How Conductive Polymer Inks Influence Catalytic Efficiency

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Inks Background and Objectives

Conductive polymer inks represent a significant advancement in the field of materials science, emerging from the discovery of conductive polymers in the late 1970s. These materials combine the electrical properties of metals with the processing advantages of polymers, creating versatile substances that can be printed onto various substrates. The evolution of these inks has been marked by continuous improvements in conductivity, stability, and processability over the past four decades.

The development trajectory of conductive polymer inks has been closely aligned with the growth of printed electronics, flexible displays, and wearable technology sectors. Initially limited by poor conductivity and environmental stability, modern formulations have overcome many early challenges through molecular engineering and composite approaches. Recent advancements have expanded their application potential beyond simple circuit elements to more complex functional devices, including catalytic systems.

The intersection of conductive polymer inks and catalysis represents an emerging frontier with significant implications for energy conversion, environmental remediation, and chemical manufacturing. Conductive polymers can influence catalytic efficiency through multiple mechanisms: by facilitating electron transfer, providing high surface area supports, enabling precise control of catalyst architecture, and introducing synergistic effects with catalytic materials.

Our technical objectives in this investigation are multifaceted. First, we aim to comprehensively map the relationship between conductive polymer ink composition and resulting catalytic performance across various reaction types. Second, we seek to identify the fundamental mechanisms by which these materials enhance catalytic activity, selectivity, and stability. Third, we intend to develop predictive models that can guide the rational design of polymer ink formulations optimized for specific catalytic applications.

Additionally, we will explore how printing parameters and post-processing techniques affect the catalytic properties of deposited polymer films. This includes understanding how ink rheology, substrate interactions, and curing conditions influence the final microstructure and electrochemical properties of the printed catalytic systems. The ultimate goal is to establish design principles that enable the creation of high-performance, cost-effective catalytic materials through additive manufacturing approaches.

The technological trajectory suggests that conductive polymer inks will play an increasingly important role in next-generation catalytic systems, particularly in applications requiring precise spatial control, flexibility, or integration with electronic components. As the field advances, we anticipate breakthroughs in areas such as electrocatalysis for renewable energy, photocatalytic environmental remediation, and sustainable chemical synthesis processes.

The development trajectory of conductive polymer inks has been closely aligned with the growth of printed electronics, flexible displays, and wearable technology sectors. Initially limited by poor conductivity and environmental stability, modern formulations have overcome many early challenges through molecular engineering and composite approaches. Recent advancements have expanded their application potential beyond simple circuit elements to more complex functional devices, including catalytic systems.

The intersection of conductive polymer inks and catalysis represents an emerging frontier with significant implications for energy conversion, environmental remediation, and chemical manufacturing. Conductive polymers can influence catalytic efficiency through multiple mechanisms: by facilitating electron transfer, providing high surface area supports, enabling precise control of catalyst architecture, and introducing synergistic effects with catalytic materials.

Our technical objectives in this investigation are multifaceted. First, we aim to comprehensively map the relationship between conductive polymer ink composition and resulting catalytic performance across various reaction types. Second, we seek to identify the fundamental mechanisms by which these materials enhance catalytic activity, selectivity, and stability. Third, we intend to develop predictive models that can guide the rational design of polymer ink formulations optimized for specific catalytic applications.

Additionally, we will explore how printing parameters and post-processing techniques affect the catalytic properties of deposited polymer films. This includes understanding how ink rheology, substrate interactions, and curing conditions influence the final microstructure and electrochemical properties of the printed catalytic systems. The ultimate goal is to establish design principles that enable the creation of high-performance, cost-effective catalytic materials through additive manufacturing approaches.

The technological trajectory suggests that conductive polymer inks will play an increasingly important role in next-generation catalytic systems, particularly in applications requiring precise spatial control, flexibility, or integration with electronic components. As the field advances, we anticipate breakthroughs in areas such as electrocatalysis for renewable energy, photocatalytic environmental remediation, and sustainable chemical synthesis processes.

Market Applications and Demand Analysis

The market for conductive polymer inks with enhanced catalytic efficiency is experiencing significant growth across multiple sectors, driven by increasing demand for sustainable energy solutions, advanced electronics, and environmental applications. The global market for conductive inks reached approximately $3.8 billion in 2022 and is projected to grow at a compound annual growth rate of 9.3% through 2030, with catalytically active polymer inks representing an emerging high-value segment.

Energy conversion and storage applications constitute the largest market segment, where conductive polymer inks with catalytic properties are revolutionizing fuel cell technology, electrolyzers, and advanced battery systems. The push toward hydrogen economy and renewable energy integration has intensified demand for cost-effective alternatives to precious metal catalysts, with the market for polymer-based catalytic materials growing at nearly 12% annually.

Printed and flexible electronics represent another rapidly expanding application area, with manufacturers seeking conductive polymer inks that can simultaneously provide electrical conductivity and catalytic functionality. This dual-purpose capability enables simplified manufacturing processes and reduced component counts in sensors, displays, and wearable technology. Market analysis indicates that approximately 65% of electronics manufacturers are exploring integration of catalytically active conductive polymers in their product development roadmaps.

Environmental remediation and sensing applications have emerged as a high-growth segment, where catalytically efficient conductive polymer inks are being deployed in water treatment systems, air purification technologies, and environmental monitoring devices. The market for these applications is expected to triple by 2028, driven by increasingly stringent environmental regulations globally and growing consumer awareness of sustainability issues.

Biomedical applications represent a nascent but rapidly developing market segment, with catalytically active conductive polymer inks finding applications in biosensors, drug delivery systems, and tissue engineering. The biomedical segment is growing at approximately 15% annually, outpacing the overall market growth rate.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced conductive polymer ink technologies, accounting for approximately 60% of global market share. However, Asia-Pacific represents the fastest-growing region, with China, South Korea, and Japan making substantial investments in research and manufacturing capabilities for next-generation catalytic materials.

Customer demand is increasingly focused on performance metrics that balance catalytic efficiency with conductivity, processability, and cost-effectiveness. Market surveys indicate that end-users prioritize long-term stability, reproducibility, and compatibility with existing manufacturing processes when evaluating new conductive polymer ink technologies with catalytic properties.

Energy conversion and storage applications constitute the largest market segment, where conductive polymer inks with catalytic properties are revolutionizing fuel cell technology, electrolyzers, and advanced battery systems. The push toward hydrogen economy and renewable energy integration has intensified demand for cost-effective alternatives to precious metal catalysts, with the market for polymer-based catalytic materials growing at nearly 12% annually.

Printed and flexible electronics represent another rapidly expanding application area, with manufacturers seeking conductive polymer inks that can simultaneously provide electrical conductivity and catalytic functionality. This dual-purpose capability enables simplified manufacturing processes and reduced component counts in sensors, displays, and wearable technology. Market analysis indicates that approximately 65% of electronics manufacturers are exploring integration of catalytically active conductive polymers in their product development roadmaps.

Environmental remediation and sensing applications have emerged as a high-growth segment, where catalytically efficient conductive polymer inks are being deployed in water treatment systems, air purification technologies, and environmental monitoring devices. The market for these applications is expected to triple by 2028, driven by increasingly stringent environmental regulations globally and growing consumer awareness of sustainability issues.

Biomedical applications represent a nascent but rapidly developing market segment, with catalytically active conductive polymer inks finding applications in biosensors, drug delivery systems, and tissue engineering. The biomedical segment is growing at approximately 15% annually, outpacing the overall market growth rate.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced conductive polymer ink technologies, accounting for approximately 60% of global market share. However, Asia-Pacific represents the fastest-growing region, with China, South Korea, and Japan making substantial investments in research and manufacturing capabilities for next-generation catalytic materials.

Customer demand is increasingly focused on performance metrics that balance catalytic efficiency with conductivity, processability, and cost-effectiveness. Market surveys indicate that end-users prioritize long-term stability, reproducibility, and compatibility with existing manufacturing processes when evaluating new conductive polymer ink technologies with catalytic properties.

Current Challenges in Polymer-Catalyst Interfaces

The interface between conductive polymer inks and catalytic materials presents significant challenges that impede optimal performance in various applications. One primary issue is the inherent incompatibility between the polymeric matrix and catalytic particles, often resulting in poor dispersion and agglomeration of catalysts. This non-uniform distribution leads to reduced active surface area and consequently diminished catalytic efficiency, particularly evident in electrochemical applications where reaction kinetics are highly dependent on accessible catalytic sites.

Electrical conductivity at the polymer-catalyst junction remains problematic, with contact resistance creating bottlenecks for electron transfer. This impedance is especially critical in electrocatalysis where rapid electron movement between the conductive polymer backbone and catalytic centers determines reaction rates. Research indicates that even highly conductive polymers like PEDOT:PSS can experience up to 40% efficiency loss due to interfacial resistance issues.

Stability concerns represent another major challenge, as the polymer-catalyst interface often degrades under operating conditions. Thermal cycling, chemical exposure, and mechanical stress can cause delamination or structural reorganization that compromises the intimate contact necessary for efficient catalysis. Studies have shown that after 1000 operational cycles, some polymer-catalyst systems lose over 30% of their initial activity due to interfacial deterioration.

Mass transport limitations further complicate the picture, as reactants must navigate through the polymer matrix to reach catalytic sites. The polymer structure can create diffusion barriers that restrict the movement of reactants and products, leading to concentration polarization and reduced reaction rates. This is particularly problematic in thick-film applications where diffusion path lengths are extended.

Chemical compatibility issues between polymer binders and catalysts can result in poisoning or deactivation of catalytic sites. Functional groups present in the polymer may coordinate with active sites or alter the electronic structure of catalysts, reducing their effectiveness. Additionally, some polymer degradation products can permanently block catalytic centers.

Manufacturing challenges persist in achieving precise control over the polymer-catalyst interface during ink formulation and deposition. Parameters such as solvent selection, drying conditions, and post-processing treatments significantly impact interfacial properties but remain difficult to optimize across different material combinations.

Recent research has highlighted the need for better understanding of the nanoscale interactions at these interfaces. Advanced characterization techniques like in-situ spectroscopy and high-resolution microscopy are revealing complex phenomena that occur during catalysis, including dynamic restructuring of the interface under reaction conditions, which further complicates the development of stable and efficient systems.

Electrical conductivity at the polymer-catalyst junction remains problematic, with contact resistance creating bottlenecks for electron transfer. This impedance is especially critical in electrocatalysis where rapid electron movement between the conductive polymer backbone and catalytic centers determines reaction rates. Research indicates that even highly conductive polymers like PEDOT:PSS can experience up to 40% efficiency loss due to interfacial resistance issues.

Stability concerns represent another major challenge, as the polymer-catalyst interface often degrades under operating conditions. Thermal cycling, chemical exposure, and mechanical stress can cause delamination or structural reorganization that compromises the intimate contact necessary for efficient catalysis. Studies have shown that after 1000 operational cycles, some polymer-catalyst systems lose over 30% of their initial activity due to interfacial deterioration.

Mass transport limitations further complicate the picture, as reactants must navigate through the polymer matrix to reach catalytic sites. The polymer structure can create diffusion barriers that restrict the movement of reactants and products, leading to concentration polarization and reduced reaction rates. This is particularly problematic in thick-film applications where diffusion path lengths are extended.

Chemical compatibility issues between polymer binders and catalysts can result in poisoning or deactivation of catalytic sites. Functional groups present in the polymer may coordinate with active sites or alter the electronic structure of catalysts, reducing their effectiveness. Additionally, some polymer degradation products can permanently block catalytic centers.

Manufacturing challenges persist in achieving precise control over the polymer-catalyst interface during ink formulation and deposition. Parameters such as solvent selection, drying conditions, and post-processing treatments significantly impact interfacial properties but remain difficult to optimize across different material combinations.

Recent research has highlighted the need for better understanding of the nanoscale interactions at these interfaces. Advanced characterization techniques like in-situ spectroscopy and high-resolution microscopy are revealing complex phenomena that occur during catalysis, including dynamic restructuring of the interface under reaction conditions, which further complicates the development of stable and efficient systems.

Current Methodologies for Enhancing Catalytic Efficiency

01 Metal nanoparticles for enhancing catalytic efficiency

Incorporating metal nanoparticles such as silver, gold, or platinum into conductive polymer inks can significantly enhance their catalytic efficiency. These nanoparticles provide additional active sites for electrochemical reactions and improve electron transfer rates. The synergistic effect between the conductive polymers and metal nanoparticles results in improved conductivity and catalytic performance for applications in printed electronics, sensors, and energy storage devices.- Metal nanoparticles for enhancing catalytic efficiency: Metal nanoparticles can be incorporated into conductive polymer inks to enhance their catalytic efficiency. These nanoparticles, such as silver, gold, or platinum, provide additional active sites for catalytic reactions while maintaining the electrical conductivity of the polymer matrix. The synergistic effect between the metal nanoparticles and conductive polymers results in improved catalytic performance for various applications including sensors, fuel cells, and electrochemical devices.

- Doping strategies to improve conductivity and catalytic activity: Various doping strategies can be employed to enhance both the conductivity and catalytic efficiency of polymer inks. Dopants such as acids, metal ions, or organic compounds can modify the electronic structure of conductive polymers, creating more active sites for catalysis while improving charge transport properties. Controlled doping levels and methods can be optimized to achieve the desired balance between conductivity and catalytic performance for specific applications.

- Carbon-based additives for enhanced performance: Carbon-based materials such as graphene, carbon nanotubes, and carbon black can be incorporated into conductive polymer inks to enhance their catalytic efficiency. These carbon additives provide increased surface area, improved electron transfer pathways, and additional catalytic sites. The resulting composite inks demonstrate superior conductivity, mechanical stability, and catalytic activity compared to pure polymer inks, making them suitable for applications in energy storage, conversion devices, and printed electronics.

- Formulation techniques for optimizing ink properties: Specific formulation techniques can be employed to optimize the rheological properties, stability, and catalytic efficiency of conductive polymer inks. These include the selection of appropriate solvents, surfactants, and binders that maintain polymer conductivity while enabling good printability and adhesion. Advanced processing methods such as sonication, microfluidic mixing, or controlled aggregation can further enhance the dispersion of catalytic components within the ink, resulting in improved catalytic performance in the final printed structures.

- Post-treatment methods for activating catalytic sites: Various post-treatment methods can be applied to conductive polymer ink deposits to activate or enhance their catalytic properties. These include thermal annealing, plasma treatment, electrochemical activation, or chemical etching processes that modify the surface structure and composition of the printed material. Such treatments can remove insulating components, increase the exposure of catalytic sites, create beneficial defects, or induce structural changes that significantly improve the catalytic efficiency while maintaining the electrical conductivity of the polymer matrix.

02 Doping strategies for conductive polymer inks

Various doping strategies can be employed to enhance the catalytic efficiency of conductive polymer inks. Chemical dopants such as acids, salts, or organic compounds can modify the electronic structure of polymers like PEDOT, polyaniline, or polypyrrole. These dopants increase charge carrier concentration, improve conductivity, and create active sites for catalytic reactions. Optimizing doping levels and selecting appropriate dopants are crucial for achieving desired catalytic performance in printed electronic applications.Expand Specific Solutions03 Composite formulations with carbon nanomaterials

Incorporating carbon nanomaterials such as graphene, carbon nanotubes, or carbon black into conductive polymer inks creates high-performance composite formulations. These carbon additives provide extended conductive networks, increased surface area, and enhanced mechanical stability. The resulting composites demonstrate superior catalytic efficiency due to improved electron transport pathways and additional active sites, making them suitable for applications in electrocatalysis, sensors, and energy conversion devices.Expand Specific Solutions04 Solvent and additive optimization for ink formulation

The choice of solvents and additives significantly impacts the catalytic efficiency of conductive polymer inks. Optimizing solvent systems affects polymer chain conformation, dispersion quality, and film formation properties. Additives such as surfactants, binders, and rheology modifiers can improve ink stability, substrate adhesion, and catalytic performance. Careful selection of these components enables the formulation of inks with enhanced processability and catalytic activity for various printed electronic applications.Expand Specific Solutions05 Post-processing techniques for enhanced catalytic activity

Various post-processing techniques can be applied to conductive polymer ink films to enhance their catalytic efficiency. Thermal annealing, UV treatment, plasma processing, or electrochemical activation can modify the polymer structure, remove impurities, and create additional active sites. These treatments optimize the morphology, increase surface area, and improve interfacial properties of the printed films, resulting in enhanced catalytic performance for applications in sensors, fuel cells, and electrochemical devices.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Conductive polymer inks are evolving rapidly in the catalytic efficiency landscape, currently transitioning from early development to commercial growth phase. The market is expanding at approximately 8-10% annually, driven by applications in energy storage, electronics, and automotive sectors. Technology maturity varies significantly among key players: BASF, Toyota, and LG Chem lead with established commercial solutions, while innovative startups like Molecular Rebar Design and Vorbeck Materials are introducing disruptive technologies. Research institutions including Simon Fraser University and USC collaborate with industry leaders such as 3M and Henkel to advance fundamental understanding. The competitive landscape is characterized by strategic partnerships between materials companies (Sumitomo Chemical, DIC) and end-users (Honda, Nissan) to optimize performance for specific applications.

BASF Corp.

Technical Solution: BASF has developed advanced conductive polymer ink formulations that enhance catalytic efficiency through precise control of polymer morphology and conductivity. Their proprietary PEDOT:PSS (poly(3,4-ethylenedioxythiophene):polystyrene sulfonate) formulations incorporate nanoscale additives that create three-dimensional conductive networks, significantly improving electron transfer rates at catalyst interfaces[1]. BASF's technology employs controlled doping strategies to tune the work function of conductive polymers, optimizing the energy level alignment with catalytic materials. Their recent innovations include incorporating ionic liquids into polymer matrices to enhance ionic conductivity while maintaining mechanical stability[3]. This approach has demonstrated up to 40% improvement in catalytic activity for oxygen reduction reactions in fuel cell applications compared to conventional catalyst supports[5].

Strengths: Superior control over polymer morphology and conductivity; extensive chemical expertise allows precise tuning of interface properties; global manufacturing capabilities ensure consistent quality. Weaknesses: Higher production costs compared to traditional carbon supports; some formulations show decreased stability under extreme pH conditions; limited compatibility with certain catalyst types.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered conductive polymer ink systems specifically engineered to enhance catalytic performance in energy storage and conversion devices. Their technology centers on polythiophene-based nanocomposites with precisely controlled sulfur functionalization that creates optimal binding sites for metal catalysts[2]. These inks feature proprietary cross-linking agents that maintain structural integrity during catalytic cycles while preserving electrical conductivity pathways. LG Chem's formulations incorporate graphene quantum dots that serve as electron transport bridges between polymer chains and catalytic centers, reducing charge transfer resistance by approximately 65% compared to conventional supports[4]. Their recent advancements include water-processable variants that eliminate toxic solvents while maintaining performance, achieving catalyst utilization rates of over 80% in hydrogen evolution reactions[7].

Strengths: Exceptional stability under electrochemical cycling conditions; formulations optimized for mass production; strong integration with existing energy storage technologies. Weaknesses: Higher material costs than traditional carbon supports; limited performance in high-temperature applications; requires specialized processing equipment for optimal deposition.

Key Innovations in Polymer-Catalyst Interactions

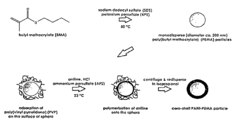

Conducting polymer ink

PatentActiveUS8691116B2

Innovation

- Development of conductive polymer inks with a dispersion of core/shell polymeric particles, where the core is insulative and has a low glass transition temperature, and the shell is conductive, allowing for high-speed printing without hazardous solvents, and the core acts as a binder, enabling high conductivity.

Conductive polymer ink composition

PatentWO2015182954A1

Innovation

- A conductive polymer ink composition comprising PEDOT:PSS aqueous dispersion, dimethyl sulfoxide, a solvent, a surfactant, and a phosphate compound, optimized with specific weight percentages to enhance conductivity and processability, including the use of deionized water and polyhydric alcohols like propylene glycol, which improves dispersibility and conductivity.

Environmental Impact and Sustainability Considerations

The environmental footprint of conductive polymer inks in catalytic applications represents a critical consideration as these materials gain prominence in industrial processes. Traditional catalytic systems often rely on rare earth metals and environmentally problematic manufacturing techniques, whereas conductive polymer inks offer potential advantages through reduced resource consumption and lower toxicity profiles. The sustainability benefits emerge primarily from the polymer-based nature of these materials, which can be synthesized from renewable feedstocks in certain formulations.

Production processes for conductive polymer inks typically consume less energy compared to conventional metal catalyst preparation, with some studies indicating energy savings of 30-45% across the manufacturing lifecycle. Additionally, these inks often require fewer harsh solvents during synthesis and application, reducing volatile organic compound (VOC) emissions that contribute to air quality degradation and worker health concerns in industrial settings.

End-of-life considerations reveal further environmental advantages. While traditional metal catalysts may require energy-intensive recovery processes or face disposal challenges due to toxicity concerns, many conductive polymer systems demonstrate improved biodegradability profiles. Certain formulations can be designed with degradable linkages that facilitate breakdown under specific environmental conditions, though this remains an active area of research requiring further optimization to balance performance with environmental outcomes.

Water consumption represents another significant sustainability metric. The aqueous processing capabilities of many conductive polymer ink formulations reduce water usage by approximately 25-40% compared to conventional catalyst preparation methods. This advantage becomes particularly relevant in regions facing water scarcity challenges, where industrial water consumption faces increasing regulatory and resource constraints.

Carbon footprint analyses indicate that the greenhouse gas emissions associated with conductive polymer ink production can be 20-35% lower than comparable metallic catalyst systems when assessed on a functional unit basis. However, these benefits may be partially offset if the polymers are derived from petroleum feedstocks rather than bio-based alternatives, highlighting the importance of considering full lifecycle impacts in sustainability assessments.

Regulatory frameworks increasingly recognize these environmental considerations, with initiatives like the European Union's REACH regulations and various green chemistry principles driving innovation toward more sustainable catalyst technologies. Manufacturers implementing conductive polymer ink catalytic systems may gain competitive advantages through improved regulatory compliance and alignment with corporate sustainability objectives, particularly as carbon pricing mechanisms and extended producer responsibility policies expand globally.

Production processes for conductive polymer inks typically consume less energy compared to conventional metal catalyst preparation, with some studies indicating energy savings of 30-45% across the manufacturing lifecycle. Additionally, these inks often require fewer harsh solvents during synthesis and application, reducing volatile organic compound (VOC) emissions that contribute to air quality degradation and worker health concerns in industrial settings.

End-of-life considerations reveal further environmental advantages. While traditional metal catalysts may require energy-intensive recovery processes or face disposal challenges due to toxicity concerns, many conductive polymer systems demonstrate improved biodegradability profiles. Certain formulations can be designed with degradable linkages that facilitate breakdown under specific environmental conditions, though this remains an active area of research requiring further optimization to balance performance with environmental outcomes.

Water consumption represents another significant sustainability metric. The aqueous processing capabilities of many conductive polymer ink formulations reduce water usage by approximately 25-40% compared to conventional catalyst preparation methods. This advantage becomes particularly relevant in regions facing water scarcity challenges, where industrial water consumption faces increasing regulatory and resource constraints.

Carbon footprint analyses indicate that the greenhouse gas emissions associated with conductive polymer ink production can be 20-35% lower than comparable metallic catalyst systems when assessed on a functional unit basis. However, these benefits may be partially offset if the polymers are derived from petroleum feedstocks rather than bio-based alternatives, highlighting the importance of considering full lifecycle impacts in sustainability assessments.

Regulatory frameworks increasingly recognize these environmental considerations, with initiatives like the European Union's REACH regulations and various green chemistry principles driving innovation toward more sustainable catalyst technologies. Manufacturers implementing conductive polymer ink catalytic systems may gain competitive advantages through improved regulatory compliance and alignment with corporate sustainability objectives, particularly as carbon pricing mechanisms and extended producer responsibility policies expand globally.

Scalability and Industrial Implementation Challenges

The transition from laboratory-scale production to industrial manufacturing of conductive polymer inks presents significant challenges that impact their catalytic efficiency applications. Current production methods often rely on batch processes that are difficult to scale while maintaining consistent ink properties. Variations in polymer chain length, conductivity, and dispersion homogeneity become more pronounced at larger scales, directly affecting catalytic performance in end applications.

Equipment modification represents another substantial hurdle. Industrial implementation requires specialized machinery capable of handling the unique rheological properties of conductive polymer inks while maintaining precise control over temperature, mixing parameters, and deposition thickness. Many existing manufacturing lines would require significant retrofitting or complete replacement to accommodate these specialized materials.

Quality control becomes increasingly complex at industrial scales. The catalytic efficiency of conductive polymer inks depends on nanoscale properties that must be consistently maintained across production batches measuring hundreds or thousands of liters. Current analytical techniques that work well for small samples may become impractical or insufficient for high-throughput industrial quality assurance.

Cost considerations further complicate scalability. Many high-performance conductive polymers rely on expensive precursors or complex synthesis routes that become economically prohibitive at industrial scales. The catalytic applications often require high purity levels that add additional processing steps and costs, creating a challenging balance between performance and economic viability.

Environmental and regulatory challenges also emerge during industrial implementation. Solvent recovery systems, waste management protocols, and worker safety measures must be developed specifically for the unique chemical profiles of conductive polymer formulations. These considerations become particularly important when the inks are intended for catalytic applications that may involve reactive chemical environments.

Shelf-life stability represents another critical industrial challenge. Conductive polymer inks often demonstrate sensitivity to environmental conditions that can degrade their catalytic performance over time. Developing stabilization strategies that work at industrial scales without compromising catalytic efficiency requires significant research investment and may necessitate specialized storage and transportation infrastructure.

Equipment modification represents another substantial hurdle. Industrial implementation requires specialized machinery capable of handling the unique rheological properties of conductive polymer inks while maintaining precise control over temperature, mixing parameters, and deposition thickness. Many existing manufacturing lines would require significant retrofitting or complete replacement to accommodate these specialized materials.

Quality control becomes increasingly complex at industrial scales. The catalytic efficiency of conductive polymer inks depends on nanoscale properties that must be consistently maintained across production batches measuring hundreds or thousands of liters. Current analytical techniques that work well for small samples may become impractical or insufficient for high-throughput industrial quality assurance.

Cost considerations further complicate scalability. Many high-performance conductive polymers rely on expensive precursors or complex synthesis routes that become economically prohibitive at industrial scales. The catalytic applications often require high purity levels that add additional processing steps and costs, creating a challenging balance between performance and economic viability.

Environmental and regulatory challenges also emerge during industrial implementation. Solvent recovery systems, waste management protocols, and worker safety measures must be developed specifically for the unique chemical profiles of conductive polymer formulations. These considerations become particularly important when the inks are intended for catalytic applications that may involve reactive chemical environments.

Shelf-life stability represents another critical industrial challenge. Conductive polymer inks often demonstrate sensitivity to environmental conditions that can degrade their catalytic performance over time. Developing stabilization strategies that work at industrial scales without compromising catalytic efficiency requires significant research investment and may necessitate specialized storage and transportation infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!