What Are the Key Parameters Affecting Conductive Polymer Inks

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Ink Technology Evolution and Objectives

Conductive polymer inks have emerged as a transformative technology in the field of printed electronics over the past three decades. The evolution began in the 1970s with the discovery of conductive polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa, who were later awarded the Nobel Prize in Chemistry in 2000. This groundbreaking work laid the foundation for the development of processable conductive polymers that could be formulated into printable inks.

The 1990s marked a significant advancement with the introduction of water-dispersible conductive polymers, particularly poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), which remains one of the most widely used conductive polymer materials. This period saw the transition from laboratory curiosity to commercial viability, with early applications in antistatic coatings and capacitors.

The 2000s witnessed rapid technological progress driven by the growing demand for flexible electronics. Researchers focused on enhancing conductivity while maintaining solution processability, resulting in conductive polymer inks with conductivities approaching those of conventional metals. This era also saw the development of specialized formulations tailored for various printing techniques, including screen printing, inkjet printing, and gravure printing.

In recent years, the focus has shifted toward addressing key challenges that limit widespread adoption. These include improving environmental stability, reducing production costs, and enhancing compatibility with high-volume manufacturing processes. The integration of nanomaterials such as carbon nanotubes and graphene into polymer matrices has opened new avenues for performance enhancement.

The primary technical objectives in conductive polymer ink development now center on several critical parameters. First, achieving higher electrical conductivity while maintaining mechanical flexibility remains paramount. Second, ensuring long-term stability under various environmental conditions, including humidity, temperature fluctuations, and UV exposure. Third, developing formulations compatible with environmentally friendly solvents to reduce ecological impact.

Additional objectives include improving adhesion to various substrate materials, enhancing printability for high-resolution patterns, and reducing the sintering or curing temperatures required for optimal performance. The ultimate goal is to create conductive polymer ink systems that can serve as viable alternatives to traditional metal-based conductors in a wide range of applications, from wearable electronics and biomedical devices to large-area sensors and photovoltaics.

The trajectory of conductive polymer ink technology points toward increasingly specialized formulations designed for specific applications and manufacturing processes, with growing emphasis on sustainability and integration with emerging technologies such as 3D printing and Internet of Things (IoT) devices.

The 1990s marked a significant advancement with the introduction of water-dispersible conductive polymers, particularly poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), which remains one of the most widely used conductive polymer materials. This period saw the transition from laboratory curiosity to commercial viability, with early applications in antistatic coatings and capacitors.

The 2000s witnessed rapid technological progress driven by the growing demand for flexible electronics. Researchers focused on enhancing conductivity while maintaining solution processability, resulting in conductive polymer inks with conductivities approaching those of conventional metals. This era also saw the development of specialized formulations tailored for various printing techniques, including screen printing, inkjet printing, and gravure printing.

In recent years, the focus has shifted toward addressing key challenges that limit widespread adoption. These include improving environmental stability, reducing production costs, and enhancing compatibility with high-volume manufacturing processes. The integration of nanomaterials such as carbon nanotubes and graphene into polymer matrices has opened new avenues for performance enhancement.

The primary technical objectives in conductive polymer ink development now center on several critical parameters. First, achieving higher electrical conductivity while maintaining mechanical flexibility remains paramount. Second, ensuring long-term stability under various environmental conditions, including humidity, temperature fluctuations, and UV exposure. Third, developing formulations compatible with environmentally friendly solvents to reduce ecological impact.

Additional objectives include improving adhesion to various substrate materials, enhancing printability for high-resolution patterns, and reducing the sintering or curing temperatures required for optimal performance. The ultimate goal is to create conductive polymer ink systems that can serve as viable alternatives to traditional metal-based conductors in a wide range of applications, from wearable electronics and biomedical devices to large-area sensors and photovoltaics.

The trajectory of conductive polymer ink technology points toward increasingly specialized formulations designed for specific applications and manufacturing processes, with growing emphasis on sustainability and integration with emerging technologies such as 3D printing and Internet of Things (IoT) devices.

Market Applications and Demand Analysis for Conductive Polymer Inks

The global market for conductive polymer inks has witnessed substantial growth in recent years, driven primarily by the expanding electronics industry and the increasing demand for flexible, lightweight, and cost-effective electronic components. The market value for conductive polymer inks reached approximately $3.1 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028, reflecting the strong market demand across various industries.

Printed electronics represents the largest application segment for conductive polymer inks, accounting for nearly 45% of the total market share. This includes applications in RFID tags, smart packaging, and flexible displays. The ability of conductive polymer inks to be printed on various substrates, including paper, plastic, and textiles, has significantly expanded their application potential beyond traditional electronic manufacturing processes.

The healthcare sector has emerged as a rapidly growing market for conductive polymer inks, particularly in biosensors and wearable medical devices. The global market for medical wearables utilizing conductive polymer technology is expected to reach $19.5 billion by 2026, driven by increasing healthcare digitization and remote patient monitoring trends. Conductive polymer inks enable the development of flexible, skin-compatible sensors that can monitor vital signs continuously without causing discomfort to patients.

Automotive applications represent another significant growth area, with conductive polymer inks being increasingly used in touch panels, heating elements, and sensors within vehicles. The automotive industry's shift toward electric vehicles and advanced driver-assistance systems has further accelerated the demand for lightweight, space-efficient electronic components that can be manufactured using conductive polymer inks.

Energy storage applications, particularly in printed batteries and supercapacitors, have shown promising growth potential. The market for printed energy storage devices is projected to grow at 22% annually through 2027, with conductive polymer inks playing a crucial role in enabling flexible and thin-form-factor energy storage solutions.

Regional analysis indicates that Asia-Pacific dominates the conductive polymer inks market, accounting for approximately 42% of global consumption, followed by North America and Europe. China, South Korea, and Japan are the leading consumers within the Asia-Pacific region, primarily due to their robust electronics manufacturing ecosystems.

Consumer demand trends indicate a growing preference for sustainable and environmentally friendly electronic components, creating opportunities for water-based conductive polymer formulations. Additionally, the increasing adoption of Internet of Things (IoT) devices across industrial and consumer applications is expected to create sustained demand for conductive polymer inks in the coming years.

Printed electronics represents the largest application segment for conductive polymer inks, accounting for nearly 45% of the total market share. This includes applications in RFID tags, smart packaging, and flexible displays. The ability of conductive polymer inks to be printed on various substrates, including paper, plastic, and textiles, has significantly expanded their application potential beyond traditional electronic manufacturing processes.

The healthcare sector has emerged as a rapidly growing market for conductive polymer inks, particularly in biosensors and wearable medical devices. The global market for medical wearables utilizing conductive polymer technology is expected to reach $19.5 billion by 2026, driven by increasing healthcare digitization and remote patient monitoring trends. Conductive polymer inks enable the development of flexible, skin-compatible sensors that can monitor vital signs continuously without causing discomfort to patients.

Automotive applications represent another significant growth area, with conductive polymer inks being increasingly used in touch panels, heating elements, and sensors within vehicles. The automotive industry's shift toward electric vehicles and advanced driver-assistance systems has further accelerated the demand for lightweight, space-efficient electronic components that can be manufactured using conductive polymer inks.

Energy storage applications, particularly in printed batteries and supercapacitors, have shown promising growth potential. The market for printed energy storage devices is projected to grow at 22% annually through 2027, with conductive polymer inks playing a crucial role in enabling flexible and thin-form-factor energy storage solutions.

Regional analysis indicates that Asia-Pacific dominates the conductive polymer inks market, accounting for approximately 42% of global consumption, followed by North America and Europe. China, South Korea, and Japan are the leading consumers within the Asia-Pacific region, primarily due to their robust electronics manufacturing ecosystems.

Consumer demand trends indicate a growing preference for sustainable and environmentally friendly electronic components, creating opportunities for water-based conductive polymer formulations. Additionally, the increasing adoption of Internet of Things (IoT) devices across industrial and consumer applications is expected to create sustained demand for conductive polymer inks in the coming years.

Current Technical Challenges in Conductive Polymer Ink Development

Despite significant advancements in conductive polymer ink technology, several critical technical challenges continue to impede widespread commercial adoption and optimal performance. The foremost challenge lies in achieving consistent electrical conductivity across different production batches. Current manufacturing processes struggle to maintain uniform dispersion of conductive particles within the polymer matrix, resulting in significant batch-to-batch variations that compromise reliability in electronic applications.

Viscosity control presents another substantial hurdle, particularly when balancing the competing requirements of printability and conductivity. Higher particle loading improves conductivity but often creates inks that are too viscous for fine-feature printing, while lower viscosity formulations may not achieve desired conductivity thresholds. This delicate balance remains difficult to optimize across diverse printing platforms and substrate materials.

Adhesion to various substrates continues to challenge developers, especially when targeting flexible electronics applications. Many conductive polymer inks exhibit poor adhesion to substrates like PET, PI, or textiles, leading to delamination during bending or stretching. Current adhesion promoters often compromise electrical performance or increase production complexity and cost.

Environmental stability represents a significant barrier to commercialization. Conductive polymer inks frequently demonstrate performance degradation when exposed to humidity, UV radiation, and temperature fluctuations. Oxidation of conductive particles and polymer matrix degradation can dramatically reduce conductivity over time, limiting product lifespan and reliability in real-world applications.

Scale-up from laboratory to industrial production introduces additional complexities. Processes that work effectively at small scales often encounter unforeseen challenges when scaled to commercial volumes. Parameters optimized in laboratory settings may require substantial recalibration during industrial implementation, creating costly delays and technical setbacks.

The cost-performance ratio remains problematic for many applications. High-performance conductive polymer inks typically incorporate expensive materials like silver nanoparticles or specialized conductive polymers, making them economically unviable for cost-sensitive applications. Alternatives using more affordable materials generally deliver inferior electrical performance or require more complex processing.

Curing conditions present another significant challenge. Many conductive polymer inks require specific thermal or photonic curing processes that may damage heat-sensitive substrates or components. Developing low-temperature curing formulations without sacrificing conductivity continues to be a technical obstacle, particularly for applications involving temperature-sensitive materials.

Standardization across the industry remains inadequate, with inconsistent testing methodologies and performance metrics making direct comparisons between different ink formulations difficult. This lack of standardization complicates material selection and slows industry-wide innovation and adoption.

Viscosity control presents another substantial hurdle, particularly when balancing the competing requirements of printability and conductivity. Higher particle loading improves conductivity but often creates inks that are too viscous for fine-feature printing, while lower viscosity formulations may not achieve desired conductivity thresholds. This delicate balance remains difficult to optimize across diverse printing platforms and substrate materials.

Adhesion to various substrates continues to challenge developers, especially when targeting flexible electronics applications. Many conductive polymer inks exhibit poor adhesion to substrates like PET, PI, or textiles, leading to delamination during bending or stretching. Current adhesion promoters often compromise electrical performance or increase production complexity and cost.

Environmental stability represents a significant barrier to commercialization. Conductive polymer inks frequently demonstrate performance degradation when exposed to humidity, UV radiation, and temperature fluctuations. Oxidation of conductive particles and polymer matrix degradation can dramatically reduce conductivity over time, limiting product lifespan and reliability in real-world applications.

Scale-up from laboratory to industrial production introduces additional complexities. Processes that work effectively at small scales often encounter unforeseen challenges when scaled to commercial volumes. Parameters optimized in laboratory settings may require substantial recalibration during industrial implementation, creating costly delays and technical setbacks.

The cost-performance ratio remains problematic for many applications. High-performance conductive polymer inks typically incorporate expensive materials like silver nanoparticles or specialized conductive polymers, making them economically unviable for cost-sensitive applications. Alternatives using more affordable materials generally deliver inferior electrical performance or require more complex processing.

Curing conditions present another significant challenge. Many conductive polymer inks require specific thermal or photonic curing processes that may damage heat-sensitive substrates or components. Developing low-temperature curing formulations without sacrificing conductivity continues to be a technical obstacle, particularly for applications involving temperature-sensitive materials.

Standardization across the industry remains inadequate, with inconsistent testing methodologies and performance metrics making direct comparisons between different ink formulations difficult. This lack of standardization complicates material selection and slows industry-wide innovation and adoption.

Current Formulation Approaches and Parameter Optimization Methods

01 Conductive polymer composition for enhanced conductivity

Conductive polymer inks can be formulated with specific polymers such as PEDOT:PSS, polyaniline, or polypyrrole to achieve high electrical conductivity. These formulations often include additives that improve the polymer chain alignment and reduce insulating barriers between conductive domains. The composition may be optimized through molecular weight control, doping levels, and polymer concentration to achieve conductivity values suitable for printed electronics applications.- Conductive polymer compositions for printable inks: Conductive polymer compositions specifically designed for printable inks that offer enhanced electrical conductivity. These compositions typically include conjugated polymers such as polyaniline, polypyrrole, or PEDOT:PSS, which are formulated with appropriate solvents and additives to achieve optimal viscosity and surface tension for printing applications while maintaining high conductivity levels.

- Additives and dopants to enhance conductivity: Various additives and dopants that can be incorporated into conductive polymer inks to significantly enhance their electrical conductivity. These include metal nanoparticles, carbon-based materials like graphene or carbon nanotubes, and ionic compounds. These additives create additional conduction pathways within the polymer matrix or modify the electronic structure of the polymers to improve charge carrier mobility.

- Processing techniques for conductivity optimization: Specific processing techniques that can be applied to conductive polymer inks to optimize their conductivity. These include post-deposition treatments such as thermal annealing, solvent annealing, or UV curing, which help to remove residual solvents, improve polymer chain alignment, and enhance inter-chain charge transport. The processing conditions significantly impact the final conductivity of the printed structures.

- Substrate interactions and interface engineering: The importance of substrate interactions and interface engineering in conductive polymer ink applications. The choice of substrate material and surface treatments can significantly affect the adhesion, morphology, and ultimately the conductivity of the printed polymer layers. Various surface modification techniques can be employed to optimize the interface between the conductive polymer ink and the substrate.

- Stability and environmental resistance of conductive inks: Methods to improve the stability and environmental resistance of conductive polymer inks, which is crucial for maintaining conductivity over time. These include encapsulation techniques, crosslinking strategies, and the incorporation of stabilizing additives that protect the conductive polymers from degradation due to oxygen, moisture, UV radiation, and mechanical stress, thereby ensuring long-term conductivity retention.

02 Nanoparticle incorporation for conductivity enhancement

The addition of conductive nanoparticles such as carbon nanotubes, graphene, or metal nanoparticles (silver, copper, gold) to polymer inks significantly enhances their electrical conductivity. These nanofillers create conductive pathways within the polymer matrix, reducing the percolation threshold and improving charge transport. The size, shape, and dispersion of these nanoparticles play crucial roles in determining the final conductivity of the printed structures.Expand Specific Solutions03 Solvent and additive systems for conductivity optimization

The choice of solvents and additives in conductive polymer ink formulations significantly impacts the final conductivity. Polar solvents can improve polymer chain extension, while certain additives like dimethyl sulfoxide or ethylene glycol can enhance conductivity by modifying the polymer morphology. Post-treatment processes such as solvent annealing or thermal treatment can further improve conductivity by removing insulating components and promoting better polymer ordering.Expand Specific Solutions04 Printing techniques and substrate interactions

The printing method and substrate characteristics significantly influence the conductivity of polymer inks. Techniques such as inkjet printing, screen printing, or flexography require specific ink rheological properties to achieve optimal conductivity. The interaction between the conductive polymer ink and the substrate affects the morphology of the dried film, with parameters such as surface energy, porosity, and roughness playing important roles in determining the final electrical performance of the printed circuit.Expand Specific Solutions05 Post-processing methods for conductivity enhancement

Various post-processing techniques can significantly improve the conductivity of printed polymer inks. These include thermal annealing, photonic sintering, plasma treatment, and chemical treatments. These processes help remove insulating components, improve polymer chain alignment, enhance cross-linking between conductive particles, and reduce contact resistance. The optimization of these post-processing parameters is crucial for achieving maximum conductivity while maintaining the integrity of the substrate and printed pattern.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Conductive Polymer Inks

The conductive polymer inks market is in a growth phase, characterized by increasing applications in printed electronics, flexible displays, and smart packaging. The global market size is estimated to exceed $3 billion, with a projected CAGR of 8-10% through 2025. Technologically, the field shows varying maturity levels across applications. Leading players like LG Chem and 3M demonstrate advanced capabilities in formulation chemistry, while specialized companies such as Vorbeck Materials and Intrinsiq Materials focus on innovative graphene-based solutions. Academic-industry partnerships are accelerating development, with institutions like MIT and Xiamen University collaborating with companies to overcome key challenges in conductivity, adhesion, and stability. The competitive landscape features both chemical giants (Henkel, DIC Corp) and specialized materials firms developing proprietary formulations.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced conductive polymer ink formulations focusing on optimizing viscosity, particle size distribution, and surface tension. Their technology utilizes PEDOT:PSS (poly(3,4-ethylenedioxythiophene):polystyrene sulfonate) as the primary conductive polymer, modified with specific additives to enhance conductivity while maintaining printability. The company has implemented a proprietary solvent system that balances evaporation rate and substrate wetting, crucial for uniform film formation. Their research has demonstrated that controlling the polymer-to-dopant ratio significantly impacts the final conductivity, with optimal ratios achieving sheet resistances below 100 Ω/sq. LG Chem's formulations incorporate stabilizers that prevent agglomeration during storage and printing, extending shelf life to over 12 months while maintaining consistent rheological properties.

Strengths: Superior stability in various environmental conditions; excellent adhesion to flexible substrates; high batch-to-batch consistency. Weaknesses: Higher cost compared to silver-based alternatives; limited maximum conductivity compared to metal-based inks; requires specific curing conditions for optimal performance.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered conductive polymer ink technology focusing on the critical parameters of particle morphology and dispersion stability. Their approach utilizes specialized surfactants and dispersing agents to maintain uniform particle distribution throughout the printing process. The company's research has identified that controlling the molecular weight distribution of conductive polymers (particularly polythiophene derivatives) directly correlates with ink viscosity and final film conductivity. 3M's formulations incorporate proprietary cross-linking agents that enhance adhesion to difficult substrates while maintaining flexibility after curing. Their studies have demonstrated that optimizing the ratio of conductive fillers to polymer binders can achieve a balance between conductivity and mechanical properties, with their advanced formulations reaching conductivities of 10^3-10^4 S/cm while maintaining elongation at break above 15%. The company has also developed temperature-responsive additives that enable lower curing temperatures (80-120°C) without sacrificing electrical performance.

Strengths: Exceptional adhesion to multiple substrate types; superior flexibility in printed circuits; excellent environmental stability with minimal conductivity drift. Weaknesses: Higher viscosity limiting application in some high-resolution printing techniques; more complex formulation requiring specialized handling; relatively higher cost compared to conventional conductive materials.

Critical Patents and Research Breakthroughs in Polymer Conductivity

Conducting polymer ink

PatentActiveUS20110048772A1

Innovation

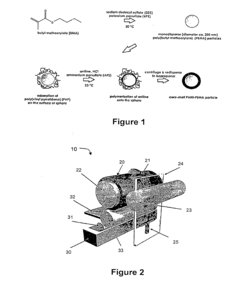

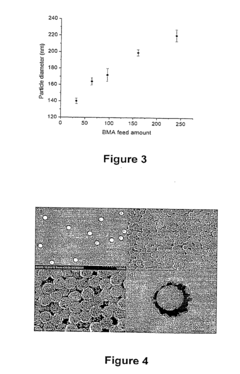

- Development of conductive polymer inks with a dispersion of core/shell polymeric particles, where the core is insulative and has a low glass transition temperature, and the shell is conductive, allowing for formulation with environmentally friendly carrier liquids and additives to control viscosity and electrical characteristics, enabling high-speed printing and high conductivity.

Conductive polymer ink composition

PatentWO2015182954A1

Innovation

- A conductive polymer ink composition comprising PEDOT:PSS aqueous dispersion, dimethyl sulfoxide, a solvent, a surfactant, and a phosphate compound, optimized with specific weight percentages to enhance conductivity and processability, including the use of deionized water and polyhydric alcohols like propylene glycol, which improves dispersibility and conductivity.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive polymer inks has become increasingly important as electronic devices proliferate globally. Traditional conductive materials often contain heavy metals and toxic substances that pose significant environmental risks during production, use, and disposal. Conductive polymer inks offer a promising alternative with potentially lower environmental footprints, though their sustainability profile requires careful consideration across the entire lifecycle.

Manufacturing processes for conductive polymer inks typically consume less energy compared to traditional metal-based conductors, reducing carbon emissions. However, the synthesis of conductive polymers often involves solvents and reagents that may be environmentally harmful if not properly managed. Recent advancements have focused on developing water-based formulations that minimize the use of volatile organic compounds (VOCs) and other hazardous chemicals, significantly improving their environmental profile.

Biodegradability represents another critical sustainability consideration. Most conventional electronic materials persist in the environment for decades or centuries, contributing to electronic waste problems. Some conductive polymers can be designed with biodegradable components or structures that facilitate breakdown under specific environmental conditions, though complete biodegradability while maintaining performance remains challenging.

Resource efficiency in production presents both opportunities and challenges. While polymer inks generally require less raw material than metal-based alternatives, some specialized conductive polymers incorporate rare elements or complex synthesis pathways that may limit their sustainability advantages. Research into bio-based precursors and renewable feedstocks shows promise for reducing dependence on petroleum-derived materials.

End-of-life considerations are particularly relevant as the electronics industry faces mounting pressure to address waste issues. Conductive polymer inks may offer advantages in recyclability compared to multi-material components, potentially enabling more efficient recovery of valuable materials. However, the integration of these inks into complex electronic devices can complicate separation and recycling processes.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance, with restrictions on hazardous substances like those in the EU's RoHS directive driving innovation toward greener alternatives. Manufacturers developing conductive polymer inks must navigate these evolving requirements while maintaining performance characteristics. Life cycle assessment (LCA) methodologies are becoming essential tools for quantifying environmental impacts and identifying improvement opportunities across production, use, and disposal phases.

The transition toward more sustainable conductive materials also presents economic considerations. While environmentally friendly formulations may carry higher initial costs, they can offer long-term advantages through regulatory compliance, consumer preference for green electronics, and potential cost savings in waste management and environmental remediation.

Manufacturing processes for conductive polymer inks typically consume less energy compared to traditional metal-based conductors, reducing carbon emissions. However, the synthesis of conductive polymers often involves solvents and reagents that may be environmentally harmful if not properly managed. Recent advancements have focused on developing water-based formulations that minimize the use of volatile organic compounds (VOCs) and other hazardous chemicals, significantly improving their environmental profile.

Biodegradability represents another critical sustainability consideration. Most conventional electronic materials persist in the environment for decades or centuries, contributing to electronic waste problems. Some conductive polymers can be designed with biodegradable components or structures that facilitate breakdown under specific environmental conditions, though complete biodegradability while maintaining performance remains challenging.

Resource efficiency in production presents both opportunities and challenges. While polymer inks generally require less raw material than metal-based alternatives, some specialized conductive polymers incorporate rare elements or complex synthesis pathways that may limit their sustainability advantages. Research into bio-based precursors and renewable feedstocks shows promise for reducing dependence on petroleum-derived materials.

End-of-life considerations are particularly relevant as the electronics industry faces mounting pressure to address waste issues. Conductive polymer inks may offer advantages in recyclability compared to multi-material components, potentially enabling more efficient recovery of valuable materials. However, the integration of these inks into complex electronic devices can complicate separation and recycling processes.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance, with restrictions on hazardous substances like those in the EU's RoHS directive driving innovation toward greener alternatives. Manufacturers developing conductive polymer inks must navigate these evolving requirements while maintaining performance characteristics. Life cycle assessment (LCA) methodologies are becoming essential tools for quantifying environmental impacts and identifying improvement opportunities across production, use, and disposal phases.

The transition toward more sustainable conductive materials also presents economic considerations. While environmentally friendly formulations may carry higher initial costs, they can offer long-term advantages through regulatory compliance, consumer preference for green electronics, and potential cost savings in waste management and environmental remediation.

Manufacturing Process Optimization and Scalability Challenges

The optimization of manufacturing processes for conductive polymer inks represents a critical challenge in transitioning from laboratory-scale production to commercial viability. Current manufacturing methods often struggle with consistency issues when scaling up, particularly in maintaining uniform particle dispersion and preventing agglomeration during large-batch production. These challenges directly impact the electrical conductivity and performance reliability of the final printed circuits or components.

Key process parameters requiring optimization include mixing protocols, temperature control systems, and curing conditions. Industrial-scale production demands precise control over shear forces during mixing to ensure homogeneous dispersion without damaging the polymer chains or conductive fillers. Temperature gradients in larger mixing vessels can create inconsistencies in viscosity and flow properties, necessitating advanced thermal management systems that may significantly increase production costs.

Solvent evaporation rates present another significant scalability challenge. Laboratory processes often rely on slow, controlled evaporation that becomes impractical at industrial scales. Accelerated drying techniques must be developed without compromising the formation of conductive pathways within the polymer matrix. Flash drying methods show promise but require careful calibration to prevent cracking or delamination in the printed layers.

Equipment compatibility issues further complicate scaling efforts. Many specialized printing systems designed for conductive polymer inks operate effectively at prototype scales but encounter mechanical limitations when adapted to high-throughput production lines. The transition from screen printing to roll-to-roll processing, while necessary for commercial viability, introduces new variables affecting ink transfer efficiency and pattern resolution.

Quality control methodologies must evolve alongside production scaling. Current inspection techniques that work well for small batches become bottlenecks in high-volume manufacturing. Automated optical inspection systems and real-time electrical testing protocols need development to maintain quality standards without impeding production rates.

Environmental considerations also impact scalability. The volatile organic compounds (VOCs) present in many conductive polymer ink formulations pose minimal concerns at laboratory scales but become significant regulatory challenges in industrial settings. Manufacturers must invest in emission control systems or reformulate inks with environmentally friendly solvents, potentially altering the established performance characteristics of their products.

Cost-effective recycling of production waste represents another scalability hurdle. The precious metals and specialized polymers in conductive inks make waste management economically significant at industrial scales. Developing closed-loop systems for solvent recovery and material reclamation will be essential for sustainable large-scale manufacturing operations.

Key process parameters requiring optimization include mixing protocols, temperature control systems, and curing conditions. Industrial-scale production demands precise control over shear forces during mixing to ensure homogeneous dispersion without damaging the polymer chains or conductive fillers. Temperature gradients in larger mixing vessels can create inconsistencies in viscosity and flow properties, necessitating advanced thermal management systems that may significantly increase production costs.

Solvent evaporation rates present another significant scalability challenge. Laboratory processes often rely on slow, controlled evaporation that becomes impractical at industrial scales. Accelerated drying techniques must be developed without compromising the formation of conductive pathways within the polymer matrix. Flash drying methods show promise but require careful calibration to prevent cracking or delamination in the printed layers.

Equipment compatibility issues further complicate scaling efforts. Many specialized printing systems designed for conductive polymer inks operate effectively at prototype scales but encounter mechanical limitations when adapted to high-throughput production lines. The transition from screen printing to roll-to-roll processing, while necessary for commercial viability, introduces new variables affecting ink transfer efficiency and pattern resolution.

Quality control methodologies must evolve alongside production scaling. Current inspection techniques that work well for small batches become bottlenecks in high-volume manufacturing. Automated optical inspection systems and real-time electrical testing protocols need development to maintain quality standards without impeding production rates.

Environmental considerations also impact scalability. The volatile organic compounds (VOCs) present in many conductive polymer ink formulations pose minimal concerns at laboratory scales but become significant regulatory challenges in industrial settings. Manufacturers must invest in emission control systems or reformulate inks with environmentally friendly solvents, potentially altering the established performance characteristics of their products.

Cost-effective recycling of production waste represents another scalability hurdle. The precious metals and specialized polymers in conductive inks make waste management economically significant at industrial scales. Developing closed-loop systems for solvent recovery and material reclamation will be essential for sustainable large-scale manufacturing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!