Conductive Polymer Inks for Wearable Technology

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Inks Background and Objectives

Conductive polymer inks represent a transformative technology that has evolved significantly over the past three decades. Initially developed in the 1980s as experimental materials with limited conductivity, these inks have progressed to become sophisticated formulations capable of delivering performance comparable to traditional metal-based conductors while offering superior flexibility and wearability. The evolution of these materials has been driven by advancements in polymer science, nanotechnology, and materials engineering, creating a convergence of disciplines that continues to push the boundaries of wearable electronics.

The fundamental composition of conductive polymer inks typically includes electrically conductive polymers such as polyaniline (PANI), polypyrrole (PPy), or poly(3,4-ethylenedioxythiophene) (PEDOT), often combined with stabilizers, solvents, and additives that enhance their printability and performance characteristics. Recent developments have focused on incorporating nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles to create hybrid formulations with enhanced conductivity and durability.

The wearable technology market has emerged as a primary driver for conductive polymer ink development, with applications ranging from health monitoring devices and smart textiles to flexible displays and electronic skin. This market is projected to reach $265 billion by 2026, with conductive inks playing a crucial role in enabling next-generation devices that seamlessly integrate with the human body and everyday clothing.

Current technical objectives in conductive polymer ink research focus on several key parameters: achieving higher electrical conductivity while maintaining flexibility; improving adhesion to textile substrates; enhancing durability against washing, stretching, and environmental factors; reducing curing temperatures to accommodate heat-sensitive substrates; and developing environmentally friendly formulations that minimize toxic components and waste.

Looking forward, the field is moving toward multi-functional inks that combine conductivity with additional properties such as antimicrobial activity, thermoregulation, or color-changing capabilities. There is also significant interest in developing self-healing conductive inks that can automatically repair damage from wear and tear, extending the lifespan of wearable electronics.

The convergence of conductive polymer ink technology with advances in printed electronics manufacturing processes, particularly roll-to-roll printing and digital fabrication techniques, is expected to enable mass production of customizable wearable devices at significantly reduced costs. This democratization of production capabilities represents a paradigm shift in how wearable technology can be designed, manufactured, and distributed globally.

The fundamental composition of conductive polymer inks typically includes electrically conductive polymers such as polyaniline (PANI), polypyrrole (PPy), or poly(3,4-ethylenedioxythiophene) (PEDOT), often combined with stabilizers, solvents, and additives that enhance their printability and performance characteristics. Recent developments have focused on incorporating nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles to create hybrid formulations with enhanced conductivity and durability.

The wearable technology market has emerged as a primary driver for conductive polymer ink development, with applications ranging from health monitoring devices and smart textiles to flexible displays and electronic skin. This market is projected to reach $265 billion by 2026, with conductive inks playing a crucial role in enabling next-generation devices that seamlessly integrate with the human body and everyday clothing.

Current technical objectives in conductive polymer ink research focus on several key parameters: achieving higher electrical conductivity while maintaining flexibility; improving adhesion to textile substrates; enhancing durability against washing, stretching, and environmental factors; reducing curing temperatures to accommodate heat-sensitive substrates; and developing environmentally friendly formulations that minimize toxic components and waste.

Looking forward, the field is moving toward multi-functional inks that combine conductivity with additional properties such as antimicrobial activity, thermoregulation, or color-changing capabilities. There is also significant interest in developing self-healing conductive inks that can automatically repair damage from wear and tear, extending the lifespan of wearable electronics.

The convergence of conductive polymer ink technology with advances in printed electronics manufacturing processes, particularly roll-to-roll printing and digital fabrication techniques, is expected to enable mass production of customizable wearable devices at significantly reduced costs. This democratization of production capabilities represents a paradigm shift in how wearable technology can be designed, manufactured, and distributed globally.

Market Demand Analysis for Wearable Electronics

The wearable electronics market has experienced exponential growth over the past decade, evolving from simple fitness trackers to sophisticated health monitoring systems, smart clothing, and augmented reality devices. Current market analysis indicates that the global wearable technology market is projected to reach $265 billion by 2026, with a compound annual growth rate (CAGR) of approximately 18% during the forecast period. This remarkable growth is primarily driven by increasing health consciousness among consumers, rising adoption of IoT, and technological advancements in flexible electronics and conductive materials.

Conductive polymer inks represent a critical component in this expanding market, as they enable the creation of flexible, stretchable, and washable electronic circuits that can be integrated seamlessly into textiles and other wearable substrates. Market research shows that approximately 65% of consumers prefer wearable devices that are comfortable, unobtrusive, and aesthetically pleasing—qualities that conductive polymer inks can help deliver.

Healthcare applications constitute the largest segment of the wearable electronics market, accounting for roughly 40% of the total market share. The demand for remote patient monitoring systems, continuous glucose monitors, and ECG monitors has surged, particularly following the COVID-19 pandemic. These medical wearables require highly reliable and biocompatible conductive materials, creating a significant opportunity for advanced polymer ink formulations.

The fitness and sports segment follows closely behind healthcare, representing approximately 30% of the market. Smart fabrics embedded with conductive polymer circuits are increasingly being adopted by professional athletes and fitness enthusiasts for performance tracking and injury prevention. Market surveys indicate that 78% of professional sports teams now utilize some form of wearable technology in their training regimens.

Consumer electronics giants are rapidly expanding their wearable product lines, with companies like Apple, Samsung, and Google investing heavily in R&D for next-generation devices. This has created a robust demand for materials that can enable thinner, lighter, and more energy-efficient wearable products. Conductive polymer inks that offer high conductivity while maintaining flexibility are particularly sought after in this segment.

Regional analysis reveals that North America currently leads the wearable electronics market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing disposable income, growing technological adoption, and the presence of major manufacturing hubs in countries like China, South Korea, and Taiwan.

Conductive polymer inks represent a critical component in this expanding market, as they enable the creation of flexible, stretchable, and washable electronic circuits that can be integrated seamlessly into textiles and other wearable substrates. Market research shows that approximately 65% of consumers prefer wearable devices that are comfortable, unobtrusive, and aesthetically pleasing—qualities that conductive polymer inks can help deliver.

Healthcare applications constitute the largest segment of the wearable electronics market, accounting for roughly 40% of the total market share. The demand for remote patient monitoring systems, continuous glucose monitors, and ECG monitors has surged, particularly following the COVID-19 pandemic. These medical wearables require highly reliable and biocompatible conductive materials, creating a significant opportunity for advanced polymer ink formulations.

The fitness and sports segment follows closely behind healthcare, representing approximately 30% of the market. Smart fabrics embedded with conductive polymer circuits are increasingly being adopted by professional athletes and fitness enthusiasts for performance tracking and injury prevention. Market surveys indicate that 78% of professional sports teams now utilize some form of wearable technology in their training regimens.

Consumer electronics giants are rapidly expanding their wearable product lines, with companies like Apple, Samsung, and Google investing heavily in R&D for next-generation devices. This has created a robust demand for materials that can enable thinner, lighter, and more energy-efficient wearable products. Conductive polymer inks that offer high conductivity while maintaining flexibility are particularly sought after in this segment.

Regional analysis reveals that North America currently leads the wearable electronics market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing disposable income, growing technological adoption, and the presence of major manufacturing hubs in countries like China, South Korea, and Taiwan.

Current State and Challenges in Conductive Polymer Technology

Conductive polymer technology has witnessed significant advancements over the past decade, establishing itself as a cornerstone for wearable electronics development. Currently, the global market is dominated by several key polymer systems including PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate), polyaniline, polypyrrole, and various carbon-based composite materials. These materials have reached commercial viability with conductivity values ranging from 1-1000 S/cm, depending on formulation and processing techniques.

The Asia-Pacific region, particularly Japan, South Korea, and China, leads in conductive polymer production and innovation, accounting for approximately 45% of global research output. North America and Europe follow with significant contributions to fundamental research and specialized applications development. This geographical distribution reflects both manufacturing capabilities and research infrastructure investments.

Despite promising developments, several critical challenges impede broader adoption of conductive polymer inks in wearable technology. Foremost among these is the conductivity-flexibility trade-off. As conductivity increases through higher loading of conductive materials, flexibility often decreases, creating a fundamental limitation for body-conforming applications. Current solutions achieve either good conductivity or excellent flexibility, but rarely both simultaneously.

Stability remains another significant hurdle. Conductive polymers frequently suffer from performance degradation when exposed to environmental factors such as humidity, UV radiation, and repeated mechanical stress. Most commercial formulations show 15-30% conductivity reduction after 500 wash cycles or 1000 hours of continuous wear, falling short of consumer expectations for everyday wearables.

Manufacturing scalability presents additional complications. Laboratory-scale production methods often employ toxic solvents or require complex processing conditions that prove difficult to scale industrially. The transition from research to mass production frequently results in performance inconsistencies and yield issues, with batch-to-batch variation exceeding 20% in conductivity metrics for some formulations.

Biocompatibility and skin sensitivity concerns further constrain development. Many conductive additives and processing aids raise toxicological questions for prolonged skin contact. Current regulatory frameworks in major markets impose stringent requirements that limit material selection and processing options.

Cost factors also present significant barriers. High-performance conductive polymer inks typically cost between $200-1000 per kilogram, substantially higher than conventional electronic materials. This price point restricts application to premium products and limits mass-market penetration.

Technical integration challenges persist in creating reliable interfaces between soft conductive polymers and rigid conventional electronics. Current connection methods often represent failure points in wearable systems, with mechanical stress at these junctions causing up to 70% of reported device failures in commercial products.

The Asia-Pacific region, particularly Japan, South Korea, and China, leads in conductive polymer production and innovation, accounting for approximately 45% of global research output. North America and Europe follow with significant contributions to fundamental research and specialized applications development. This geographical distribution reflects both manufacturing capabilities and research infrastructure investments.

Despite promising developments, several critical challenges impede broader adoption of conductive polymer inks in wearable technology. Foremost among these is the conductivity-flexibility trade-off. As conductivity increases through higher loading of conductive materials, flexibility often decreases, creating a fundamental limitation for body-conforming applications. Current solutions achieve either good conductivity or excellent flexibility, but rarely both simultaneously.

Stability remains another significant hurdle. Conductive polymers frequently suffer from performance degradation when exposed to environmental factors such as humidity, UV radiation, and repeated mechanical stress. Most commercial formulations show 15-30% conductivity reduction after 500 wash cycles or 1000 hours of continuous wear, falling short of consumer expectations for everyday wearables.

Manufacturing scalability presents additional complications. Laboratory-scale production methods often employ toxic solvents or require complex processing conditions that prove difficult to scale industrially. The transition from research to mass production frequently results in performance inconsistencies and yield issues, with batch-to-batch variation exceeding 20% in conductivity metrics for some formulations.

Biocompatibility and skin sensitivity concerns further constrain development. Many conductive additives and processing aids raise toxicological questions for prolonged skin contact. Current regulatory frameworks in major markets impose stringent requirements that limit material selection and processing options.

Cost factors also present significant barriers. High-performance conductive polymer inks typically cost between $200-1000 per kilogram, substantially higher than conventional electronic materials. This price point restricts application to premium products and limits mass-market penetration.

Technical integration challenges persist in creating reliable interfaces between soft conductive polymers and rigid conventional electronics. Current connection methods often represent failure points in wearable systems, with mechanical stress at these junctions causing up to 70% of reported device failures in commercial products.

Current Technical Solutions for Wearable Conductive Inks

01 Conductive polymer compositions for printable electronics

Conductive polymer inks can be formulated with specific polymers like PEDOT:PSS, polyaniline, or polythiophene derivatives to create printable electronic components. These formulations typically include solvents, binders, and additives that enhance conductivity while maintaining suitable viscosity for various printing methods. The resulting inks enable the fabrication of flexible circuits, sensors, and other electronic devices through conventional printing techniques.- Conductive polymer compositions for printable electronics: Conductive polymer inks can be formulated with specific polymers like PEDOT:PSS, polyaniline, or polythiophene derivatives to create printable electronic components. These formulations typically include solvents, binders, and additives that enhance conductivity while maintaining suitable viscosity for various printing methods. The resulting inks enable the fabrication of flexible circuits, sensors, and other electronic devices through conventional printing techniques.

- Carbon-based additives for enhanced conductivity: Incorporating carbon-based materials such as graphene, carbon nanotubes, or carbon black into polymer inks significantly improves their electrical conductivity. These carbon additives create conductive networks within the polymer matrix, reducing resistance and enhancing charge transport properties. The dispersion quality and loading percentage of these carbon materials are critical factors in determining the final conductivity and printability of the ink formulations.

- Metal nanoparticle incorporation techniques: Metal nanoparticles, particularly silver, copper, and gold, can be incorporated into polymer inks to achieve high conductivity. These nanoparticles are typically surface-modified to prevent aggregation and ensure stable dispersion in the polymer matrix. Post-deposition treatments like thermal or photonic sintering help to form continuous conductive pathways by removing organic components and fusing the metal particles, resulting in enhanced electrical performance while maintaining compatibility with flexible substrates.

- Solvent systems and rheological modifiers: The selection of appropriate solvent systems and rheological modifiers is crucial for conductive polymer ink performance. Mixed solvent systems can be tailored to control evaporation rates and ensure proper film formation, while rheological modifiers adjust viscosity and surface tension for compatibility with various printing methods. These components influence ink stability, substrate wetting, pattern resolution, and ultimately the electrical properties of the printed structures.

- Post-processing techniques for conductivity enhancement: Various post-processing methods can significantly improve the conductivity of printed polymer inks. These include thermal annealing, photonic sintering, plasma treatment, and chemical reduction processes. Such treatments remove residual solvents, improve polymer chain alignment, reduce junction resistance between conductive particles, and enhance overall film morphology. The optimization of these post-processing parameters is essential for achieving maximum conductivity while maintaining compatibility with temperature-sensitive substrates.

02 Carbon-based additives for enhanced conductivity

Incorporating carbon-based materials such as graphene, carbon nanotubes, or carbon black into polymer inks significantly improves their electrical conductivity. These carbon additives create conductive networks within the polymer matrix, reducing sheet resistance and enhancing current flow. The dispersion quality of these carbon materials in the ink formulation is critical for achieving uniform conductivity and preventing agglomeration that could impair printing performance.Expand Specific Solutions03 Metal nanoparticle incorporation techniques

Metal nanoparticles, particularly silver, gold, and copper, can be incorporated into polymer inks to achieve high conductivity. These formulations typically include stabilizers to prevent nanoparticle aggregation and sintering aids that promote particle fusion during post-deposition treatment. The particle size distribution and surface functionalization are carefully controlled to ensure proper dispersion in the polymer matrix while maintaining the ink's rheological properties suitable for various printing processes.Expand Specific Solutions04 Solvent systems and rheology modifiers

The selection of appropriate solvent systems and rheology modifiers is crucial for conductive polymer ink performance. Mixed solvent systems can be tailored to control evaporation rates and surface tension, affecting print quality and film formation. Rheology modifiers adjust viscosity and thixotropic properties to make the inks compatible with specific printing methods such as screen printing, inkjet printing, or flexography. These components significantly impact the ink's stability, shelf life, and printing resolution.Expand Specific Solutions05 Post-processing techniques for conductivity enhancement

Various post-processing methods can significantly improve the conductivity of printed polymer inks. These include thermal annealing, photonic sintering, plasma treatment, and chemical reduction processes. Such treatments remove residual solvents, improve polymer chain alignment, and enhance inter-particle connections in composite inks. The optimization of these post-processing parameters is essential for achieving maximum conductivity while maintaining compatibility with temperature-sensitive substrates like flexible plastics or paper.Expand Specific Solutions

Key Industry Players in Conductive Polymer Development

The conductive polymer inks market for wearable technology is in a growth phase, with increasing demand driven by the expanding wearable electronics sector. The market is projected to show significant expansion as applications in flexible electronics and smart textiles gain traction. Technologically, the field is advancing rapidly with companies at different maturity levels. Industry leaders like Henkel AG, DuPont, and TE Connectivity are driving commercial innovation with established product lines, while specialized players such as Vorbeck Materials and PolyIC focus on proprietary graphene-based solutions. Academic institutions including South China University of Technology and Clemson University are contributing fundamental research to improve conductivity, flexibility, and biocompatibility. The ecosystem demonstrates a healthy balance between large chemical corporations and specialized materials startups, indicating a competitive landscape with room for technological differentiation.

Henkel AG & Co. KGaA

Technical Solution: Henkel has pioneered LOCTITE ECI 8000 series conductive polymer inks specifically engineered for wearable technology applications. Their formulations utilize a proprietary blend of PEDOT:PSS (poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate)) modified with secondary dopants to achieve sheet resistances as low as 10 ohms/square while maintaining flexibility. The company's technology incorporates specialized cross-linking agents that form covalent bonds between the polymer chains and textile substrates, resulting in exceptional durability through repeated washing cycles (30+ industrial washes) and mechanical stress. Henkel's inks are water-based and environmentally friendly, eliminating the need for harmful solvents during application. Their latest innovations include thermoformable variants that maintain conductivity even after heat-molding processes, enabling integration with complex 3D wearable structures. The inks are compatible with screen printing, inkjet, and aerosol jet deposition methods, allowing versatile manufacturing approaches for different wearable applications from health monitoring to smart clothing.

Strengths: Excellent washability and durability, environmentally friendly water-based formulation, and compatibility with multiple deposition techniques. Weaknesses: Lower conductivity compared to metal-based alternatives, temperature sensitivity limiting some high-power applications, and requires careful control of humidity during application and curing processes.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced conductive polymer inks specifically designed for wearable technology applications. Their proprietary PE873 and PE874 stretchable conductive inks utilize silver flakes embedded in a polymer matrix that maintains conductivity even under significant strain (up to 100% elongation while maintaining >90% conductivity). These formulations incorporate specialized elastomeric binders that enable printing on various textile substrates including polyester, nylon, and cotton blends. DuPont's technology employs a unique dual-cure mechanism combining thermal and UV curing processes to achieve optimal adhesion and durability through repeated washing cycles and mechanical stress. Their latest generation incorporates nanosilver particles alongside microflakes to create hierarchical structures that maintain electrical pathways even during extreme deformation, making them particularly suitable for fitness tracking and medical monitoring wearables that require consistent performance during body movement.

Strengths: Superior stretchability while maintaining conductivity, excellent washability (20+ standard wash cycles), and compatibility with multiple textile substrates. Weaknesses: Higher cost compared to carbon-based alternatives, requires specialized curing equipment, and has limited shelf life (6-12 months) requiring controlled storage conditions.

Core Patents and Innovations in Conductive Polymer Formulations

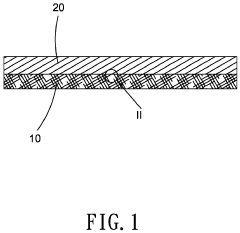

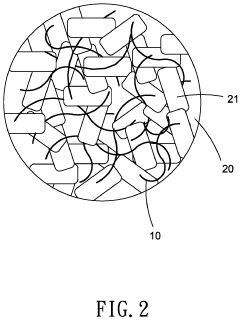

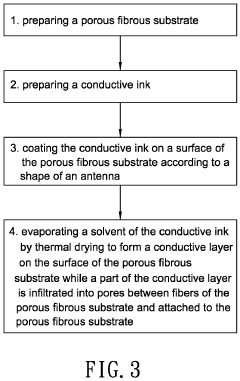

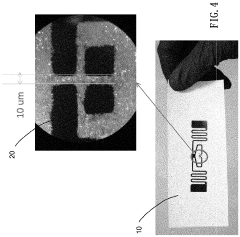

Conductive ink for use in manufacturing radio frequency identification (RFID) tag antenna and method for manufacturing RFID tag antenna

PatentInactiveEP3591012A1

Innovation

- A conductive ink comprising sheet-like carbon materials, such as graphite, combined with conductive fillers and dispersants, is used without polymer binders, allowing for a compact and dense conductive layer formation through a rolling process, enhancing conductivity and adhesion.

Sustainability and Biocompatibility Considerations

The sustainability and biocompatibility of conductive polymer inks represent critical considerations for their application in wearable technology. As these materials interface directly with human skin for extended periods, their environmental impact and biological interactions must be thoroughly evaluated. Current research indicates that traditional conductive inks often contain heavy metals and toxic solvents that pose significant environmental and health concerns throughout their lifecycle.

Environmental sustainability assessments of conductive polymer inks must consider raw material sourcing, manufacturing processes, usage phase, and end-of-life disposal. Recent innovations have focused on developing water-based formulations that eliminate harmful volatile organic compounds (VOCs) while maintaining electrical performance. These eco-friendly alternatives typically demonstrate reduced carbon footprints compared to conventional silver-based inks, with studies reporting up to 40% lower environmental impact across production cycles.

Biodegradability represents another crucial aspect of sustainability for wearable electronics. Research teams at leading institutions have developed conductive polymers incorporating naturally derived components such as cellulose, chitosan, and other biopolymers that maintain functionality while offering improved degradability. These materials show promising decomposition rates under controlled conditions, though challenges remain in balancing biodegradability with long-term electrical stability and mechanical durability.

From a biocompatibility perspective, conductive polymer inks must meet stringent requirements for skin contact applications. Cytotoxicity testing has revealed that PEDOT:PSS formulations, when properly purified, demonstrate excellent biocompatibility with minimal inflammatory responses in both in vitro and in vivo models. However, additives and processing agents used to enhance conductivity or printability may introduce biocompatibility concerns that require careful screening and elimination.

Allergenic potential represents a significant consideration for wearable applications. Recent clinical studies involving extended wear tests have identified specific polymer formulations with minimal sensitization risks, though individual variations in skin reactivity necessitate comprehensive testing protocols. Manufacturers are increasingly adopting hypoallergenic design principles, eliminating common sensitizers while maintaining electrical performance.

The integration of antimicrobial properties into conductive polymer inks has emerged as an innovative approach to enhance biocompatibility. Incorporating natural antimicrobial agents such as certain essential oils or silver nanoparticles at controlled concentrations can inhibit bacterial growth without compromising skin compatibility. This multifunctional approach addresses hygiene concerns associated with prolonged wearable device usage while potentially reducing skin irritation caused by microbial colonization.

Regulatory frameworks governing the sustainability and biocompatibility of wearable electronics continue to evolve, with standards such as ISO 10993 providing guidelines for biological evaluation. Forward-looking research is increasingly focused on developing standardized testing methodologies specifically tailored to conductive polymer inks in wearable applications, addressing the unique challenges posed by these materials at the skin-electronics interface.

Environmental sustainability assessments of conductive polymer inks must consider raw material sourcing, manufacturing processes, usage phase, and end-of-life disposal. Recent innovations have focused on developing water-based formulations that eliminate harmful volatile organic compounds (VOCs) while maintaining electrical performance. These eco-friendly alternatives typically demonstrate reduced carbon footprints compared to conventional silver-based inks, with studies reporting up to 40% lower environmental impact across production cycles.

Biodegradability represents another crucial aspect of sustainability for wearable electronics. Research teams at leading institutions have developed conductive polymers incorporating naturally derived components such as cellulose, chitosan, and other biopolymers that maintain functionality while offering improved degradability. These materials show promising decomposition rates under controlled conditions, though challenges remain in balancing biodegradability with long-term electrical stability and mechanical durability.

From a biocompatibility perspective, conductive polymer inks must meet stringent requirements for skin contact applications. Cytotoxicity testing has revealed that PEDOT:PSS formulations, when properly purified, demonstrate excellent biocompatibility with minimal inflammatory responses in both in vitro and in vivo models. However, additives and processing agents used to enhance conductivity or printability may introduce biocompatibility concerns that require careful screening and elimination.

Allergenic potential represents a significant consideration for wearable applications. Recent clinical studies involving extended wear tests have identified specific polymer formulations with minimal sensitization risks, though individual variations in skin reactivity necessitate comprehensive testing protocols. Manufacturers are increasingly adopting hypoallergenic design principles, eliminating common sensitizers while maintaining electrical performance.

The integration of antimicrobial properties into conductive polymer inks has emerged as an innovative approach to enhance biocompatibility. Incorporating natural antimicrobial agents such as certain essential oils or silver nanoparticles at controlled concentrations can inhibit bacterial growth without compromising skin compatibility. This multifunctional approach addresses hygiene concerns associated with prolonged wearable device usage while potentially reducing skin irritation caused by microbial colonization.

Regulatory frameworks governing the sustainability and biocompatibility of wearable electronics continue to evolve, with standards such as ISO 10993 providing guidelines for biological evaluation. Forward-looking research is increasingly focused on developing standardized testing methodologies specifically tailored to conductive polymer inks in wearable applications, addressing the unique challenges posed by these materials at the skin-electronics interface.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for conductive polymer inks represents a critical factor in their commercial viability for wearable technology applications. Current production methods vary significantly in terms of scalability, with some techniques remaining confined to laboratory settings while others have successfully transitioned to industrial-scale production. Screen printing and inkjet printing have demonstrated considerable promise for large-scale manufacturing, with several companies already implementing these processes for commercial production of flexible electronic components.

Cost analysis reveals that material expenses constitute approximately 40-60% of the total production costs for conductive polymer inks. The primary cost drivers include high-purity monomers, specialized dopants, and stabilizing agents. PEDOT:PSS, one of the most widely used conductive polymers, has seen a gradual price reduction of approximately 15-20% over the past five years due to improved synthesis methods and increased production volumes, yet remains significantly more expensive than traditional metallic conductors on a per-unit conductivity basis.

Equipment investment represents another substantial cost factor, particularly for advanced deposition systems. Initial capital expenditure for industrial-scale printing equipment ranges from $200,000 to over $1 million, depending on precision requirements and throughput capacity. However, these costs can be amortized over large production volumes, making them less prohibitive for established manufacturers than for startups or research institutions.

Process optimization presents significant opportunities for cost reduction. Recent advancements in formulation chemistry have improved ink stability and shelf life, reducing waste and rework rates by up to 30% in some production environments. Additionally, innovations in low-temperature curing processes have decreased energy consumption during the manufacturing process, with some systems reporting energy savings of 40-50% compared to traditional thermal curing methods.

Supply chain considerations also impact manufacturing scalability. The specialized nature of many conductive polymer components creates vulnerability to supply disruptions. Several manufacturers have begun implementing dual-sourcing strategies and investing in alternative material development to mitigate these risks. Vertical integration has emerged as another strategy, with companies like DuPont and Henkel acquiring smaller specialty chemical producers to secure their supply chains.

Regulatory compliance adds another layer of complexity to manufacturing scale-up. Environmental regulations regarding solvent use and disposal vary significantly across regions, potentially necessitating different formulations for global markets. The transition from laboratory to industrial production often requires substantial reformulation to comply with workplace safety standards and environmental regulations, adding development costs and potentially delaying market entry.

Cost analysis reveals that material expenses constitute approximately 40-60% of the total production costs for conductive polymer inks. The primary cost drivers include high-purity monomers, specialized dopants, and stabilizing agents. PEDOT:PSS, one of the most widely used conductive polymers, has seen a gradual price reduction of approximately 15-20% over the past five years due to improved synthesis methods and increased production volumes, yet remains significantly more expensive than traditional metallic conductors on a per-unit conductivity basis.

Equipment investment represents another substantial cost factor, particularly for advanced deposition systems. Initial capital expenditure for industrial-scale printing equipment ranges from $200,000 to over $1 million, depending on precision requirements and throughput capacity. However, these costs can be amortized over large production volumes, making them less prohibitive for established manufacturers than for startups or research institutions.

Process optimization presents significant opportunities for cost reduction. Recent advancements in formulation chemistry have improved ink stability and shelf life, reducing waste and rework rates by up to 30% in some production environments. Additionally, innovations in low-temperature curing processes have decreased energy consumption during the manufacturing process, with some systems reporting energy savings of 40-50% compared to traditional thermal curing methods.

Supply chain considerations also impact manufacturing scalability. The specialized nature of many conductive polymer components creates vulnerability to supply disruptions. Several manufacturers have begun implementing dual-sourcing strategies and investing in alternative material development to mitigate these risks. Vertical integration has emerged as another strategy, with companies like DuPont and Henkel acquiring smaller specialty chemical producers to secure their supply chains.

Regulatory compliance adds another layer of complexity to manufacturing scale-up. Environmental regulations regarding solvent use and disposal vary significantly across regions, potentially necessitating different formulations for global markets. The transition from laboratory to industrial production often requires substantial reformulation to comply with workplace safety standards and environmental regulations, adding development costs and potentially delaying market entry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!