What Characterizes High-performance Conductive Polymer Inks

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Inks Evolution and Objectives

Conductive polymer inks have evolved significantly over the past three decades, transforming from laboratory curiosities to commercially viable materials with diverse applications. The journey began in the 1970s with the discovery of electrically conductive polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa, who were later awarded the Nobel Prize in Chemistry in 2000. This groundbreaking work laid the foundation for the development of processable conductive polymers that could be formulated into inks.

The 1990s marked a crucial transition period when researchers began focusing on making these materials solution-processable, enabling their application as printable inks. PEDOT:PSS (poly(3,4-ethylenedioxythiophene):polystyrene sulfonate) emerged as a breakthrough material during this era, offering a balance of conductivity and processability that had previously been unattainable.

The early 2000s witnessed significant advancements in formulation techniques, with researchers developing methods to enhance conductivity while maintaining printability. Secondary doping approaches, solvent treatments, and the incorporation of nanomaterials became common strategies to boost performance. Concurrently, printing technologies evolved to accommodate these new materials, with inkjet, screen, and gravure printing methods being adapted specifically for conductive polymer inks.

Recent developments have focused on creating high-performance inks that combine excellent electrical conductivity with mechanical flexibility, environmental stability, and compatibility with various substrates. The integration of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles into polymer matrices has pushed conductivity values closer to those of traditional metal conductors while maintaining the inherent advantages of polymers.

The primary objective in this field is to develop conductive polymer inks that achieve metal-like conductivity (>10,000 S/cm) while maintaining solution processability and mechanical flexibility. Additional goals include enhancing environmental stability to ensure long-term performance under various conditions, reducing production costs to compete with traditional conductive materials, and improving sustainability through the use of environmentally friendly solvents and processing methods.

Future technical objectives include developing multi-functional inks that combine conductivity with other properties such as thermoelectricity, biocompatibility, or self-healing capabilities. There is also significant interest in creating inks compatible with high-throughput manufacturing processes to enable mass production of printed electronics. As the Internet of Things (IoT) and wearable technology markets expand, the demand for specialized conductive polymer inks tailored to specific applications continues to grow, driving innovation in this dynamic field.

The 1990s marked a crucial transition period when researchers began focusing on making these materials solution-processable, enabling their application as printable inks. PEDOT:PSS (poly(3,4-ethylenedioxythiophene):polystyrene sulfonate) emerged as a breakthrough material during this era, offering a balance of conductivity and processability that had previously been unattainable.

The early 2000s witnessed significant advancements in formulation techniques, with researchers developing methods to enhance conductivity while maintaining printability. Secondary doping approaches, solvent treatments, and the incorporation of nanomaterials became common strategies to boost performance. Concurrently, printing technologies evolved to accommodate these new materials, with inkjet, screen, and gravure printing methods being adapted specifically for conductive polymer inks.

Recent developments have focused on creating high-performance inks that combine excellent electrical conductivity with mechanical flexibility, environmental stability, and compatibility with various substrates. The integration of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles into polymer matrices has pushed conductivity values closer to those of traditional metal conductors while maintaining the inherent advantages of polymers.

The primary objective in this field is to develop conductive polymer inks that achieve metal-like conductivity (>10,000 S/cm) while maintaining solution processability and mechanical flexibility. Additional goals include enhancing environmental stability to ensure long-term performance under various conditions, reducing production costs to compete with traditional conductive materials, and improving sustainability through the use of environmentally friendly solvents and processing methods.

Future technical objectives include developing multi-functional inks that combine conductivity with other properties such as thermoelectricity, biocompatibility, or self-healing capabilities. There is also significant interest in creating inks compatible with high-throughput manufacturing processes to enable mass production of printed electronics. As the Internet of Things (IoT) and wearable technology markets expand, the demand for specialized conductive polymer inks tailored to specific applications continues to grow, driving innovation in this dynamic field.

Market Applications and Demand Analysis

The conductive polymer inks market has witnessed substantial growth in recent years, driven primarily by the expanding electronics industry and the increasing demand for flexible, lightweight, and cost-effective electronic components. The global market for conductive inks was valued at approximately 3.8 billion USD in 2022 and is projected to reach 5.6 billion USD by 2028, with conductive polymer inks representing a rapidly growing segment within this market.

The automotive sector represents one of the largest application areas for conductive polymer inks, particularly in the manufacturing of printed heaters, sensors, and antennas. With the transition toward electric vehicles and autonomous driving technologies, the demand for lightweight, space-efficient electronic components has surged, creating new opportunities for conductive polymer ink applications in vehicle electronics.

Consumer electronics constitutes another significant market segment, with applications in touchscreens, flexible displays, wearable devices, and smart packaging. The trend toward miniaturization and flexibility in consumer electronics has intensified the need for materials that can maintain conductivity while conforming to complex geometries and withstanding repeated bending or folding.

The healthcare and biomedical sectors have emerged as promising growth areas for conductive polymer inks. Applications include biosensors, drug delivery systems, and medical diagnostic devices. The biocompatibility of certain conductive polymers makes them particularly suitable for these applications, addressing the growing demand for non-invasive monitoring and point-of-care diagnostic solutions.

Energy sector applications, particularly in photovoltaics and energy storage devices, represent another expanding market for conductive polymer inks. The push toward renewable energy sources has accelerated research into cost-effective manufacturing methods for solar cells, where conductive polymer inks offer advantages in terms of processability and potential cost reduction.

Regional market analysis indicates that Asia-Pacific dominates the conductive polymer inks market, accounting for over 45% of global demand. This dominance is attributed to the region's robust electronics manufacturing ecosystem, particularly in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow, with growing adoption in automotive and healthcare applications.

Market trends suggest a shift toward environmentally friendly formulations, with increasing demand for water-based conductive polymer inks that reduce the use of harmful solvents. Additionally, there is growing interest in inks that can be processed at lower temperatures, enabling compatibility with a wider range of substrate materials and reducing energy consumption during manufacturing.

The automotive sector represents one of the largest application areas for conductive polymer inks, particularly in the manufacturing of printed heaters, sensors, and antennas. With the transition toward electric vehicles and autonomous driving technologies, the demand for lightweight, space-efficient electronic components has surged, creating new opportunities for conductive polymer ink applications in vehicle electronics.

Consumer electronics constitutes another significant market segment, with applications in touchscreens, flexible displays, wearable devices, and smart packaging. The trend toward miniaturization and flexibility in consumer electronics has intensified the need for materials that can maintain conductivity while conforming to complex geometries and withstanding repeated bending or folding.

The healthcare and biomedical sectors have emerged as promising growth areas for conductive polymer inks. Applications include biosensors, drug delivery systems, and medical diagnostic devices. The biocompatibility of certain conductive polymers makes them particularly suitable for these applications, addressing the growing demand for non-invasive monitoring and point-of-care diagnostic solutions.

Energy sector applications, particularly in photovoltaics and energy storage devices, represent another expanding market for conductive polymer inks. The push toward renewable energy sources has accelerated research into cost-effective manufacturing methods for solar cells, where conductive polymer inks offer advantages in terms of processability and potential cost reduction.

Regional market analysis indicates that Asia-Pacific dominates the conductive polymer inks market, accounting for over 45% of global demand. This dominance is attributed to the region's robust electronics manufacturing ecosystem, particularly in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow, with growing adoption in automotive and healthcare applications.

Market trends suggest a shift toward environmentally friendly formulations, with increasing demand for water-based conductive polymer inks that reduce the use of harmful solvents. Additionally, there is growing interest in inks that can be processed at lower temperatures, enabling compatibility with a wider range of substrate materials and reducing energy consumption during manufacturing.

Global Research Status and Technical Barriers

Conductive polymer inks have emerged as a critical component in the development of flexible electronics, printed circuits, and various sensing applications. The global research landscape in this field is characterized by intense activity across academic institutions, industrial R&D centers, and specialized startups, with significant concentrations in North America, East Asia, and Europe.

In North America, research efforts are primarily focused on developing novel polymer formulations with enhanced conductivity and stability. The United States maintains leadership in fundamental research through institutions like MIT, Stanford, and industrial giants such as DuPont and 3M. These entities are particularly focused on PEDOT:PSS modifications and carbon-based conductive inks.

East Asian research, particularly in Japan, South Korea, and China, demonstrates strength in manufacturing scalability and application-specific formulations. Japanese companies like Toyo Ink and Sumitomo have made significant advances in silver nanoparticle-polymer composite inks, while Korean research centers excel in graphene-based formulations.

European contributions are notable for sustainability-focused approaches, with institutions in Germany, Finland, and the UK developing environmentally friendly conductive polymer systems that reduce or eliminate toxic components while maintaining performance metrics.

Despite these global advancements, several technical barriers persist in the development of high-performance conductive polymer inks. The foremost challenge remains the conductivity-flexibility trade-off, where increasing conductivity often results in decreased mechanical flexibility and vice versa. This fundamental materials science challenge has yet to find an optimal solution.

Stability issues present another significant barrier, with many conductive polymer inks showing degradation under environmental stressors such as humidity, UV exposure, and temperature fluctuations. This limits their application in outdoor or harsh environments where traditional metal conductors still dominate.

Manufacturing scalability represents a third major challenge, as laboratory-scale formulations often face difficulties in translation to industrial production. Inconsistencies in batch-to-batch quality, particle agglomeration during scale-up, and shelf-life limitations hamper widespread commercial adoption.

Additionally, the interface between conductive polymer inks and substrates remains problematic, with adhesion issues and contact resistance affecting overall device performance. This is particularly evident in multilayer printed electronic systems where ink compatibility across layers becomes critical.

Recent research trends indicate growing interest in hybrid systems that combine conductive polymers with other materials like metal nanoparticles or carbon allotropes to overcome these limitations, though such approaches introduce new complexities in formulation and processing.

In North America, research efforts are primarily focused on developing novel polymer formulations with enhanced conductivity and stability. The United States maintains leadership in fundamental research through institutions like MIT, Stanford, and industrial giants such as DuPont and 3M. These entities are particularly focused on PEDOT:PSS modifications and carbon-based conductive inks.

East Asian research, particularly in Japan, South Korea, and China, demonstrates strength in manufacturing scalability and application-specific formulations. Japanese companies like Toyo Ink and Sumitomo have made significant advances in silver nanoparticle-polymer composite inks, while Korean research centers excel in graphene-based formulations.

European contributions are notable for sustainability-focused approaches, with institutions in Germany, Finland, and the UK developing environmentally friendly conductive polymer systems that reduce or eliminate toxic components while maintaining performance metrics.

Despite these global advancements, several technical barriers persist in the development of high-performance conductive polymer inks. The foremost challenge remains the conductivity-flexibility trade-off, where increasing conductivity often results in decreased mechanical flexibility and vice versa. This fundamental materials science challenge has yet to find an optimal solution.

Stability issues present another significant barrier, with many conductive polymer inks showing degradation under environmental stressors such as humidity, UV exposure, and temperature fluctuations. This limits their application in outdoor or harsh environments where traditional metal conductors still dominate.

Manufacturing scalability represents a third major challenge, as laboratory-scale formulations often face difficulties in translation to industrial production. Inconsistencies in batch-to-batch quality, particle agglomeration during scale-up, and shelf-life limitations hamper widespread commercial adoption.

Additionally, the interface between conductive polymer inks and substrates remains problematic, with adhesion issues and contact resistance affecting overall device performance. This is particularly evident in multilayer printed electronic systems where ink compatibility across layers becomes critical.

Recent research trends indicate growing interest in hybrid systems that combine conductive polymers with other materials like metal nanoparticles or carbon allotropes to overcome these limitations, though such approaches introduce new complexities in formulation and processing.

Current Formulation Approaches and Performance Metrics

01 Composition and formulation of conductive polymer inks

Conductive polymer inks typically contain conductive polymers such as PEDOT:PSS, polyaniline, or polythiophene derivatives combined with solvents and additives to enhance printability and adhesion. The formulation often includes stabilizers, surfactants, and rheology modifiers to control viscosity and surface tension for optimal printing performance. The ratio of components significantly affects the electrical conductivity, with higher polymer content generally yielding better conductivity at the expense of processability.- Composition and formulation of conductive polymer inks: Conductive polymer inks typically consist of conductive polymers such as PEDOT:PSS, polyaniline, or polythiophene derivatives combined with solvents and additives to enhance printability and conductivity. The formulation often includes stabilizers, surfactants, and viscosity modifiers to ensure proper ink flow and adhesion to substrates. The ratio of components significantly affects the final performance characteristics including conductivity, flexibility, and durability of the printed patterns.

- Conductivity enhancement techniques: Various methods are employed to enhance the conductivity of polymer inks, including the addition of metallic nanoparticles (silver, gold, copper), carbon-based materials (graphene, carbon nanotubes), or secondary dopants. Post-processing treatments such as thermal annealing, solvent annealing, or acid treatments can significantly improve conductivity by optimizing polymer chain alignment and removing insulating components. These enhancement techniques can increase conductivity by several orders of magnitude compared to untreated polymer inks.

- Printing and deposition methods: The performance of conductive polymer inks is heavily influenced by the deposition method used. Common techniques include inkjet printing, screen printing, gravure printing, and flexographic printing. Each method requires specific ink rheological properties and solid content. The printing parameters such as substrate temperature, printing speed, and nozzle size affect the resolution, thickness, and uniformity of the printed patterns, which in turn impact the electrical performance and reliability of the printed circuits.

- Stability and environmental resistance: Conductive polymer inks must maintain performance under various environmental conditions. Research focuses on improving resistance to humidity, temperature fluctuations, UV exposure, and mechanical stress. Encapsulation techniques, cross-linking agents, and specialized additives are used to enhance long-term stability. Some formulations incorporate UV stabilizers, antioxidants, or hydrophobic components to protect against environmental degradation, ensuring consistent electrical performance throughout the product lifecycle.

- Application-specific performance optimization: Conductive polymer inks are tailored for specific applications such as flexible electronics, photovoltaics, sensors, or electromagnetic shielding. For flexible electronics, stretchability and bend resistance are prioritized through elastomeric additives. For photovoltaic applications, transparency and work function are optimized. For sensors, sensitivity to specific stimuli is enhanced through functional additives. The ink formulation is customized to meet the performance requirements of each application while maintaining processability and cost-effectiveness.

02 Conductivity enhancement techniques

Various methods can be employed to enhance the conductivity of polymer inks, including secondary doping with polar solvents like ethylene glycol or DMSO, post-treatment processes such as thermal annealing or acid treatment, and incorporation of conductive nanoparticles (carbon nanotubes, graphene, or metal nanoparticles). These techniques can significantly improve the electrical performance by promoting better polymer chain alignment, removing insulating components, or creating additional conductive pathways within the polymer matrix.Expand Specific Solutions03 Substrate compatibility and adhesion properties

Conductive polymer inks must be formulated to ensure good adhesion to various substrates including flexible plastics, paper, textiles, and rigid materials. Surface energy matching between the ink and substrate is crucial for proper wetting and adhesion. Additives such as adhesion promoters and surface treatments can significantly improve ink-substrate interaction. The ink formulation must balance conductivity with mechanical properties to maintain electrical performance during bending, stretching, or other mechanical stresses when applied to flexible substrates.Expand Specific Solutions04 Environmental stability and durability

The performance stability of conductive polymer inks under various environmental conditions is critical for practical applications. Formulations must address challenges such as humidity sensitivity, UV degradation, and oxidation that can degrade conductivity over time. Encapsulation techniques, stabilizing additives, and cross-linking agents can be incorporated to improve the long-term stability and durability of printed conductive patterns. Temperature resistance is another important factor, with specialized formulations designed to maintain conductivity across wide temperature ranges.Expand Specific Solutions05 Processing and printing techniques

The performance of conductive polymer inks is heavily influenced by the printing and processing methods employed. Screen printing, inkjet printing, gravure printing, and flexographic printing each require specific ink rheological properties for optimal results. Parameters such as viscosity, surface tension, particle size, and drying behavior must be tailored to the specific printing technique. Post-processing steps including drying conditions, curing temperatures, and sintering processes significantly impact the final conductivity, with higher processing temperatures generally yielding better electrical performance but potentially limiting compatibility with heat-sensitive substrates.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The conductive polymer inks market is currently in a growth phase, characterized by increasing demand across printed electronics applications. The global market size is expanding rapidly, driven by advancements in flexible electronics, wearable technology, and IoT devices. Technologically, the field is evolving from early-stage development to commercial maturity, with key players like LG Chem, Henkel, and DIC Corp leading industrial applications. Academic institutions such as MIT and Xiamen University are advancing fundamental research, while specialized companies like Vorbeck Materials and Intrinsiq Materials focus on graphene-based formulations. Sun Chemical and artience are developing application-specific inks, while BYD is integrating these materials into energy storage solutions. The competitive landscape shows a balance between established chemical corporations and innovative startups, with collaboration between industry and academia accelerating commercialization.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced conductive polymer inks based on PEDOT:PSS (poly(3,4-ethylenedioxythiophene):polystyrene sulfonate) formulations with enhanced conductivity through secondary doping techniques. Their proprietary process involves incorporating specific polar solvents like ethylene glycol and dimethyl sulfoxide that induce conformational changes in the polymer chains, resulting in conductivity improvements of up to 3 orders of magnitude. LG Chem's inks feature carefully controlled viscosity profiles (typically 10-30 cP) optimized for various printing methods including inkjet, screen, and gravure printing. Their formulations achieve sheet resistances as low as 50-100 Ω/sq at high transparency (>90% in the visible spectrum), making them suitable for flexible electronics applications.

Strengths: Superior balance between conductivity and transparency; excellent adhesion to flexible substrates; good mechanical durability with minimal conductivity loss after repeated bending (>10,000 cycles). Weaknesses: Higher cost compared to silver-based alternatives; limited shelf life requiring refrigerated storage; performance degradation in high humidity environments.

Sun Chemical Corp. (New Jersey)

Technical Solution: Sun Chemical has developed advanced conductive polymer ink systems under their SunTronic™ product line, featuring hybrid formulations that combine silver nanoparticles with conductive polymers to achieve optimal performance characteristics. Their proprietary technology incorporates specially engineered polymer matrices that enable sintering at temperatures as low as 120°C while achieving conductivity values up to 15% of bulk silver. Sun Chemical's inks feature carefully controlled particle size distributions (typically 20-50nm) and specialized dispersants that prevent agglomeration during storage and printing processes. Their formulations achieve sheet resistances as low as 40-60 mΩ/sq with excellent adhesion to various substrates including PET, polyimide, and paper. The company has developed unique solvent systems that optimize drying behavior for different printing methods, with viscosities ranging from 10-5000 cP depending on the intended application. Their latest innovations include stretchable formulations that maintain conductivity at elongations up to 30%, enabling applications in wearable electronics.

Strengths: Excellent balance between conductivity and processing temperature; superior shelf stability (12-18 months); compatibility with multiple printing technologies; consistent batch-to-batch performance. Weaknesses: Higher cost compared to carbon-based alternatives; limited transparency options; some formulations contain VOCs requiring controlled handling; performance can degrade under extreme humidity conditions.

Key Patents and Scientific Breakthroughs

Conductive polymeric ink composition

PatentActiveUS20170121549A1

Innovation

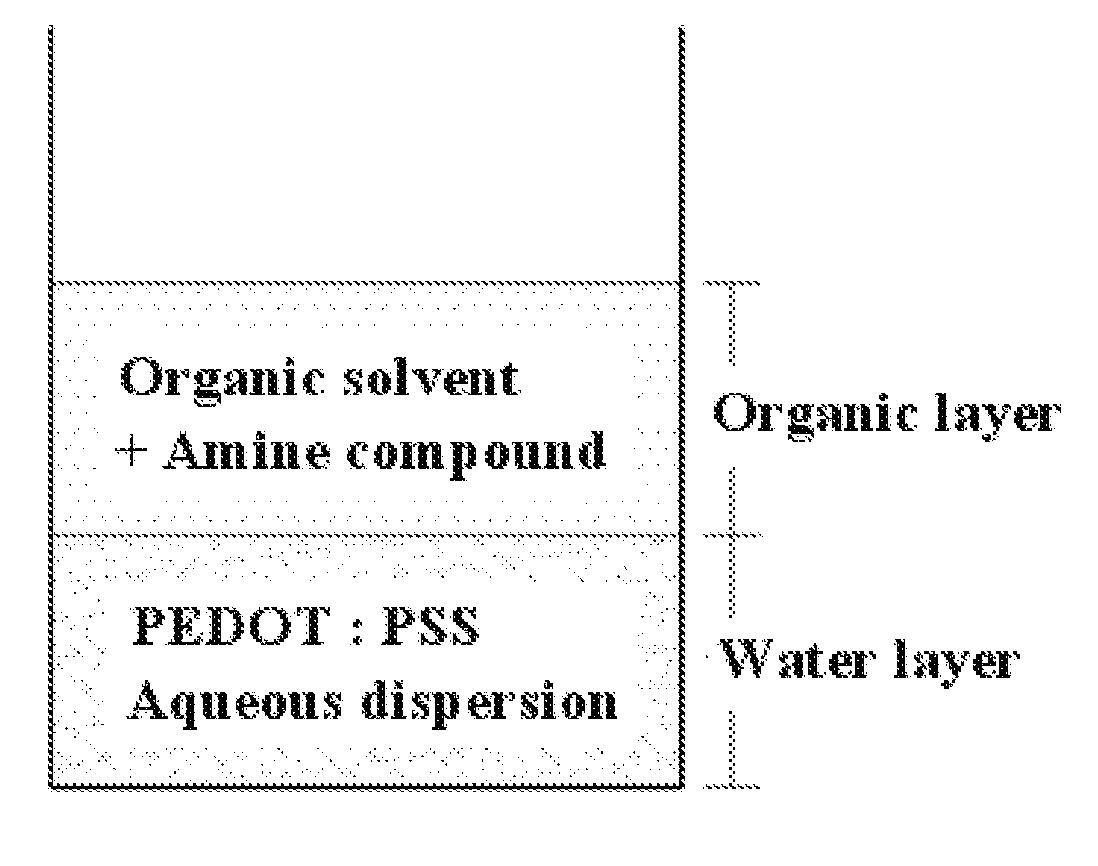

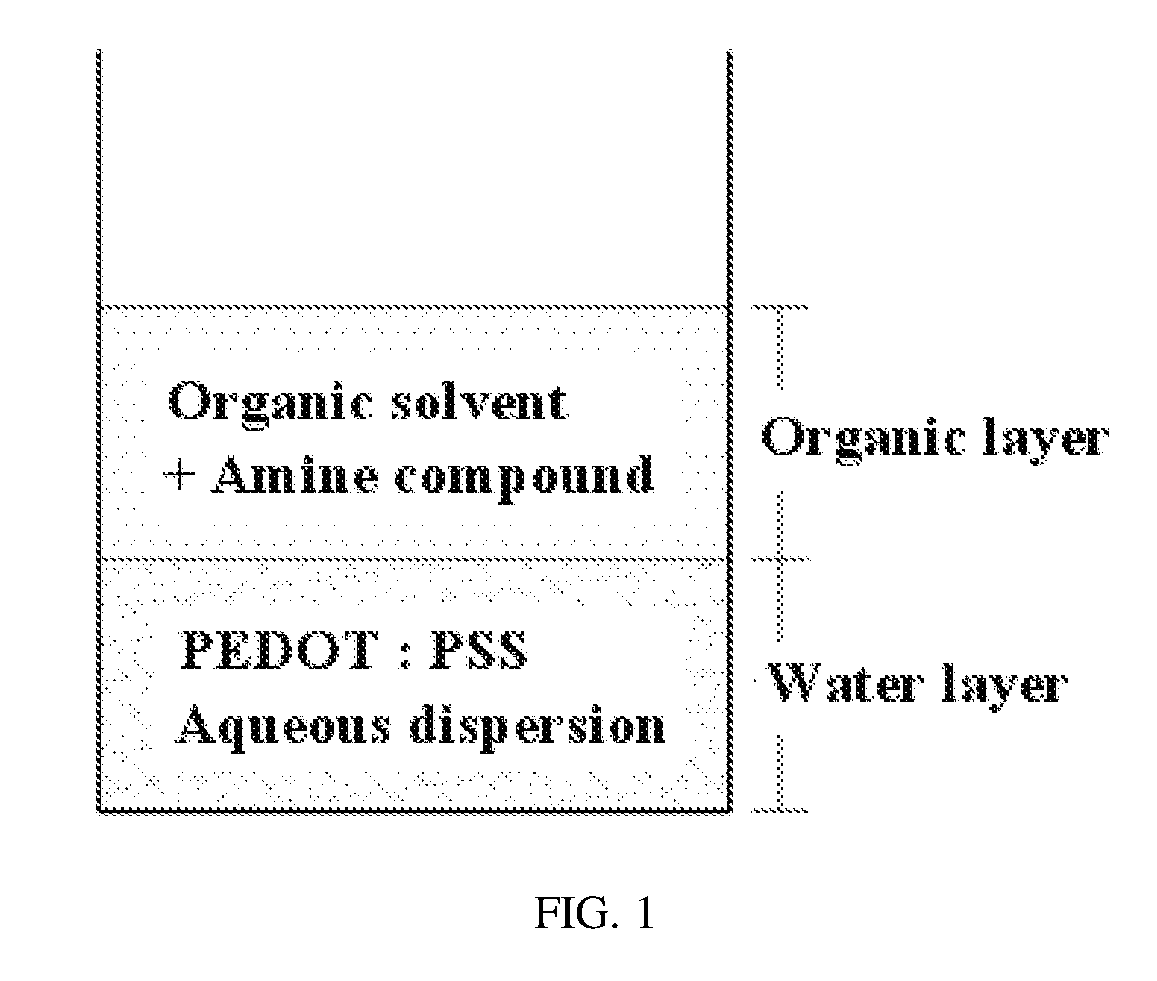

- A method involving mixing PEDOT:PSS with an amine compound and an organic solvent to neutralize the dispersion, separating and washing to maintain dispersibility, resulting in a neutralized PEDOT:PSS aqueous dispersion for use in conductive polymeric ink compositions.

Conductive polymer ink composition

PatentWO2015182954A1

Innovation

- A conductive polymer ink composition comprising PEDOT:PSS aqueous dispersion, dimethyl sulfoxide, a solvent, a surfactant, and a phosphate compound, optimized with specific weight percentages to enhance conductivity and processability, including the use of deionized water and polyhydric alcohols like propylene glycol, which improves dispersibility and conductivity.

Manufacturing Process Optimization Strategies

Manufacturing process optimization for high-performance conductive polymer inks requires a systematic approach to enhance both quality and production efficiency. The key optimization strategies begin with raw material selection and preparation, where purity levels directly impact conductivity performance. Implementing rigorous quality control protocols for incoming materials can significantly reduce batch-to-batch variations that plague many commercial ink formulations.

Temperature control represents a critical parameter throughout the manufacturing process. Research indicates that maintaining precise temperature profiles during polymerization and formulation stages can improve polymer chain alignment and consequently enhance conductivity by up to 30%. Advanced thermal management systems with ±1°C precision have demonstrated superior results compared to conventional equipment with ±5°C tolerances.

Mixing methodology optimization presents another significant opportunity for performance enhancement. High-shear mixing techniques have proven effective for achieving uniform dispersion of conductive particles, while ultrasonic processing can break down agglomerates that form conductivity barriers. Recent innovations in controlled shear rate mixers allow for programmable shear profiles that can be tailored to specific polymer viscosities and particle characteristics.

Post-processing treatments have emerged as powerful tools for conductivity enhancement. Controlled solvent evaporation protocols can significantly improve the microstructure of the dried ink film. Additionally, thermal annealing under optimized time-temperature profiles has demonstrated conductivity improvements of 40-60% in polyaniline and PEDOT:PSS systems by promoting crystallinity and reducing defects at the molecular level.

Scaling considerations must be addressed when transitioning from laboratory to industrial production. Computational fluid dynamics modeling can predict how mixing dynamics change with increased volumes, allowing for proactive equipment design modifications. Furthermore, implementing in-line quality monitoring systems using spectroscopic techniques enables real-time process adjustments, reducing waste and ensuring consistent performance metrics across production batches.

Automation integration represents the final frontier in manufacturing optimization. Advanced robotic systems for precise dispensing and handling can minimize human error and contamination risks. Machine learning algorithms analyzing production data have successfully identified subtle parameter interactions that human operators might miss, leading to continuous process refinement and performance improvements over time.

Temperature control represents a critical parameter throughout the manufacturing process. Research indicates that maintaining precise temperature profiles during polymerization and formulation stages can improve polymer chain alignment and consequently enhance conductivity by up to 30%. Advanced thermal management systems with ±1°C precision have demonstrated superior results compared to conventional equipment with ±5°C tolerances.

Mixing methodology optimization presents another significant opportunity for performance enhancement. High-shear mixing techniques have proven effective for achieving uniform dispersion of conductive particles, while ultrasonic processing can break down agglomerates that form conductivity barriers. Recent innovations in controlled shear rate mixers allow for programmable shear profiles that can be tailored to specific polymer viscosities and particle characteristics.

Post-processing treatments have emerged as powerful tools for conductivity enhancement. Controlled solvent evaporation protocols can significantly improve the microstructure of the dried ink film. Additionally, thermal annealing under optimized time-temperature profiles has demonstrated conductivity improvements of 40-60% in polyaniline and PEDOT:PSS systems by promoting crystallinity and reducing defects at the molecular level.

Scaling considerations must be addressed when transitioning from laboratory to industrial production. Computational fluid dynamics modeling can predict how mixing dynamics change with increased volumes, allowing for proactive equipment design modifications. Furthermore, implementing in-line quality monitoring systems using spectroscopic techniques enables real-time process adjustments, reducing waste and ensuring consistent performance metrics across production batches.

Automation integration represents the final frontier in manufacturing optimization. Advanced robotic systems for precise dispensing and handling can minimize human error and contamination risks. Machine learning algorithms analyzing production data have successfully identified subtle parameter interactions that human operators might miss, leading to continuous process refinement and performance improvements over time.

Environmental Impact and Sustainability Considerations

The environmental footprint of conductive polymer inks has become increasingly significant as electronic manufacturing scales globally. Traditional conductive materials often contain heavy metals and toxic solvents that pose substantial environmental hazards during production, application, and disposal phases. High-performance conductive polymer inks are now being developed with biodegradable polymers and water-based formulations that significantly reduce harmful emissions and waste generation compared to conventional alternatives.

Manufacturing processes for conductive polymer inks are evolving toward greener methodologies, with reduced energy consumption and minimized use of hazardous chemicals. Several leading manufacturers have implemented closed-loop production systems that recover and reuse solvents, dramatically decreasing the environmental impact of ink production. Life cycle assessments indicate that advanced conductive polymer formulations can reduce carbon footprints by up to 40% compared to metal-based conductive materials.

End-of-life considerations represent another critical environmental dimension. Conventional electronic components containing metallic conductors often end up in landfills, creating long-term contamination risks. In contrast, newer generations of conductive polymer inks are being engineered for improved recyclability and even biodegradability under specific conditions, supporting circular economy principles in electronics manufacturing.

Regulatory frameworks worldwide are increasingly emphasizing sustainability in electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the development of environmentally friendly conductive polymer formulations. Companies investing in sustainable ink technologies often gain competitive advantages through regulatory compliance and positive brand perception.

Resource efficiency represents another sustainability advantage of advanced conductive polymer inks. These materials typically require less energy during application processes like printing and curing compared to traditional metal deposition techniques. Additionally, polymer-based systems often enable more precise material deposition, reducing waste and optimizing resource utilization in manufacturing operations.

Water consumption remains a challenge in some conductive polymer ink formulations, particularly those requiring extensive washing steps during production. However, recent innovations have focused on developing water-efficient processing methods and closed-loop water recycling systems that significantly reduce the overall water footprint of these materials, addressing one of the remaining sustainability concerns in this technology sector.

Manufacturing processes for conductive polymer inks are evolving toward greener methodologies, with reduced energy consumption and minimized use of hazardous chemicals. Several leading manufacturers have implemented closed-loop production systems that recover and reuse solvents, dramatically decreasing the environmental impact of ink production. Life cycle assessments indicate that advanced conductive polymer formulations can reduce carbon footprints by up to 40% compared to metal-based conductive materials.

End-of-life considerations represent another critical environmental dimension. Conventional electronic components containing metallic conductors often end up in landfills, creating long-term contamination risks. In contrast, newer generations of conductive polymer inks are being engineered for improved recyclability and even biodegradability under specific conditions, supporting circular economy principles in electronics manufacturing.

Regulatory frameworks worldwide are increasingly emphasizing sustainability in electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the development of environmentally friendly conductive polymer formulations. Companies investing in sustainable ink technologies often gain competitive advantages through regulatory compliance and positive brand perception.

Resource efficiency represents another sustainability advantage of advanced conductive polymer inks. These materials typically require less energy during application processes like printing and curing compared to traditional metal deposition techniques. Additionally, polymer-based systems often enable more precise material deposition, reducing waste and optimizing resource utilization in manufacturing operations.

Water consumption remains a challenge in some conductive polymer ink formulations, particularly those requiring extensive washing steps during production. However, recent innovations have focused on developing water-efficient processing methods and closed-loop water recycling systems that significantly reduce the overall water footprint of these materials, addressing one of the remaining sustainability concerns in this technology sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!