically enhances electrical conductivity, flexibility, peelability, and scratch resistance when dried.

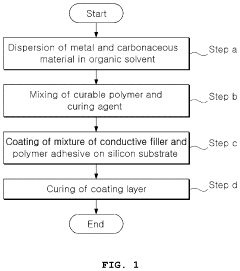

Conductive polymer composite for adhesion to flexible substrate and method for preparing same

PatentActiveUS11866623B2

Innovation

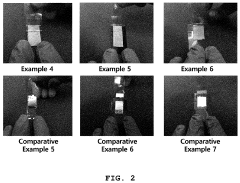

- A conductive polymer composite is developed, comprising a polymer adhesive with a curable polymer and curing agent, and a conductive filler of metal and carbonaceous materials, specifically silver and multi-walled carbon nanotubes, which is formulated to provide improved adhesion, flexibility, and stretchability on flexible substrates.

Manufacturing Scalability and Process Integration

The scalability of conductive polymer ink manufacturing represents a critical challenge for the widespread adoption of flexible electronics technologies. Current laboratory-scale production methods often fail to translate effectively to industrial-scale manufacturing, creating a significant bottleneck in commercialization efforts. Batch-to-batch consistency remains problematic, with variations in viscosity, particle size distribution, and conductivity properties occurring when production volumes increase.

Integration of conductive polymer ink processes into existing electronics manufacturing lines presents additional complexities. Traditional electronics manufacturing relies on high-temperature processes incompatible with many flexible substrates, necessitating the development of low-temperature curing methods. Roll-to-roll (R2R) processing shows particular promise, enabling continuous production of flexible electronic components at high throughput rates, though challenges in registration accuracy and pattern resolution persist.

Equipment compatibility issues further complicate manufacturing scale-up. Specialized printing equipment designed for conductive polymer inks must interface seamlessly with existing production infrastructure. Modifications to standard screen printing, inkjet printing, and gravure printing equipment are often necessary to accommodate the unique rheological properties of conductive polymer formulations.

Quality control methodologies require significant adaptation when transitioning from laboratory to industrial production. In-line monitoring systems capable of detecting conductivity variations, adhesion failures, and mechanical integrity issues must be implemented to ensure consistent product performance. Current inspection technologies struggle to identify subtle defects that may impact long-term reliability of flexible electronic components.

Cost considerations heavily influence manufacturing scalability decisions. While economies of scale eventually reduce per-unit costs, initial capital investments for specialized equipment and process development remain substantial. Material waste during production scale-up represents another significant cost factor, with optimization of ink deposition processes critical for minimizing expensive conductive material losses.

Environmental and regulatory factors increasingly impact manufacturing decisions. Solvent recovery systems, emission controls, and waste treatment processes must be integrated into production facilities, adding complexity and cost. The development of water-based conductive polymer ink formulations offers a promising direction for addressing these concerns while potentially simplifying certain aspects of the manufacturing process.

Integration of conductive polymer ink processes into existing electronics manufacturing lines presents additional complexities. Traditional electronics manufacturing relies on high-temperature processes incompatible with many flexible substrates, necessitating the development of low-temperature curing methods. Roll-to-roll (R2R) processing shows particular promise, enabling continuous production of flexible electronic components at high throughput rates, though challenges in registration accuracy and pattern resolution persist.

Equipment compatibility issues further complicate manufacturing scale-up. Specialized printing equipment designed for conductive polymer inks must interface seamlessly with existing production infrastructure. Modifications to standard screen printing, inkjet printing, and gravure printing equipment are often necessary to accommodate the unique rheological properties of conductive polymer formulations.

Quality control methodologies require significant adaptation when transitioning from laboratory to industrial production. In-line monitoring systems capable of detecting conductivity variations, adhesion failures, and mechanical integrity issues must be implemented to ensure consistent product performance. Current inspection technologies struggle to identify subtle defects that may impact long-term reliability of flexible electronic components.

Cost considerations heavily influence manufacturing scalability decisions. While economies of scale eventually reduce per-unit costs, initial capital investments for specialized equipment and process development remain substantial. Material waste during production scale-up represents another significant cost factor, with optimization of ink deposition processes critical for minimizing expensive conductive material losses.

Environmental and regulatory factors increasingly impact manufacturing decisions. Solvent recovery systems, emission controls, and waste treatment processes must be integrated into production facilities, adding complexity and cost. The development of water-based conductive polymer ink formulations offers a promising direction for addressing these concerns while potentially simplifying certain aspects of the manufacturing process.

Environmental Impact and Sustainability Considerations

The environmental implications of conductive polymer inks in flexible electronics represent a critical consideration as this technology advances toward widespread commercial adoption. Traditional electronic manufacturing processes often involve hazardous materials and energy-intensive procedures that generate substantial waste. Conductive polymer inks offer promising alternatives with potentially reduced environmental footprints, though several aspects require careful assessment.

Production of conductive polymer inks typically involves fewer toxic chemicals compared to conventional metal-based conductive materials. Many polymer formulations utilize water-based systems rather than volatile organic compounds (VOCs), significantly reducing harmful emissions during manufacturing and application processes. This characteristic aligns with increasingly stringent environmental regulations worldwide and addresses growing consumer demand for greener electronics.

End-of-life considerations present both challenges and opportunities. Flexible electronics incorporating conductive polymer inks may facilitate more efficient recycling processes compared to rigid conventional electronics. The potential for biodegradable or compostable substrates paired with environmentally benign conductive polymers could revolutionize electronic waste management. However, current recycling infrastructure remains largely unprepared for processing these novel materials, creating a temporary gap in sustainable disposal options.

Energy consumption represents another critical sustainability factor. Printing techniques used to deposit conductive polymer inks typically operate at lower temperatures than traditional metal deposition methods, potentially reducing energy requirements during manufacturing. Additionally, roll-to-roll processing enabled by these materials offers significant efficiency improvements over batch processing methods, further reducing the carbon footprint of electronic device production.

Resource utilization efficiency merits particular attention. While conductive polymers reduce dependence on rare or precious metals like silver and gold, they often incorporate other materials that may face supply constraints. Developing formulations that maximize conductivity while minimizing resource-intensive components remains an active research priority. Circular economy approaches, including recovery and reuse of polymer materials, show promise for addressing these concerns.

Lifecycle assessment studies indicate that flexible electronics using conductive polymer inks may achieve carbon footprint reductions of 30-60% compared to conventional rigid electronics, depending on specific applications and manufacturing processes. However, these assessments must consider the potentially shorter operational lifespan of some flexible devices, which could offset initial environmental gains if replacement cycles accelerate.

Production of conductive polymer inks typically involves fewer toxic chemicals compared to conventional metal-based conductive materials. Many polymer formulations utilize water-based systems rather than volatile organic compounds (VOCs), significantly reducing harmful emissions during manufacturing and application processes. This characteristic aligns with increasingly stringent environmental regulations worldwide and addresses growing consumer demand for greener electronics.

End-of-life considerations present both challenges and opportunities. Flexible electronics incorporating conductive polymer inks may facilitate more efficient recycling processes compared to rigid conventional electronics. The potential for biodegradable or compostable substrates paired with environmentally benign conductive polymers could revolutionize electronic waste management. However, current recycling infrastructure remains largely unprepared for processing these novel materials, creating a temporary gap in sustainable disposal options.

Energy consumption represents another critical sustainability factor. Printing techniques used to deposit conductive polymer inks typically operate at lower temperatures than traditional metal deposition methods, potentially reducing energy requirements during manufacturing. Additionally, roll-to-roll processing enabled by these materials offers significant efficiency improvements over batch processing methods, further reducing the carbon footprint of electronic device production.

Resource utilization efficiency merits particular attention. While conductive polymers reduce dependence on rare or precious metals like silver and gold, they often incorporate other materials that may face supply constraints. Developing formulations that maximize conductivity while minimizing resource-intensive components remains an active research priority. Circular economy approaches, including recovery and reuse of polymer materials, show promise for addressing these concerns.

Lifecycle assessment studies indicate that flexible electronics using conductive polymer inks may achieve carbon footprint reductions of 30-60% compared to conventional rigid electronics, depending on specific applications and manufacturing processes. However, these assessments must consider the potentially shorter operational lifespan of some flexible devices, which could offset initial environmental gains if replacement cycles accelerate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!